Electric and bag-type composite dust removing device and treatment method thereof

A combination technology of dust removal device and electric bag, which is applied in the direction of combination device, separation method, chemical instrument and method, etc., can solve the problems of uneven distribution of flow field of bag filter, increase of filter bag resistance, and decrease of filter bag life, and achieve Reasonable use of the factory use area, the use of the factory use area, and the effect of increasing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

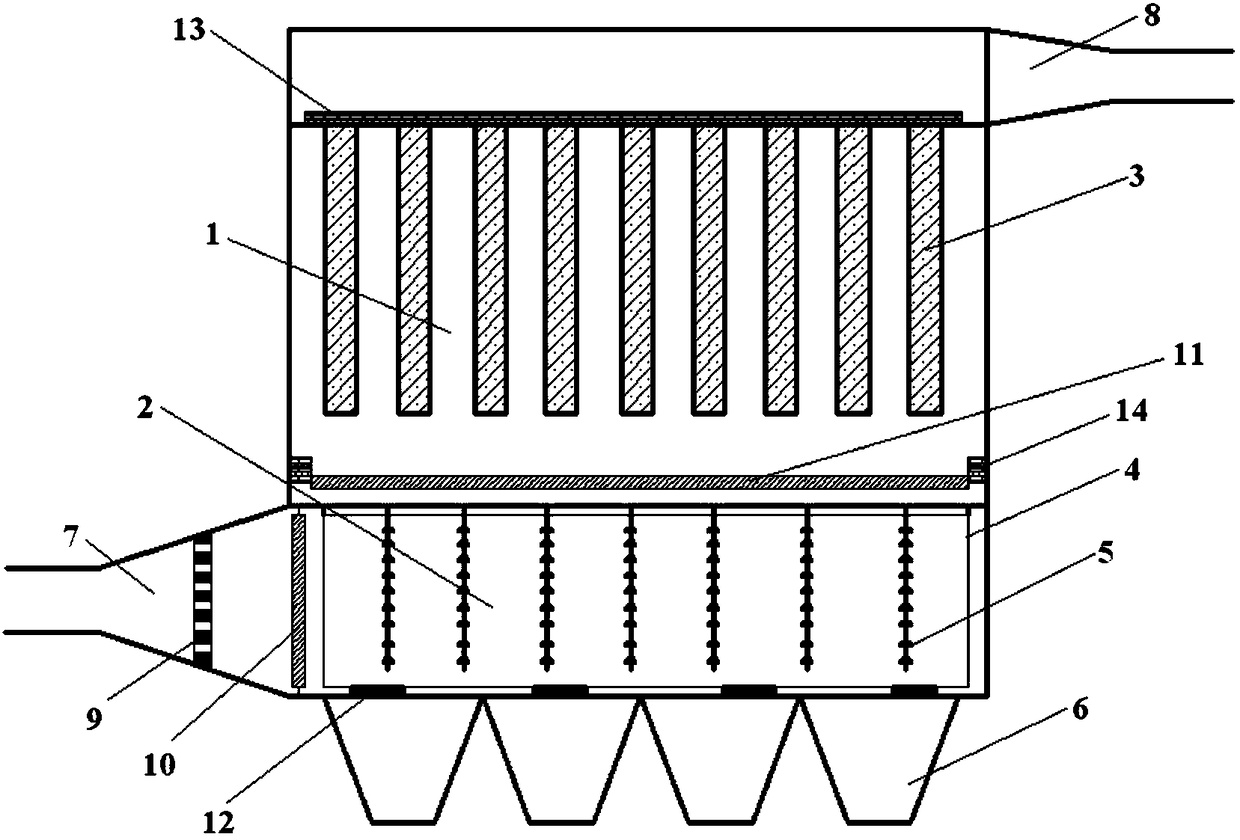

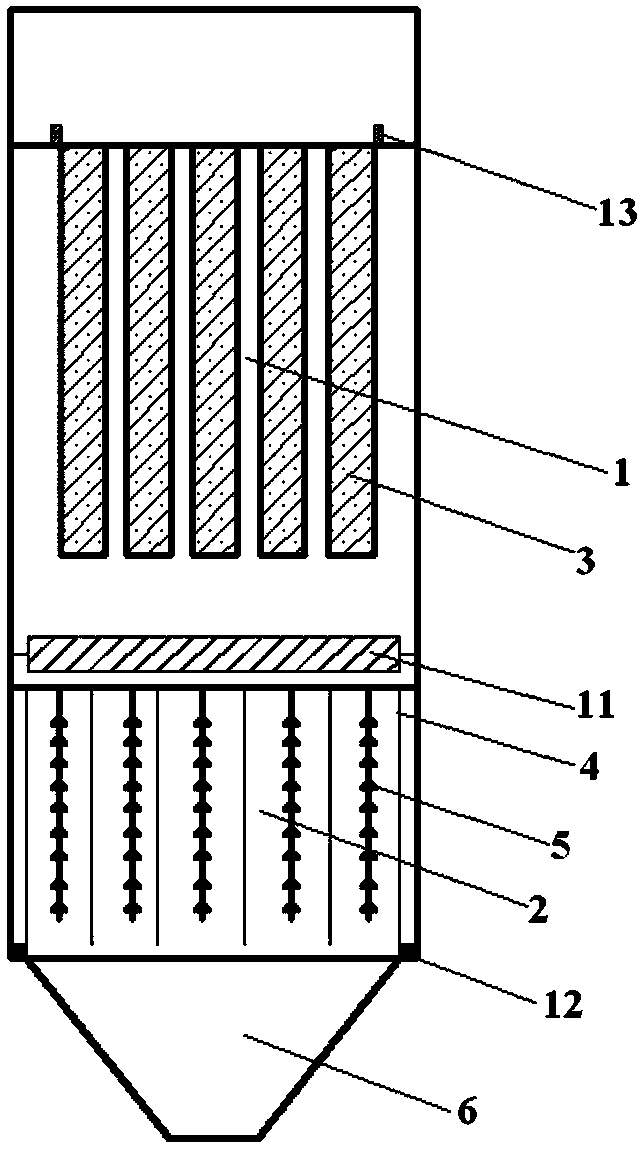

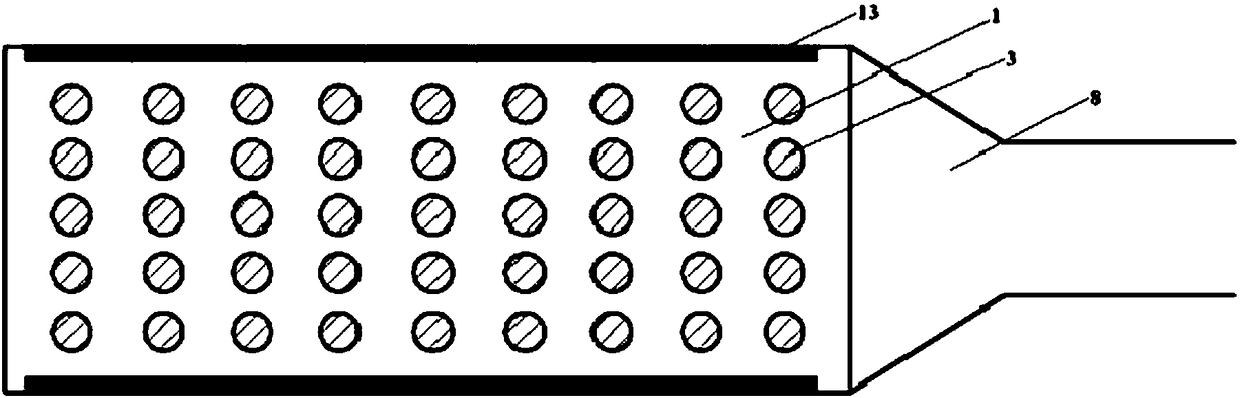

[0065] This embodiment provides a kind of electric bag composite dedusting device and its processing method, such as Figure 1-Figure 4 As shown, the electrostatic bag composite dust removal device includes an electrostatic dust removal area 2 placed at the lower part of the device and a bag dust removal area 1 placed above the electrostatic dust removal area 2. Gas inlet 7, the top of the device opposite to the flue gas inlet 7 is provided with a flue gas outlet 8 connected to the bag dust removal area 1, and a first deflector is provided between the flue gas inlet 7 and the electrostatic precipitator area 2 10. A second deflector 11 is set between the electrostatic precipitator area 2 and the bag filter area 1 .

[0066] Wherein, the height of the bag dust removal area 1 is twice the height of the electrostatic precipitator area 2, a bottom ash hopper 6 is set under the electrostatic precipitator area 2, and a first rapping cleaning machine is set between the electrostatic p...

Embodiment 2

[0076] This embodiment provides an electric bag composite dedusting device and its processing method. The electric bag composite dedusting device includes an electrostatic precipitator area 2 placed at the bottom of the device and a cloth bag dedusting area 1 placed above the electrostatic precipitator area 2. The bottom side of the device is provided with a flue gas inlet 7 connected to the electrostatic precipitator area 2, and the top side of the device opposite to the flue gas inlet 7 is provided with a flue gas outlet 8 connected to the bag dust removal area 1. The flue gas inlet 7 A first guide plate 10 is provided between the electrostatic precipitator area 2 and a second guide plate 11 is provided between the electric precipitator area 2 and the bag dust removal area 1 .

[0077] Wherein, the height of the bag dust removal area 1 is twice the height of the electrostatic precipitator area 2, a bottom ash hopper 6 is set under the electrostatic precipitator area 2, and a ...

Embodiment 3

[0084] This embodiment provides an electric bag composite dust removal device and its processing method. The structure of the electric bag composite dust removal device refers to the structure in Example 1, the only difference is:

[0085] The height of the bag dust removal area 1 is 4 times the height of the electrostatic precipitator area 2; the cathode line 5 array includes 1200 cathode lines 5, 40 cathode lines 5 are set in each row, and 30 cathode lines 5 are set in each column; the filter bag 3 array includes 750 filter cloth bags 3, each row is provided with 30 filter cloth bags 3, and each row is provided with 25 filter cloth bags 3; The included angle of the horizontal line is 135°, so that the airflow direction of the flue gas entering the electrostatic precipitator area 2 is 135° of the included angle of the horizontal line, and the residence time of the flue gas in the electrostatic precipitator area 2 is increased by 3 seconds; the second deflector 11 is an airflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com