Double-membrane microelectrostatic precipitator

A technology of dust collector and micro-electricity, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of dangerous installation and use, difficult operation and maintenance, complex equipment structure, etc., and achieve safe and simple operation , low operation and maintenance and operating costs, and the effect of eliminating white smoke from the chimney

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

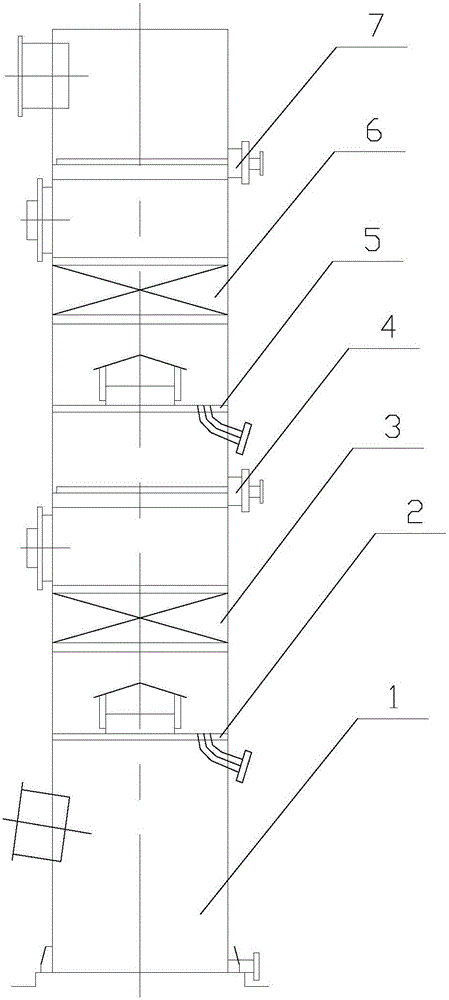

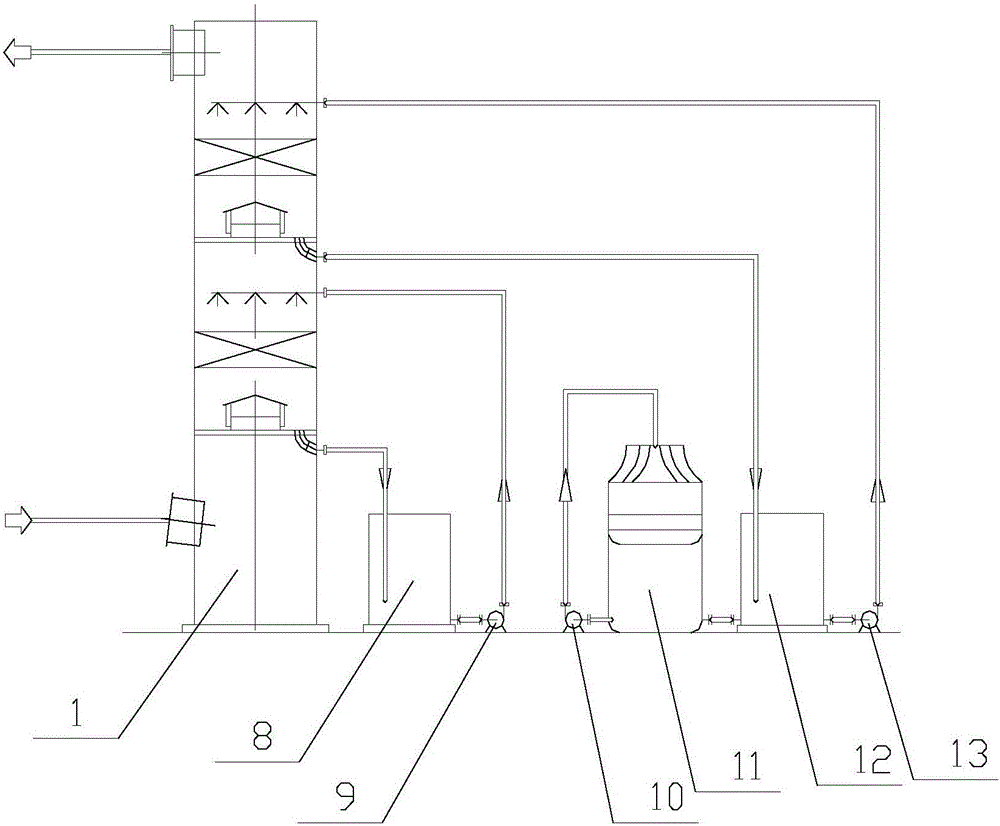

[0011] Such as figure 1 As shown, this specific embodiment adopts the following technical scheme: it includes a main body 1, a first-level dust capture section and a second-level dust capture section, and the main body 1 is provided with a first-level dust capture section and a second-level dust capture section, wherein the first-level dust capture section The section is composed of a first-level three-dimensional mass transfer liquid collection tray 2, a first-stage thin-film micro-electrocoagulation combination layer 3 and a first-level film distribution device 4, and a first-level thin-film micro-electrocoagulation combination layer is arranged above the first-level three-dimensional mass transfer liquid collection pan 2. Layer 3, the first-level thin film micro-electrocoagulation and layer 3 are provided with a first-level membrane distributor 4, and the upper part of the first-level membrane distributor 4 is provided with a second-level dust capture section. The second-lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com