Surge arrester and related manufacturing method

A lightning arrester and resistor technology, used in resistors, overvoltage protection resistors, non-adjustable metal resistors, etc., can solve problems such as dependence, reduce material costs, reduce manufacturing/assembly time, and simplify the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The principles of the disclosure will now be described with reference to a number of example embodiments illustrated in the accompanying drawings. Although example embodiments of the present disclosure are shown in the drawings, it will be understood that the description of the embodiments is only for those skilled in the art to better understand and thereby implement the present disclosure, and not to limit the scope of the present disclosure in any way. .

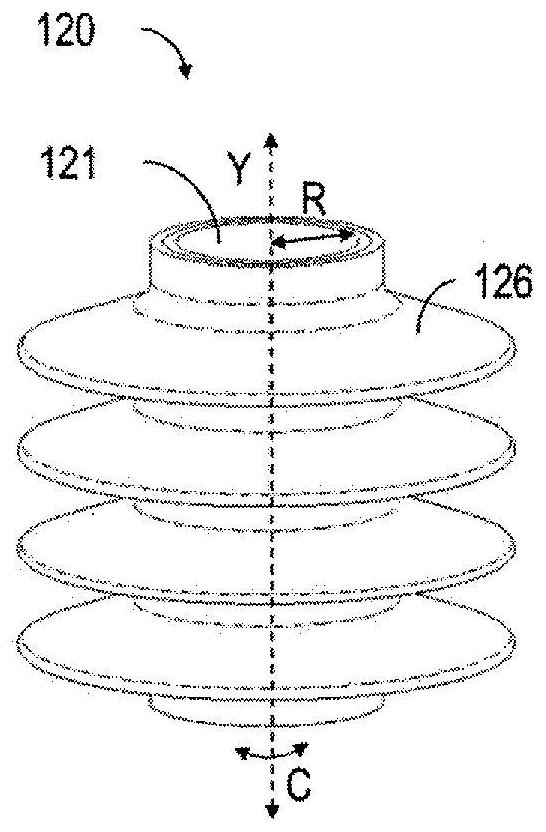

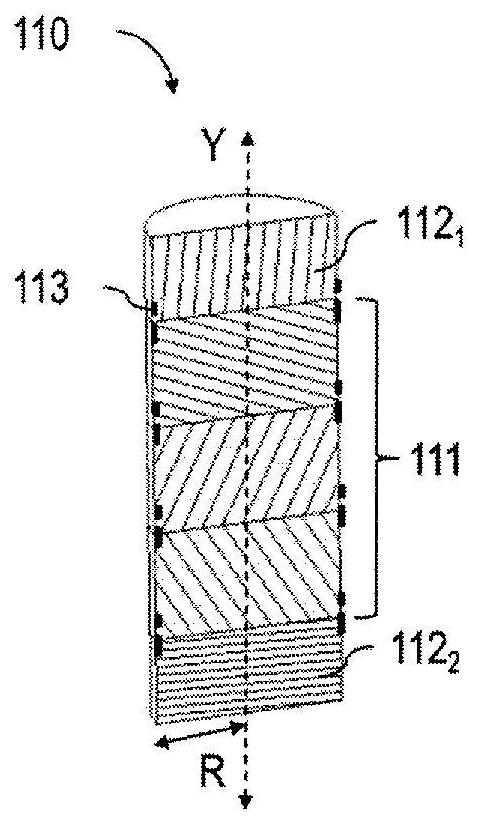

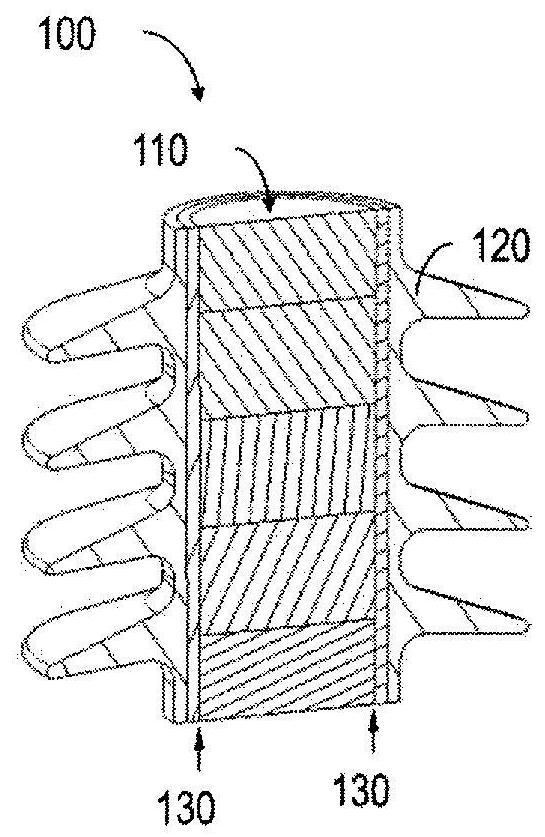

[0066] Figure 1a-Figure 1c A lightning arrester 100 according to an embodiment of the present disclosure is shown. The arrester 100 generally includes an active component 110 and a separately fabricated flexible housing 120 . Such as Figure 1a As shown, the active component 110 includes a generally cylindrical lateral surface and extends in a longitudinal direction Y. As shown in FIG. The separately manufactured flexible housing 120 defines an inner bore 121 in the longitudinal direction Y. The inner bore 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com