Method for preparing medium-low temperature SCR denitration catalyst and catalyst prepared by same

A denitrification catalyst and catalyst technology, applied in the field of denitrification catalysts, can solve problems such as production process deviation, product qualification rate drop, sludge plasticity, and water content, etc., to meet the requirements of ultra-low NOx emissions and facilitate production costs , The effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific embodiments, but the present invention is not limited to the following embodiments. Examples:

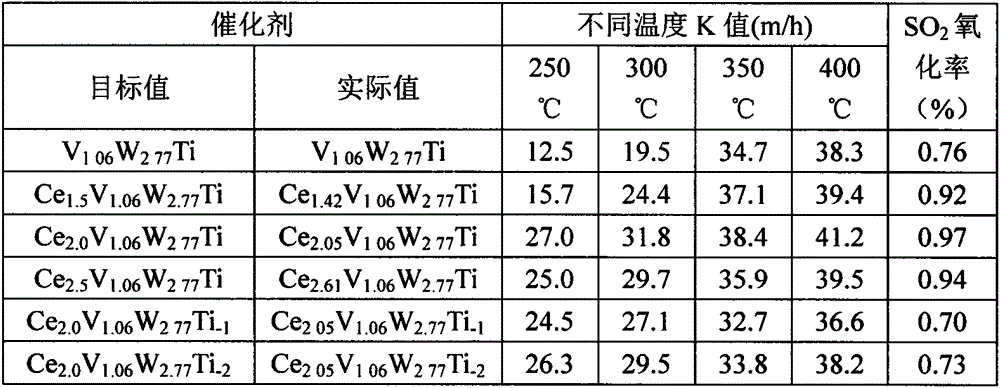

[0025] The prepared catalyst is CeO 2 -V 2 O 5 -WO 3 / TiO 2 , The series of catalysts prepared in the experiment are denoted as CexVyWzTi, where x, y, z represent CeO in the catalyst 2 , V 2 O 5 , WO 3 The mass percentage of, y, z values vary with the catalyst substrate.

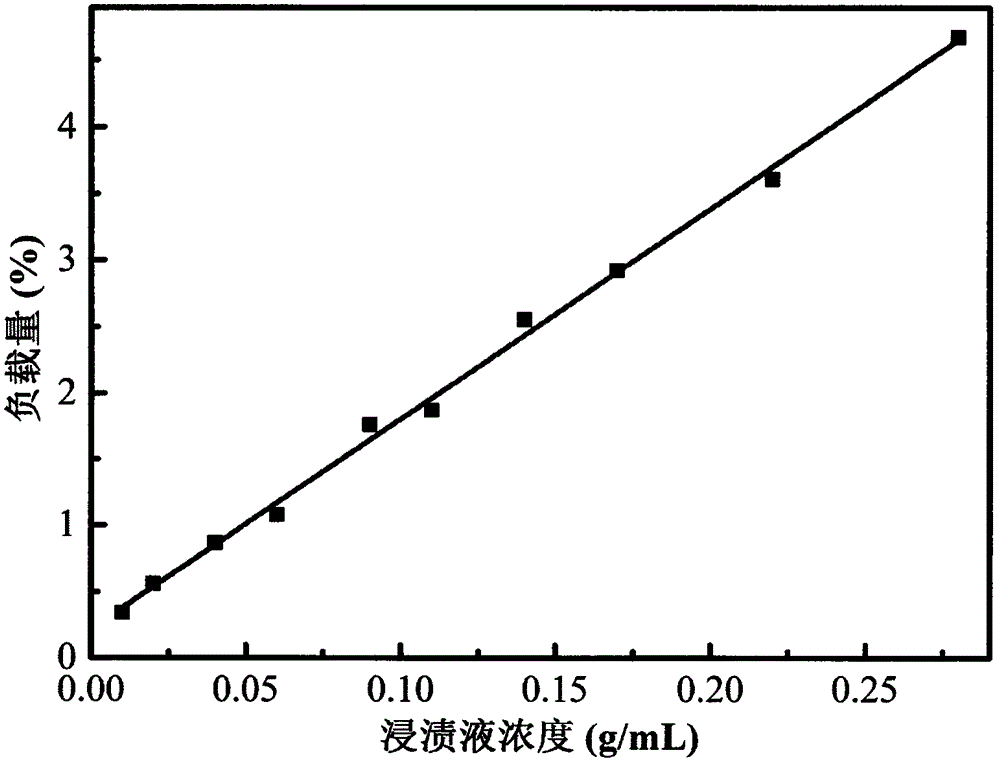

[0026] Impregnation curve drawing experiment (only introduce the optimal conditions)

[0027] Table 1 Concentration of impregnating solution and dosage of cerium nitrate

[0028] Sample serial numberM1M2M3M4M5M6M7M8M9M10 Soaking solution concentration (g / mL) 0.010.020.040.060.090.110.140.170.220.28

[0029] Prepare 10 different concentrations of cerium nitrate solution at 30°C (specifically as shown in Table 1), which can be completely dissolved in 8 minutes under ultrasonic conditions (it can be completely dissolved in 11 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com