Patents

Literature

56results about How to "Meet ultra-low emission requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

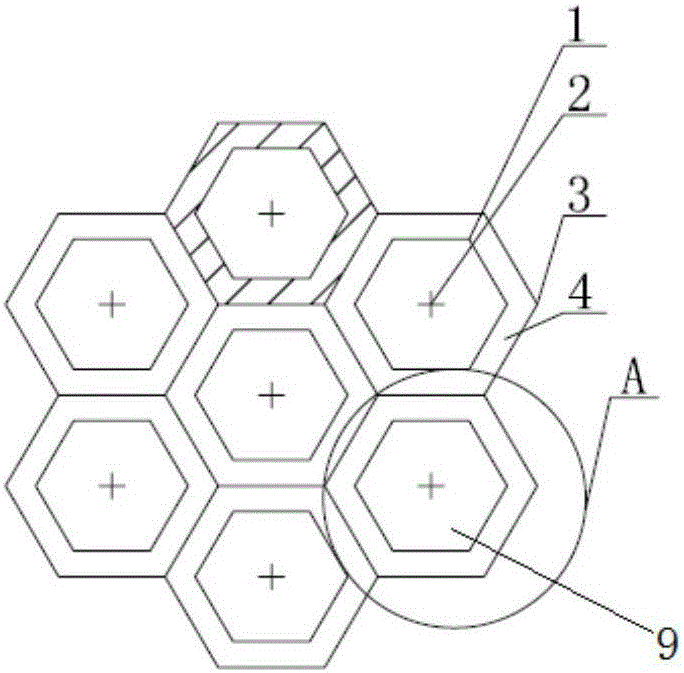

Dedusting and demisting device of spiral flow plate

ActiveCN104874235AGood effect of dust removal and fog removalReduce energy consumptionDispersed particle separationCycloneFlue gas

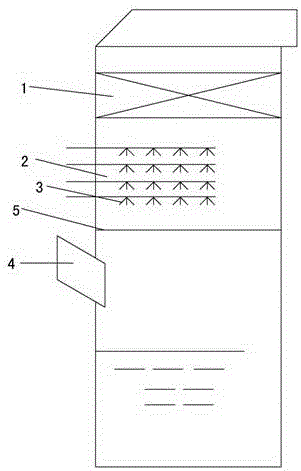

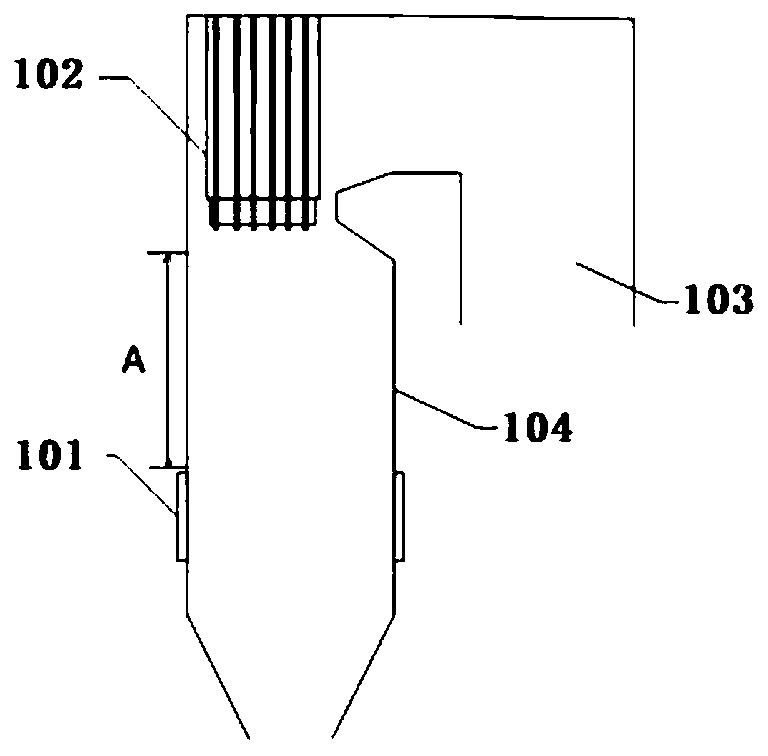

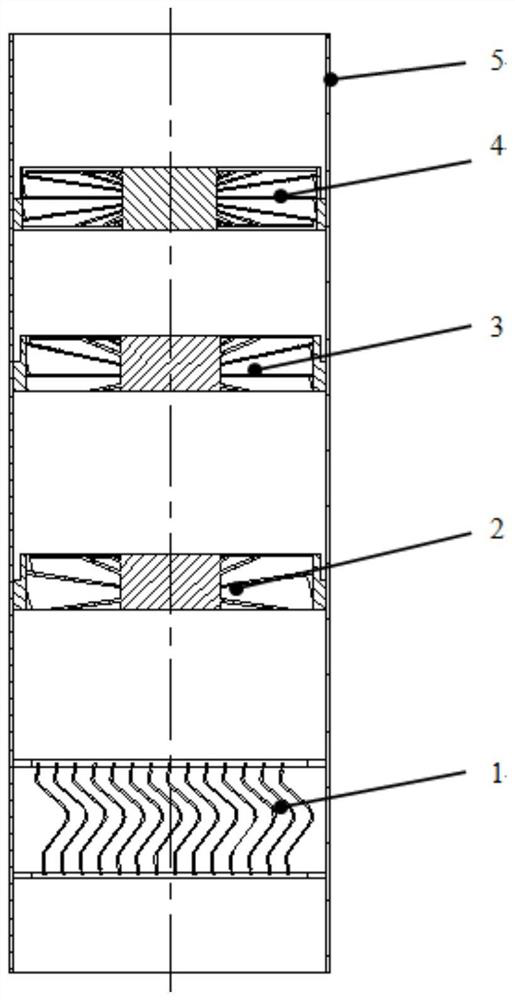

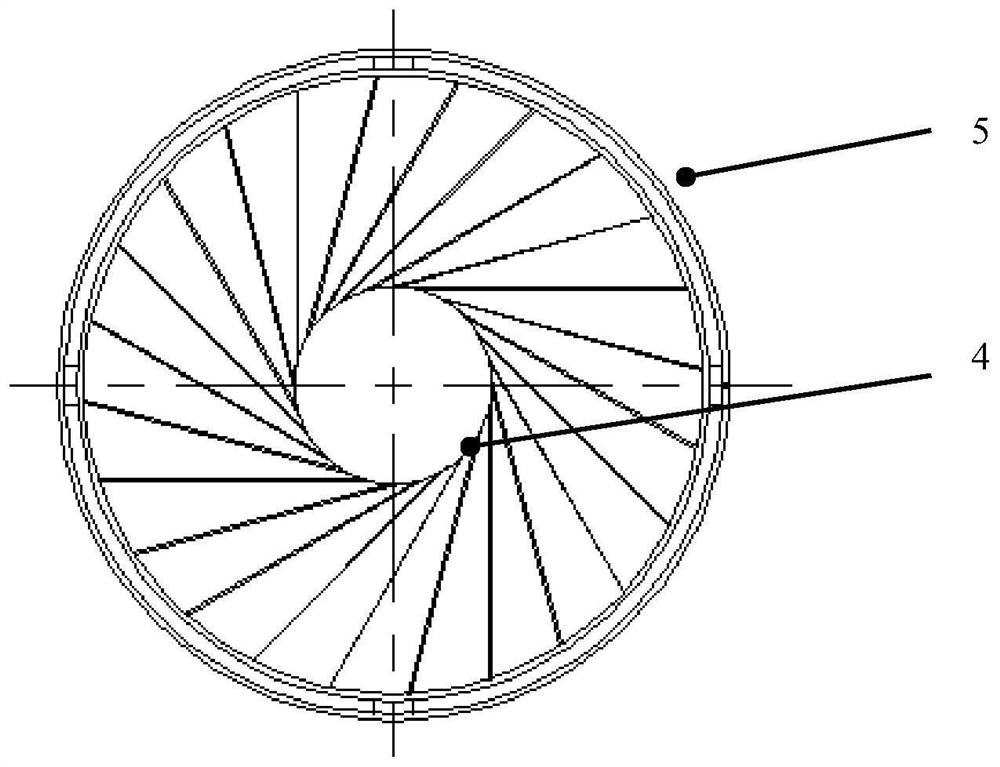

The invention discloses a dedusting and demisting device of a spiral flow plate. The dedusting and demisting device comprises a plurality of dedusting and demisting units, wherein each dedusting and demisting unit comprises a hollow overflowing barrel body, a spiral flow cyclone is arranged in the overflowing barrel body, a flue gas guiding device is connected to the lower part of the spiral flow cyclone, the flue gas guiding device is fixedly connected with the overflowing barrel body, a blowing hole is formed in the flue gas guiding device, and a discharge hole is formed in the inner wall of the overflowing barrel body; the flue gas guiding device is a variable cross-section truncated cone-shaped hollow barrel body of which the cross-sectional area changes continuously, and the upper end surface of the truncated cone-shaped hollow barrel body is connected with the spiral flow cyclone. By using the flue gas guiding device, continuous change of the airflow moving state is realized, the stability of a formed liquid film is good, and secondary entrainment of liquid drops is effectively prevented. Compared with a dedusting and demisting device without the guiding device, the gas distribution state is more uniform, and local disturbance of airflow which passes through the spiral flow cyclone is effectively reduced, so that the airflow moving state is more stable, and the stability of the formed liquid film is better.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

Swirling de-swirling coupled efficient dedusting and demisting assembly

ActiveCN105642024AAvoid bringing outPlay a role in inertia removalDispersed particle separationFriction lossFlue gas

The invention relates to a swirling de-swirling coupled efficient dedusting and demisting assembly. The assembly is arranged above a spraying layer in a desulfurizing absorption tower, and comprises multiple dedusting and demisting units, wherein each dedusting and demisting unit comprises an outer cylinder, and a first stage of centrifugal swirling plate, a second stage of centrifugal swirling plate and a de-swirling hydrophobic plate provided at the top of a hollow complex cylinder aslant which are sequentially and parallelly arranged inside the outer cylinder from bottom to top, and gaps for liquid film falling are reserved among the outer edge of the first stage of centrifugal swirling plate, the outer edge of the second stage of centrifugal swirling plate and the inner wall of the outer cylinder. Compared with the prior art, the swirling de-swirling coupled efficient dedusting and demisting assembly has the advantages of simple and compact overall structure, low investment cost, good operation stability, no scaling blockage risks, capability of realizing deep dedusting and demisting on saturated wet flue gas after desulfurizing, low resistance loss, and good application prospect under lower investment cost and operating cost.

Owner:SHANGHAI JIAO TONG UNIV

Composite dioxygen oxidizing and denitrifying process method and device

InactiveCN106178899AImprove denitrification efficiencyMeet ultra-low emission requirementsGas treatmentDispersed particle separationFlue gasSodium chlorite

The invention belongs to the technical field of denitrifying treatment of nitrate-containing flue gas and particularly provides a composite dioxygen oxidizing and denitrifying process method. The composite dioxygen oxidizing and denitrifying process method comprises the following steps of: weighing and mixing a denitrifying agent and water to prepare denitrifying liquid, wherein the denitrifying agent mainly comprises sodium chlorite and sodium hypochlorite according to the weight ratio of 3-5:1; mixing the denitrifying liquid and nitrate-containing flue gas to be treated so as to carry out denitrifying reaction. The invention also provides a corresponding composite dioxygen oxidizing and denitrifying device. The dioxygen oxidizing and denitrifying method and device provided by the invention have the advantages that the denitrifying efficiency is high, the cost for infrastructure at the earlier stage and operation at the later stage is lower, the reliability is good, and denitrifying treatment for difficultly-treated low-temperature flue gas exhausted by furnace types such as a chain furnace, an incinerator and a kiln furnace and the like can be realized.

Owner:山东格润内泽姆环保科技有限公司

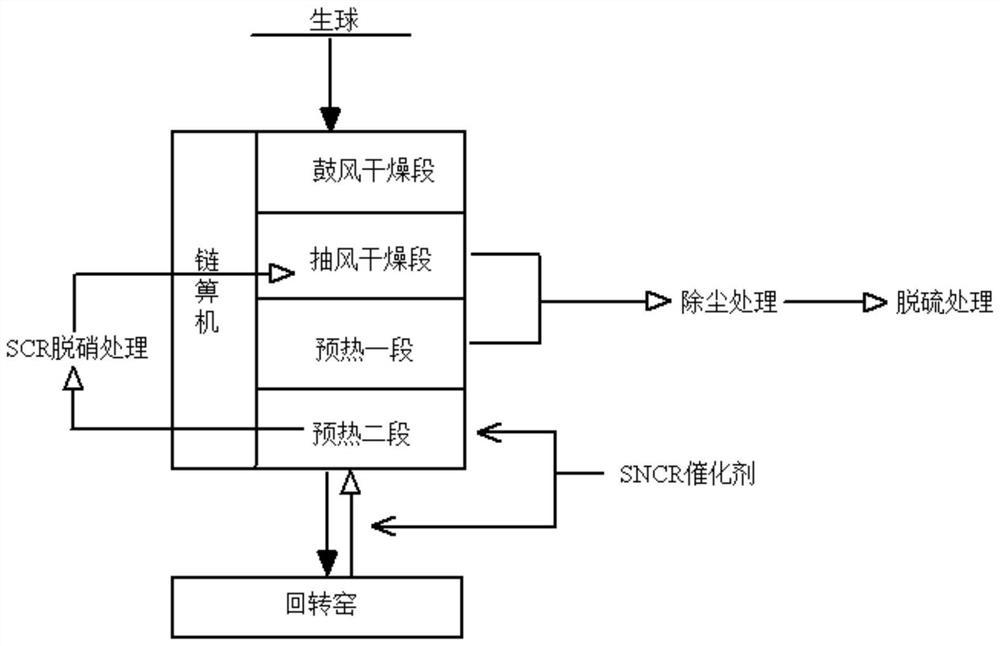

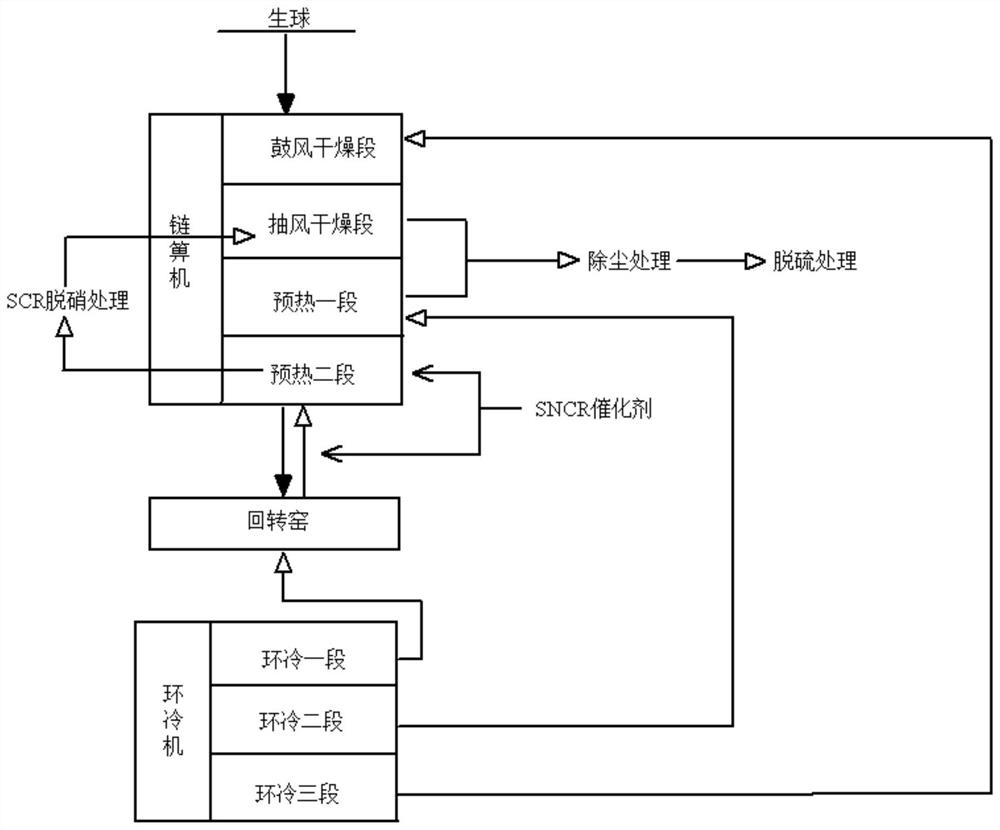

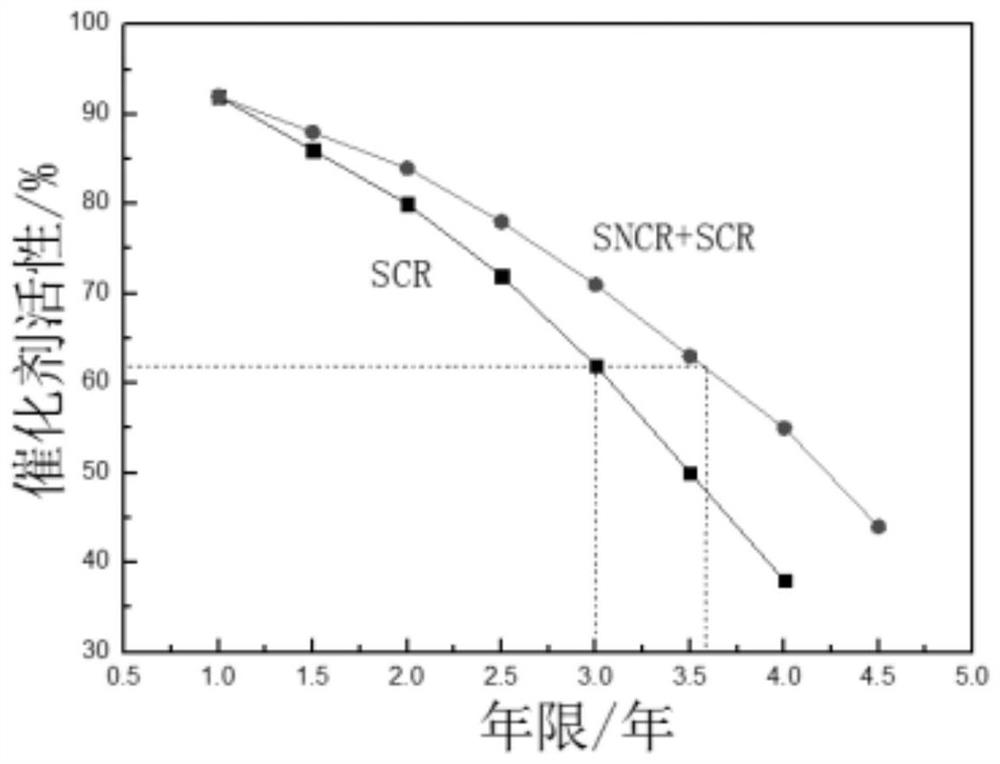

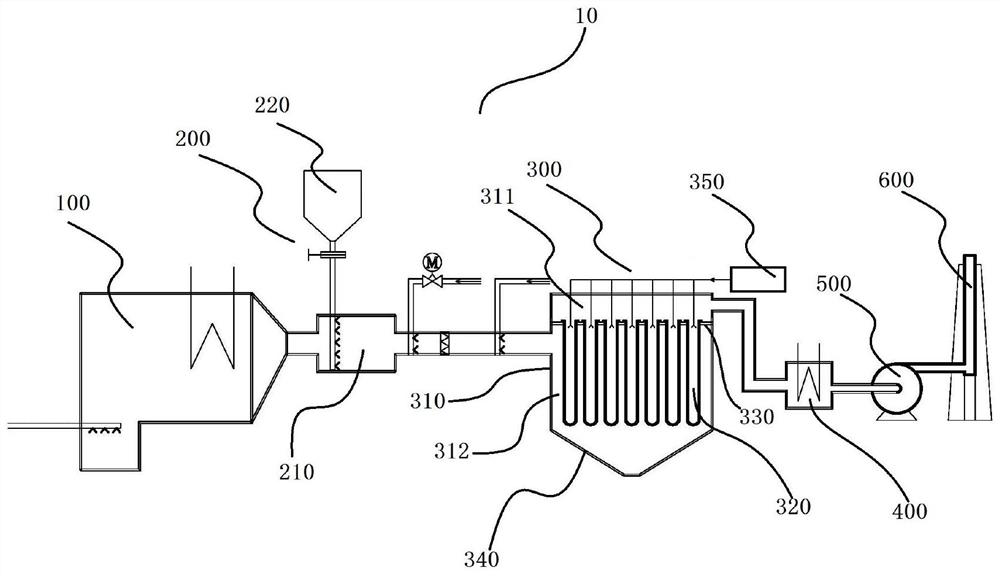

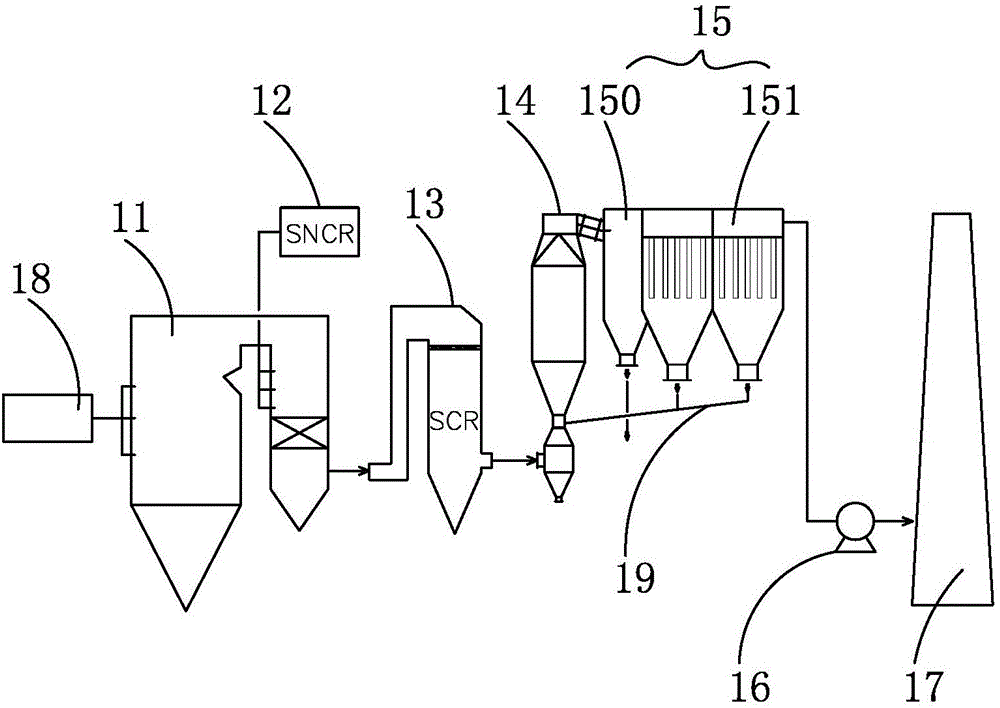

Flue gas treatment process and treatment system

ActiveCN113908677ALow investment costLow running costGas treatmentRotary drum furnacesPtru catalystThermodynamics

The invention discloses a chain grate-rotary kiln flue gas treatment process and treatment system. A control method of an SNCR-SCR coupling denitration system is adopted, a composite additive is added into an SNCR denitration catalyst or a novel SNCR composite ammonia agent is provided; and meanwhile, a movable airflow balance plate is additionally arranged between a PH section and a TPH section of a chain grate, the air pressure of the TPH section is controlled to be larger than or equal to the air pressure of the PH section by utilizing the position change of the airflow balance plate, so that the problem that the content of NOx in flue gas of the TPH section is increased due to the fact that high-NOx-content waste gas of the PH section flees towards the TPH section is prevented. The optimal coupling ultralow NOx emission technology can be formed, the denitration efficiency can be effectively guaranteed on the premise that SNCR ammonia consumption is reduced, meanwhile, the service lifetime of an SCR denitration catalyst can be prolonged, and the denitration operation cost and investment cost of the system are obviously reduced. The utilization efficiency of a flue gas denitration reducing agent is further improved, and the escape amount of NH3 is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

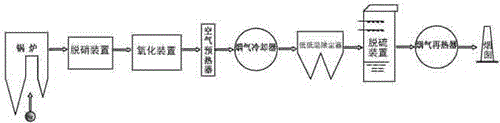

Device and method for removing pollutants in flue gas

InactiveCN106474890AMeet environmental protection requirementsMeet ultra-low emission requirementsGas treatmentDispersed particle separationAir preheaterElectricity

The invention provides a device and a method for removing pollutants in flue gas. The device comprises a boiler, wherein the flue gas from the boiler sequentially passes by a denitration device, an oxidation device, an air preheater, a flue gas cooler, a low-low temperature dust remover, a desulfurizer and a flue gas reheater and is discharged from a chimney. Nitrogen oxide and mercury in the flue gas can be removed simultaneously in the desulfurization process; free mercury in the flue gas is oxidized with a strong oxidizer before the flue gas enters an ammonia desulfurization system, ionic Hg<2+> is fixed by an properly supplemented aid, and Hg<2+> is removed together with the flue gas in a dust removal system; the environment-friendly requirements can be met with an SNCR process instead of a high-investment SCR process after NOX is oxidized, and investment is reduced; a low-low temperature dust removal technology is adopted, the concentration of flue gas dust at an inlet of a desulfurization system is reduced, and the desulfurization system can meet the requirement for ultralow emission without adopting wet-type electric precipitation.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

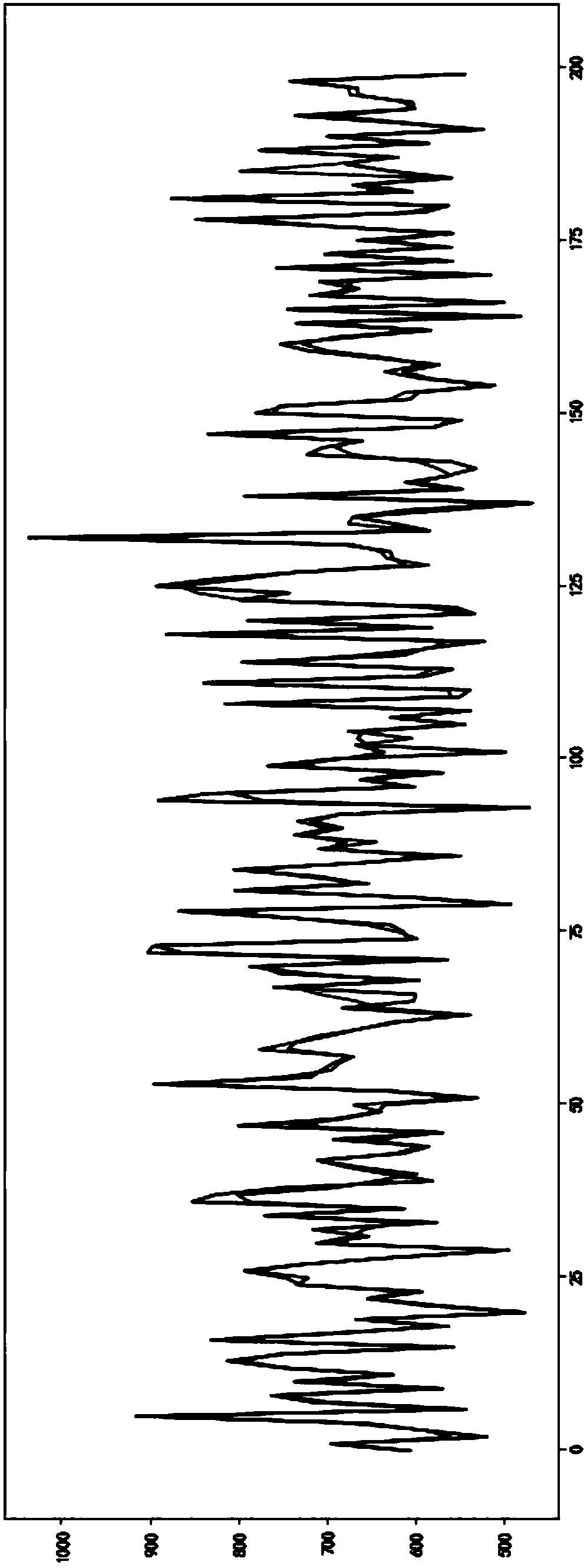

Random forest model based power-station boiler flue gas denitration method

ActiveCN109426144AFitting EfficientSolve processing problemsGas treatmentDispersed particle separationPower stationControl system

The invention provides a random forest model based power-station boiler flue gas denitration method, and belongs to the technical field of denitration in a power plant. The method comprises the following steps that S1) an OFA air door instruction, a low-nitrogen air door instruction, a secondary wind pressure, a mill fan running station, a hearth oxygen content, a set main steam flow of a flue gasdenitration system are set as independent variable parameters and the inlet NOx concentration of an SCR reactor is set as a dependent variable parameter of a training model; S2) historical data of the independent and dependent variable parameters of the flue gas denitration system is recorded; S3) the historical data of the independent and dependent variable parameters is input to a random forestmodel to obtain a random forest denitration model; S4) during denitratio, a predicted value of the inlet NOx concentration of the SCR reactor is obtained from the random forest model; and S5) the opening degree of an ammonia supply control valve is calculated according ot the predicted value of the inlet NOx concentration of the SCR reactor, and ammonia spraying denitration is carried out. The problems of nonlinearity and much delay of a control object of the SCR ammonia spraying control system in the prior art are solved.

Owner:邢台国泰发电有限责任公司

Flue gas pollutant removal system suitable for small-scale unit

PendingCN111760436APromote absorptionEfficient desulfurizationGas treatmentDispersed particle separationFiberFlue gas

The invention discloses a flue gas pollutant removal system suitable for a small-scale unit. The system comprises a boiler, a desulfurization absorption device, a dust nitrate filtering device, a waste heat recovery device, an induced draft fan and a chimney which are sequentially connected through a pipeline, wherein the desulfurization absorption device comprises a desulfurization reaction device and a desulfurizing agent bin, the desulfurizing agent bin is connected above the desulfurization reaction device through a pipeline, and the desulfurization reaction device is connected with the boiler through a pipeline; and the dust nitrate filtering device comprises a box body and a plurality of ceramic fiber filtering pipes, the box body is connected with the desulfurization reaction devicethrough a pipeline, and the plurality of ceramic fiber filtering pipes are arranged in the box body. According to the flue gas pollutant removal system provided by the invention, three flue gas purification processes of dust removal, desulfurization and denitrification can be completed in one device, and the flue gas pollutant removal system is an integrated flue gas purification process system,occupies a small area, is suitable for the small-scale unit, and can meet stricter ultralow emission requirements.

Owner:上海电气电站环保工程有限公司

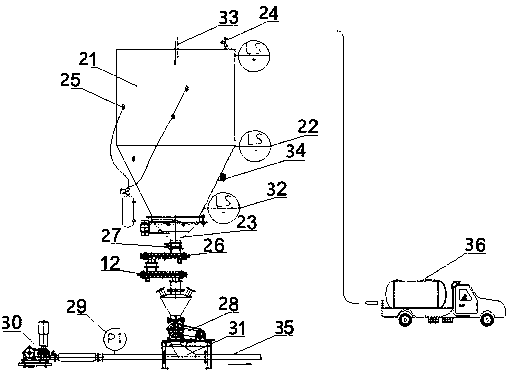

Device and process method for ERDIII cement plant ultra-low emission denitration

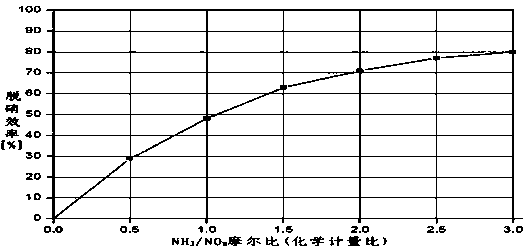

PendingCN110218584AReduce escapeReduce the burden of denitrificationGas treatmentDispersed particle separationDecompositionAmmonia

The invention discloses a device and a process method for ERDIII cement plant ultra-low emission denitration. The device for ERDIII cement plant ultra-low emission denitration comprises a decomposition furnace and a powder denitration agent conveying unit, wherein the bottom part of the decomposition furnace is provided with a secondary wind inlet which is connected with a cement rotary kiln; thedecomposition furnace comprises a reducing zone, a main burning zone, a reburning zone and a burnout zone from bottom to top; the reducing zone is equipped with a reducing zone saturated steam catalytic burner; the reburning zone is equipped with a reburning zone saturated steam catalytic burner; the main burning zone is connected with tertiary wind; the burnout zone is connected with burnout wind; and the discharge pipe of the powder denitration agent conveying unit is connected with a denitration agent spray gun which is connected with the reburning zone. According to the invention, throughintroduction of a denitration catalyst, the usage amount of ammonia water for denitration is reduced; the cost is saved; ammonia escape is reduced; more economy and environmental friendliness are achieved; and due to reduction of ammonia escape, corrosion to subsequent equipment is avoided.

Owner:上海三融环保工程有限公司

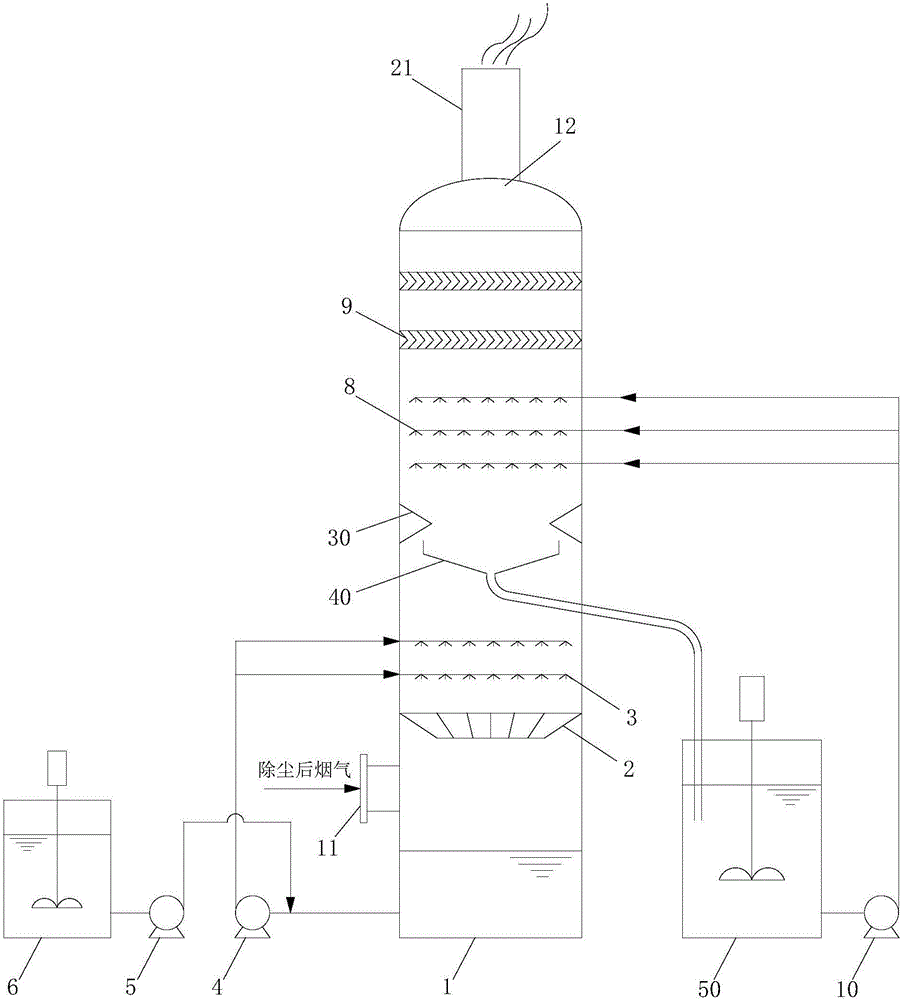

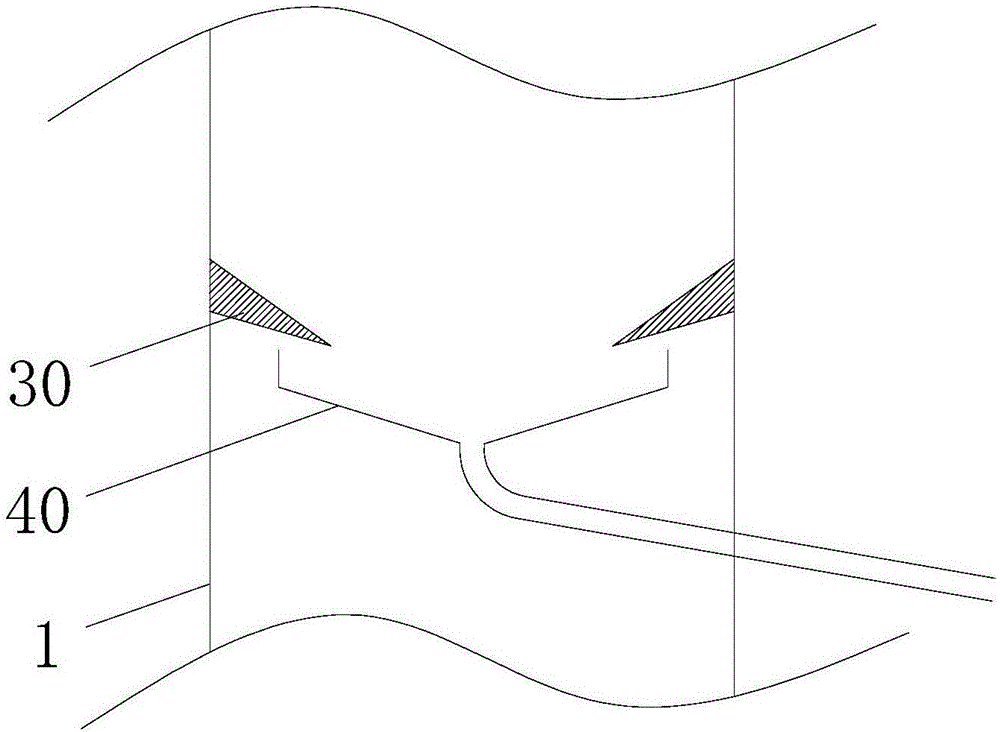

Single-tower and dual-cycle desulfurizing system and desulfurizing technology

InactiveCN109107357AAchieve series effectImprove solubilityGas treatmentCalcium/strontium/barium sulfatesFlue gasSlurry

The invention relates to a single-tower and dual-cycle desulfurizing system which comprises a desulfurizing tower and an oxidizing tower, wherein the tower body of the desulfurizing tower is providedwith a flue gas inlet, a flue gas outlet, a first limestone slurry inlet, a first oxidized air inlet, a gypsum slurry discharge port and a first limestone slurry outlet; a first-level spray layer, a tray, a second-level spray layer and a demister are arranged in the desulfurizing tower from bottom to top; the first limestone slurry outlet is connected with the first-level spray layer through a pipeline and a first limestone slurry circulating pump; the demister is provided with a demister flushing water system; the tray is connected with the oxidizing tower through a pipeline; the oxidizing tower is also provided with a second limestone slurry inlet, a second oxidized air inlet and a second limestone slurry outlet; the second limestone slurry outlet is connected with the second-level spraylayer through a pipeline and a second limestone slurry circulating pump. The desulfurizing system provided by the invention realizes a higher desulfurizing efficiency and also can obtain gypsum withperfect quality.

Owner:吉林省京能水处理技术有限公司

Sound-wave-coupling rotational flow-rotation eliminating efficient dust removing and defogging device

ActiveCN106237724ASatisfied that the dust content is less than 5mg/Nm

<sup>3</sup>

ultra-low emission requirementsGood effect of dust removal and fog removalAuxillary pretreatmentSprayerFlue gas

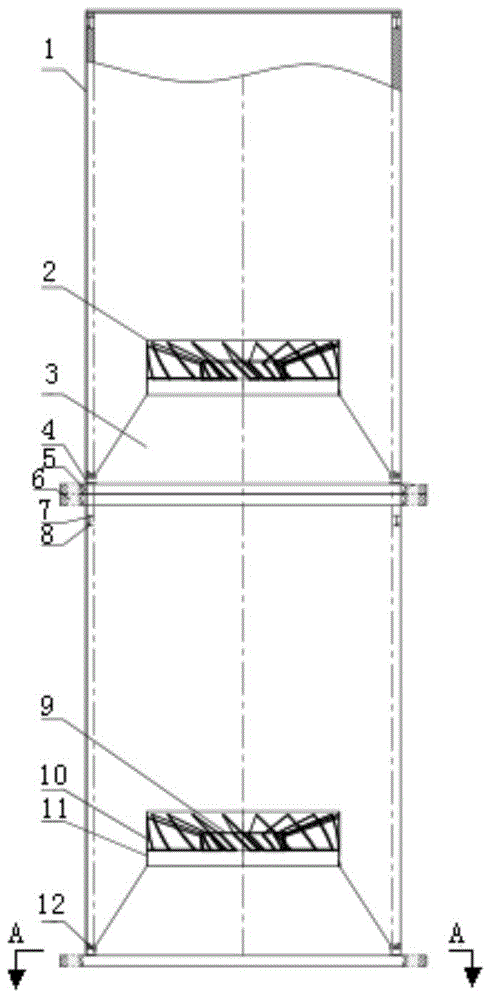

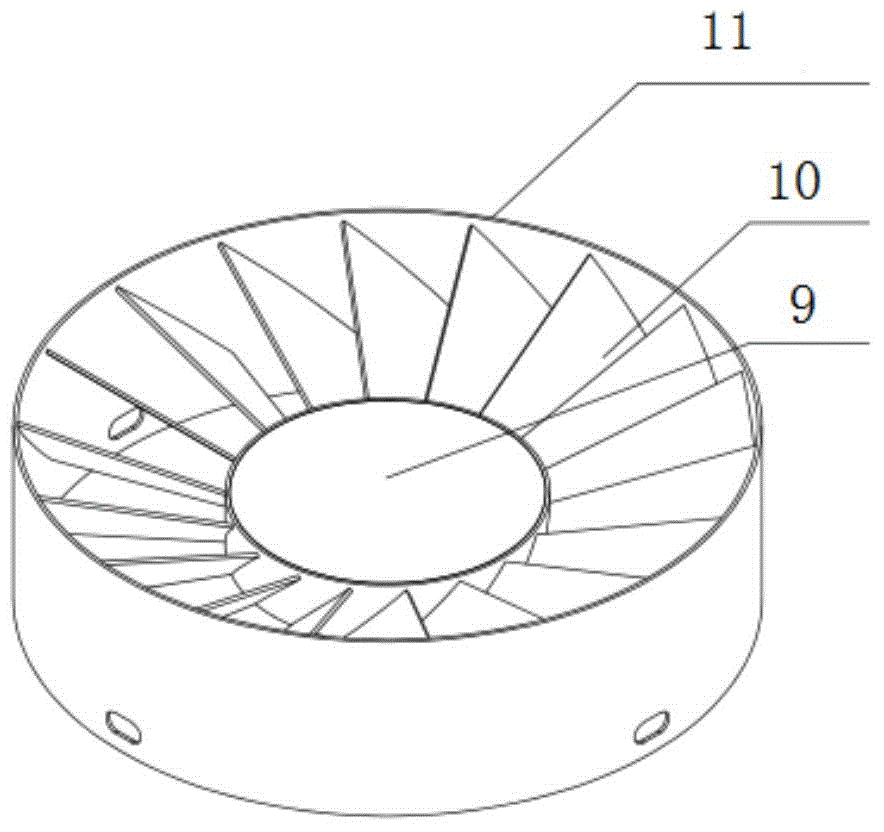

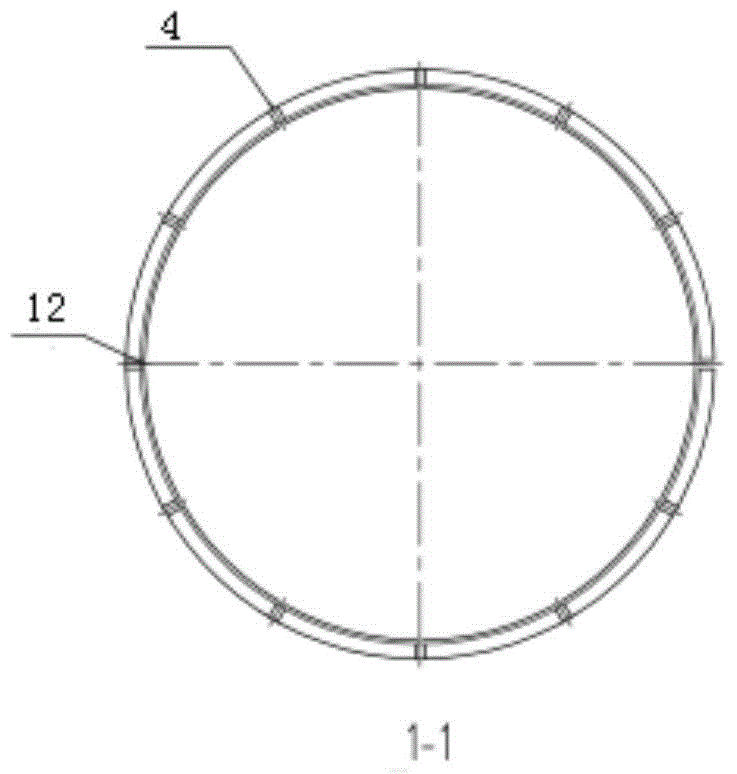

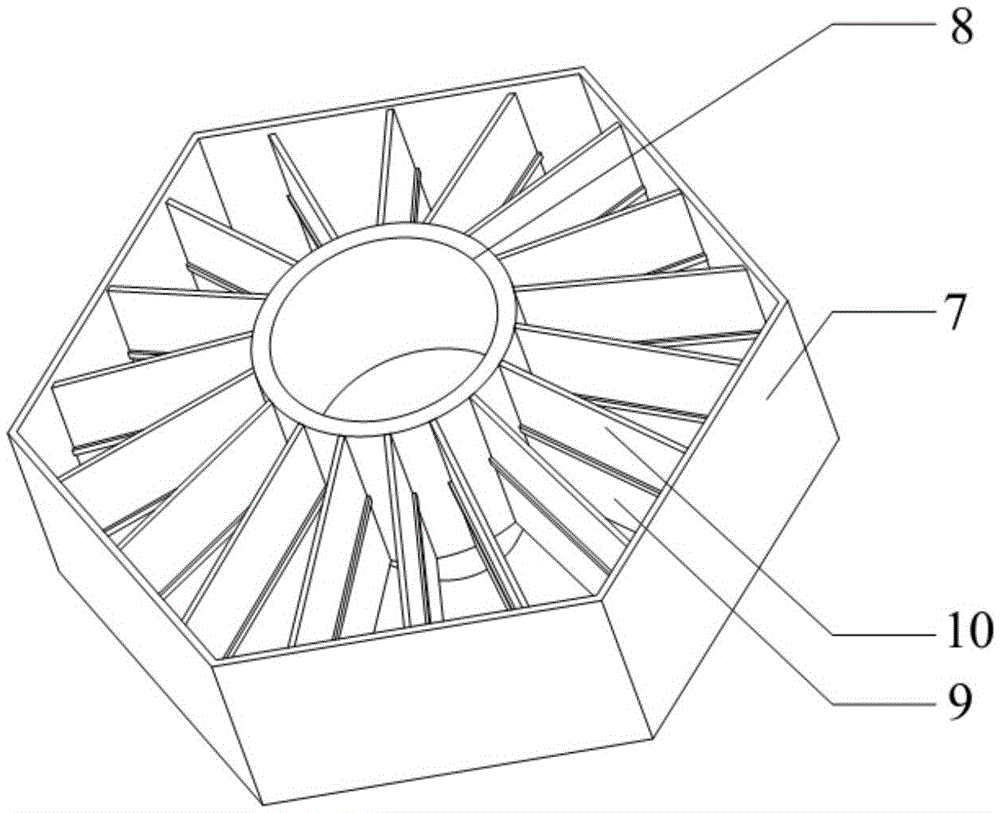

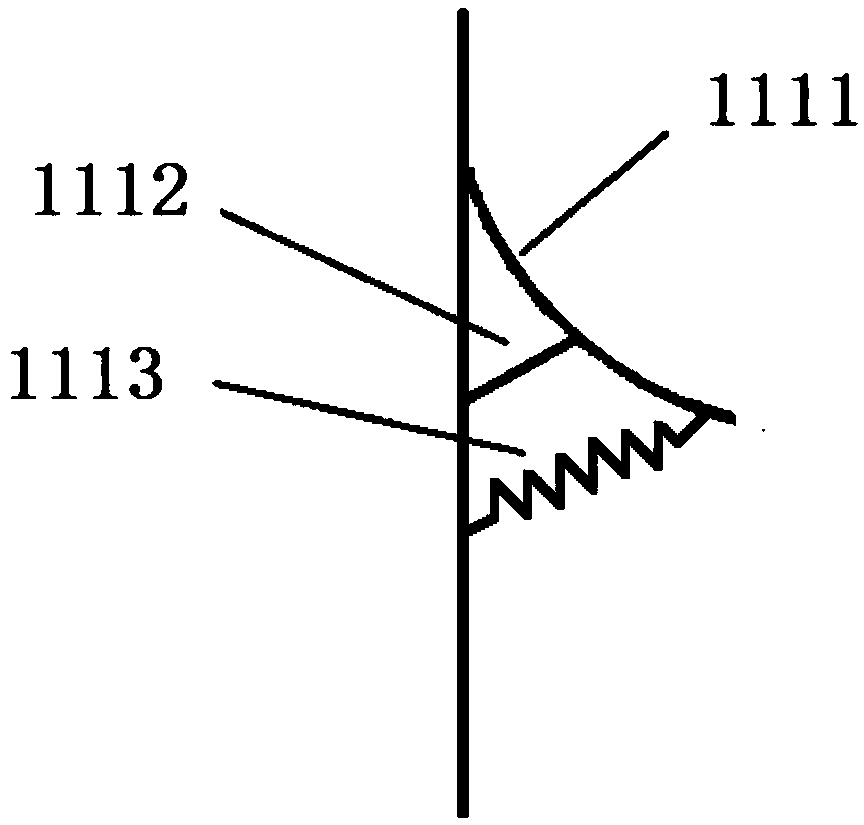

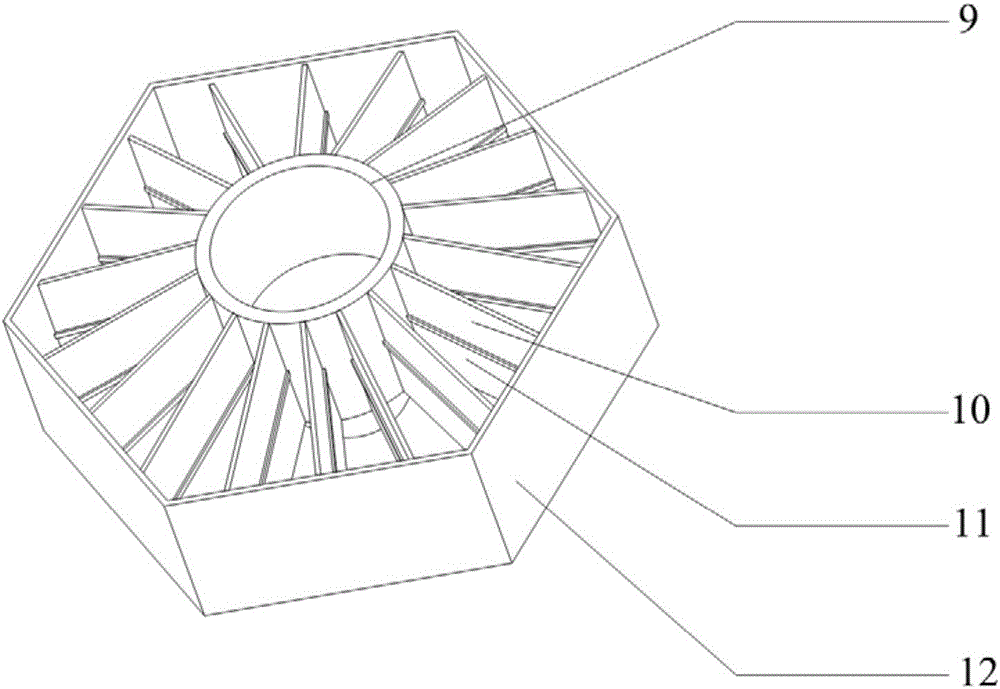

The invention relates to a sound-wave-coupling rotational flow-rotation eliminating efficient dust removing and defogging device. The sound-wave-coupling rotational flow-rotation eliminating efficient dust removing and defogging device is arranged above a spraying layer in a desulfurization absorption tower and comprises a plurality of dust removing and defogging units which are parallelly mounted. Each dust removing and defogging unit comprises an outer cylinder, a primary centrifugal rotational-flow plate, a secondary centrifugal rotational-flow plate and a rotation-eliminating hydrophobic plate, wherein the primary centrifugal rotational-flow plate and the secondary centrifugal rotational-flow plate are sequentially parallelly arranged in the outer cylinder from bottom to top, the rotation-eliminating hydrophobic plate is obliquely arranged at the top of the outer cylinder, a sound wave generator is arranged at the center of the primary centrifugal rotation-flow plate, and a washing water sprayer is arranged between the sound wave generator and the secondary centrifugal rotation-flow plate. Compared with the prior art, the sound-wave-coupling rotational flow-rotation eliminating efficient dust removing and defogging device has the advantages that the device integrates the features of sound wave and rotational-flow centrifugal dust removing and defogging, and the device is simple and compact in overall structure, low in investment cost, good in operation stability, free of scaling and blocking risks, capable of achieving deep dust removing and defogging of saturated wet flue gas after desulfurization under low investment cost and operation cost, low in resistance loss and promising in application prospect.

Owner:SHANGHAI JIAO TONG UNIV

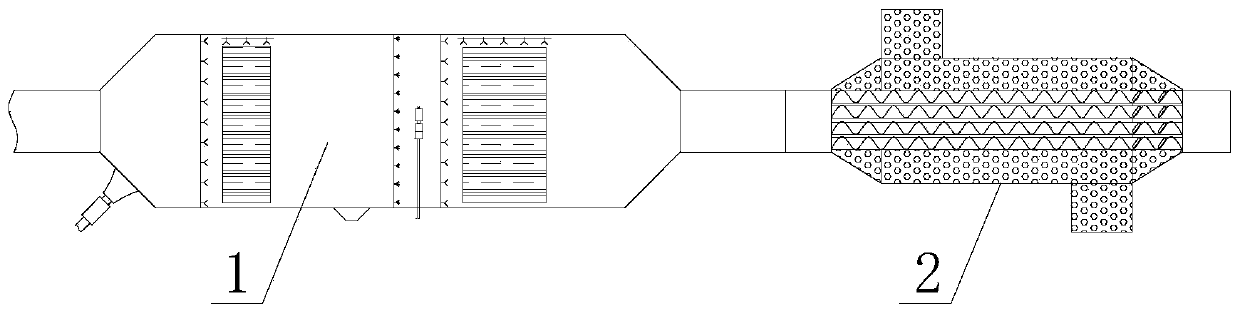

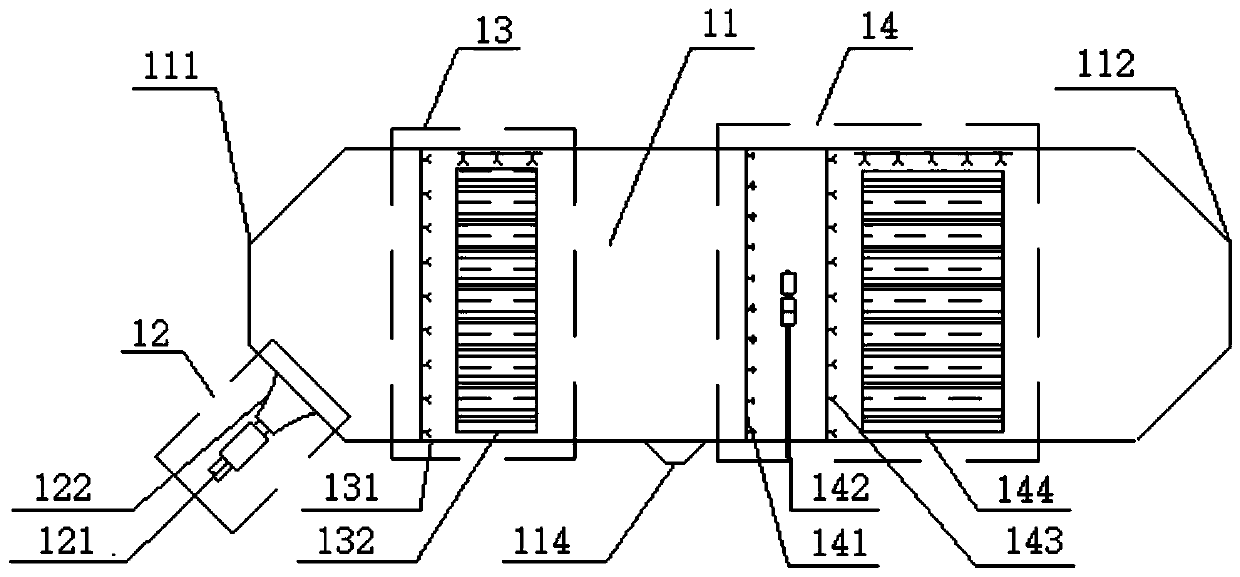

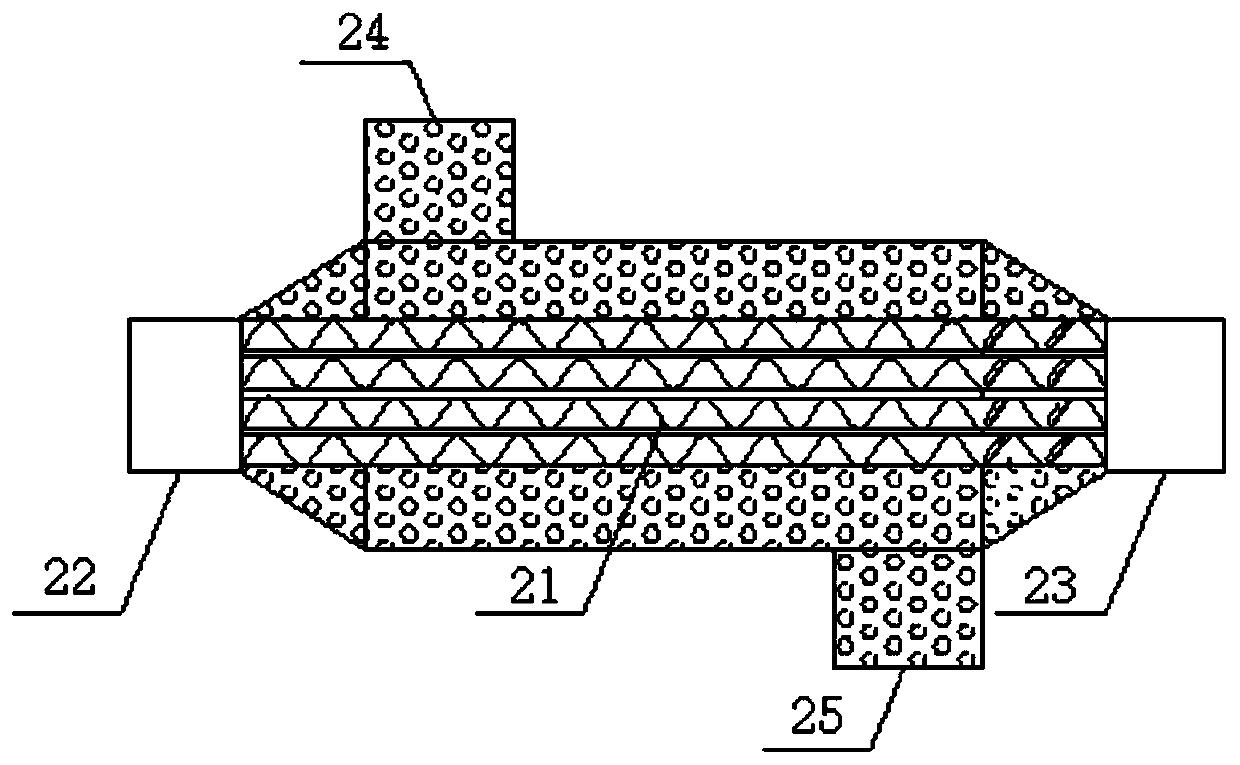

Smoke ultra-low emission purification equipment of coal-fired industrial boiler

ActiveCN106524205AMeet ultra-low emission requirementsGas treatmentEmission preventionCombustionBiochemical engineering

The invention relates to smoke ultra-low emission purification equipment of a coal-fired industrial boiler. The smoke ultra-low emission purification equipment of the coal-fired industrial boiler comprises SNCR denitrification equipment communicating with a boiler body, and a desulfurization and denitrification dust removal assembly communicating with a smoke outlet flue of the boiler. The sulfurization and denitrification dust removal assembly is connected with a purified air outlet. When the boiler is a medium-small coal-fired industrial boiler with unstable combustion and loads, the SNCR denitrification equipment is medium-temperature denitrification equipment, and the denitrification temperature is 500-800 DEG C. When the boiler is a medium-large coal-fired industrial boiler with stable combustion and loads, the SNCR denitrification equipment is high-temperature denitrification equipment, and the denitrification temperature is 800-1100 DEG C. The purification equipment can meet the ultra-low emission requirements that the smoke exhaust concentration is smaller than or equal to 5 mg / m<3>, the SO2 emission concentration is smaller than or equal to 35 mg / m<3>, and the NOx emission concentration is smaller than or equal to 50 mg / m<3>.

Owner:科林环保技术有限责任公司

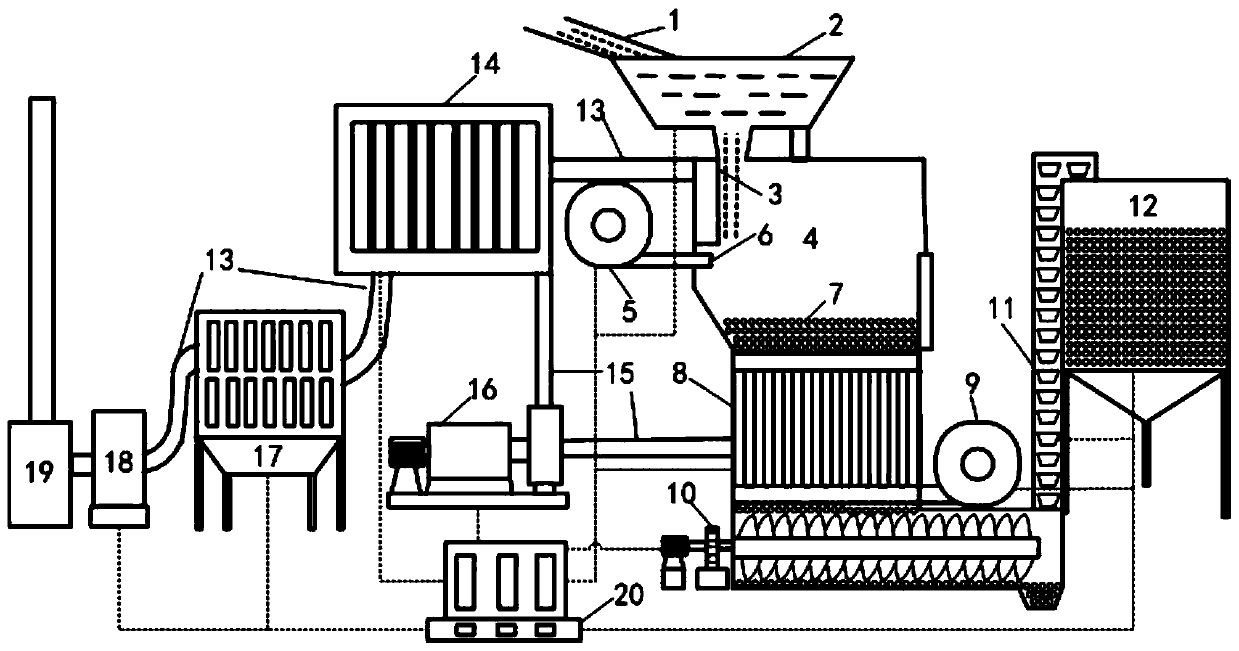

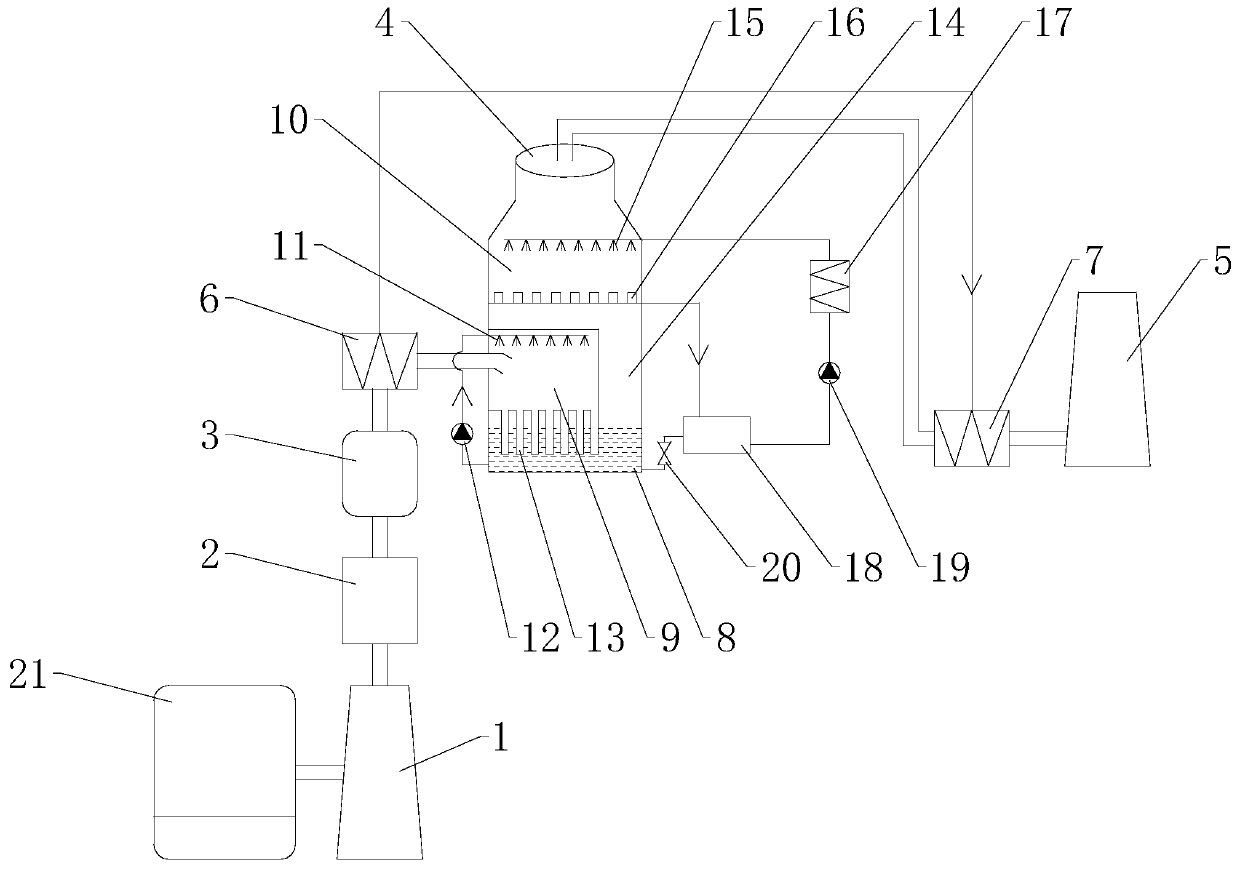

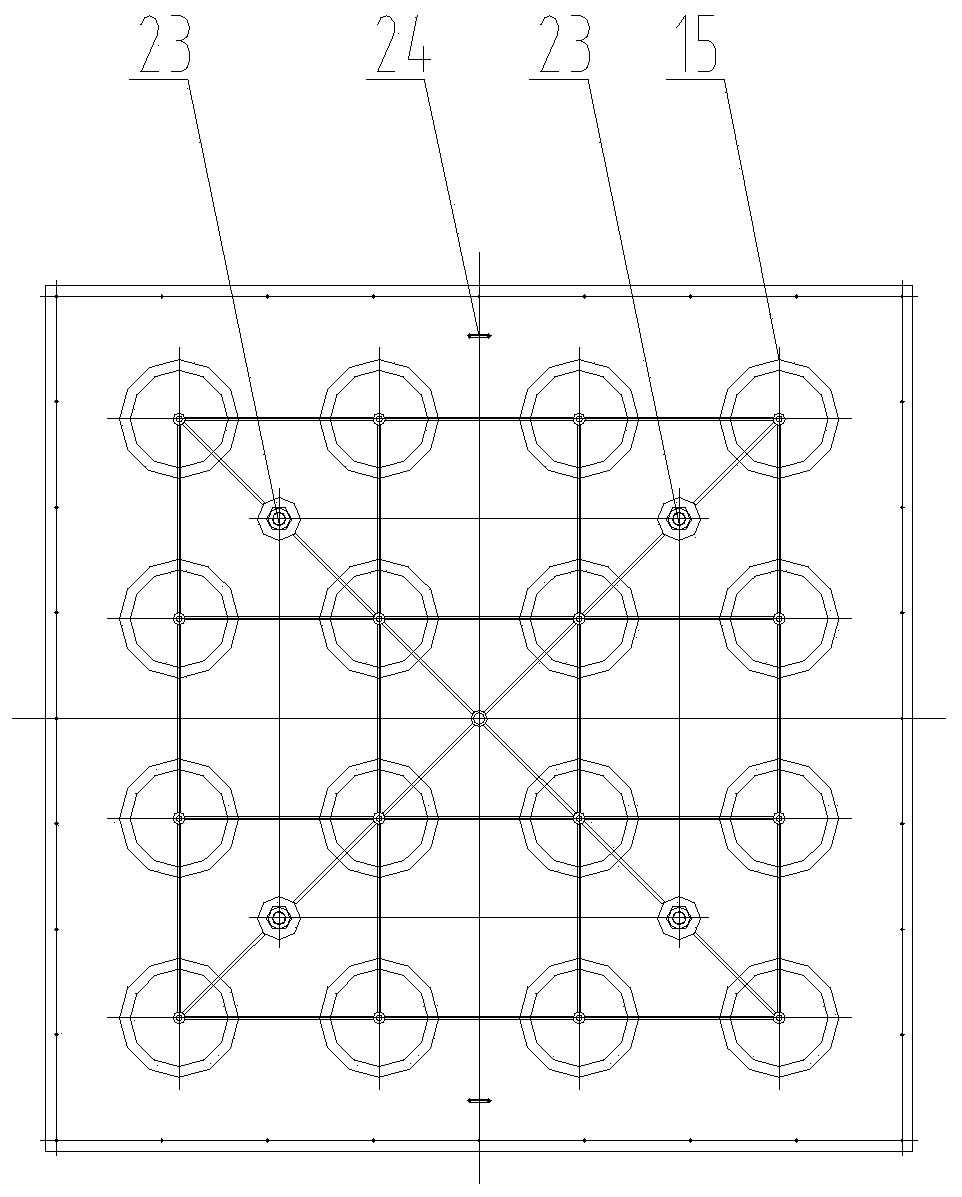

Device and method for glass granulation and waste heat recovery of molten smelting slag

PendingCN110117164AThe process is simpleHigh degree of equipment automationDomestic cooling apparatusGlass shaping apparatusSlagTundish

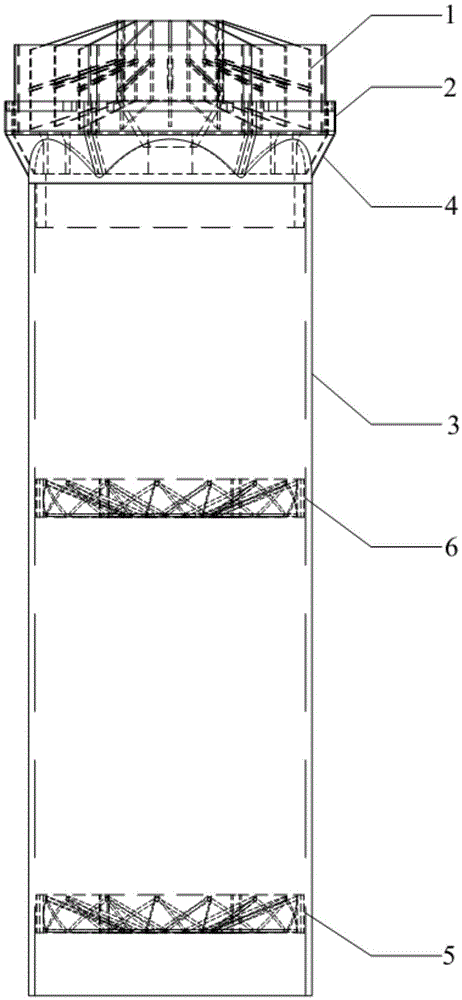

The invention relates to a device and method for glass granulation and waste heat recovery of molten smelting slag. The device comprises a chute (1), a tundish (2), a flow guide groove (3), a granulating chamber (4), a granulating fan (5), a blast groove (6), a tubular heat exchanger (8), a cooling fan (9), a spiral discharge device (10), a lifter, preferably a bucket lifter (11), a finished product bin (12), a platy heat exchanger (14), a first steam pipe (15), a second steam pipe (15), a power generator set (16) and a purifying and discharging apparatus. The molten smelting slag is convertedinto vitreous particles through the device in order to facilitate resource utilization; meanwhile, waste heat recovery is carried out, maximum recovery of molten smelting slag resources is realized,and the high-efficiency, well-equipped, automated, harmless and resourceful treatment of the molten smelting slag is achieved, and ultra-low emission is realized in the treatment process; the device has an outstanding process and the advantage of being environmentally friendly.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

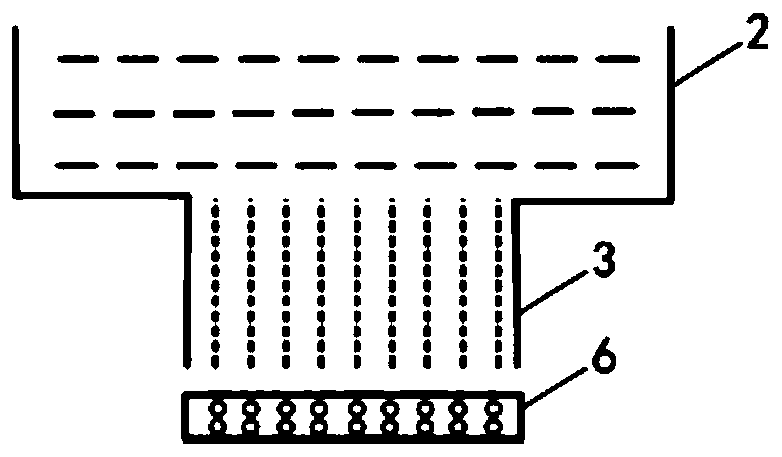

Electric and bag-type composite dust removing device and treatment method thereof

The invention provides an electric and bag-type composite dust removing device and a treatment method thereof. The electric and bag-type composite dust removing device comprises an electric dust removing zone arranged at the lower part thereof and a bag-type dust removing zone arranged above the electric dust removing zone, wherein a flue gas inlet connected with the electric dust removing zone isformed in one side of the bottom of the electric and bag-type composite dust removing device; a flue gas outlet connected with the bag-type dust removing zone is formed in one side, opposite to the flue gas inlet, of the top of the electric and bag-type composite dust removing device; a first flow guiding plate is arranged between the flue gas inlet and the electric dust removing zone; and a second flow guiding plate is arranged between the electric dust removing zone and the bag-type dust removing zone. In the electric and bag-type composite dust removing device, flue gas is charged and trapped by the electric dust removing zone and upwardly enters the bag-type zone for dust removal, so that the flue gas is prevented from rightly scouring a filter cloth bag, the service life of the filter cloth bag is prolonged, the floor area of the electric and bag-type composite dust removing device is reduced, and the factory using area is reasonably utilized; through arrangement of the gas flowguiding plates, the flow direction of a gas flow can be changed, the residence time of the flue gas in the electric dust removing zone can be prolonged, the flue gas flow can be prevented from forminga dead zone in the electric dust removing zone, and the dust removing efficiency can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low-temperature and low-pressure steam production device in power station boiler and process method

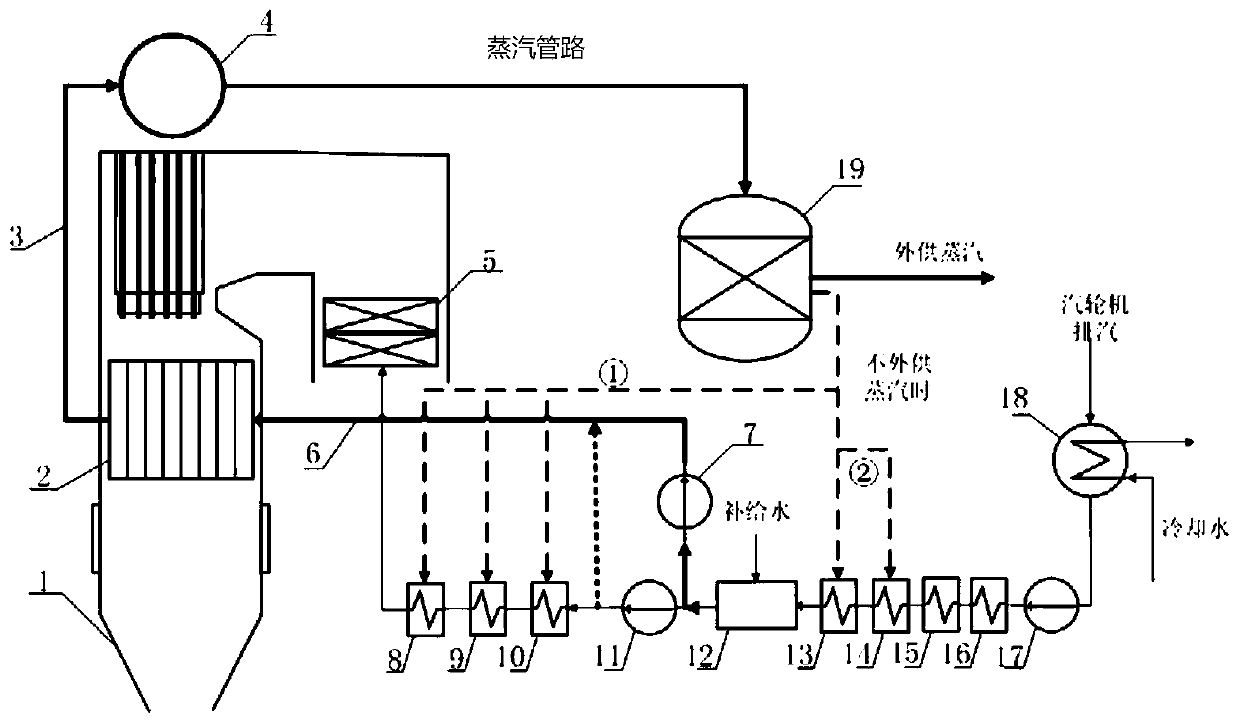

ActiveCN111336493AHigh operating costsMeet ultra-low emission requirementsBoiler drums/headersSuperheating controlPhysicsWater circulation

The invention discloses a low-temperature and low-pressure steam production device in a power station boiler and a process method. The low-temperature and low-pressure steam production device comprises a wall type steam generator, a steam header and an external supply steam mixing station; the wall type steam generator is arranged between SOFA air of a low NO<x> burner and a platen superheater ina boiler furnace; the wall type steam generator is provided with an introduction pipe which is used for introducing make-up water; the wall type steam generator communicates with the steam header through a lead-out pipe; and the steam header communicates with the external supply steam mixing station through a superheated steam pipeline, and the external supply steam mixing station is used for achieving external supply of steam. According to the the process method and the low-temperature and low-pressure steam production device in the power station boiler, the required low-temperature and low-pressure steam can be produced under the condition that the main steam quantity and the steam-water circulation system of a unit are not influenced.

Owner:XI AN JIAOTONG UNIV

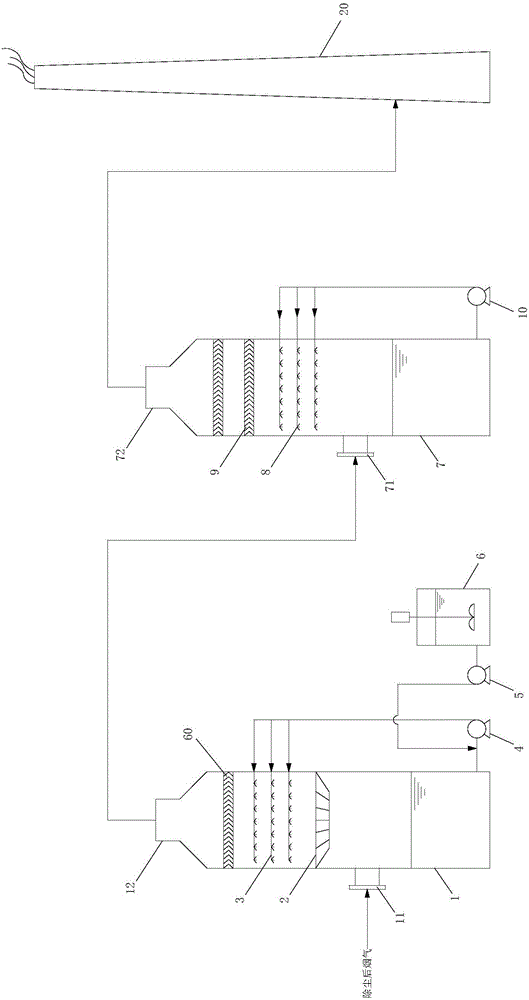

Flue gas desulfurization, denitrification and dust removal system for biomass circulating fluidized bed boiler

InactiveCN110975582ALow investment costExtended service lifeCombination devicesGas treatmentBiomassCirculating fluidized bed boiler

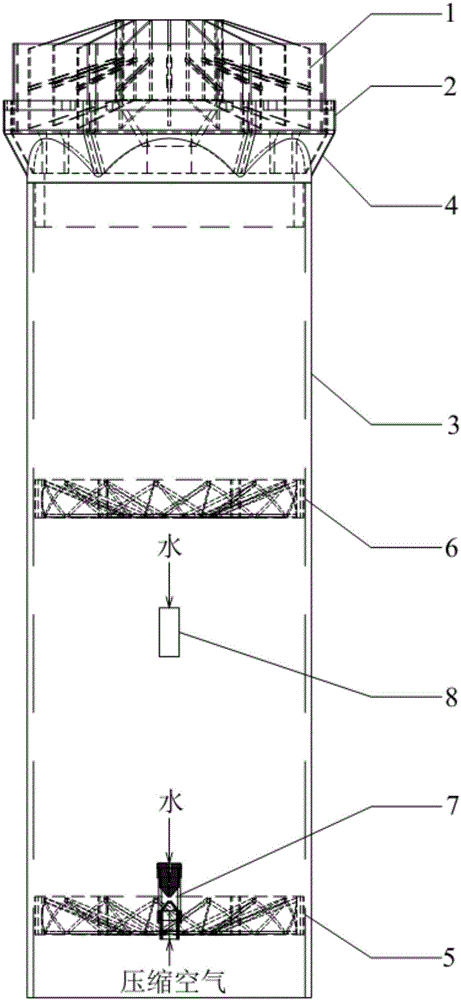

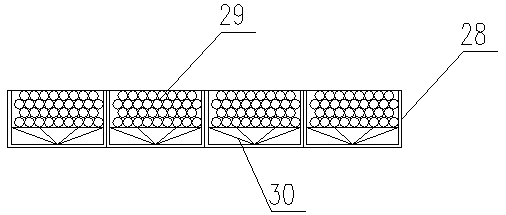

The intention discloses a flue gas desulfurization, denitrification and dust removal system of a biomass circulating fluidized bed boiler, and mainly relates to the technical field of environmental protection equipment. An ammonia water storage tank and a demineralized water tank are connected with a static mixer which is connected to a microwave turbulent flow spray gun through an ammonia water distribution module; wherein a compressed air storage tank is connected with the microwave turbulent flow spray gun through a compressed air distribution module and a cooling air distribution module respectively, the microwave turbulent flow spray gun is arranged in an inlet flue of a cyclone separator and provided with a plurality of nozzles arranged along the flow direction of flue gas, an outletflue of the boiler is connected with a dust removal device, and the flue gas subjected to dust removal enters a desulfurization device, wherein a spraying layer, a rotor turbulence high-efficiency dust and mist removing device and a mist eliminator are sequentially arranged in the desulfurization tower body from bottom to top, the rotor turbulence high-efficiency dust and mist removing device inthe desulfurization device comprises a rotor turbulence module, the rotor turbulence module is divided into an upper part and a lower part, the upper part is provided with a filler ball, and the lowerpart is provided with a flow guide device to enhance flue gas mixing and increase flue gas swirl efficiency.

Owner:山东中航天业科技有限公司

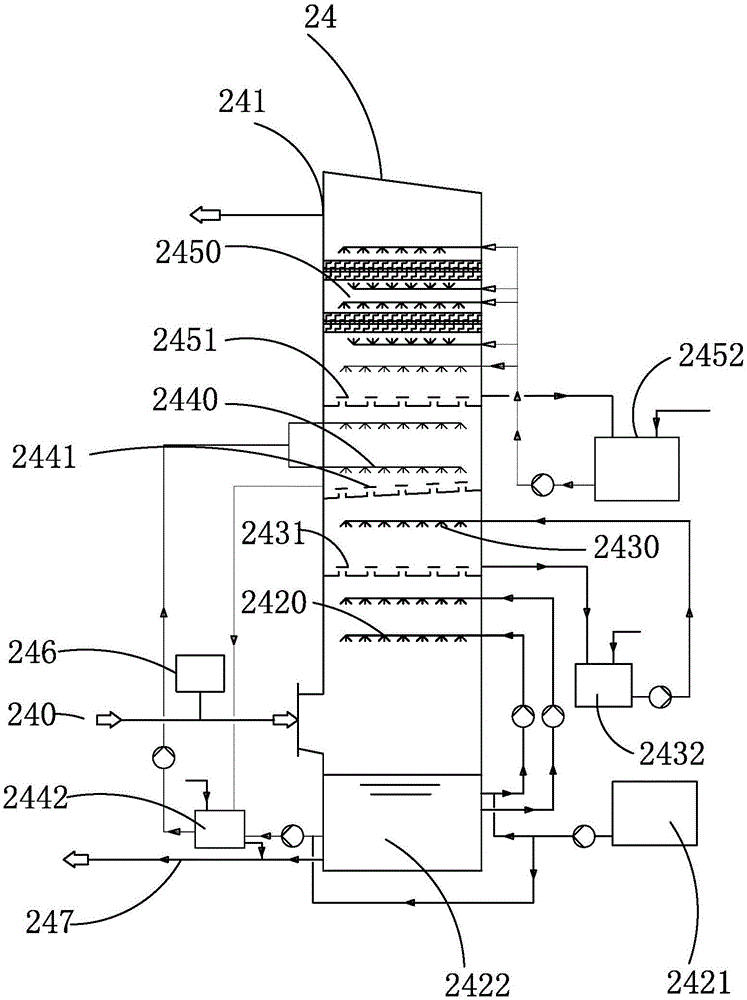

Deep deacidification and white smoke removing system and method for flue gas of garbage power plant

InactiveCN110115924AReduce the temperatureReduce moisture contentCombination devicesGas treatmentSlurryWater content

The invention discloses a deep deacidification and white smoke removing system and method for flue gas of a garbage power plant. The system comprises a temperature reducing tower. The flue gas is introduced into a wet tower after preliminary deacidification by means of a semi-drying method, first deacidification is completed in a spraying bin, and then the flue gas is introduced into a slurry tankfor a gas-liquid reaction to complete second deacidification so that the deacidification efficiency of the flue gas can reach 90% or above; at the same time, the flue gas is condensed and dehumidified in a dehumidifying layer to reduce the water content in the flue gas, so that the two processes including deacidification and white smoke removing are integrally completed in the wet tower; during spraying deacidification, a certain guarantee is provided for the reaction time of spraying slurry and the flue gas, the slurry is in full contact with the flue gas, the demand for the height of a tower body is not high, and the energy consumption of the system is reduced; the flue gas is introduced into the slurry tank through a descending pipe after being subjected to spraying deacidification inthe spraying bin, acid gas removal and deep dust removal are further carried out through a slurry reaction, and ultra-low emission requirements are met.

Owner:凤阳海泰科能源环境管理服务有限公司

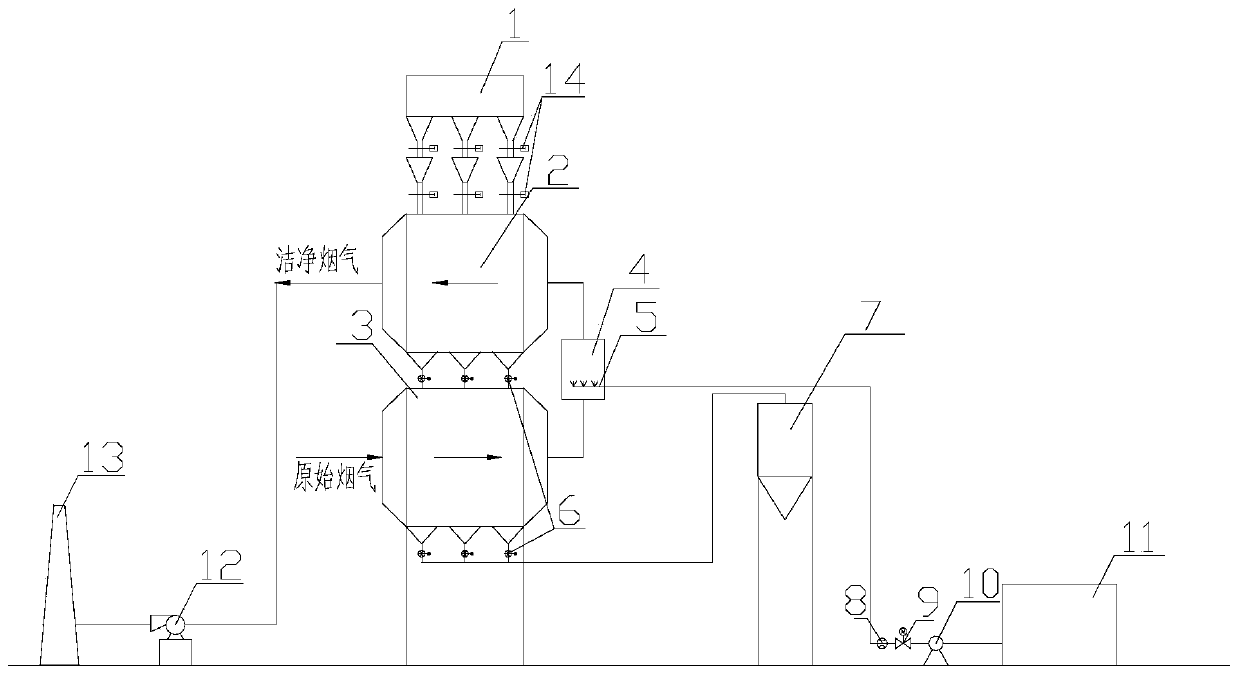

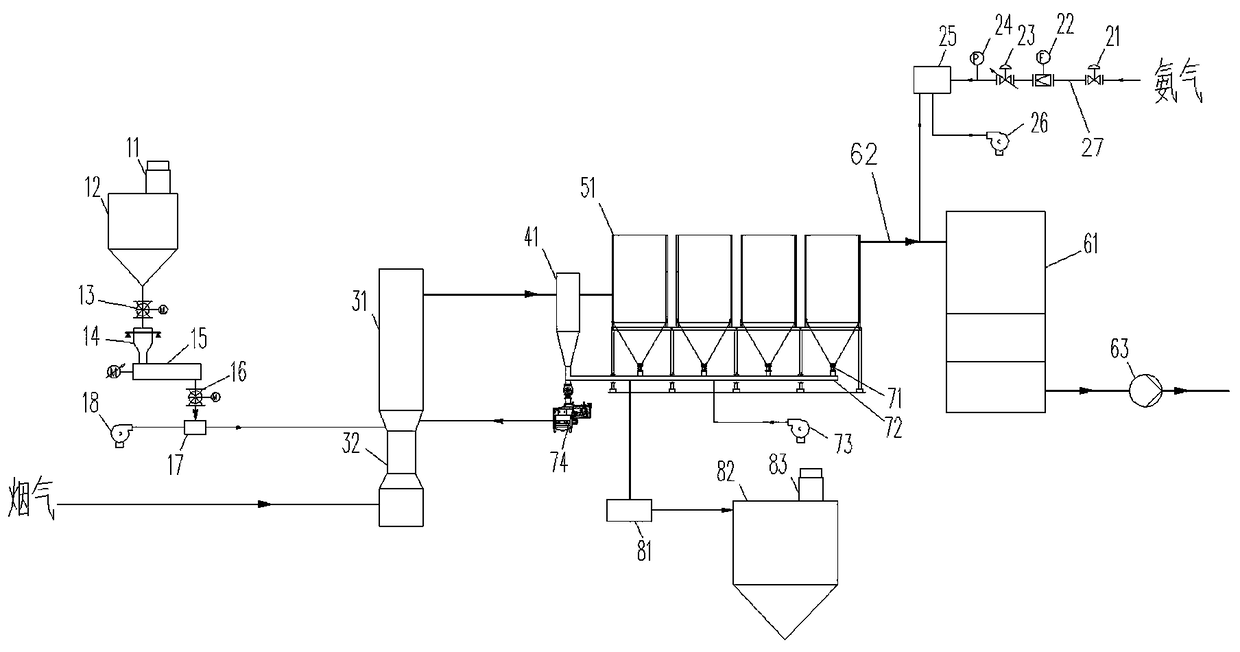

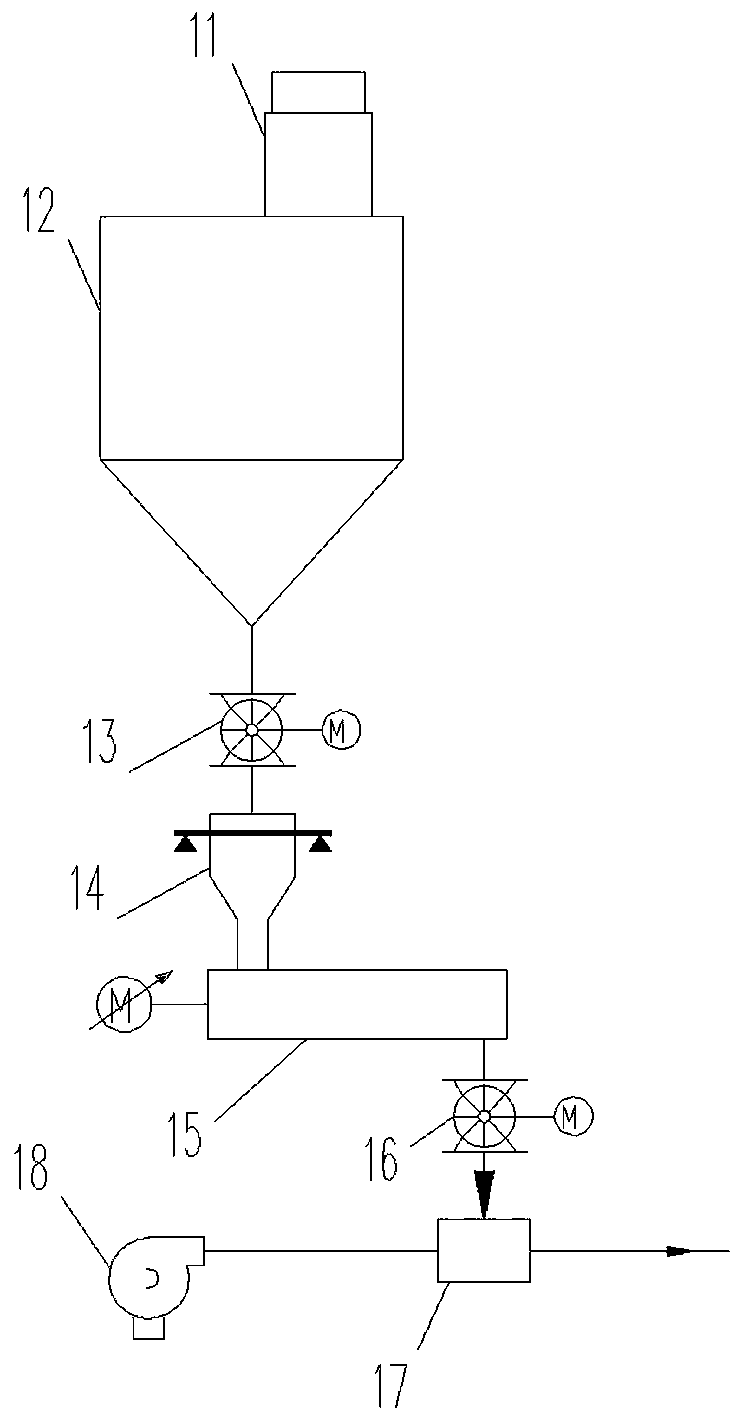

Activated coke flue desulfurization and denitrification integrated treating system

PendingCN110292847ATake advantage ofAchieve desulfurizationGas treatmentDispersed particle separationHandling systemStorage tank

The invention discloses an activated coke flue desulfurization and denitrification integrated treating system. The system mainly includes a desulfurization and denitrification integrated reactor, an ammonium hydroxide storage tank, an ammonia spraying and mixing tower, an ammonium hydroxide pump, a waste coke cabin and an induced draft fan. Original flue from a boiler enters a desulfurization module of the reactor through a desulfurization inlet of the desulfurization and denitrification integrated reactor, the flue is in contact with activated coke inside the reactor, SO2 in the flue is adsorbed by the activated coke inside the reactor to be removed, desulfurized flue enters the ammonia spraying and mixing tower to be fully mixed with ammonium hydroxide in the ammonium hydroxide storage tank and then enters a denitrification module of the reactor, NOx in the flue reacts with ammonia inside the reactor to be reduced into N2 through low-temperature catalysis of the activated coke, cleanflue obtained after desulfurization and denitrification is conveyed into a chimney through the induced draft fan to be discharged, and waste coke generated in the reactor is conveyed into the waste coke cabin. The activated coke flue desulfurization and denitrification integrated treating system has the advantages of being low in investment and running cost, simple in structure and reliable during running.

Owner:HUANENG CLEAN ENERGY RES INST

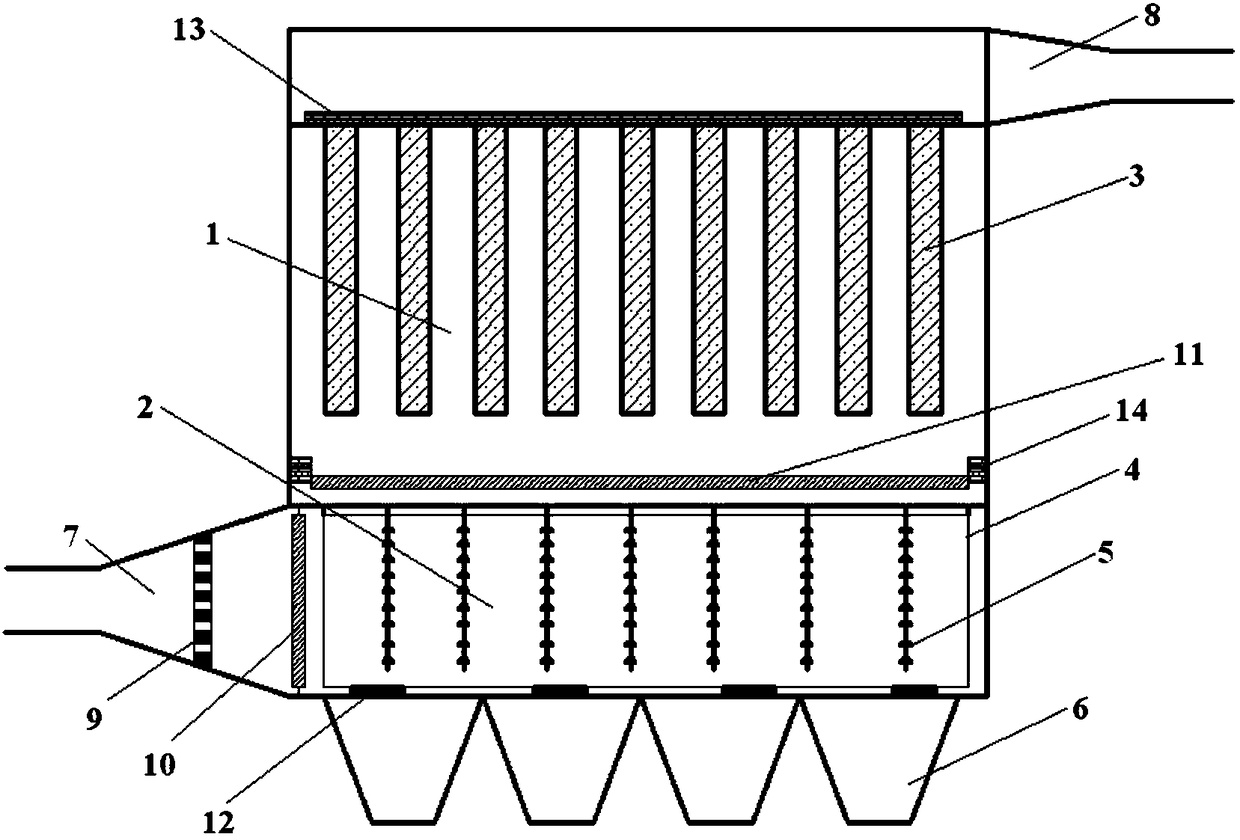

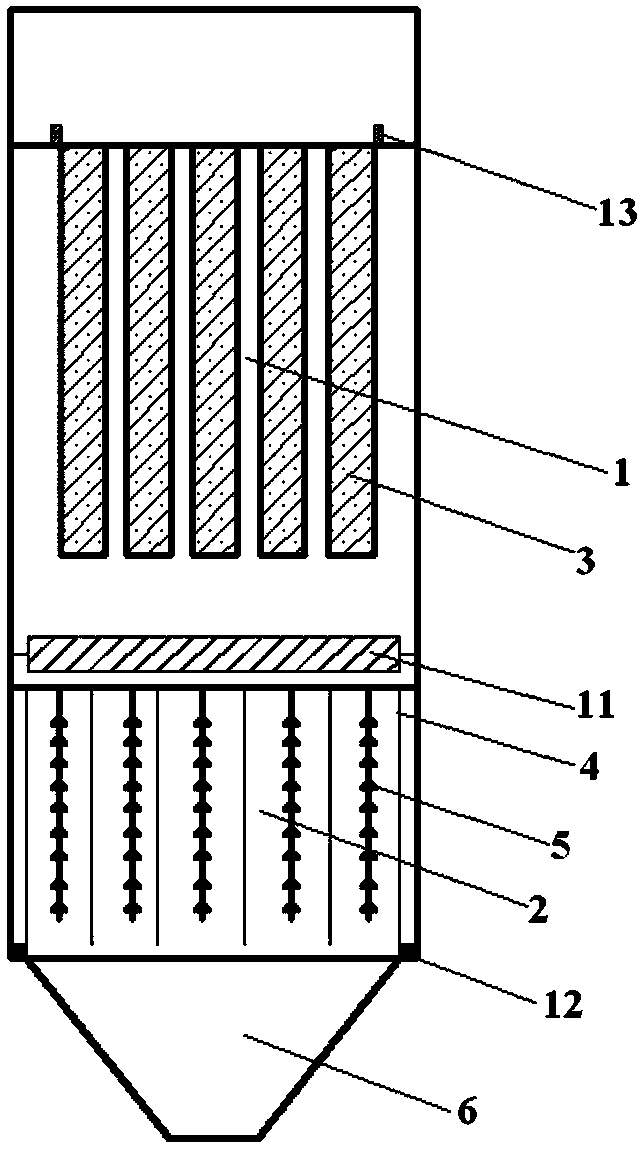

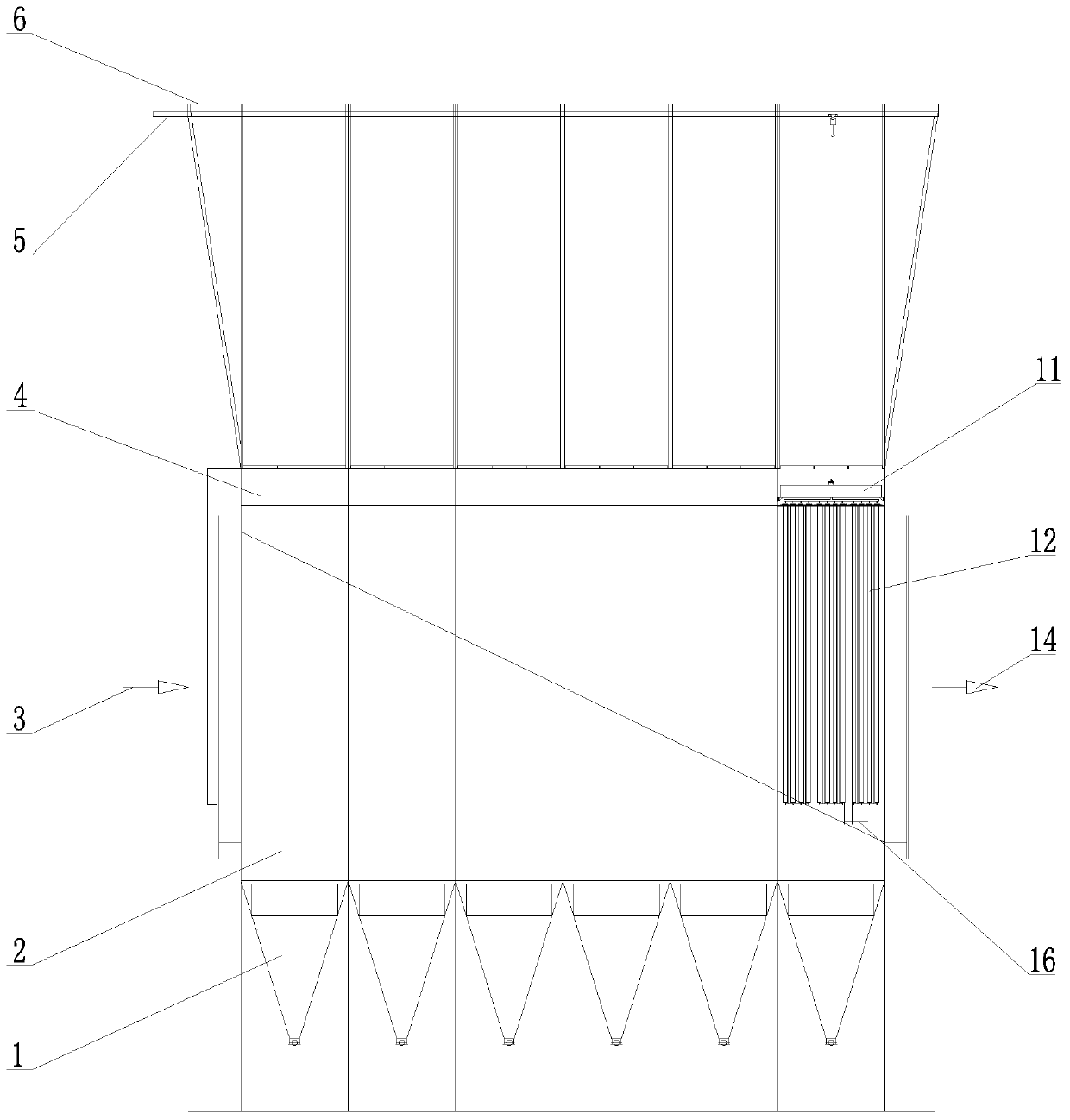

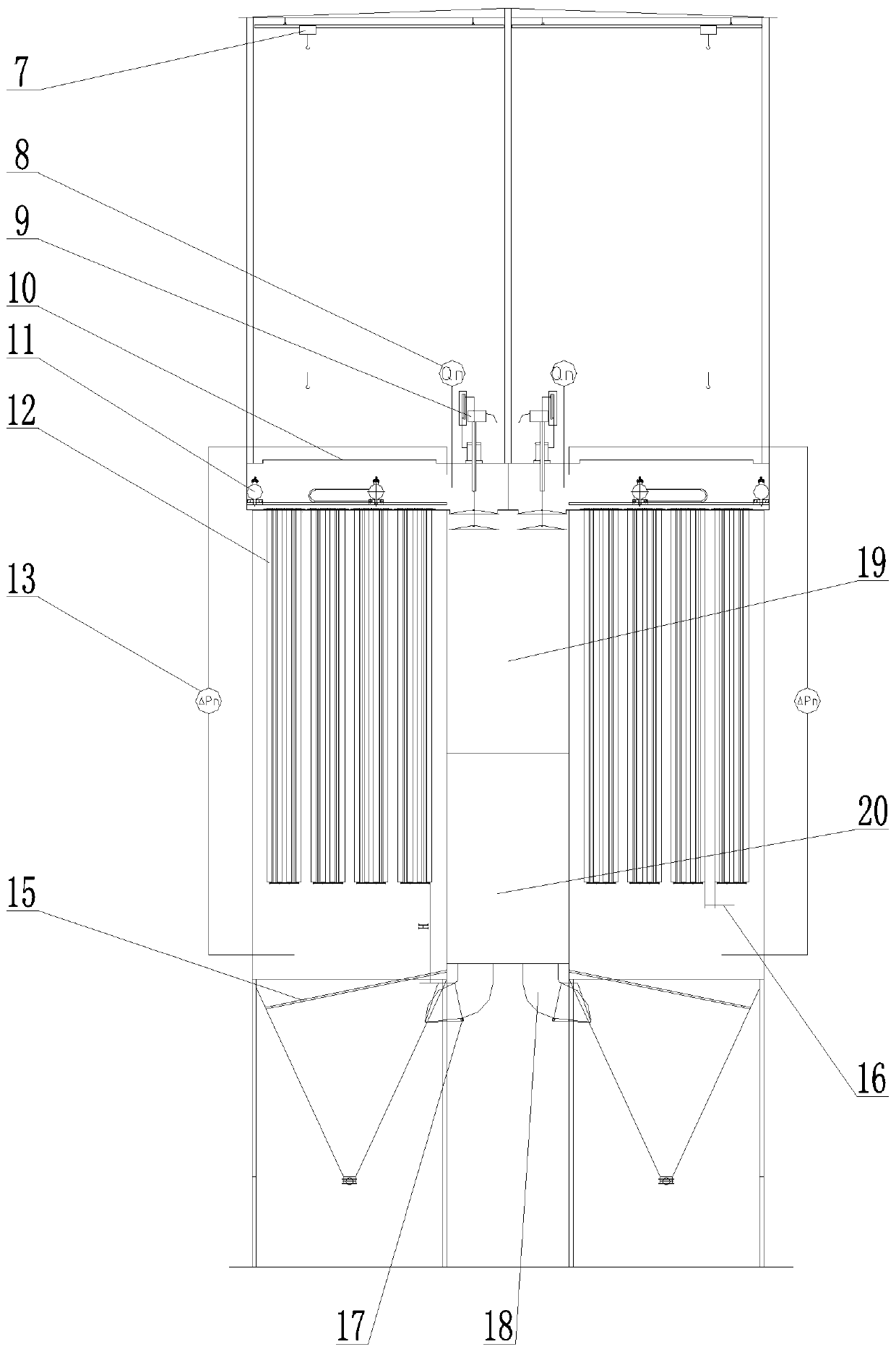

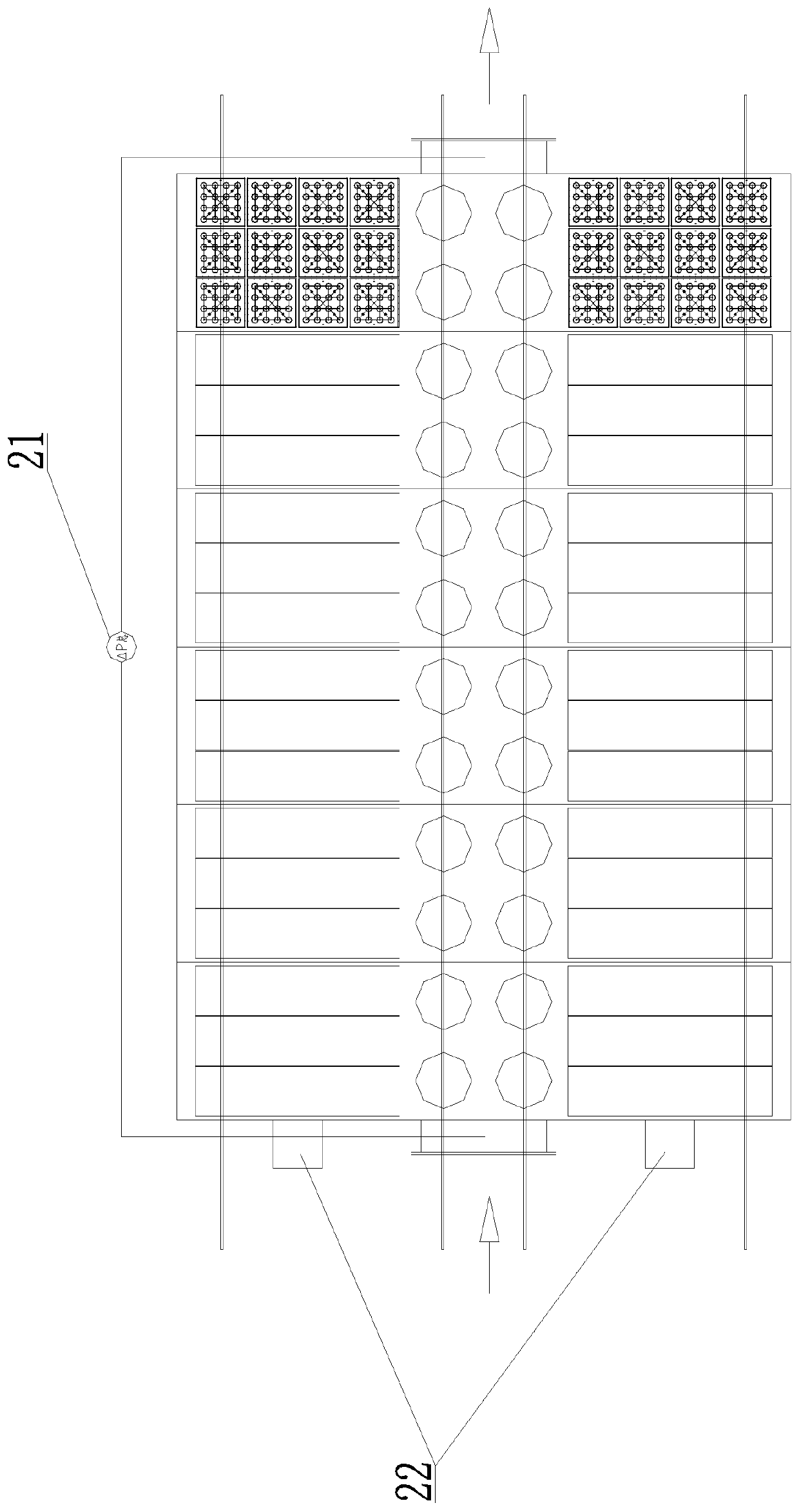

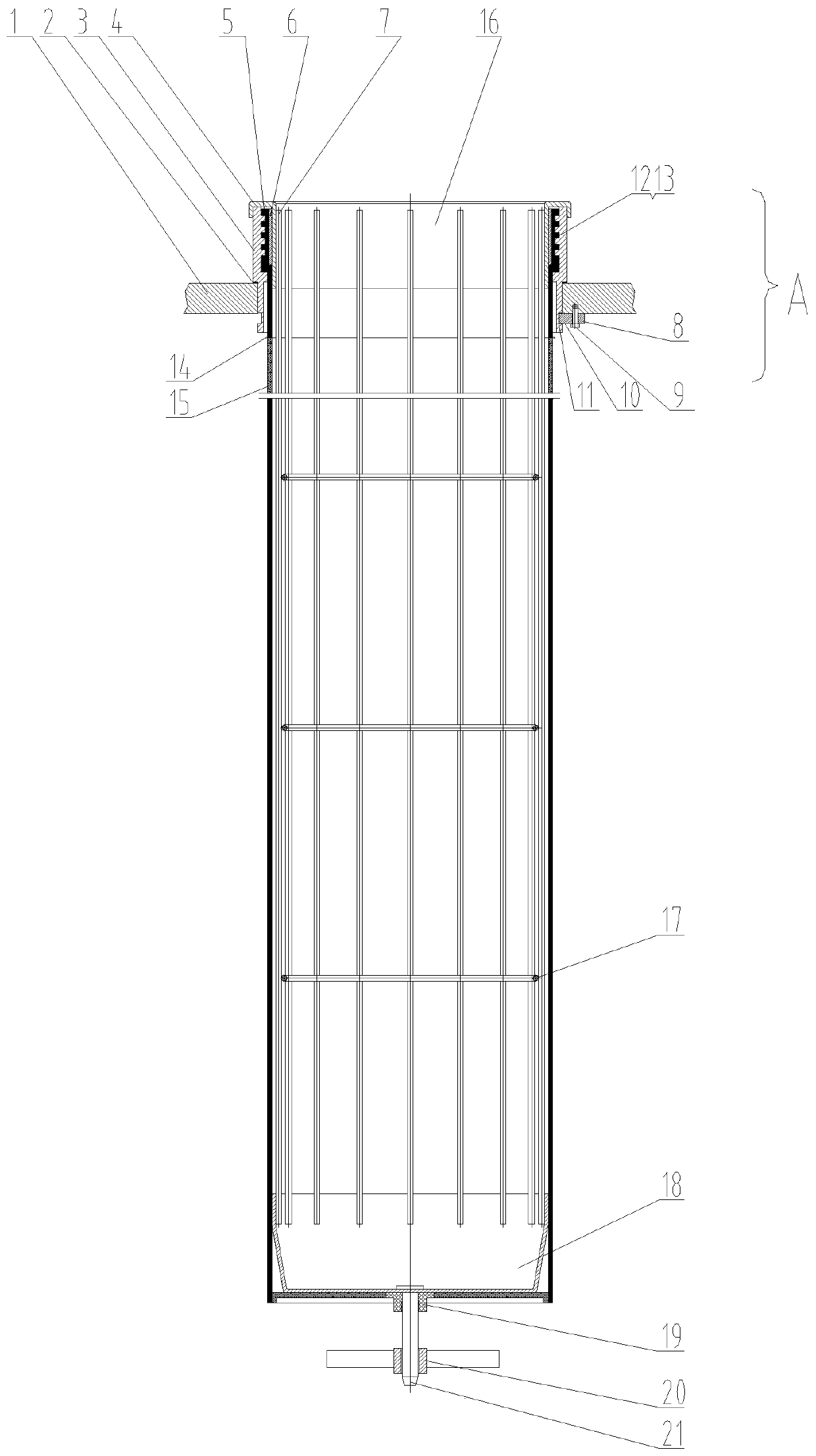

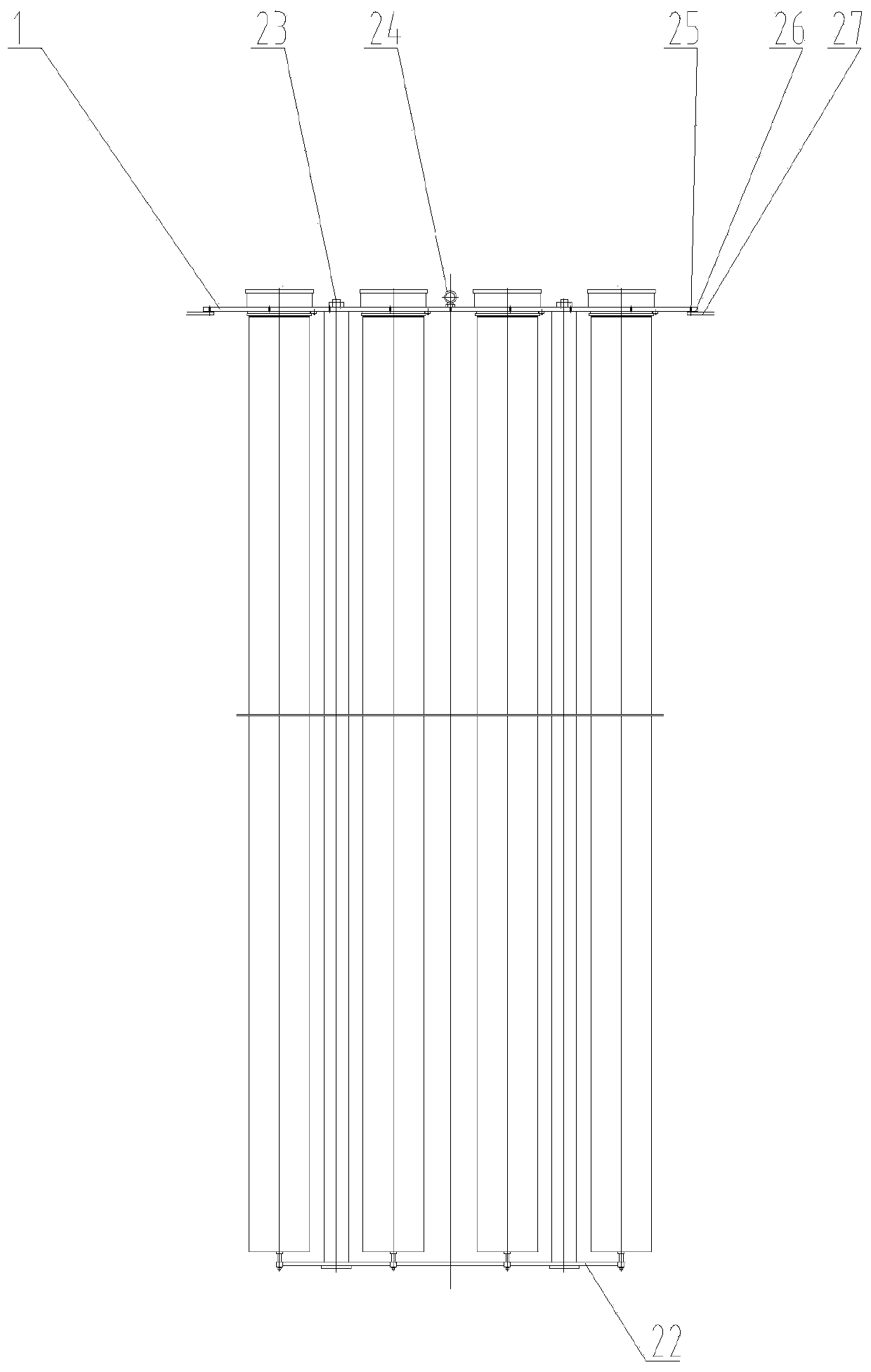

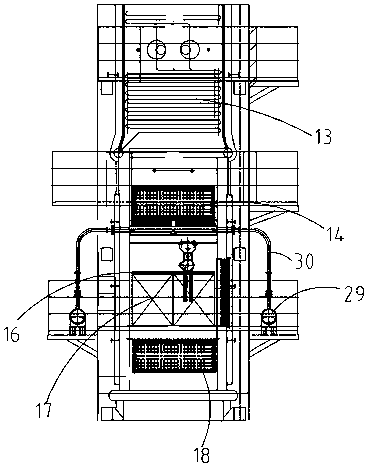

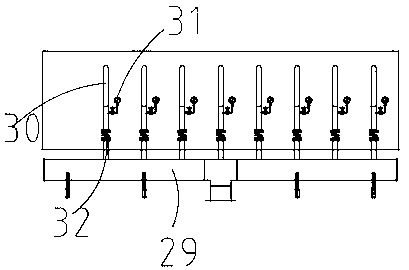

Stable ultra-low emission pulse-jet bag-type dust collector

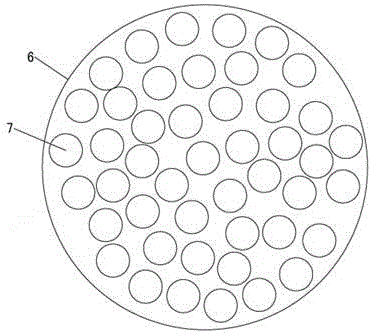

PendingCN109847477AReduce resistanceSmooth air flowDispersed particle filtrationInlet channelInlet valve

The invention relates to a stable ultra-low emission pulse-jet bag-type dust collector which comprises lifting devices and a plurality of rows of pulse-jet bag-type dust collectors. Each pulse-jet bag-type dust collector comprises a plurality of dust chambers; each dust chamber comprises an upper box, a middle box and an ash hopper; a movable progressive bag jetting device is arranged above each upper box; a plurality of clustered modular filter bag assemblies are arranged in each middle box; the plurality of clustered modular filter bag assemblies are jointed and mounted at a transfer storageposition; each clustered modular filter bag assembly comprises a tube nest and through holes for hanging of filter bags are formed in the tube nest in the form of an N1*N2 array; a uniform rising-airflow distribution channel is disposed between the filter bag assemblies; an air outlet channel and an air inlet channel are formed between the plurality of rows of dust collectors; the air inlet channel is connected to each dust chamber through a branch air inlet pipe and an air inlet valve is arranged on the branch air inlet pipe; an intake air balancing guide plate is arranged in front of an airinlet; and a descending off-line valve is mounted on the top of each upper box. According to the invention, ultra-low emission of the stable ultra-low emission pulse-jet bag-type dust collector is realized.

Owner:WUXI HONGQI DUST COLLECTOR EQUIP

High-temperature desulfurization and denitrification flue gas dust removal system

InactiveCN108786409AReduce particulate matter concentrationParticulate matter concentration does not increaseCombination devicesGas treatmentFlue gasNitric oxide

The invention discloses a high-temperature desulfurization and denitrification flue gas dust removal system, which comprises a lime storage and conveying part, a desulfurization settling part, a contact agent filter part, a denitrification part, an ammonia gas supply part, a slaked lime circulating part and a byproduct collection part, wherein all the components cooperate with one another to forman organic whole; a dry desulfurization tower and a slaked lime cyclic use technology are adopted to control SO2 treatment of flue gas of a glass melter, so that under the conditions of a high cycle ratio and relatively low Ca / S, SO2 discharge is standardized, and desulfurization treatment is completed at a high-temperature section in combination with a contact agent filter dust remover; meanwhile, desulfurized byproducts enter the contact agent filter dust remover for dust removal, so that the concentration of particulate matters in the flue gas is reduced, and a rear-end SCR denitrificationreactor is protected; the SCR denitrification reactor is adopted to control nitric oxide, so that a catalyst is protected; meanwhile, no particulate matters are produced in the denitrification reaction, so that the concentration of the particulate matters discharged by the flue gas cannot be increased.

Owner:SHENZHEN TRIUMPH TECH ENG +1

Purification technology of flue gas

InactiveCN107349766AMeet ultra-low emission requirementsEasy to operateGas treatmentDispersed particle filtrationSodium bicarbonateFlue gas

The invention discloses a purification technology of flue gas. The purification technology comprises the steps that the flue gas enters from a gas inlet in the bottom of a primary desulfurizing tower, wherein multiple water pipes are vertically arranged in the primary desulfurizing tower, multiple spray nozzles are evenly arranged on the water pipes, and a spray device is arranged on the top of the primary desulfurizing tower; the flue gas enters the primary desulfurizing tower, meanwhile the spray device on the top of the primary desulfurizing tower and the spray nozzles all spray out a sodium bicarbonate solution; the flue gas is exhausted from a gas outlet in the top of the primary desulfurizing tower and enters a gas inlet in the top of a secondary desulfurizing tower; a desulfurizing agent is humidified by a humidifier arranged on the top of the secondary desulfurizing tower and enters the secondary desulfurizing tower; refrigeration is conducted; a denitration agent is prepared; multiple denitration spray guns are arranged on the side wall of a denitration tower, the denitration spray guns are connected with a denitration agent container, the denitration agent is mixed with the flue gas, and the spray time is controlled through the sectional area of a flue and the flow velocity so that the denitration reaction can be sufficient; dust removal is conducted. The purification technology is simple, easy and convenient to operate, high in denitration efficiency and low in maintenance cost.

Owner:BATOU LIGHT IND VOCATIONAL TECHN COLLEGE

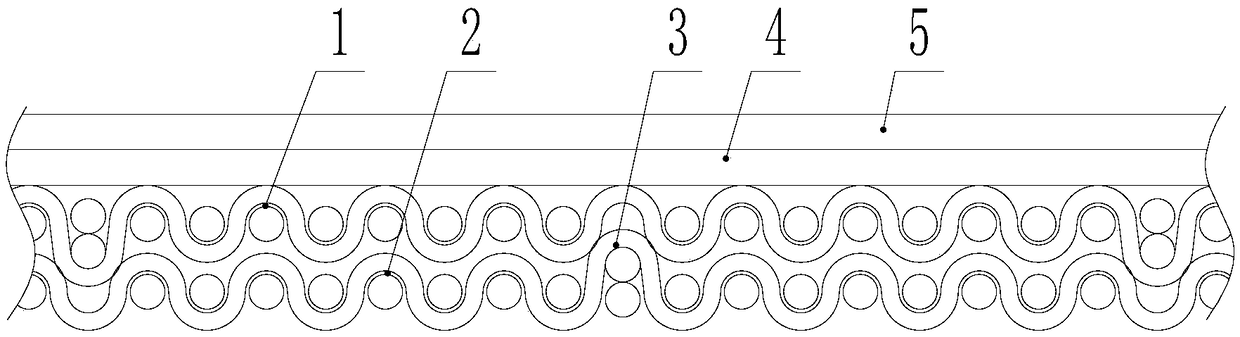

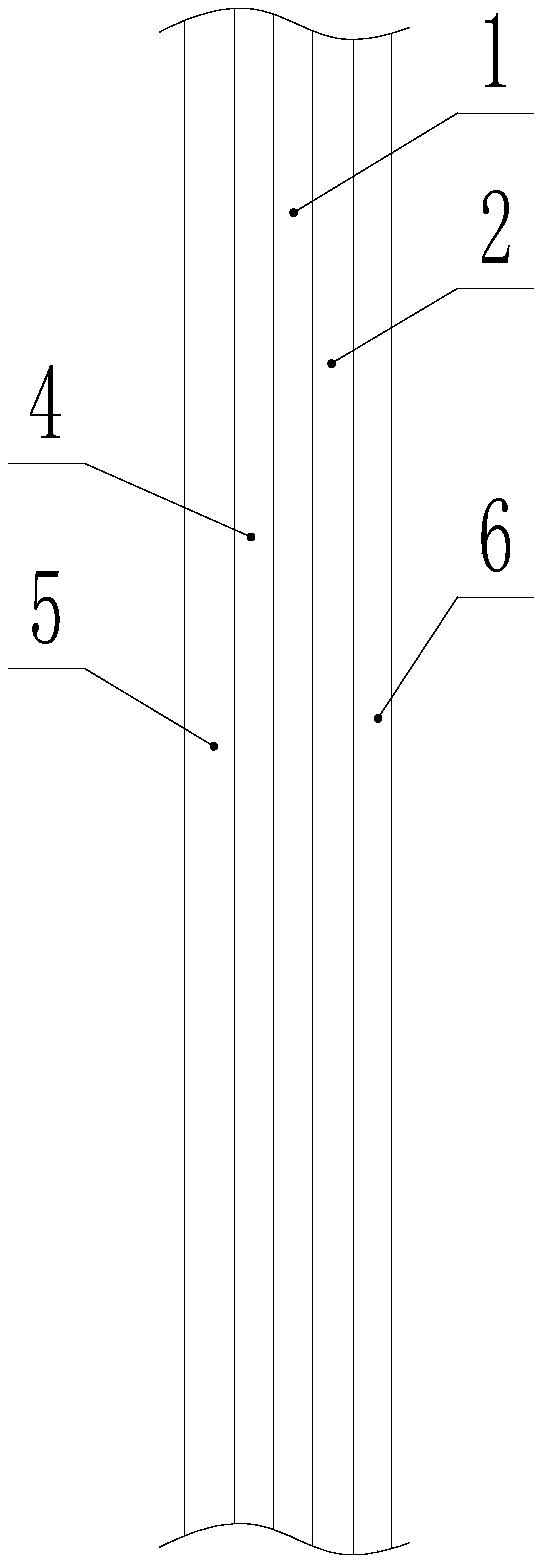

Double-layer filter material and filter bag

The invention relates to the technical field of industrial flue gas filtering materials and particularly relates to a double-layer filter material and a filter bag. The double-layer filter material comprises an upper filter layer and a lower filter layer. The upper and lower filter layers are connected through a joint point. A high-temperature coating film layer is arranged on one side of the upper filter layer far away from the lower filter layer. The high-temperature coating film layer is connected to the upper filter layer through the coating layer. A filter bag is prepared from any one ofthe double-layer filter materials. The filter material is divided into an upper filter layer and a lower filter layer. According to different effects of the upper and lower layers, the filter materials are rationally selected so that the strength is increased and the use requirements under the working conditions are satisfied. The high-temperature coating film layer, the coating layer, the upper filter layer and the lower filter layer form four-stage high-efficiency filtration and satisfy the ultra-low emission requirements of dust. The double-layer filter material has a high filtration precision, high tensile strength and a long service life and is easy to promote and use.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

Sintering mixer flue gas dedusting and whitening device

PendingCN111068356AFunctionalMeet ultra-low emission requirementsGas treatmentDispersed particle separationFlue gasDust control

The invention discloses a flue gas dedusting and whitening device of a sintering mixer. The device comprises a condensation rotational flow water collecting device connected with a sound wave agglomeration dust removing device. The sound wave agglomeration dust removal equipment comprises an equipment shell, one end of the equipment shell is provided with an equipment inlet; wherein one end of theequipment shell is provided with an equipment inlet, the other end of the equipment shell is provided with an equipment outlet, a sound wave descaling module is arranged on the equipment shell at theequipment inlet, at least a first agglomeration module or a second agglomeration module is arranged in the equipment shell, and the first agglomeration module comprises a first washing assembly and afirst dust removal assembly which are sequentially arranged in the direction from the equipment inlet to the equipment outlet; and the second agglomeration module comprises a seed particle generationassembly, a sound wave agglomeration assembly, a second washing assembly and a second dust removal assembly, which are sequentially arranged in the direction from the equipment inlet to the equipmentoutlet. The device provided by the invention solves the problem of high dust emission of the flue gas of the sintering mixer and the problem of smoke plume emission of diffused flue gas by utilizingthe combination of the sound wave agglomeration dust removal equipment and the condensation rotational flow water collection equipment.

Owner:NANJING CHANGRONG ACOUSTIC INC +2

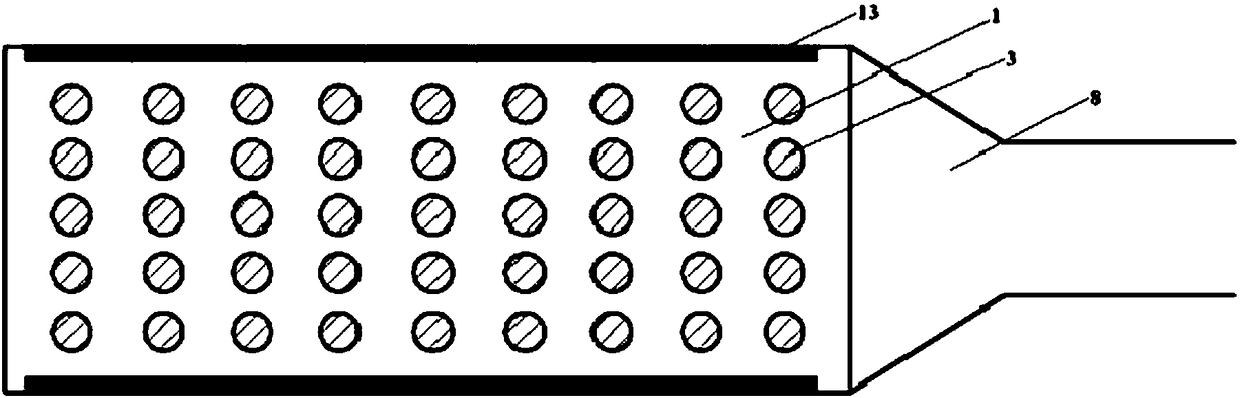

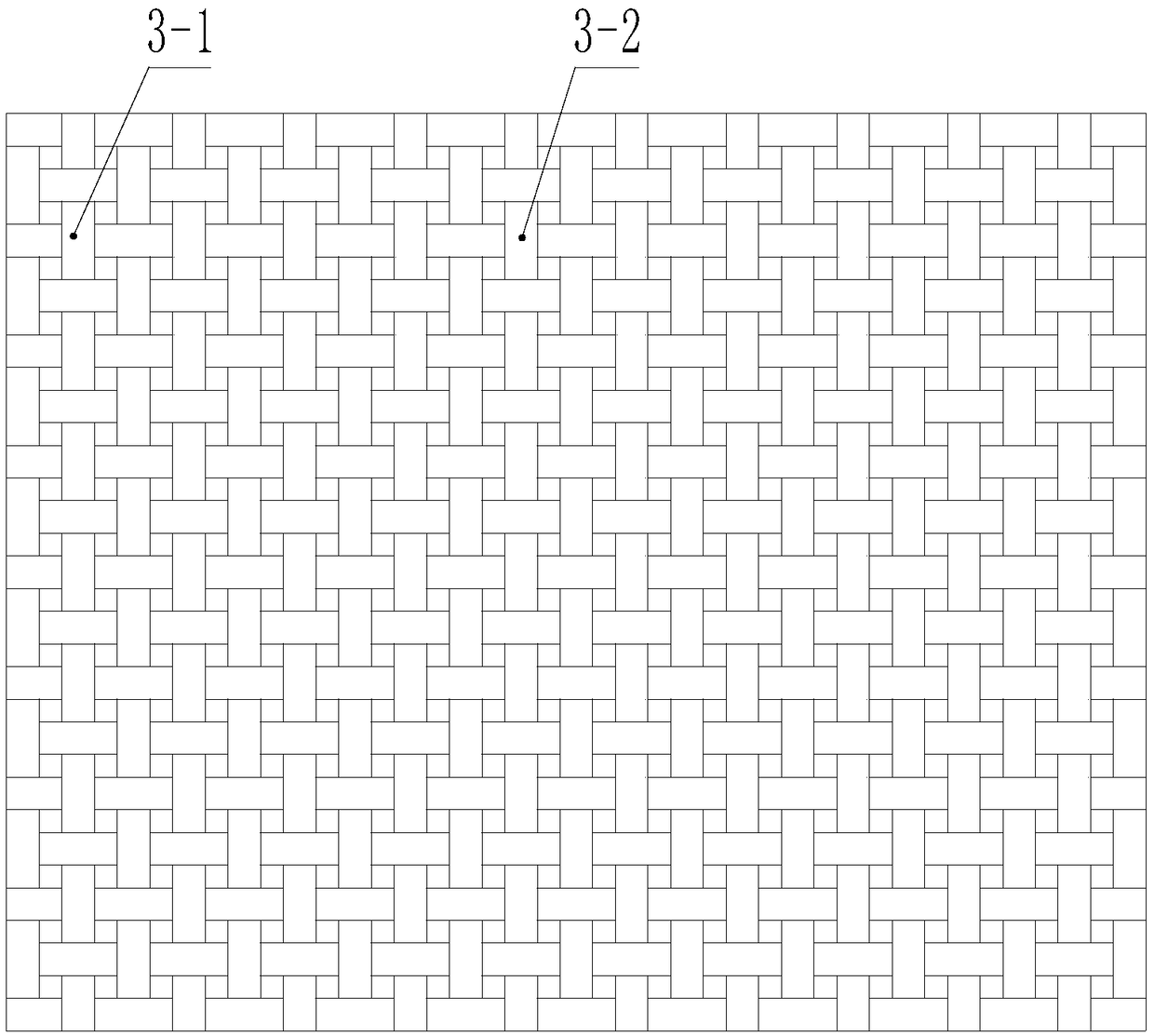

Cluster-type modular filter bag assembly capable of meeting ultra-low emission requirements

PendingCN109847478AImproved sealingReduce manufacturing assembly timeDispersed particle filtrationEngineeringMechanical engineering

The invention relates to a cluster-type modular filter bag assembly capable of meeting ultra-low emission requirements. The filter bag assembly comprises a plurality of cluster-type modular filter bagassemblies and filter bag assembly fixing apparatuses, wherein each cluster-type modular filter bag assembly comprises a porous plate, through holes are opened on the porous plate according to N1 x N2, a filter bag is installed in each through hole, hanging ears are installed on the porous plate, the porous plate is fixed to a second frame plate, each filter bag assembly fixing apparatus comprises short pipes, the short pipes are installed in each through hole of the porous plate, each short pipe is clamped with the clamping inclined surface of a clamping wedge block by a clamping groove, aninner side sealing groove of each short pipe and an outer side sealing groove of each filter bag head are interlocked, a bag cage is inserted into each filter bag, a skeleton top cover is clamped on the short pipes, a positioning pin shaft is installed on each skeleton bottom cover, a sealing pin sleeve is installed at the bottom of each filter bag, one end of each positioning pin shaft is inserted in each sealing pin sleeve, the other end of each positioning pin shaft is inserted in each positioning pin sleeve of a first frame plate, and the first frame plate and the porous plate are connected together by connecting rods. The filter bag assembly can effectively and steadily meet the ultra-low emission requirements.

Owner:WUXI HONGQI DUST COLLECTOR EQUIP

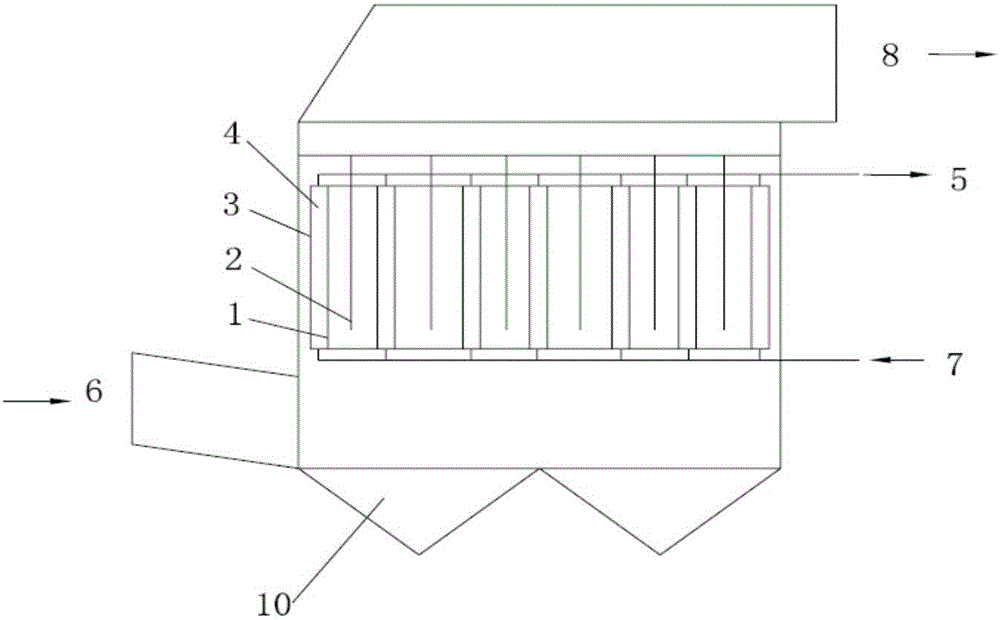

Flue gas deep purification system adopting phase-change coagulation and charged processing integration

InactiveCN105709554AReduce emission concentrationAchieving Phase Change CondensationCombination devicesAuxillary pretreatmentFlue gasEngineering

The invention provides a flue gas deep purification system adopting phase-change coagulation and charged processing integration. The system comprises a flue gas inlet, a flue gas outlet, a cooling medium inlet, a cooling medium outlet, multiple purification units and a liquid collecting tank, wherein the cooling medium inlet and the cooling medium outlet are communicated with the purification units, and the liquid collecting tank is arranged at the bottom of the purification system; the purification units are vertically arranged in the purification system and are fixedly connected, each purification unit comprises anode plates, an inner cavity, cathode wires and a circulating cooling device, the anode plates are mutually connected to form the inner cavity, the cathode wires are arranged in the inner cavity, wet flue gas flows in the inner cavity, the circulating cooling device is arranged on the peripheries of the anode plates, a cooling medium flows in the device and is input from the bottom and output from the top, and the flowing direction of the cooling medium is opposite to that of the wet flue gas; the wall surface temperature of each anode plate is adjustable. According to the system, deep purification charged processing and phase-change coagulation are integrally designed, and through combination of fine-particle coagulation and large-particle charged removing effect, the particle removing effect is improved; transformation is not limited by field and space.

Owner:GUODIAN SCI & TECH RES INST

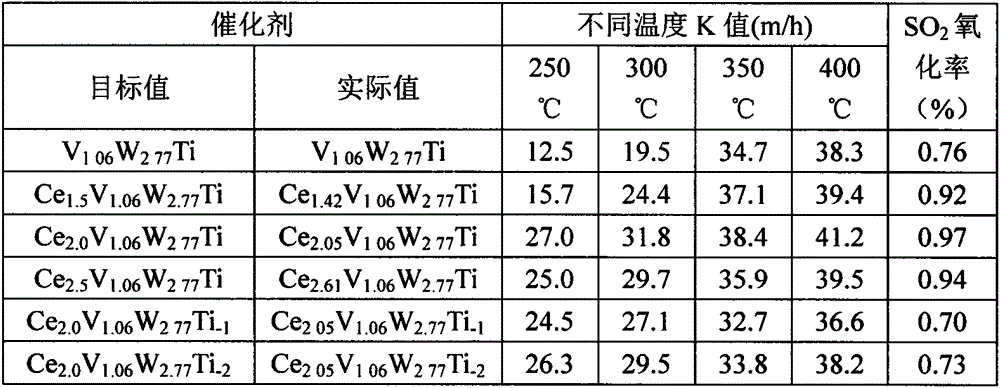

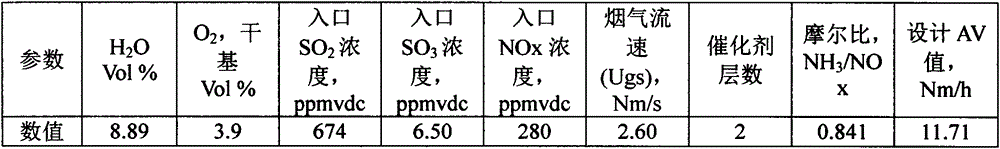

Method for preparing medium-low temperature SCR denitration catalyst and catalyst prepared by same

InactiveCN106268772AIncrease production costImprove resource utilizationGas treatmentHeterogenous catalyst chemical elementsThermal treatmentOrganic chemistry

The invention discloses a method for preparing a medium-low temperature SCR denitration catalyst and the catalyst prepared by the method. The preparation method comprises the following steps: impregnating a catalyst base material into an introduced component impregnation liquid having a series concentration, heating the impregnated sample to detect the content of a target component, and drawing a relation curve of the concentration of the impregnation liquid and the content of the corresponding component; calculating the concentration of the impregnation liquid at the required content of the target component according to the relation curve; then, treating the base material by an impregnation method the same as that in the impregnation curve drawing stage; and finally, heating the catalyst to obtain a finished product. The method can be used for solving the conflict problem between the introduced component and the catalyst formula, treating a catalyst module, modifying an inactivated traditional catalyst into a medium-low temperature catalyst in a regenerating process, and is easy to operate and simple in equipment. The prepared catalyst has a good denitration activity at 250-420 DEG C, and has a SO2 oxidation rate less than 1 percent at high temperature. The method and the catalyst have a relatively high industrial application level.

Owner:ZHEJIANG ZHENENG CATALYST TECH CO LTD

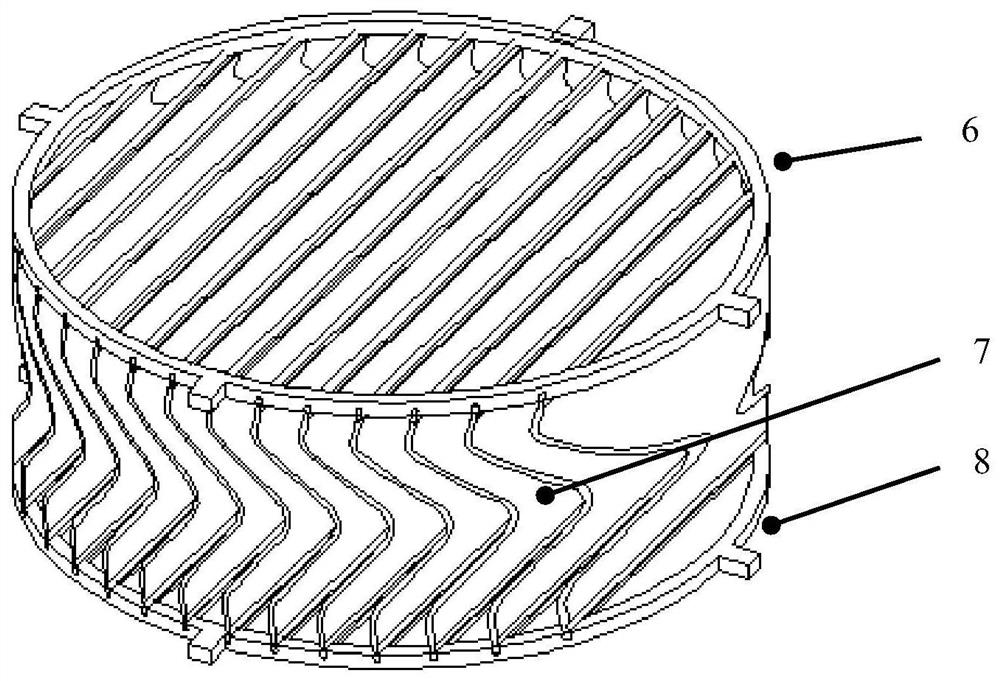

Multistage combined tubular demister

PendingCN112569697AEasy to operateLow costDispersed particle separationEngineeringMechanical engineering

The invention relates to a multistage combined tubular demister. The demister comprises a tube bundle cylinder, a first-stage demisting element, a second-stage demisting element, a third-stage demisting element and a fourth-stage demisting element, the first-stage demisting element, the second-stage demisting element, the third-stage demisting element and the fourth-stage demisting element are coaxially and sequentially arranged in the tube bundle cylinder from bottom to top, the first-stage demisting element is provided with corrugated plate blades, the second-stage demisting element, the third-stage demisting element and the fourth-stage demisting element are provided with flat plate type guide vanes, each stage of demisting element has the separation capacity of liquid drops with different particle sizes and the corresponding resistance characteristic, and the demisting process is graded. The superposing effect of the separation effect is achieved through the multiple stages of demisting elements, the separation performance is guaranteed with the minimum pressure loss, and ultra-low and ultra-clean emission of flue gas in the desulfurizing tower is achieved.

Owner:DATANG ENVIRONMENT IND GRP

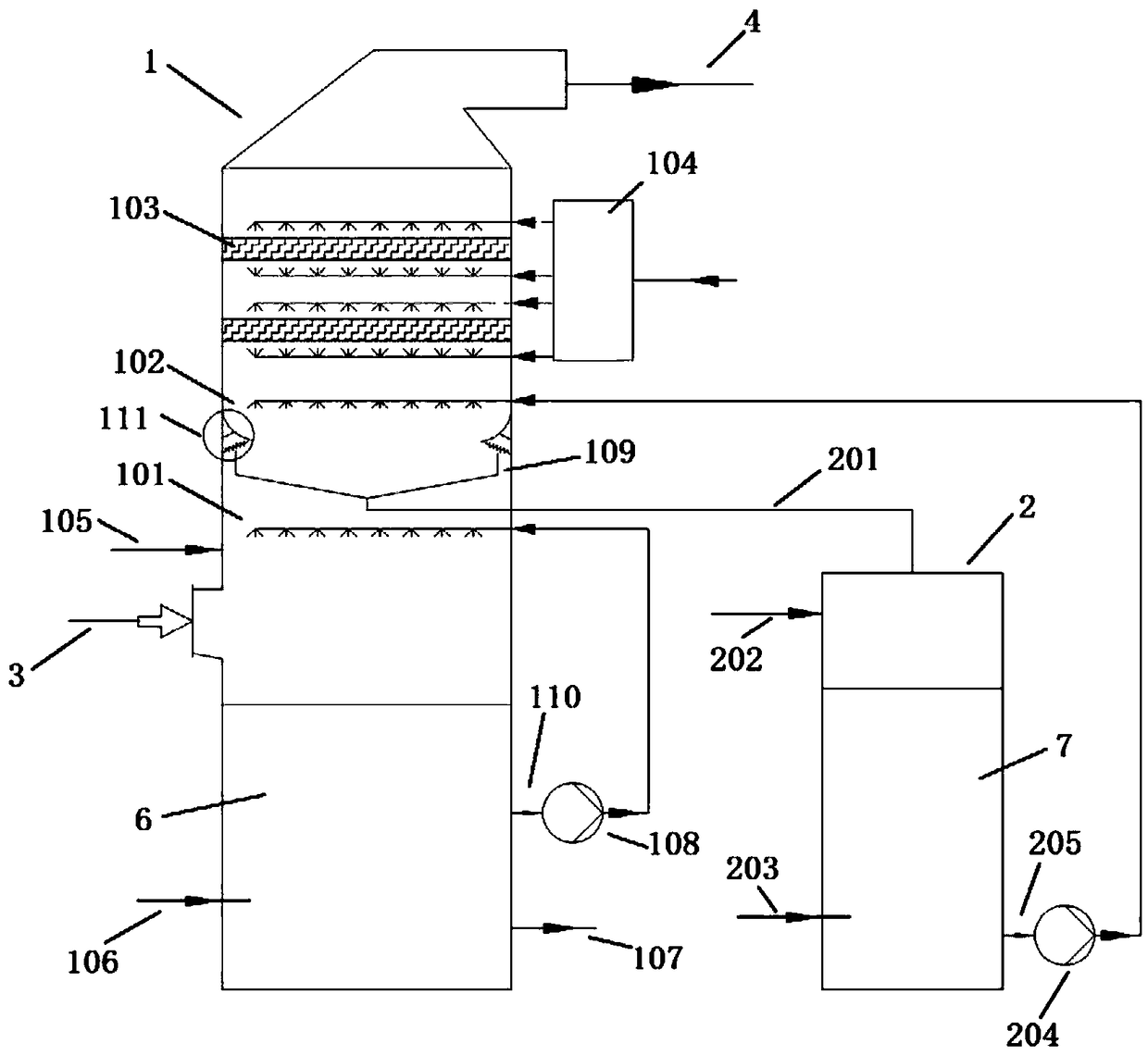

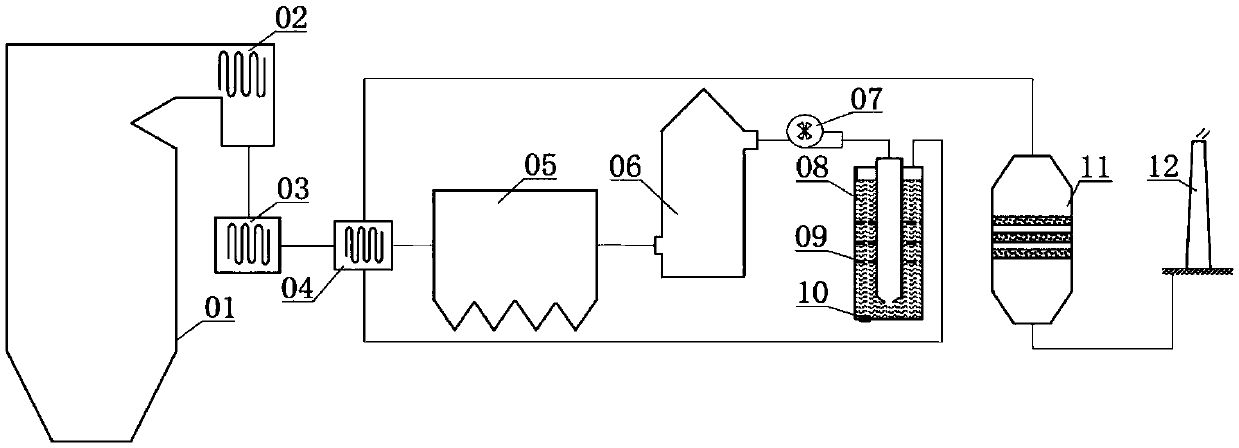

System and method for ultralow discharge of boiler flue gas

ActiveCN109621661AAchieve emissionsImportant environmental benefitsCombination devicesGas treatmentAir preheaterFlue gas

The invention belongs to the technical field of atmosphere contaminant control, and particularly relates to a system and method for ultralow discharge of boiler flue gas. The system comprises a hearth, a coal economizer, an air preheater, a heat exchanger, a dust remover, a desulfurizing tower, an induced draft fan, a cleaning device, a denigration reactor and a chimney. The method comprises the steps that boiler flus gas enters the dust remover through the coal economizer, the air preheater and the heat exchanger, after dust removal is performed, the flue gas enters a desulfurizing tower, after desulfurization, the flue gas is fed into the cleaning device through the induced draft fan, after the flue gas is cleaned, the flue gas is heated through the heat exchanger and then enters the denigration reactor, and finally, the flue gas is exhausted through the chimney. According to the system and method for ultralow discharge of boiler flue gas, the ultralow discharge requirements that thesmoke concentration is not larger than 5 mg / Nm<3>, the SO2 concentration is not larger than 35 mg / Nm<3>, and the NOx concentration is not larger than 50 mg / Nm<3> are met.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

A cyclone-race-coupling high-efficiency dust and mist removal component

ActiveCN105642024BGood effect of dust removal and fog removalMeet ultra-low emission requirementsDispersed particle separationFriction lossFlue gas

The invention relates to a swirling de-swirling coupled efficient dedusting and demisting assembly. The assembly is arranged above a spraying layer in a desulfurizing absorption tower, and comprises multiple dedusting and demisting units, wherein each dedusting and demisting unit comprises an outer cylinder, and a first stage of centrifugal swirling plate, a second stage of centrifugal swirling plate and a de-swirling hydrophobic plate provided at the top of a hollow complex cylinder aslant which are sequentially and parallelly arranged inside the outer cylinder from bottom to top, and gaps for liquid film falling are reserved among the outer edge of the first stage of centrifugal swirling plate, the outer edge of the second stage of centrifugal swirling plate and the inner wall of the outer cylinder. Compared with the prior art, the swirling de-swirling coupled efficient dedusting and demisting assembly has the advantages of simple and compact overall structure, low investment cost, good operation stability, no scaling blockage risks, capability of realizing deep dedusting and demisting on saturated wet flue gas after desulfurizing, low resistance loss, and good application prospect under lower investment cost and operating cost.

Owner:SHANGHAI JIAO TONG UNIV

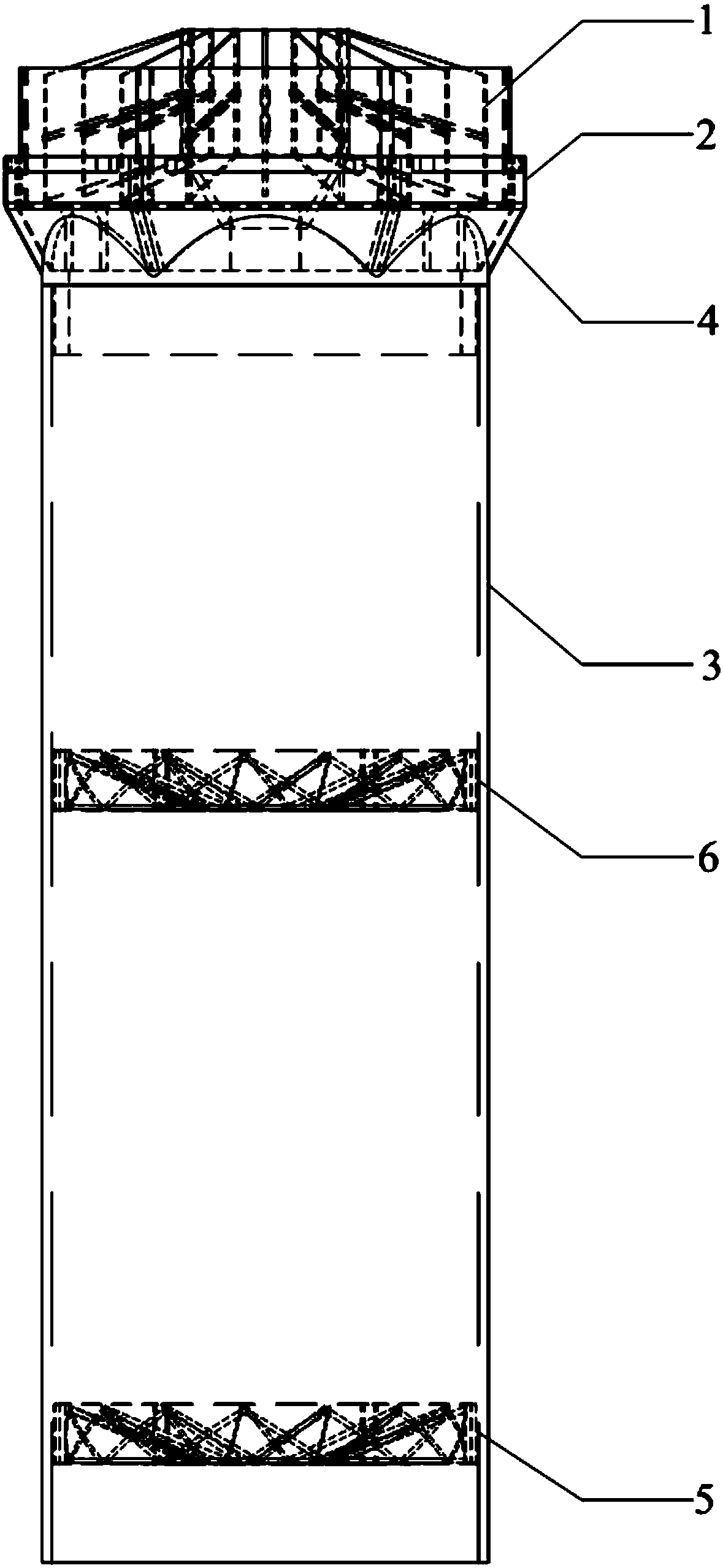

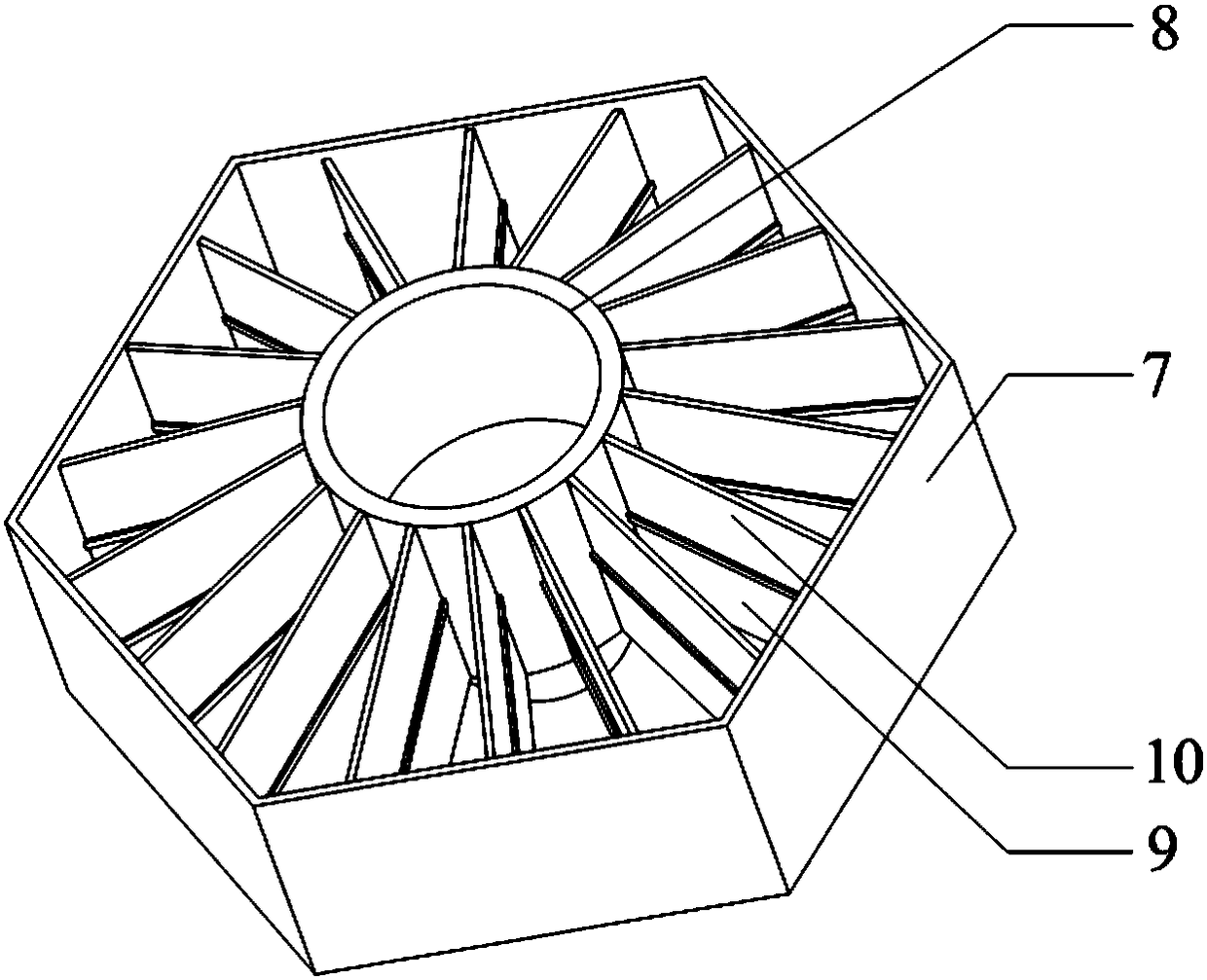

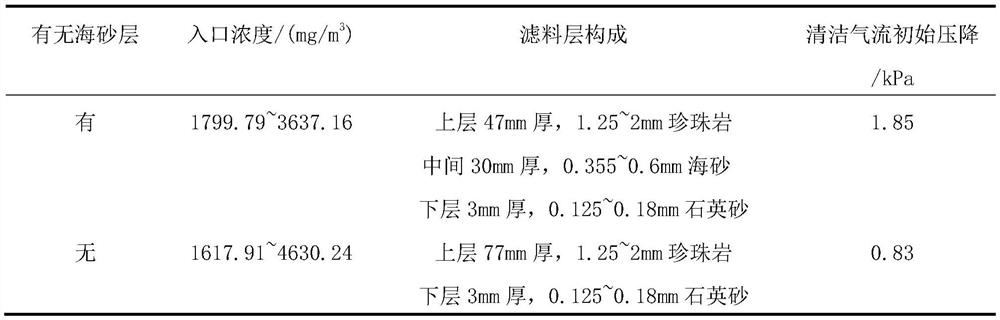

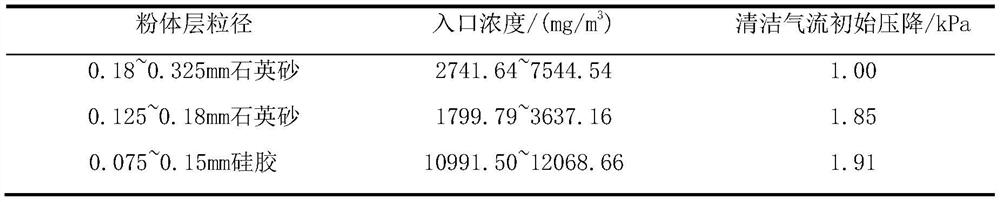

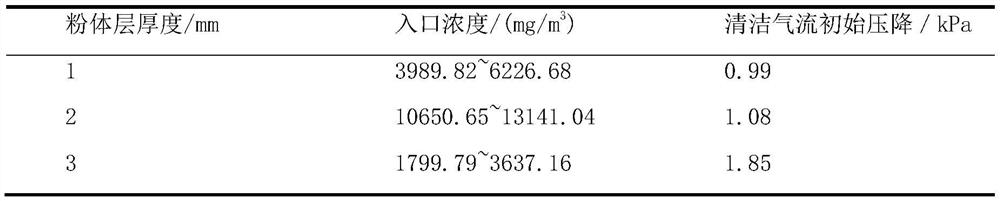

A high-temperature gas-solid separation filter combined with multi-layer cascade filter material and filter membrane

ActiveCN111111334BImprove purification efficiencyLow export concentrationDispersed particle filtrationTransportation and packagingFiltrationMaterials science

The invention discloses a high-temperature gas-solid separation filter combined with multi-layer cascade filter materials and filter membranes, which consists of three particle layers and one filter membrane. The upper layer of the granular layer is a perlite layer with larger particles, the middle layer is a sea sand layer with smaller particles, the lower layer is a powder layer composed of fine quartz sand, and the filter layer is below the powder layer. Due to the use of high-temperature-resistant cascade filter materials and filter membranes, dust of different sizes is intercepted layer by layer, which reduces the resistance of the powder cake layer and filter membrane and prolongs the filtration time; on the other hand, ensures the initial filtration. Effect. The filter has the following advantages: high purification efficiency, the purification efficiency of fine particles below 5um can reach more than 99.99%, and the initial outlet concentration is lower than 10mg / m 3 , the stable outlet concentration is lower than 4mg / m 3 ; Low energy consumption, pressure drop less than 2kPa, can meet the ultra-low emission requirements of coal-fired power plants and combined cycle power generation (IGCC) high-temperature gas purification requirements.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

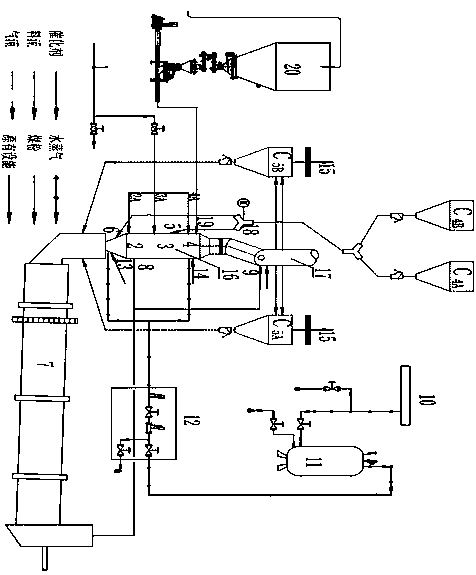

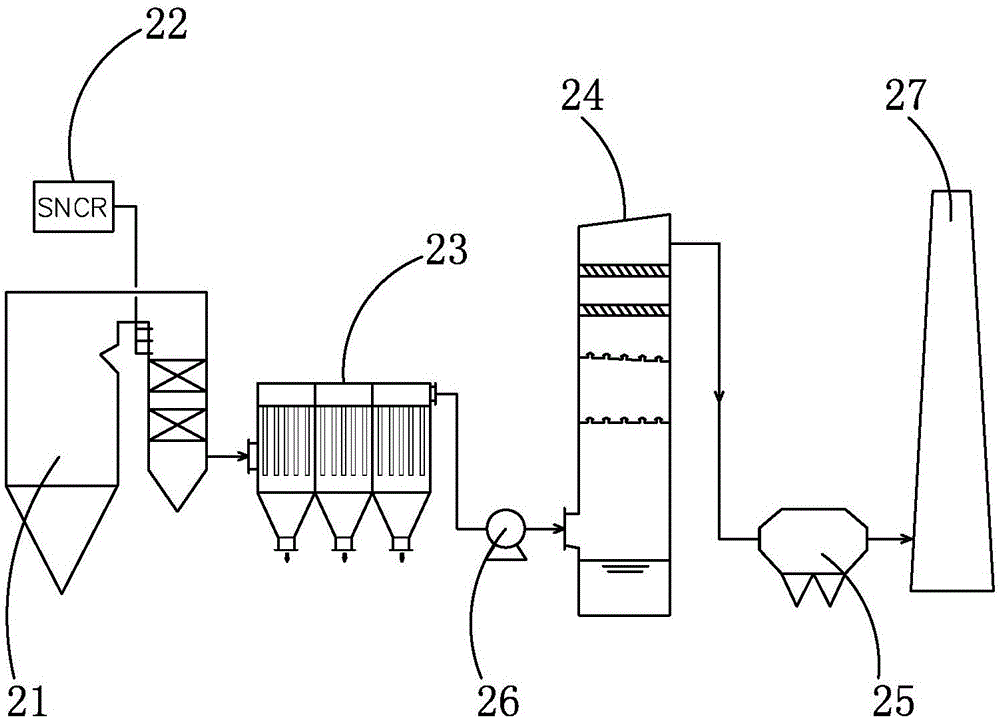

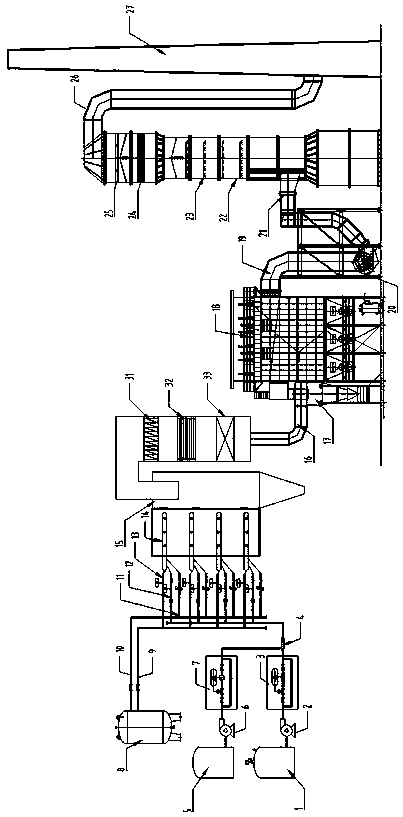

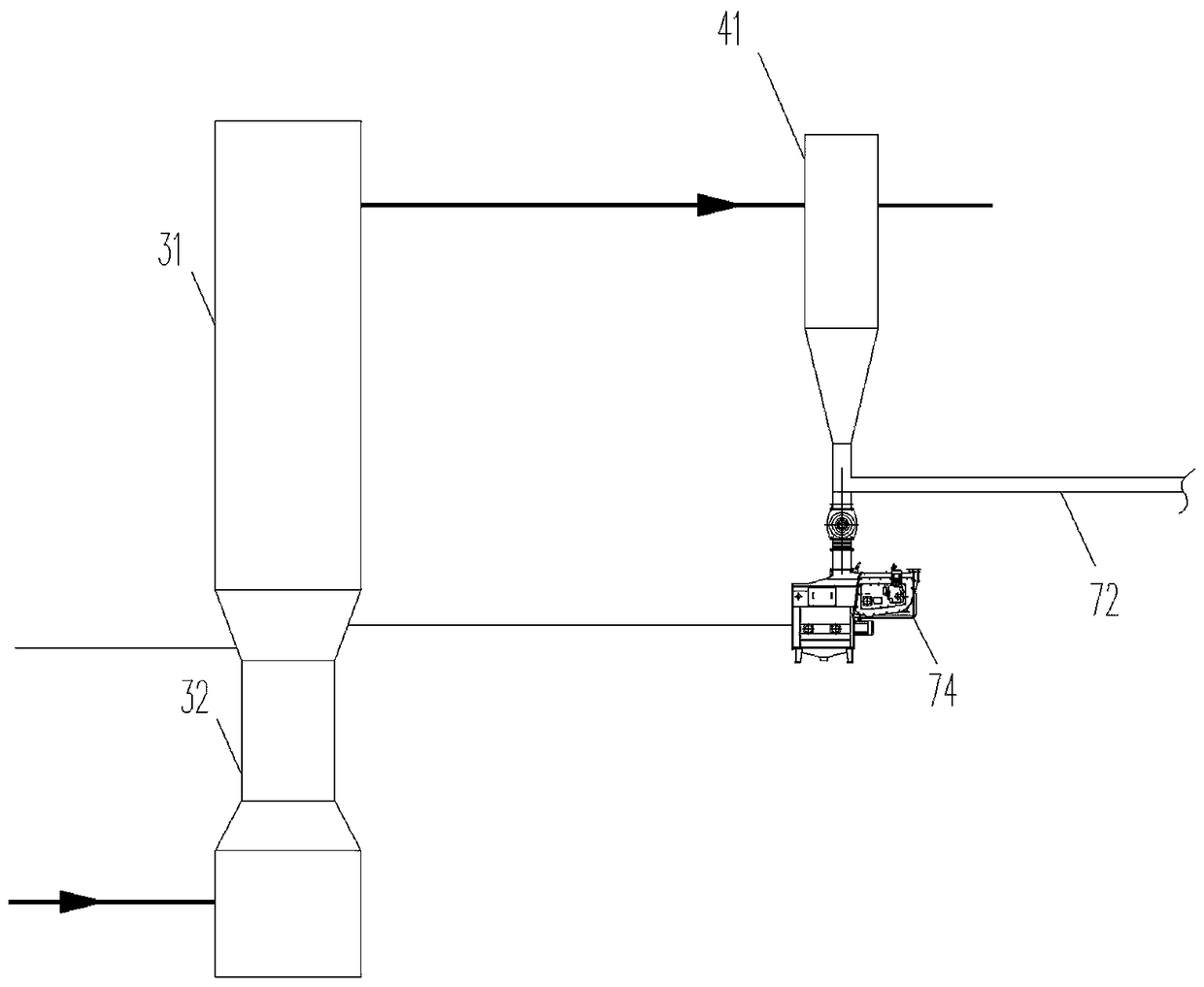

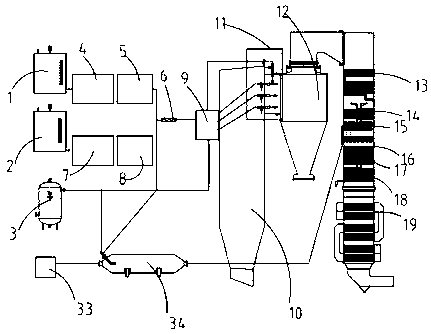

Combined flue gas denitrification system

ActiveCN105964142BOvercoming Ultra-Low Emissions RequirementsOvercome the SNCR denitrification efficiency to meet the requirements of ultra-low emissionsDispersed particle separationAir preheaterWater storage tank

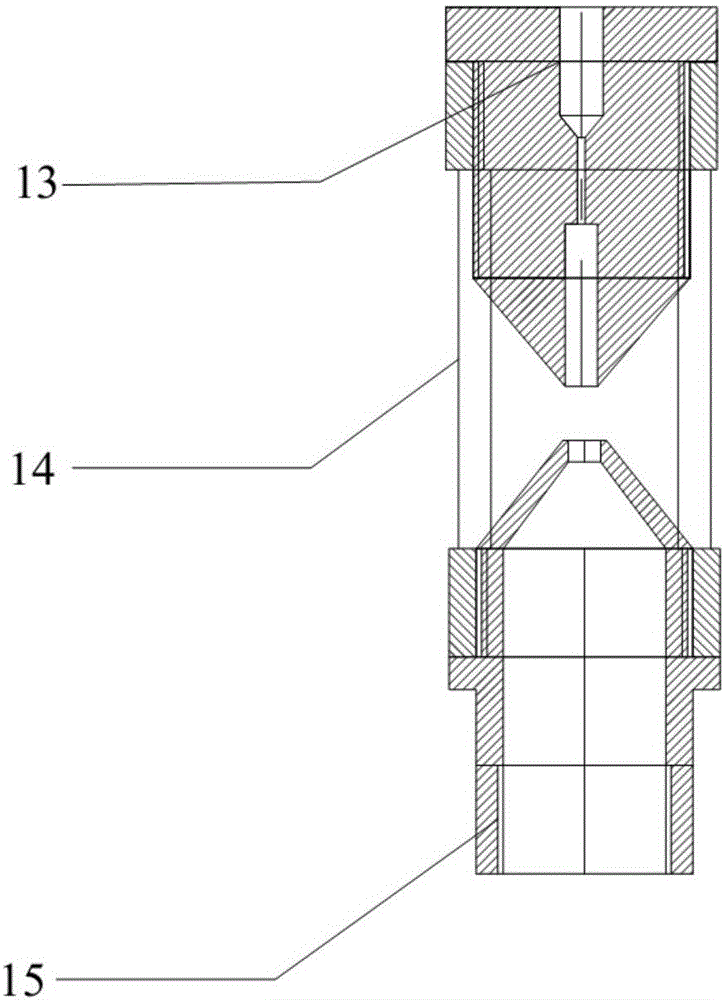

The invention provides a combined type flue gas denitration system which comprises a desalted water tank, an ammonia water storage tank and a compressed air storage tank. The desalted water tank is connected with a static mixer by a desalted water delivering module and a desalted water metering and adjusting module, the ammonia water storage tank is connected with the static mixer by an ammonia water delivering module and an ammonia water metering and adjusting module, the static mixer is connected with the compressed air storage tank and a distributing module, an SNCR (selective non-catalytic reduction) spray module is connected with the distributing module and is arranged at a flue gas outlet of a hearth of a boiler, a cyclone separator is connected to the flue gas outlet of the hearth of the boiler, a tail heated device is connected with the cyclone separator and comprises a superheater, a high-temperature coal economizer, a flue gas flow guide device, ammonia spray grids, a catalysis module, a low-temperature coal economizer and an air preheater which are sequentially arranged from top to bottom, and the ammonia spray grids are connected with an ammonia gas generating mechanism. The combined type flue gas denitration system has the advantages that good denitration effects can be realized, and problems of dust accumulation, abrasion and the like of catalysts can be effectively solved.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com