Substrate treating apparatus

一种基板处理装置、处理位置的技术,应用在电气元件、半导体/固态器件制造、电路等方向,能够解决残渣、不能清洁干净地干燥基板等问题,达到提高生产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

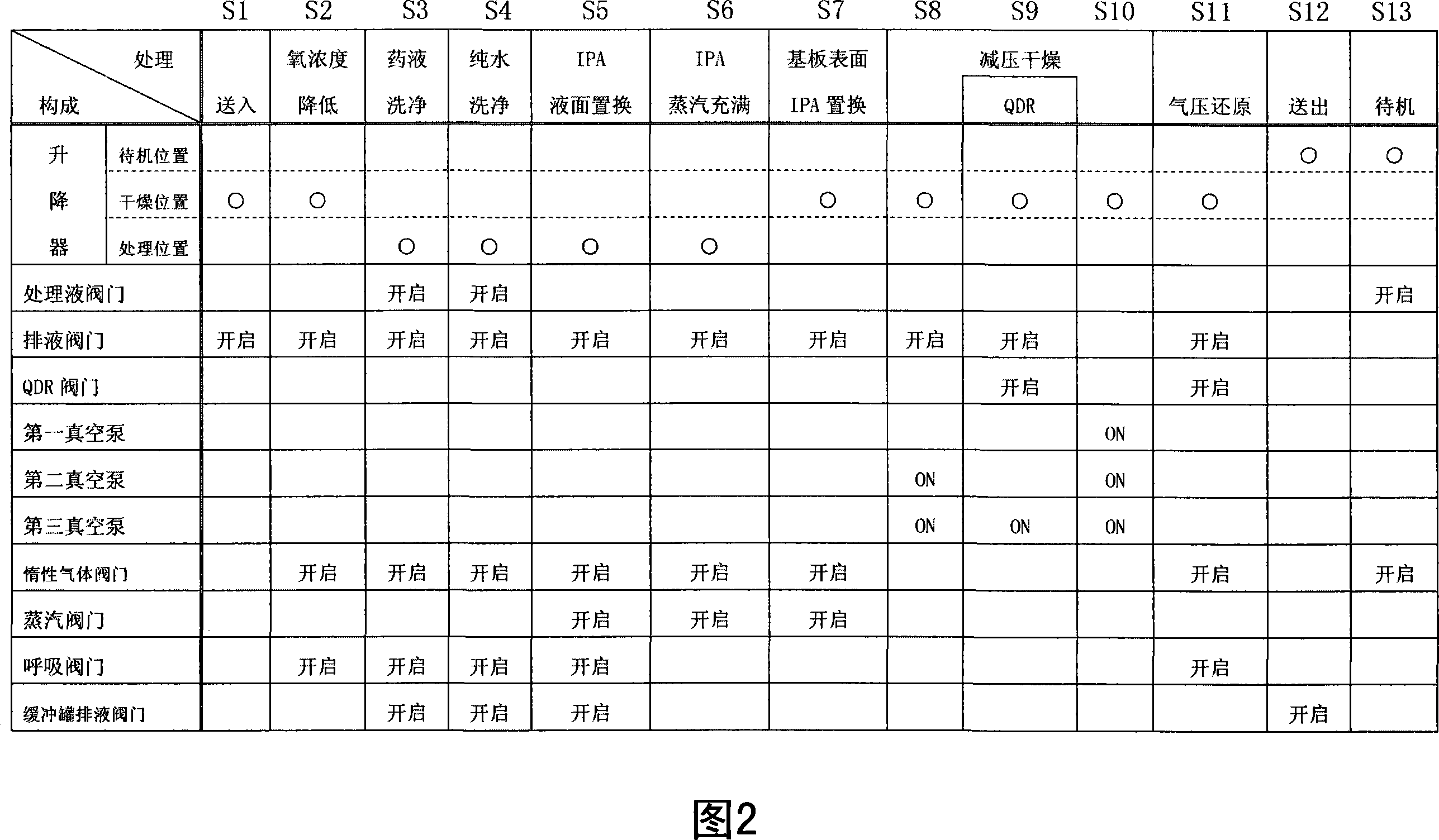

[0022] Hereinafter, Embodiment 1 of the present invention will be described with reference to the drawings.

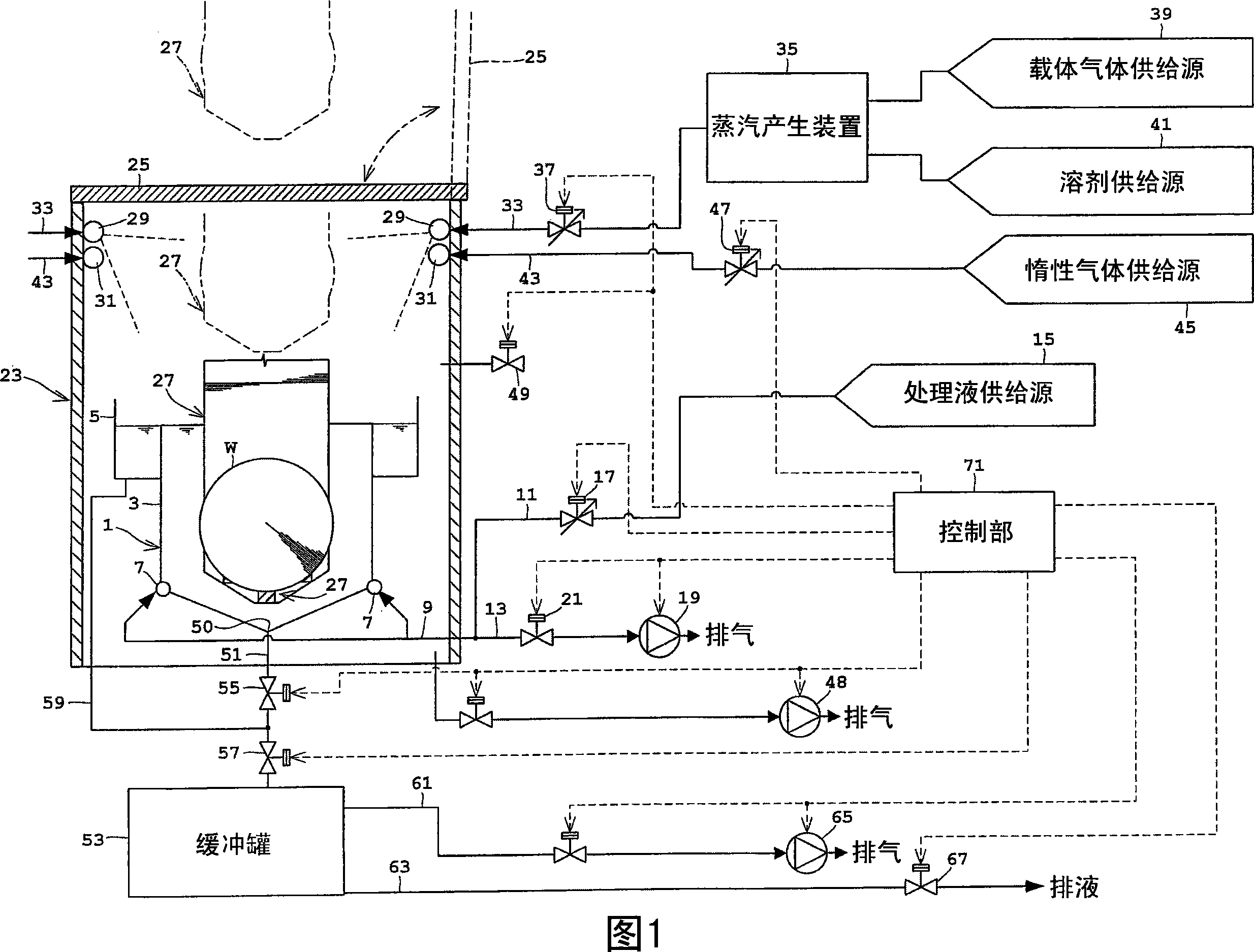

[0023] FIG. 1 is a schematic configuration diagram of a substrate processing apparatus according to the first embodiment.

[0024] The substrate processing apparatus of this embodiment has a processing tank 1 that stores a processing liquid. The processing tank 1 has an inner tank 3 that stores a processing liquid and accommodates a substrate W, and an outer tank 5 that collects the processing liquid overflowing from the inner tank 3 . Two injection pipes 7 for supplying the treatment liquid into the inner tank 3 are arranged at the bottom of the inner tank 3 , and a pipe 9 is connected to the injection pipes 7 . The piping 9 is branched into a supply pipe 11 and a suction pipe 13 . The supply pipe 11 is connected to a processing liquid supply source 15, and the flow rate thereof is controlled by a processing liquid valve 17 constituted by a control valve. The sucti...

Embodiment 2

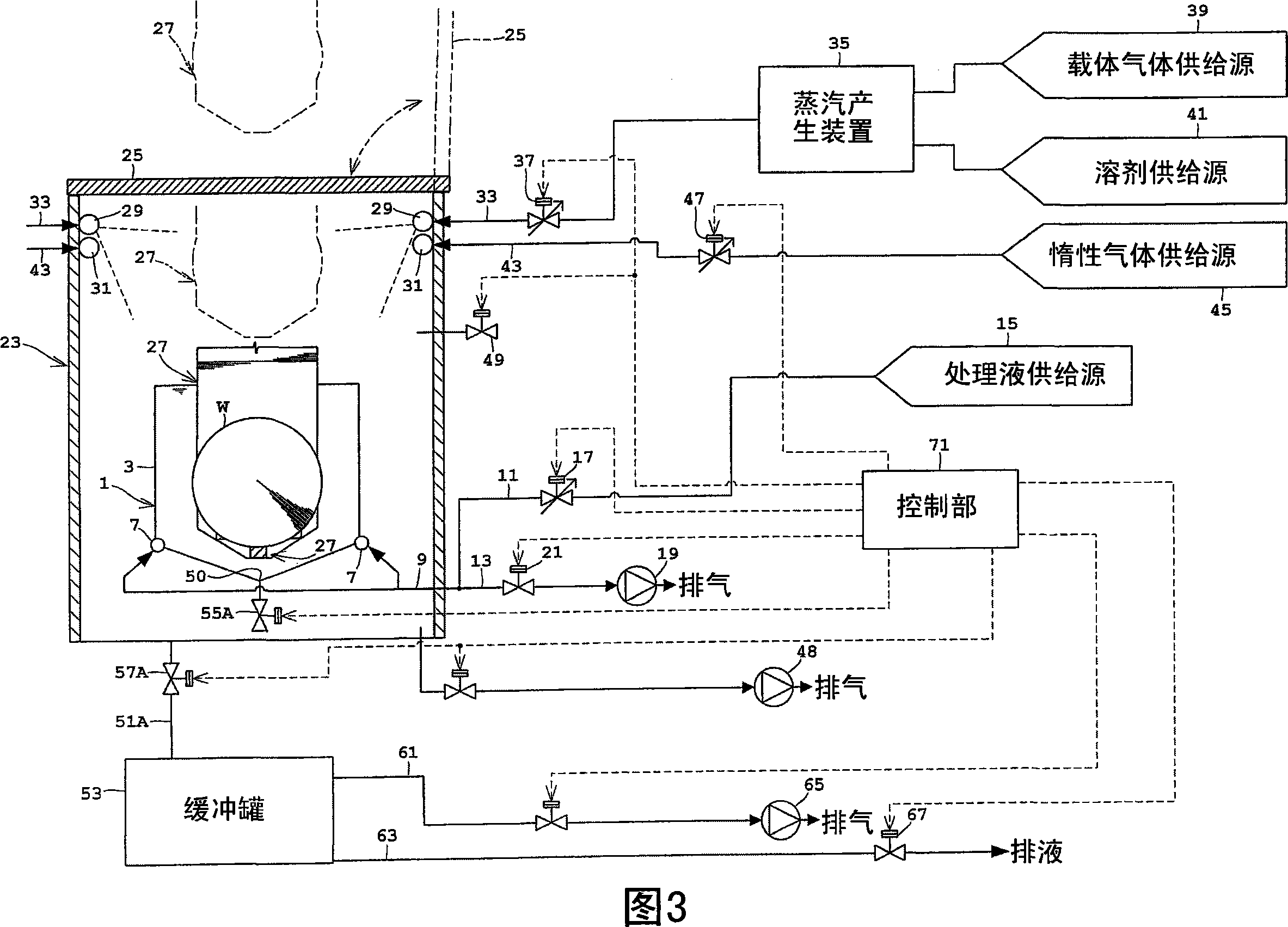

[0047] Embodiment 2 of the present invention will be described below with reference to the drawings.

[0048] FIG. 3 is a schematic configuration diagram of a substrate processing apparatus according to the second embodiment, and the same configurations as those of the first embodiment described above are denoted by the same reference numerals, so detailed description thereof will be omitted.

[0049] The differences between the substrate processing apparatus of the second embodiment and the configuration of the first embodiment described above are as follows.

[0050] That is, the processing tank 1 only has the inner tank 3 without the outer tank 5; the QDR valve 55A is arranged at the discharge port 50 of the inner tank 3, and when the liquid is discharged from the QDR valve 55A, the processing liquid in the inner tank 3 is temporarily discharged into the processing chamber In room 23. A discharge pipe 51A communicating with the buffer tank 53 is installed at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com