Stable ultra-low emission pulse-jet bag-type dust collector

A bag-type dust collector and pulse injection technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of excessive emission of dust collectors, unbalanced resistance of dust collectors, high air leakage rate of dust collectors, etc. Achieve the effect of reducing secondary pollution, improving replacement operating conditions, and improving dust removal and filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

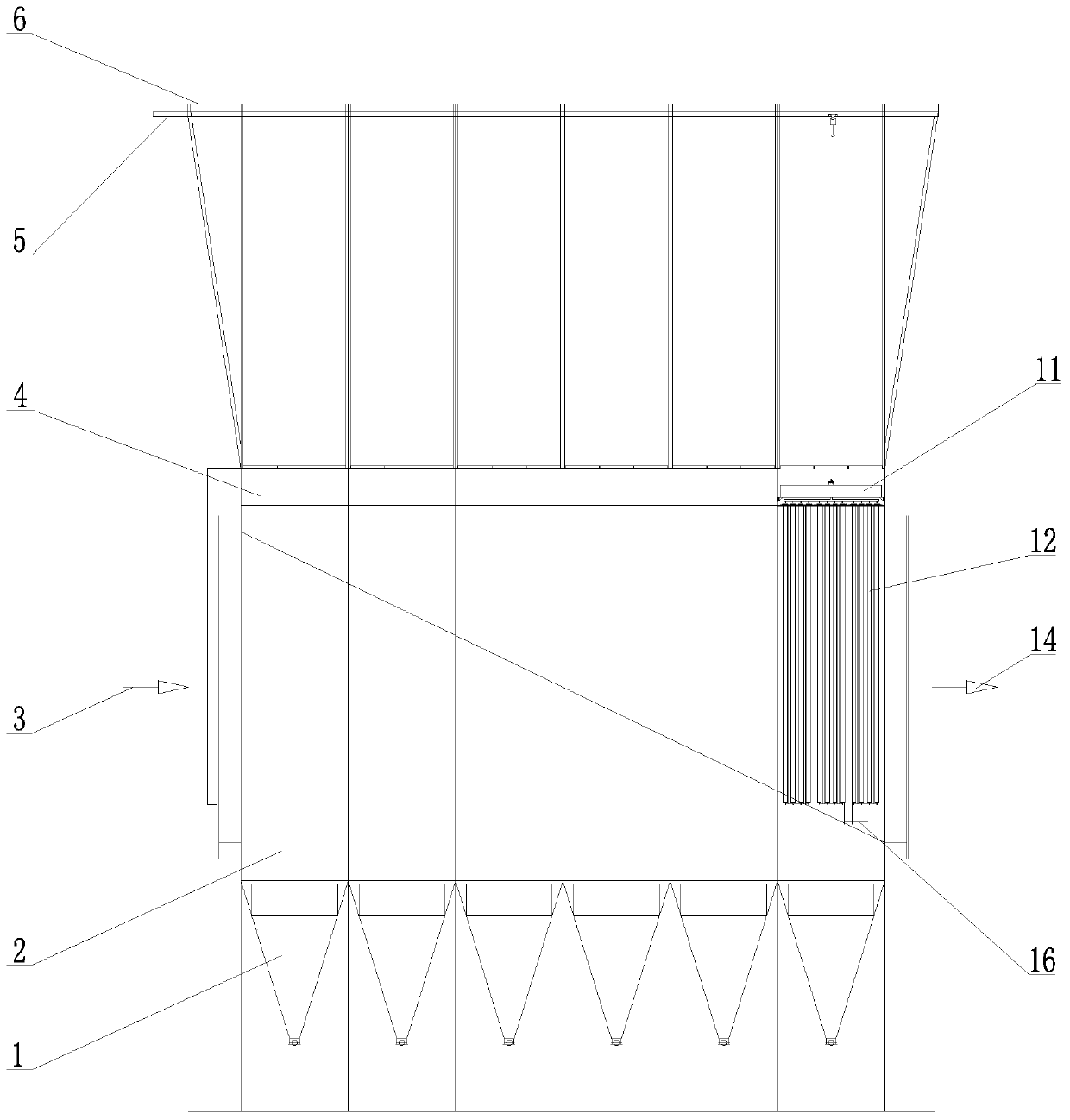

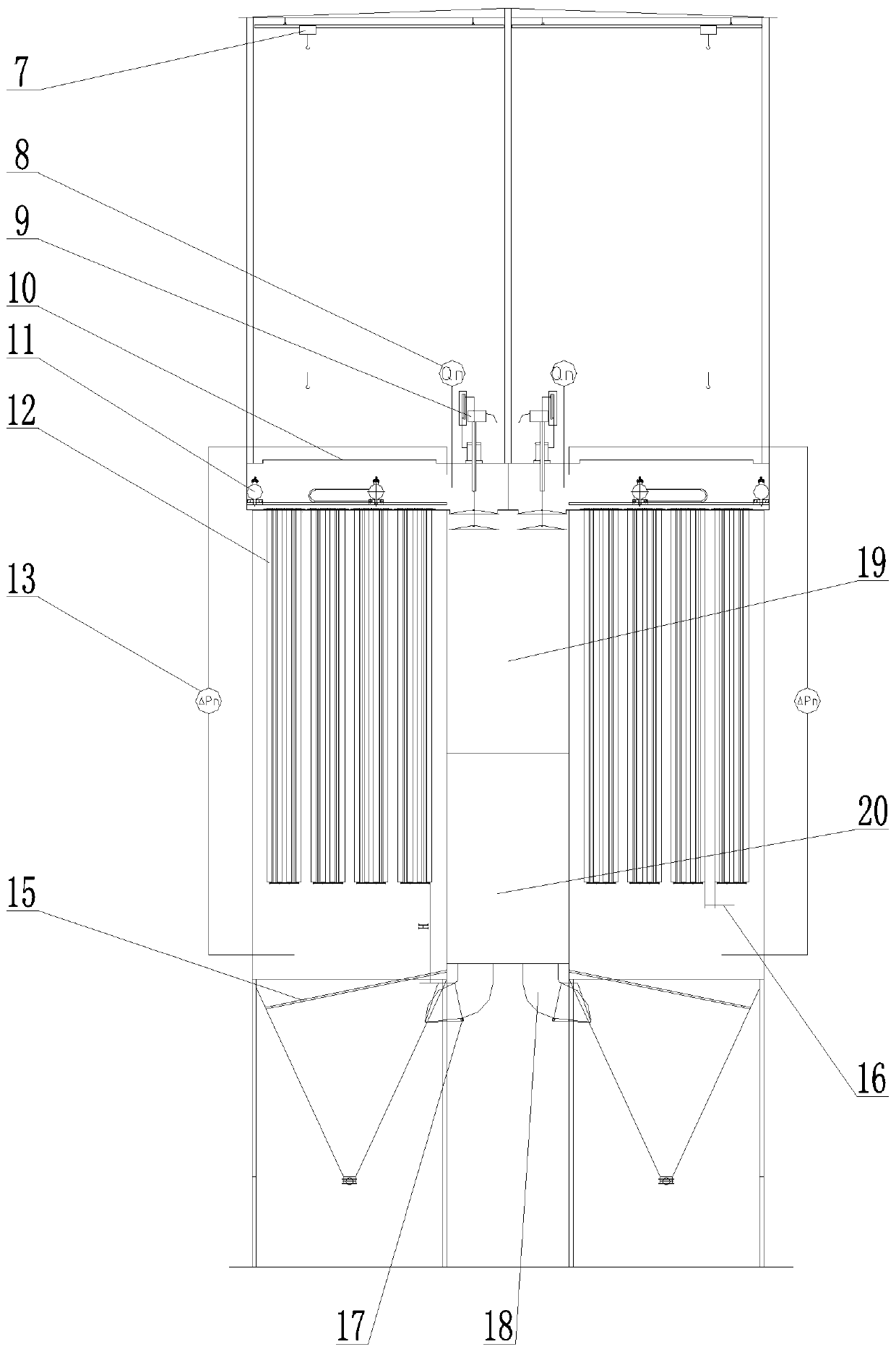

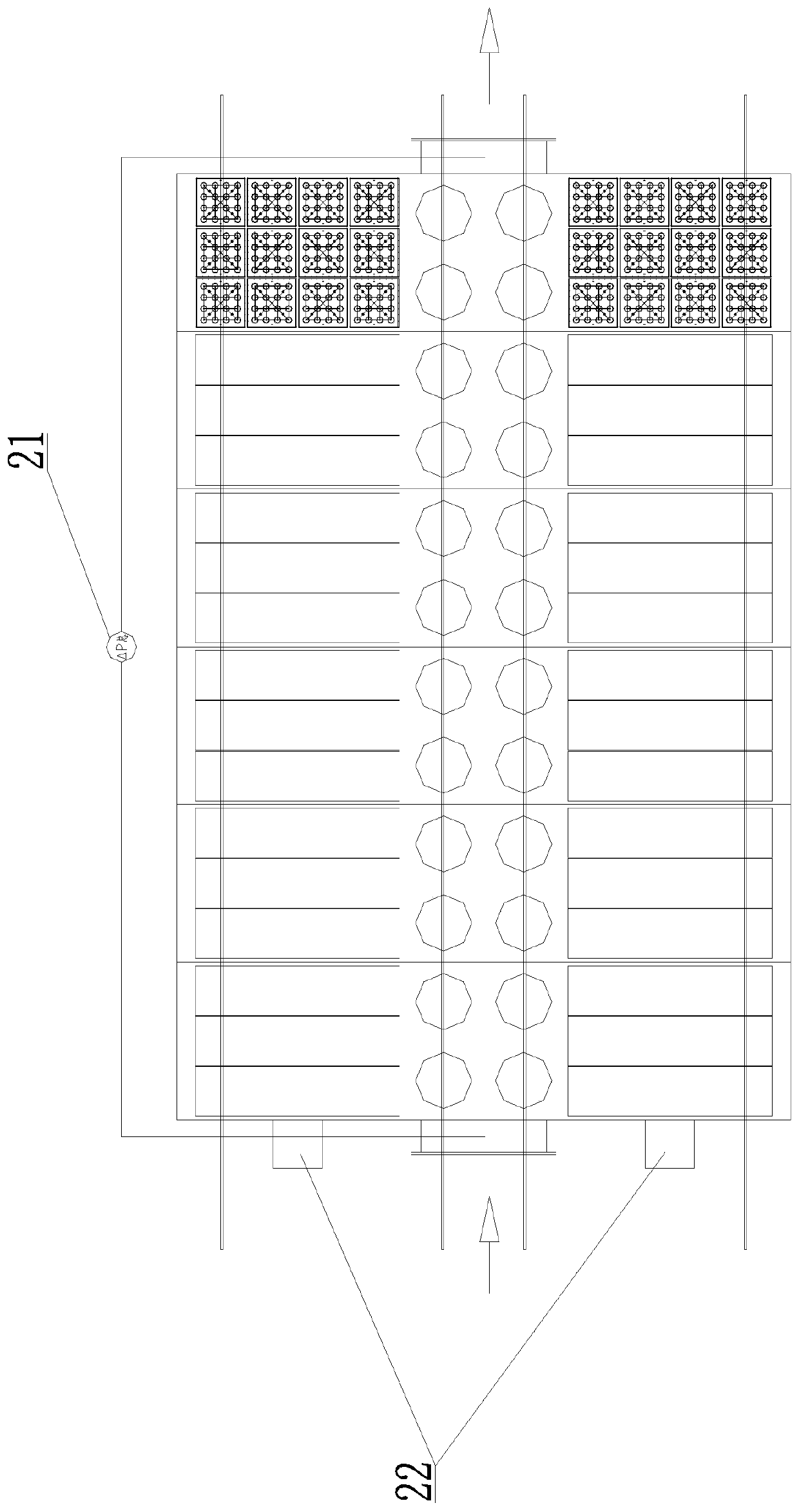

[0046] figure 1 It is a schematic diagram of the present invention. like figure 1 As shown, a pulse-jet bag-type dust collector capable of stable ultra-low emissions includes multiple single-girder suspension crane rails 5 on the top and multiple rows of pulse-jet bag-type dust collectors with rooms as units. In this embodiment, there are two rows of pulse-jet bag-type dust collectors with room as the unit. Crane 7 is installed in the single girder suspension crane rail 5. A rainproof roof 6 is installed above the single girder suspension crane track 5 of the open-air operation. The pulse jet bag filter includes multiple dust chambers. The dust removal chamber includes an upper box body 4, a middle box body 2 and an ash hopper 1 from top to bottom. The pulse jet bag filter is equipped with an inlet and outlet differential pressure detection devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com