A treatment method for sick and dead livestock and poultry

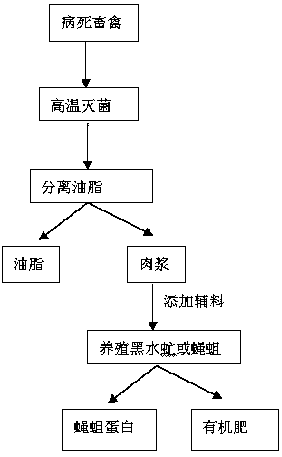

A treatment method and technology for dead livestock and poultry, which is applied in the field of treatment of dead livestock and poultry, can solve the problems of young pupae not being fully digested, short growth cycle of fly maggots, and low utilization rate of raw materials, so as to achieve no damage to organic matter, improve conversion efficiency, The effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Sick and dead livestock and poultry are pulverized by a pulverizer and enter the high-temperature cooking equipment through an auger. After high-temperature sterilization at 120°C and 8 atmospheres for 4 hours, the oil is refined by a centrifuge and loaded into barrels after the oil is fully stratified. After the meat slurry in the lower layer is sprayed into the mixer and mixed with the straw, the protein content in the mixture is about 15%. The black soldier fly larvae are connected to the black soldier fly larvae through the quantitative conveyor belt, and enter the transformation room for transformation. The temperature of the transformation room is controlled at 30-37°C. After 10 days of transformation, the mixture of larvae and insect droppings was separated by a vibrating sieve to obtain larvae and insect droppings. The larvae are dried in vacuum and low temperature to make fly maggot protein. According to quantitative measurement, 60 kg of dried pupa protein can ...

Embodiment 2

[0029] Sick and dead livestock and poultry directly enter the high-temperature cooking equipment, and after high-temperature sterilization at 120°C and 8 atmospheres for 4 hours, the oil will be sucked into the oil storage tank after the oil is fully stratified. The meat slurry in the lower layer is sprayed into the mixer and mixed with the bran. The protein content of the mixture is about 15%. It is connected to the housefly larvae through the quantitative conveyor belt, and enters the transformation room for transformation. The temperature of the transformation room is controlled at 30-37°C. After 4-5 days, the mixture of larvae and insect droppings is separated by a vibrating sieve to obtain larvae and insect droppings. The larvae are dried under vacuum and low temperature to make fly maggot protein. According to quantitative measurement, 62 kg of dry young pupa protein can be obtained per ton of dead livestock and poultry, and the worm manure is matured and dried to make or...

Embodiment 3

[0031] Sick and dead livestock and poultry are pulverized by a pulverizer and enter the high-temperature cooking equipment through an auger. After 4 hours of high-temperature sterilization at 120°C and 8 atmospheres, the meat slurry enters a dryer for drying, and the powder formed after drying is sent to an oil press for deoiling. Add appropriate amount of water and bran to the deoiled residue cake to mix, the water content is 70%, the protein content in the mixture is about 15%, insert EM bacteria, 37 degrees, anaerobic fermentation for 6 days, and the fermentation product is transported quantitatively Bring black soldier fly larvae into the transformation room for transformation. The temperature of the transformation room is controlled at 30-37°C. After 9-10 days of transformation, the mixture of larvae and insect droppings is separated by a vibrating sieve to obtain larvae and insect droppings. The larvae are dried under vacuum and low temperature to make fly maggot protein....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com