Swirling de-swirling coupled efficient dedusting and demisting assembly

A defogging component and derotation technology, which is applied in the field of flue gas purification, can solve the problems of large pressure loss, high dust removal and defogging efficiency, and small pressure loss of the cyclone plate dust removal and fog removal device, and achieves high dust removal and fog removal efficiency. No risk of fouling and clogging, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

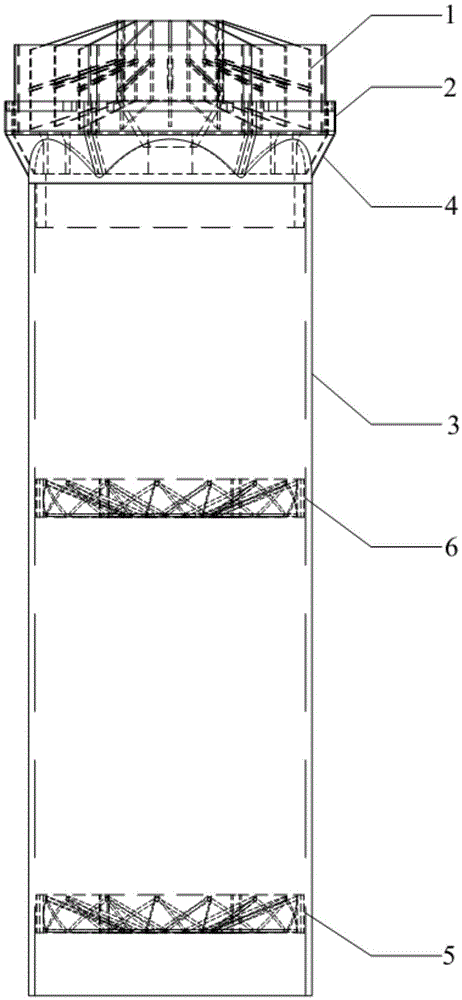

[0040] Such as figure 1As shown, a swirl-race coupling high-efficiency dedusting and mist removal assembly is arranged above the spray layer in the desulfurization absorption tower and includes multiple dust and mist removal units. The dust and mist removal units include an outer cylinder, a From bottom to top, the first-stage centrifugal swirl plate 5, the second-stage centrifugal swirl plate 6, and the racemic hydrophobic plate 1 obliquely arranged on the top of the outer cylinder are arranged in parallel in the outer cylinder body. The first-stage centrifugal swirl plate There is a gap between the outer edge of the plate 5, the outer edge of the second-stage centrifugal swirl plate 6 and the inner wall of the outer cylinder.

[0041] Wherein, the outer cylinder is composed of an upper cylinder 2 with a regular hexagonal cross-section, a cylindrical lower cylinder 3, and a transition pipe 4 arranged between the upper cylinder 2 and the cylindrical lower cylinder 3. The racem...

Embodiment 2

[0050] In this embodiment, the cross section of the upper cylinder 2 of the outer cylinder is a regular hexagon, and the diameter of the circumscribed circle of the upper cylinder 2 is 400 mm, and the outer diameter of the cylindrical lower cylinder 3 is 300 mm.

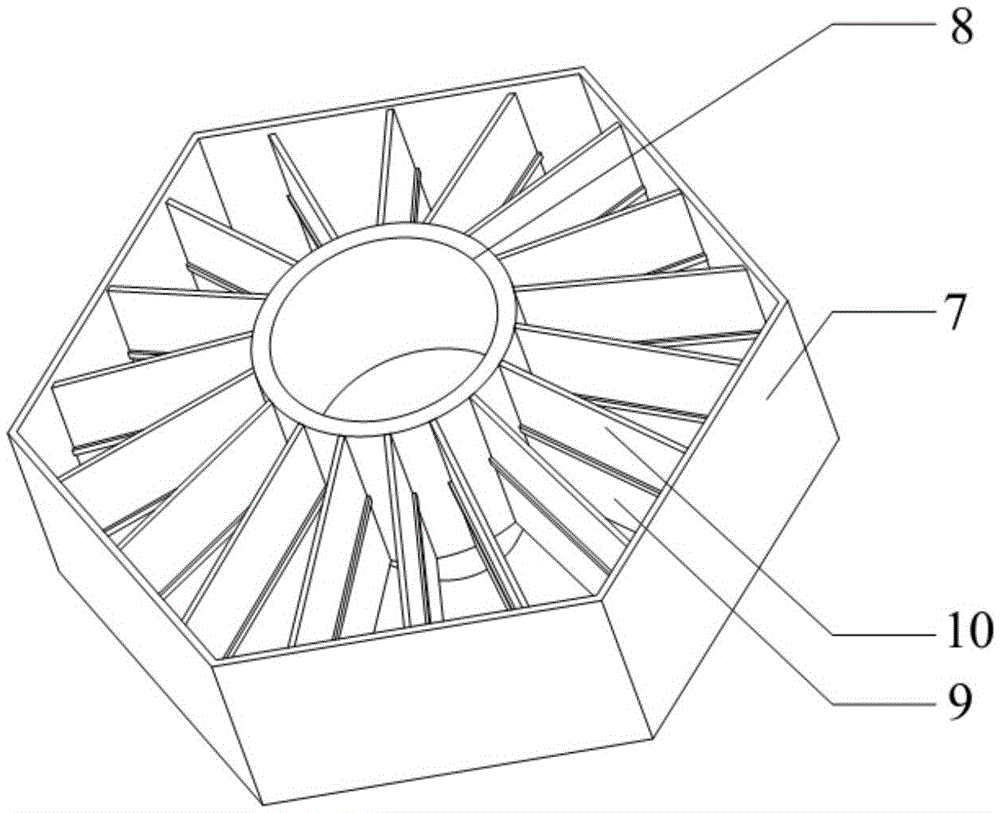

[0051] The cross-section of the plate frame 7 in the racemic hydrophobic plate 1 is a regular hexagon, and there are 24 racemic blades 9 in total; the included angle between the racemic hydrophobic plate 1 and the horizontal direction is 85°.

[0052] The elevation angle between the guide vanes in the first-stage centrifugal swirl plate 5 and the second-stage centrifugal swirl plate 6 and the horizontal plane is 45°, and the outer edge of the first-stage centrifugal swirl plate 5 and the second-stage The gap between the outer edge of the centrifugal swirl plate 6 and the inner wall of the outer cylinder is 20mm.

[0053] All the other are with embodiment 1.

Embodiment 3

[0055] In this embodiment, the cross section of the upper cylinder 2 of the outer cylinder is a regular hexagon, and the diameter of the circumscribed circle of the upper cylinder 2 is 500 mm, and the outer diameter of the cylindrical lower cylinder 3 is 400 mm.

[0056] The cross-section of the plate frame 7 in the racemic hydrophobic plate 1 is a regular hexagon, and there are 12 racemic blades 9 in total; the included angle between the racemic hydrophobic plate 1 and the horizontal direction is 80°.

[0057] The elevation angle between the guide vanes in the first-stage centrifugal swirl plate 5 and the second-stage centrifugal swirl plate 6 and the horizontal plane is 30°, and the outer edge of the first-stage centrifugal swirl plate 5 and the second-stage The gap between the outer edge of the centrifugal swirl plate 6 and the inner wall of the outer cylinder is 5mm.

[0058] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com