Cluster-type modular filter bag assembly capable of meeting ultra-low emission requirements

A modular and clustered technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve problems such as high labor intensity, low work efficiency, and excessive deformation of flower plates, so as to reduce operational safety risks , shorten the manufacturing and assembly time, eliminate the effect of skew and swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

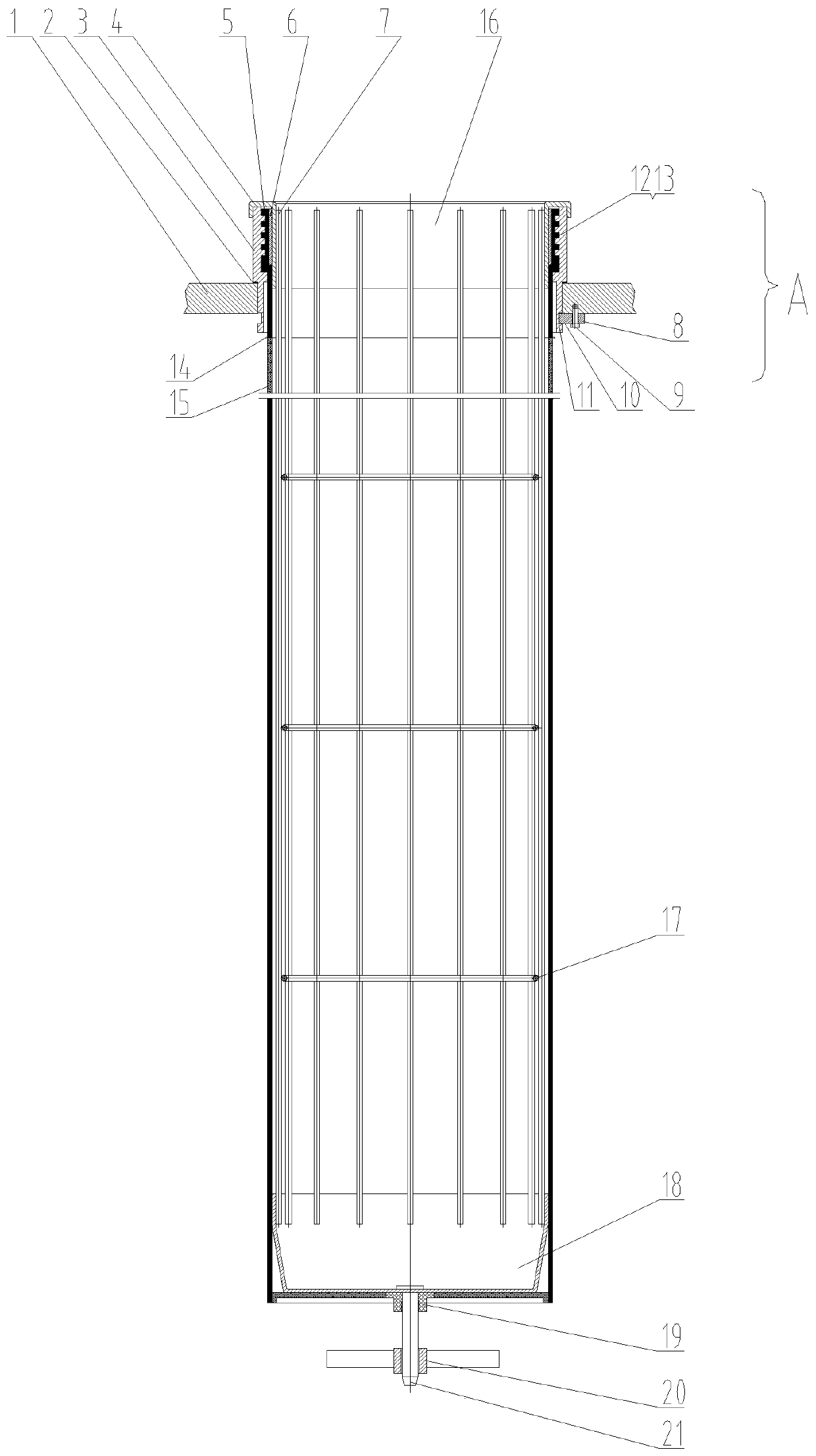

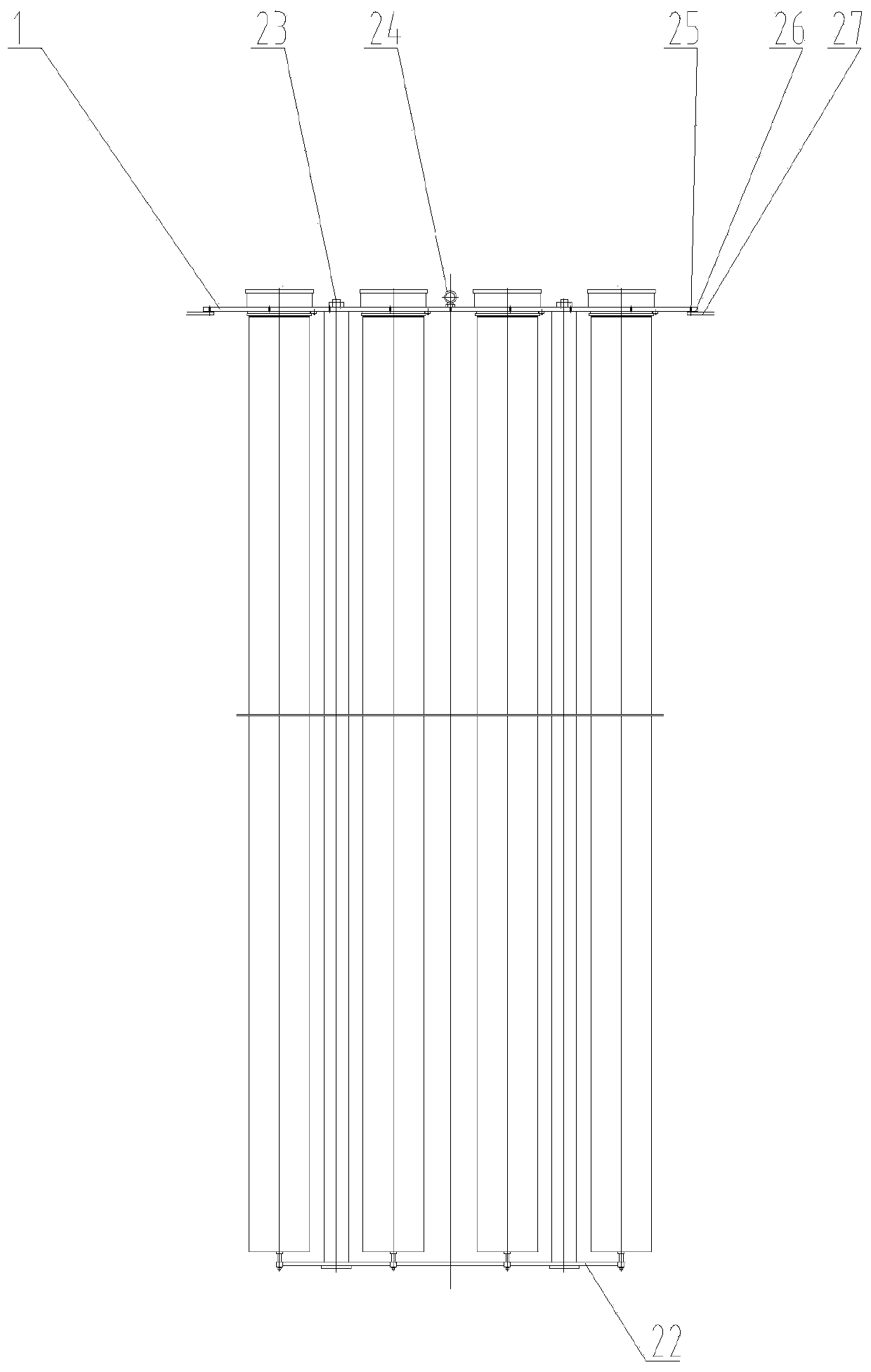

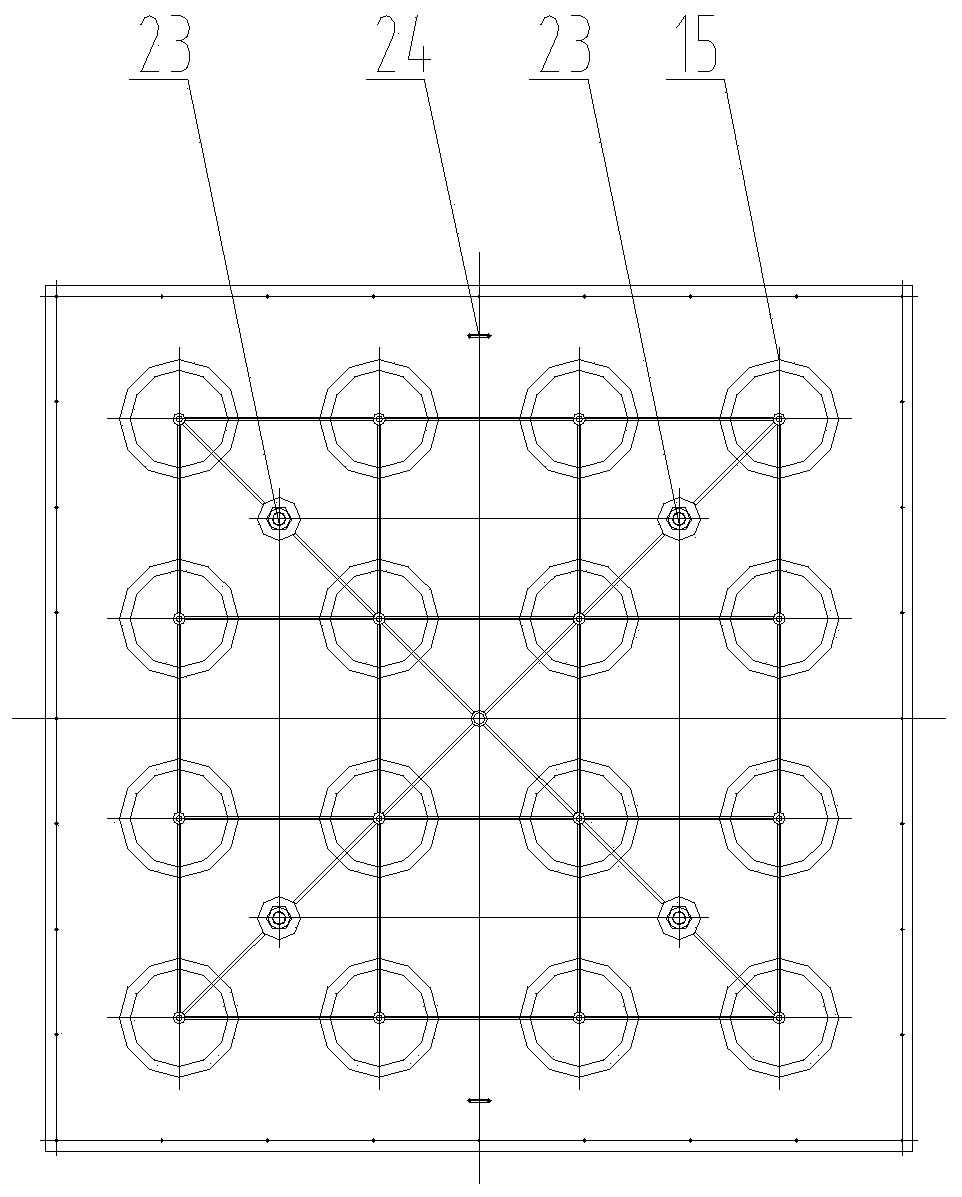

[0035] figure 1 It is a schematic diagram of the present invention, figure 2 is a side view of a clustered modular filter bag assembly, image 3 It is a top view of a clustered modular filter bag assembly. combine figure 1 , figure 2 and image 3 , a clustered modular filter bag assembly that can meet ultra-low emission requirements, including a plurality of clustered modular filter bag assemblies and a filter bag assembly fixing device.

[0036] Figure 4 for figure 1 Enlarged image at A. combine figure 1 , Figure 4 , the cluster modular filter bag assembly includes a flower plate 1 . According to N on flower board 1 1 ×N 2 A rectangular array of through holes is opened, and N is a natural number ≥ 3. A plurality of filter bags 15 are installed in the through holes. Hanging lugs 24 for lifting are installed on the flower plate 1 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com