Composite multi-layer dust-raising-preventing anode and electric dust remover with composite multi-layer dust-raising-preventing anode

An electrostatic precipitator and anti-dust technology, which is applied in the field of flue gas pollutant control and electrostatic precipitator, can solve the problems of low re-adsorption efficiency of secondary dust, reduction of dust removal electric field strength, and difficulty in releasing dust charge, so as to avoid back corona. phenomenon, reasonable and uniform corona current, the effect of improving the utilization rate of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

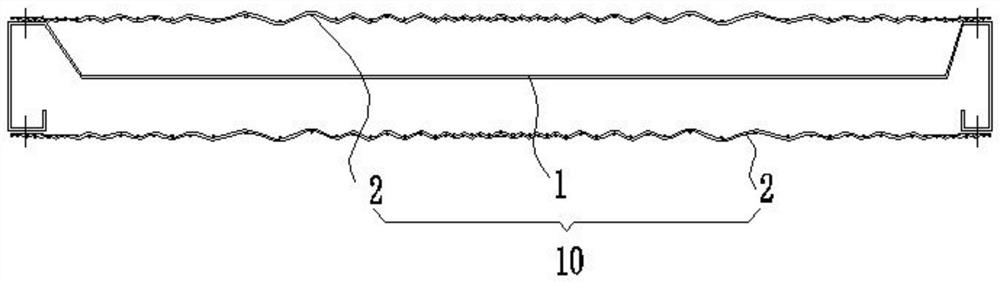

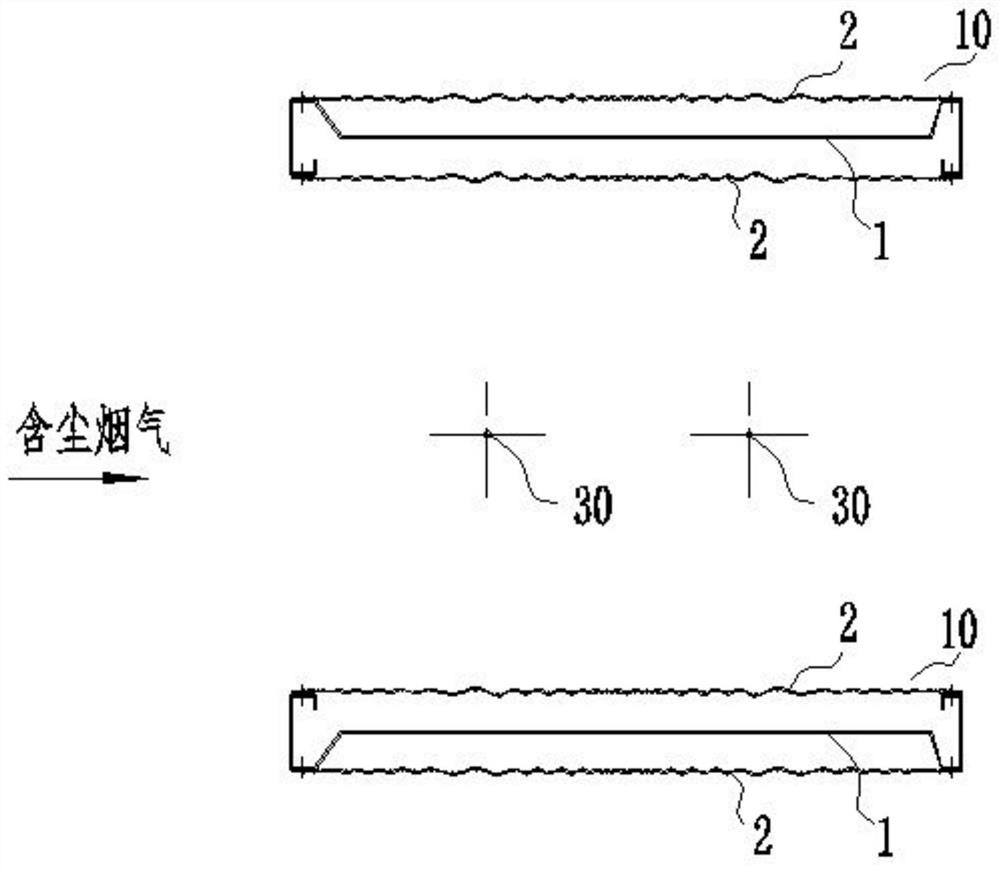

[0029] refer to Figure 1 to Figure 4 , the present invention is a composite multi-layer dust-proof anode, the composite multi-layer dust-proof anode 10 includes an intermediate anode plate 1, filter plates 2 symmetrically arranged on both sides of the intermediate anode plate 1, and the filter plate 2 has Open holes, the filter plate 2 and the intermediate anode plate 1 are separated by a certain distance, forming an electric field shielding area between the two, and the intermediate anode plate 1 is a flat plate or a profiled plate.

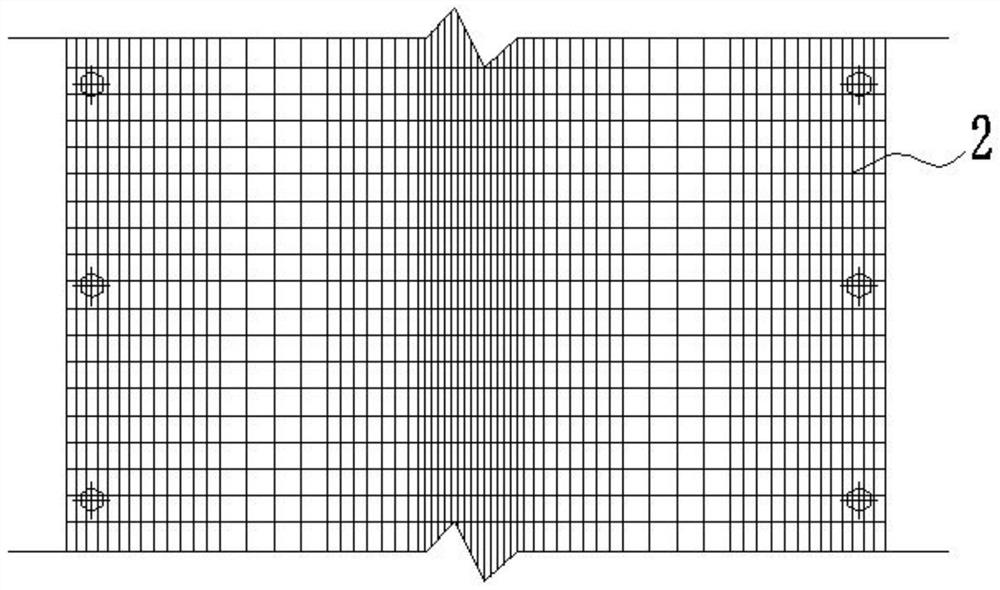

[0030] Further, the filter plate 2 is a layer of metal mesh or a porous plate, and both sides of the filter plate 2 are fixedly connected to the middle anode plate 1 by screws, pressing plates or welding. The filter plate 2 is provided with areas with different opening ratios along the horizontal direction of the anode plate, and the opening ratios of the filter plates 2 on both sides of the middle anode plate 1 are consistent, and the two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com