Mechanical cooling tower white smoke removing device

A mechanical cooling, white smoke technology, applied in the direction of water shower cooler, direct contact heat exchanger, heat exchanger type, etc., can solve the problem of blank, avoid secondary atomization, reduce resistance and volume , the effect of reducing the amount of water vapor evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

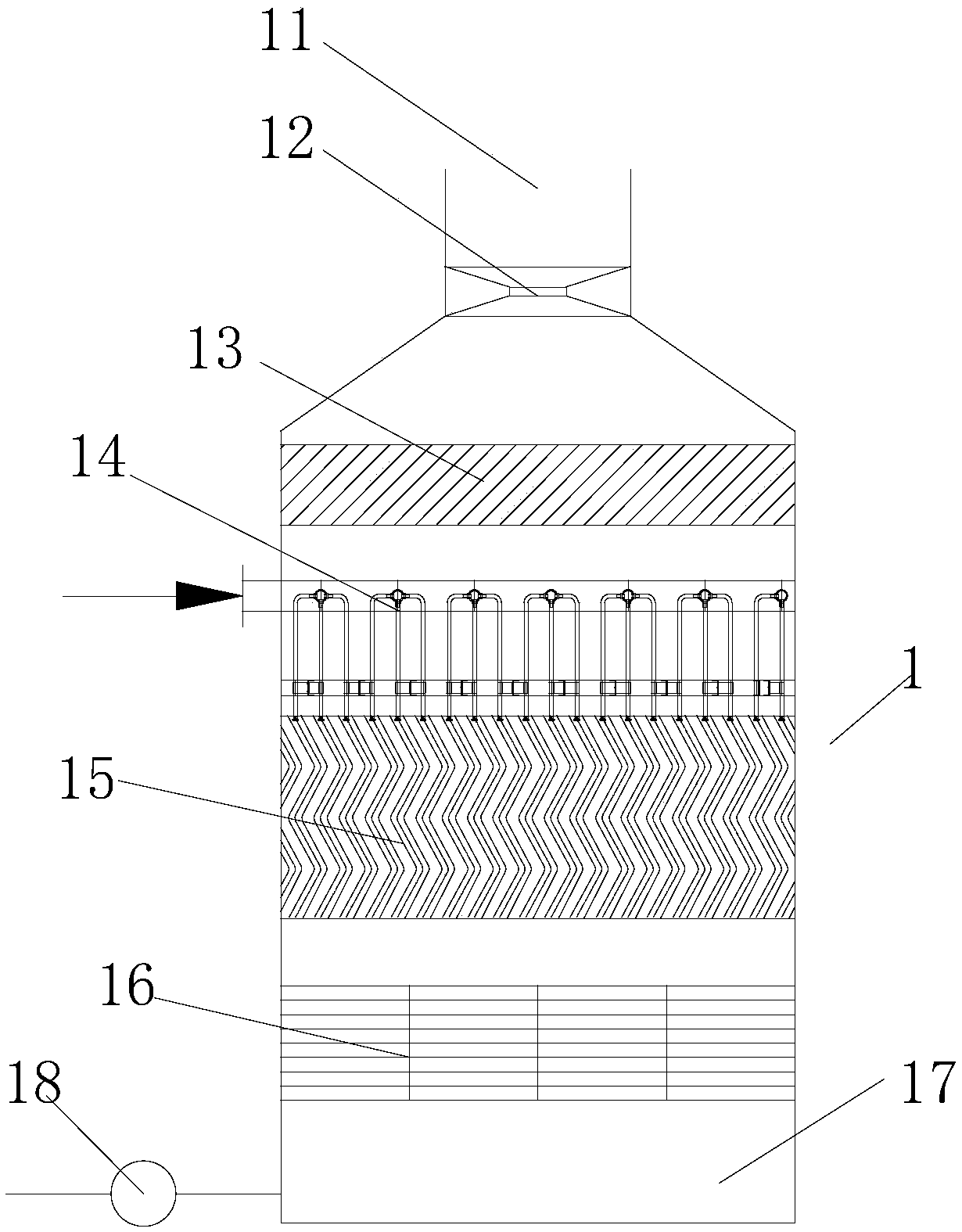

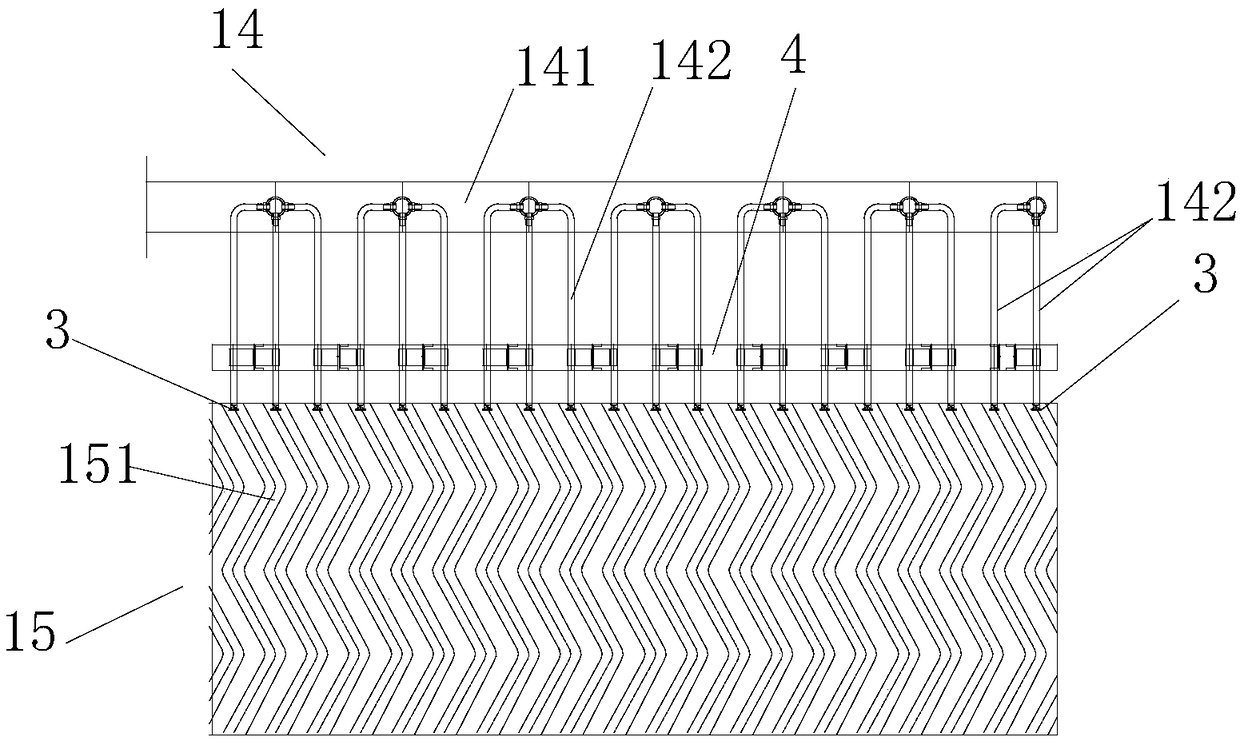

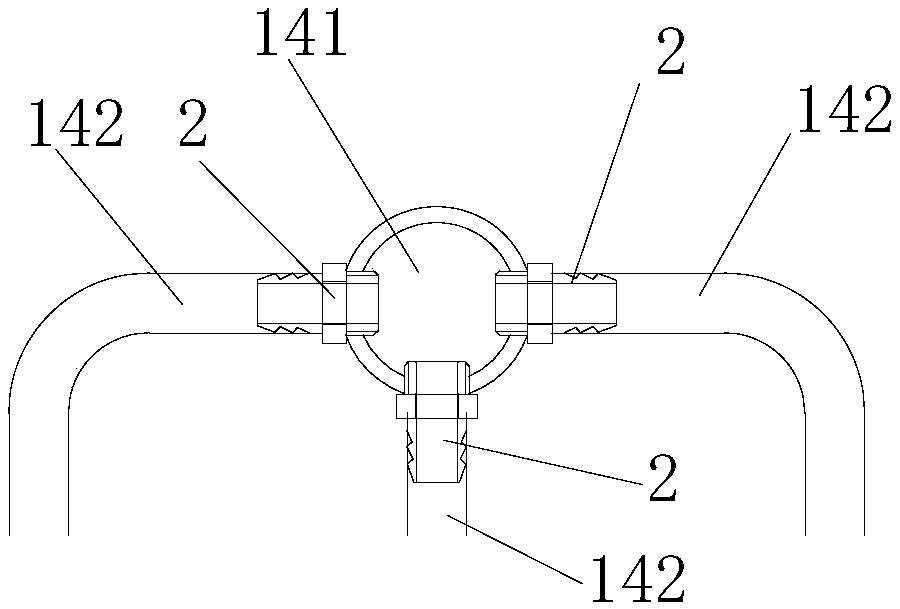

[0020] Embodiment 1: refer to Figure 1-6 . A mechanical cooling tower white smoke elimination device, comprising a tower body 1, the upper end of the tower body 1 is provided with an exhaust port 11, the exhaust port 11 is provided with a fan 12, and the lower part of the exhaust port is sequentially provided with a demister 13, cloth Water system 14, heat exchange packing 15, air intake grille 16, the bottom of the tower body 1 below the air intake grille 16 is used as a circulating water tank 17, inside the heat exchange packing 15 are distributed a number of water flow channels 151 and a number of adjacent water flow channels 151 The air flow channel 152, the water distribution system 14 includes a water distribution main pipe 141 and a water distribution branch pipe 142, the water distribution main pipe 141 is located below the demister 13 above the heat exchange packing 15, and the water distribution main pipe 141 passes through several water distribution branch pipes 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com