Low-temperature and low-pressure steam production device in power station boiler and process method

A low-temperature, low-pressure, production device technology, applied in steam generation, steam superheating, boiler water pipes, etc., can solve the problems of increasing steam production cost, daily maintenance cost of power plant, uneconomical, and decreased energy quantity and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

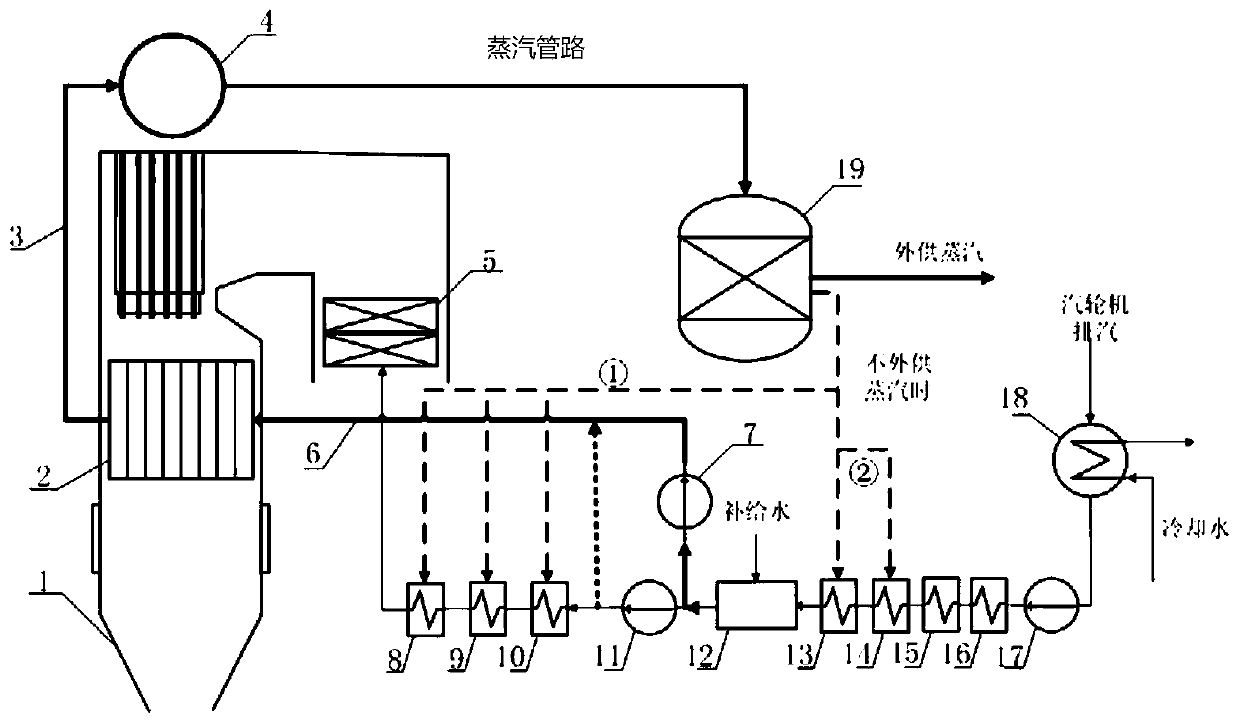

[0200] When external steam supply is required, select the water intake point according to the required low-temperature and low-pressure steam parameters. If the required low-temperature and low-pressure steam is high, select the pipeline between the feed water pump and the third high-pressure heater as the water intake point; otherwise, select the feed water pump The pipeline between the deaerator and the deaerator takes water. At this time, an additional low-pressure feed water pump needs to be installed to increase the feed water pressure by 1.0-5.0MPa to overcome the pressure loss in the pipeline. In this case, 100t / h of 1.3MPa saturated steam needs to be supplied externally, so water is taken from the pipeline between the feedwater pump and the deaerator, and a low-pressure feedwater pump is installed to increase the feedwater pressure to obtain a saturated steam with a pressure of 0.79104MPa and a temperature of 443.1K Water, adjust the flow of low-pressure feed water pump...

Embodiment 2

[0202]When external steam supply is not required, the water intake point can be selected between the feed water pump and the third high-pressure heater. The feed water heating process is similar to Case 1. After the superheated steam enters the external steam supply mixing station, it passes through the pressure reducing valve and spray water Reduce the temperature to the appropriate pressure and temperature parameters, produce 5.945MPa, 386.7 ℃ superheated steam can be passed into the first high-pressure heater, or the steam with corresponding parameters can be passed into the second low-pressure heater, or the first high-pressure heater, the second high-pressure heater The heater and the third high-pressure heater replace or partially replace the steam extraction from the high and low pressure cylinders of the steam turbine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com