Flue gas desulfurization system for sheet glass industry melting furnace

A flat glass and desulfurization system technology, which is applied in gas treatment, membrane technology, and dispersed particle separation, can solve the problems of a large amount of waste, large investment, and occupation, and achieve the effects of eliminating white smoke, increasing specific surface area, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

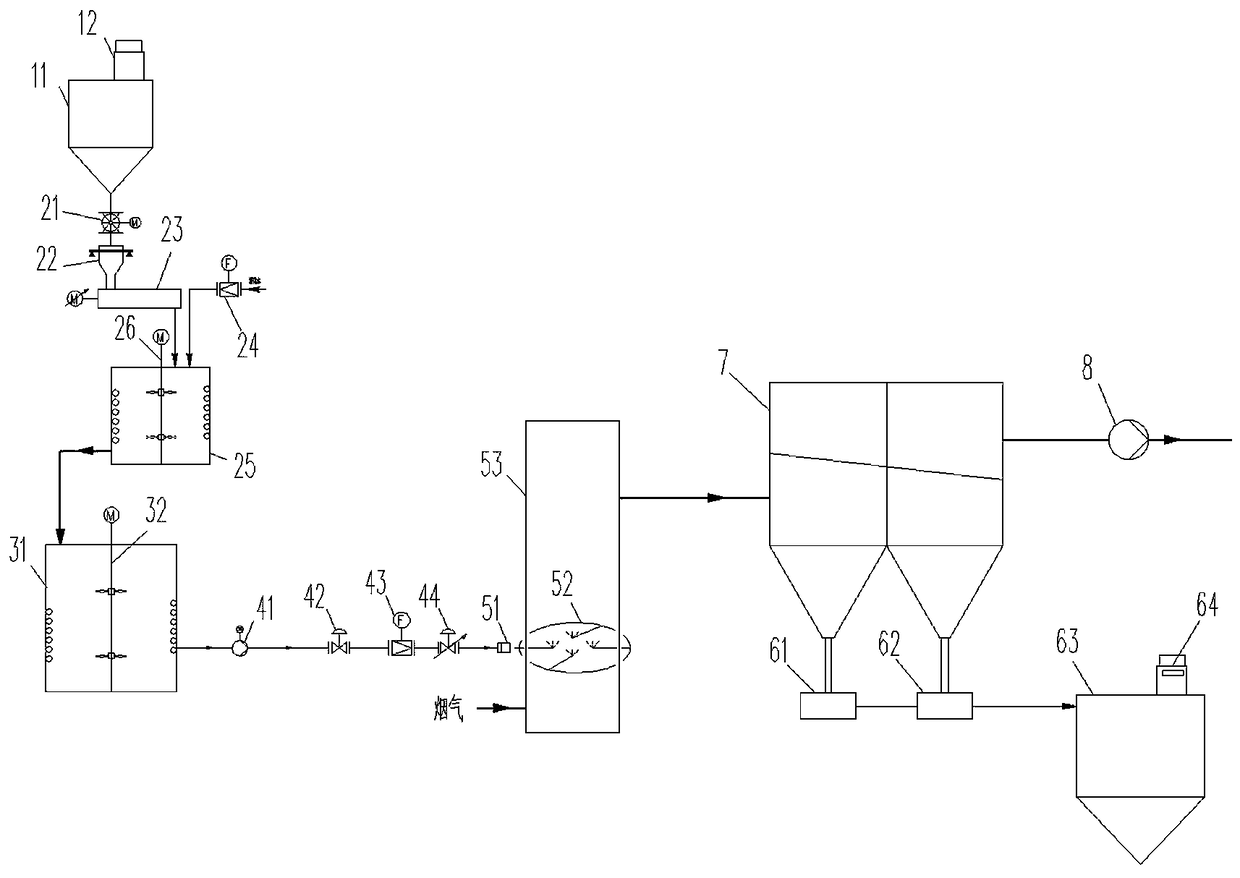

[0038] Such as figure 1 As shown, the present invention provides a flue gas desulfurization system for a flat glass industrial furnace, comprising:

[0039] a. Sodium carbonate storage department,

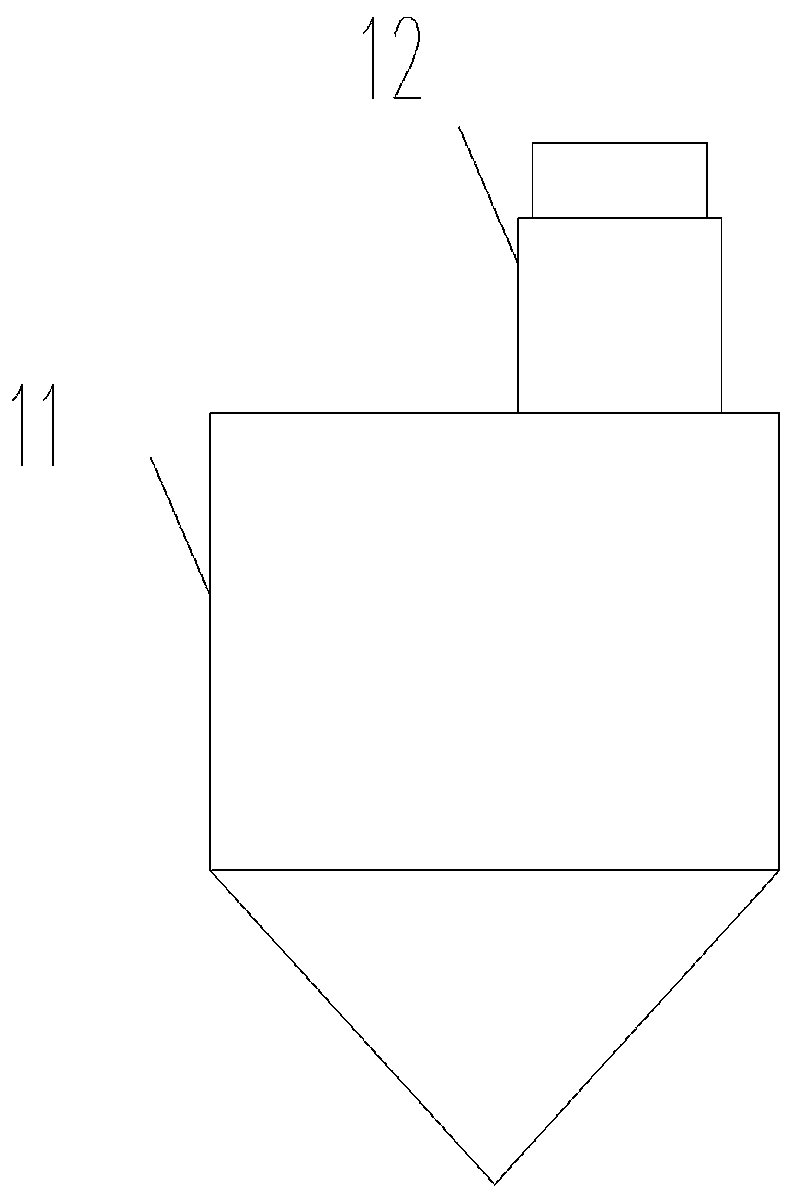

[0040] combine figure 2 As shown, the sodium carbonate storage part comprises a sodium carbonate storage bin 11, and the top of the sodium carbonate storage bin 11 is provided with a first dust collector 12;

[0041] b. Sodium carbonate dissolving part,

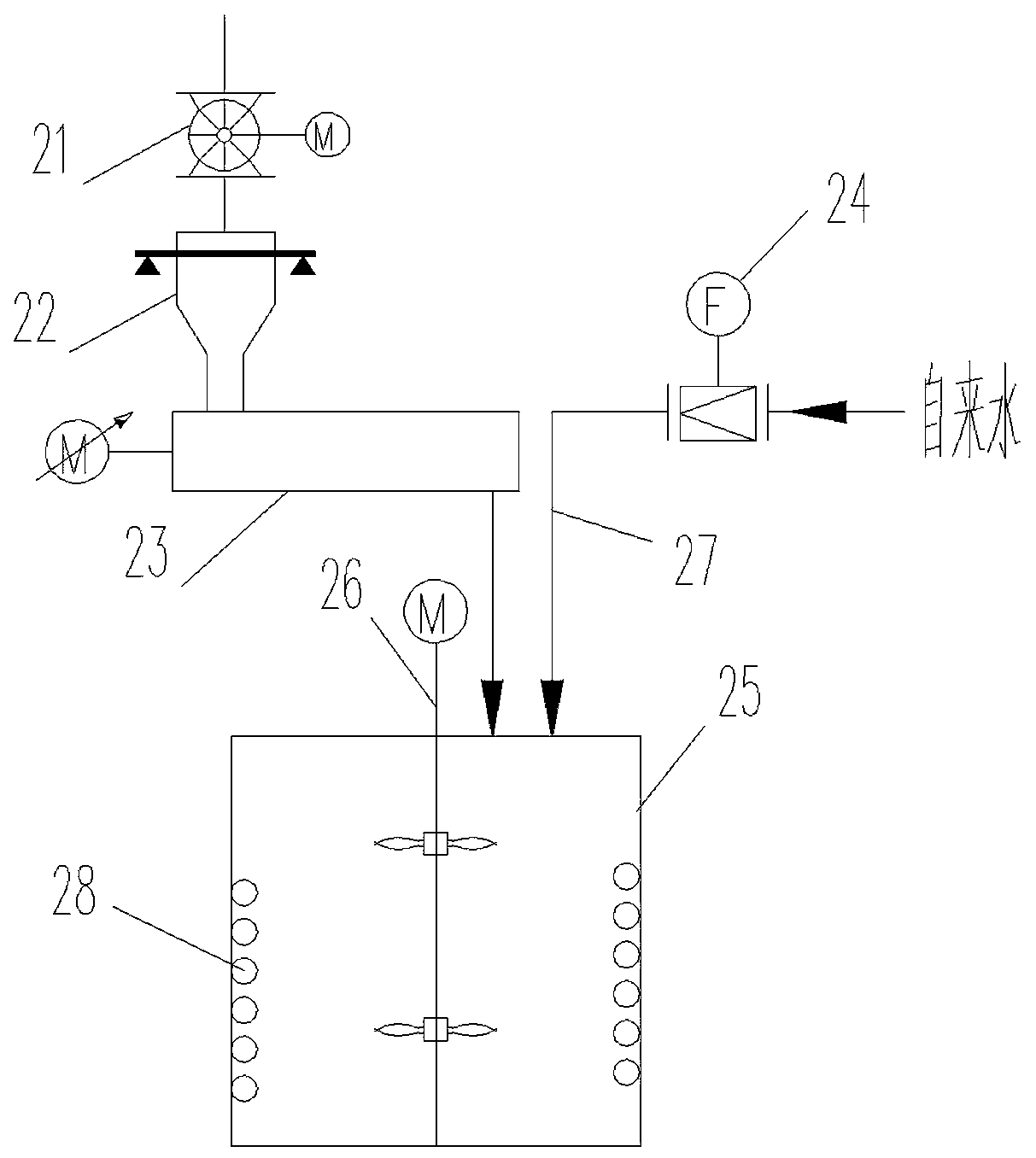

[0042] combine image 3 Shown, sodium carbonate dissolving section comprises the rotary valve 21 that is located at sodium carbonate storage bin 11 below, and rotary valve 21 inlets are connected with sodium carbonate storage bin 11 bottoms, and the bottom of rotary valve 21 is successively provided with interconnected scales from top to bottom. Heavy warehouse 22, screw conveyor 23 and sodium carbonate dissolving tank 25, the top of sodium carbonate dissolving tank 25 is connected with water supply pipe 27, water supply pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com