A high-temperature gas-solid separation filter combined with multi-layer cascade filter material and filter membrane

A solid separation and filter technology, which is applied in the field of high-temperature gas-solid separation filters, can solve the problems of low purification efficiency of fine particles and high dust outlet concentration, and achieve the effect of low dust outlet concentration and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0030] High-temperature gas-solid separation filter combined with multi-layer cascade filter material and filter membrane, such as figure 1 As shown, the upper layer is a perlite layer with larger particles, the middle layer is a sea sand layer with smaller particles, the lower layer is a fine quartz sand powder layer, and a filter membrane layer is added below the quartz sand layer. Combine the fine particle layer of the last stage of the particle layer with the filter membrane to form a fixed powder layer similar to the dust layer, so that the fine dust particles can obtain higher dust removal efficiency in the initial stage of filtration. At the same time, due to the effect of cascade filtration, large dust particles are basically captured by the upper filter material, and most of the dust particles captured by the powder layer are smaller dust particles, so the service life of the fixed powder layer can also be greatly improved. Compared with the traditional particle layer...

Embodiment 1

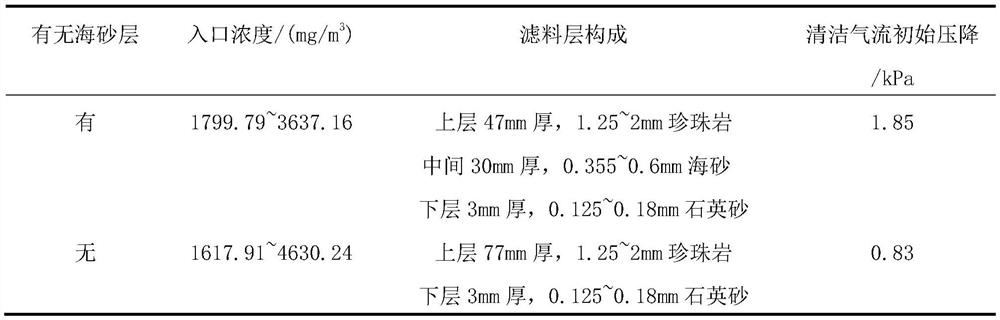

[0034] This embodiment provides a filter method in which different layers of cascaded filter materials and stainless steel filter membranes are combined, from which it can be determined that three layers of filter materials are beneficial to improve dust removal efficiency.

[0035] The total height of the particle layer filter material is 80mm, and the influence of the presence or absence of sea sand layer on the dust removal performance of the combination of multi-layer filter material and stainless steel filter membrane (25um) is investigated by using 5000-mesh experimental fly ash. The filtration gas velocity is 0.18m / s, and the concentration at the inlet of the experiment, the composition of the filter layer and the initial pressure drop are shown in Table 1.

[0036] Table 1 The experimental conditions of the influence of the number of filter material layers on the effect of gas-solid separation

[0037]

[0038] The effect of the number of layers of filter material o...

Embodiment 2

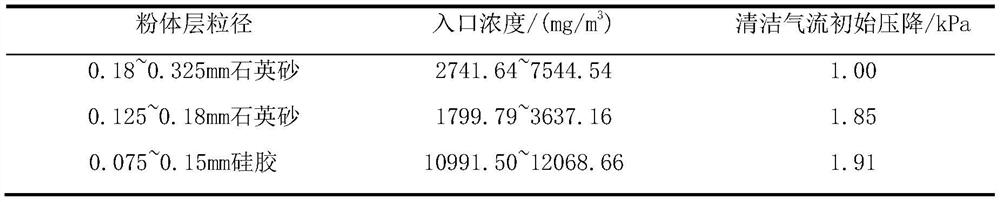

[0040] This embodiment provides a method for changing the particle size of the powder layer of a filter combined with a multi-layer cascade filter material and a stainless steel filter membrane, from which it can be determined that the suitable particle size of the powder layer is 0.125-0.18mm.

[0041] Maintain the 25um stainless steel filter membrane, and the upper layer is 47mm thick, 1.25-2mm perlite, the middle layer is 30mm thick, 0.355-0.6mm sea sand, the lower 3mm thick powder layer remains unchanged, and the particle size of the powder layer is changed. 5000 mesh fly ash was used to investigate the effect of powder layer particle size on dust removal performance. The filter air velocity is 0.18m / s, the dust inlet concentration of different powder layer particle sizes and the pressure loss of the clean airflow are shown in Table 2.

[0042] Table 2 Experimental conditions for the effect of powder layer particle size on the effect of gas-solid separation

[0043]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com