Sintering mixer flue gas dedusting and whitening device

A mixer and flue gas technology, applied in the field of metallurgy, can solve problems such as high humidity of flue gas, inability to directly discharge flue gas particles, and hidden dangers to the personal safety of cleaning personnel, and achieve the effect of low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

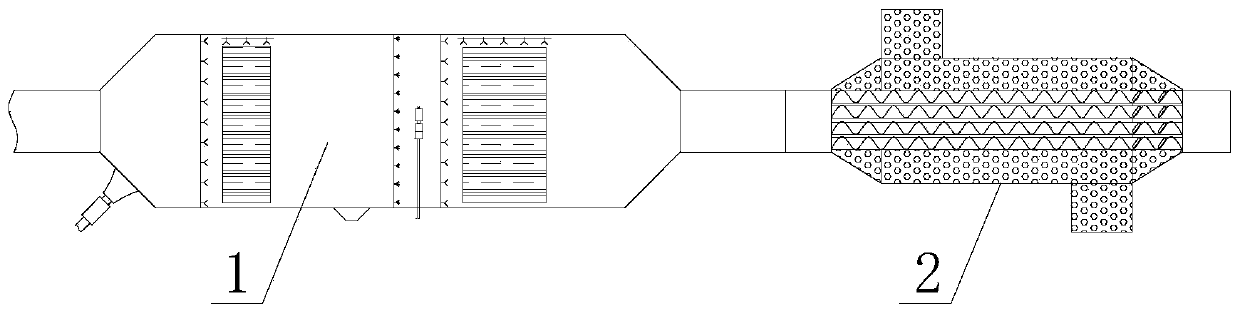

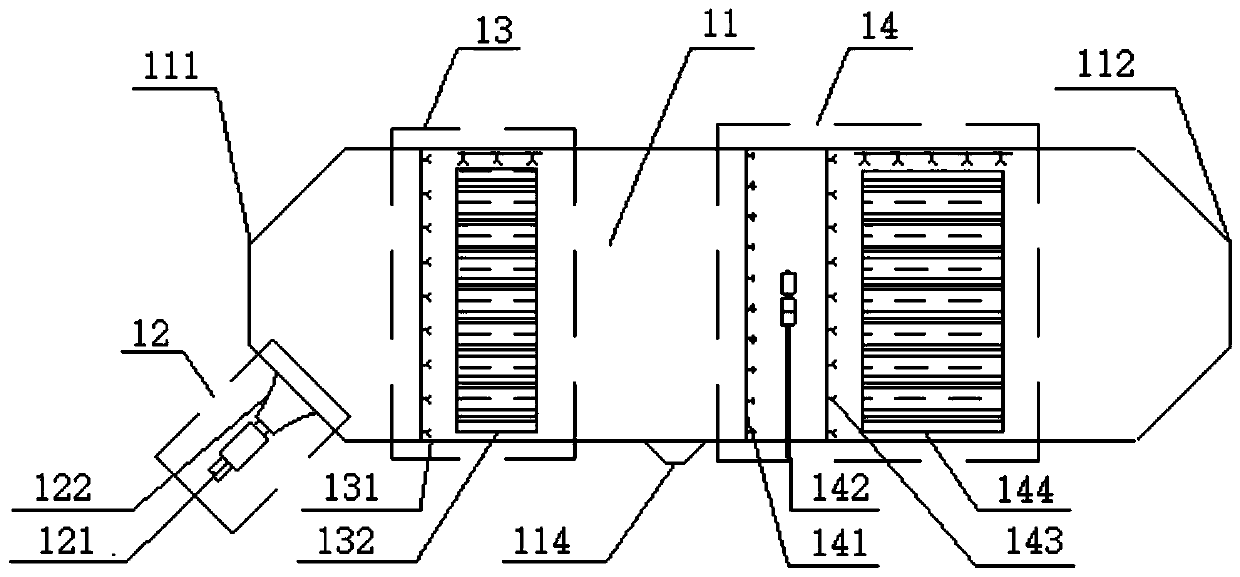

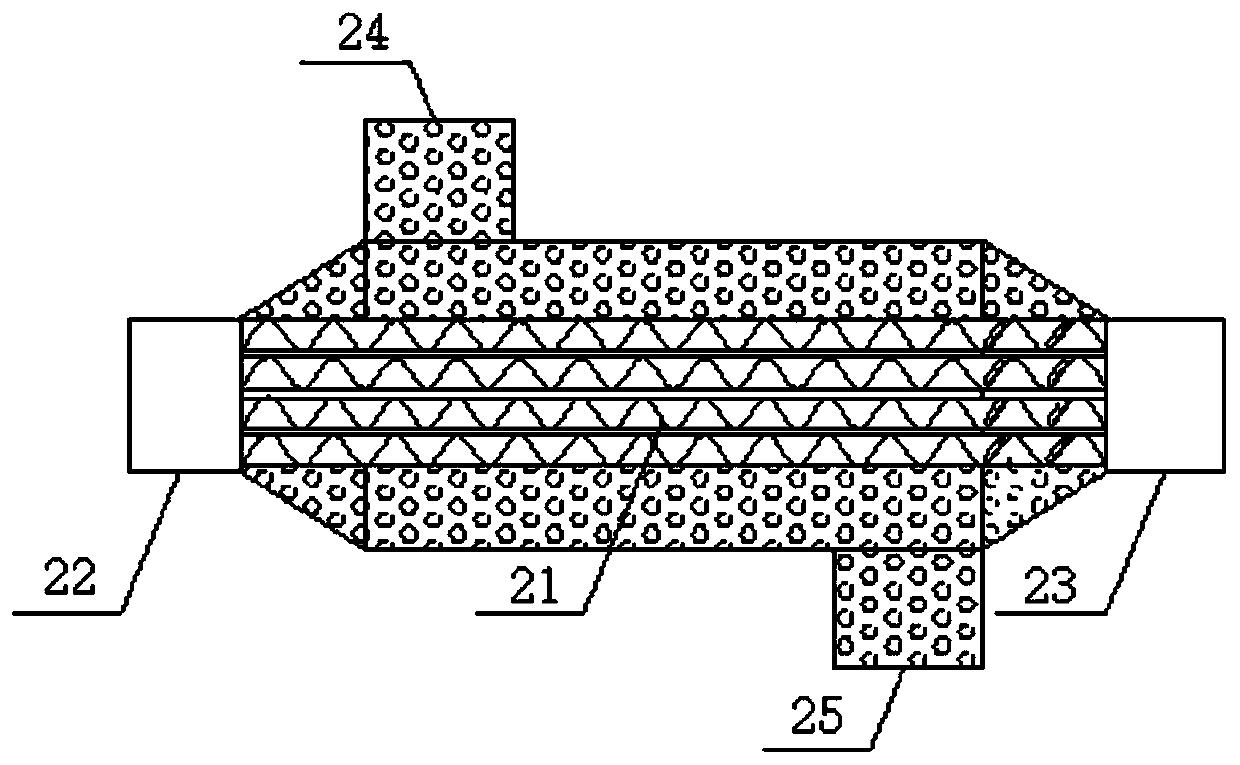

[0032] Such as figure 1 As shown, the flue gas dedusting and whitening device of the sintering mixer provided in this embodiment includes the sonic agglomeration and dedusting equipment 1 , and the output end of the sonic agglomeration and dedusting equipment 1 is connected to the condensation cyclone water collection equipment 2 . Such as figure 2 As shown, the sonic agglomeration and dedusting equipment 1 includes a device housing 11, one end of the device housing 11 is provided with an equipment inlet 111, and the other end is provided with an equipment outlet 112, and the equipment housing 11 at the equipment inlet 111 is provided with a sonic descaling module 12, and the equipment housing The body 11 is provided with a first agglomeration module 13 and a second agglomeration module 14, the first agglomeration module 13 is arranged closer to the equipment inlet 111 than the second agglomeration module 14, and the first agglomeration module 13 includes The first washing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com