Novel top and side vibration combined type electric dust remover

An electrostatic precipitator and combined technology, which is applied in the field of the new type of top-strike and side-strike combined electrostatic precipitators, can solve the problem of low utilization rate of the site, achieve the effect of compact overall layout, ensure safe and reliable operation, and facilitate online maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

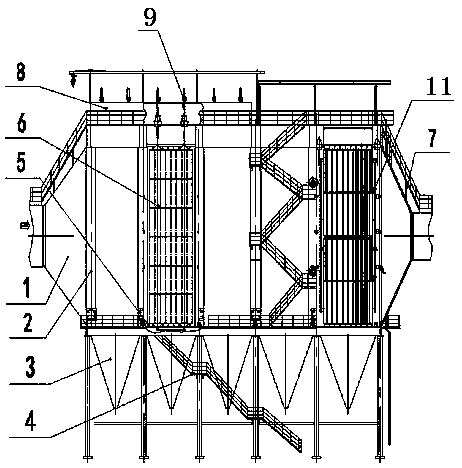

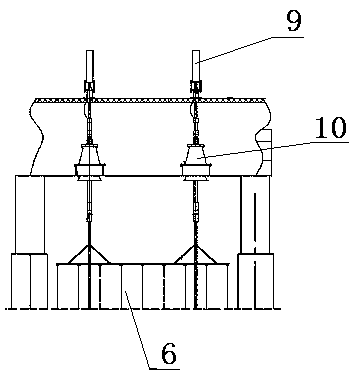

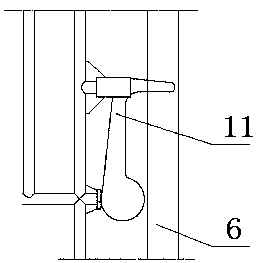

[0017] Such as figure 1 As shown, the first three electric field cathodes adopt the top electromagnetic rapping method, and the latter two electric field cathodes adopt the side rapping method as an example.

[0018] When the dust-laden flue gas flows through the intake smoke box 1 and enters the shell assembly 2, after being ionized by the high-voltage electric field composed of the cathode system 6 and the anode system 5, the dust is collected by the cathode system 6 and the anode system 5, and the clean The flue gas is discharged through the gas outlet smoke box 7.

[0019] The cathode system 6 and the anode system 5 vibrate the collected dust into the ash storage system 3 for collection and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com