A process and method for eliminating smoke plume through flue gas reheating in combination with CO low-temperature denitration

A low-temperature denitrification and flue gas reheating technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of secondary pollution air preheaters, threats to the ecological environment, high biological toxicity, etc., and achieve high denitrification efficiency , avoid sulfur inactivation, the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

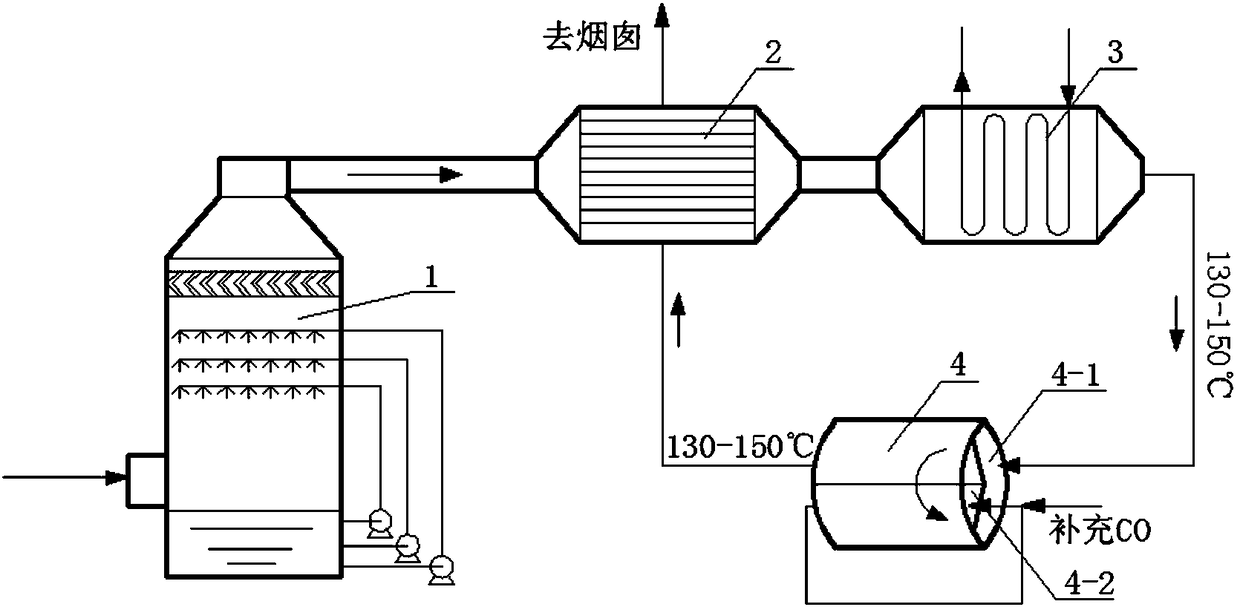

[0036]On the flue behind the wet desulfurization tower 1 of the coal-fired power plant, the gas-gas plate heat exchanger 2, the flue gas heater 3 and the rotary low-temperature denitration reactor 4 are connected in sequence. The low-temperature denitration reactor 4 is divided into nitrogen oxide adsorption Zone 4-1 and CO reduction zone 4-2. The flue gas in the flue behind the induced draft fan enters from the flue gas inlet of the wet desulfurization tower 1, removes sulfur oxides in the flue gas through wet desulfurization, and enters the gas-gas plate heat exchange from the flue gas outlet of the wet desulfurization tower 1 The heat source of gas-gas plate heat exchanger 2 comes from the flue gas at 130°C, and the wet flue gas after desulfurization is heated to 100-120°C, and the flue gas at 100-120°C enters the flue gas for heating The reactor 3 is further heated to 130-150°C. The heat source comes from high-temperature hot water at 150°C, steam turbine extraction or gas...

Embodiment 2

[0038] On the flue behind the wet desulfurization tower 1 of the coal-fired power plant, the gas-gas plate heat exchanger 2, the flue gas heater 3 and the circulating fluidized bed reactor 4 are connected in sequence, and the circulating fluidized bed reactor 4 is divided into an ascending zone The catalyst bed material is loaded in the bed, and the bed material circulates in the ascending zone and the descending zone. The flue gas in the flue behind the induced draft fan enters from the flue gas inlet of the wet desulfurization tower 1, removes sulfur oxides in the flue gas through wet desulfurization, and enters the gas-gas plate heat exchange from the flue gas outlet of the wet desulfurization tower 1 The heat source of gas-gas plate heat exchanger 2 comes from the flue gas at 130°C, and the wet flue gas after desulfurization is heated to 100-120°C, and the flue gas at 100-120°C enters the flue gas for heating The reactor 3 is further heated to 130-150°C, the heat source co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com