Patents

Literature

33 results about "Pre-RC assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

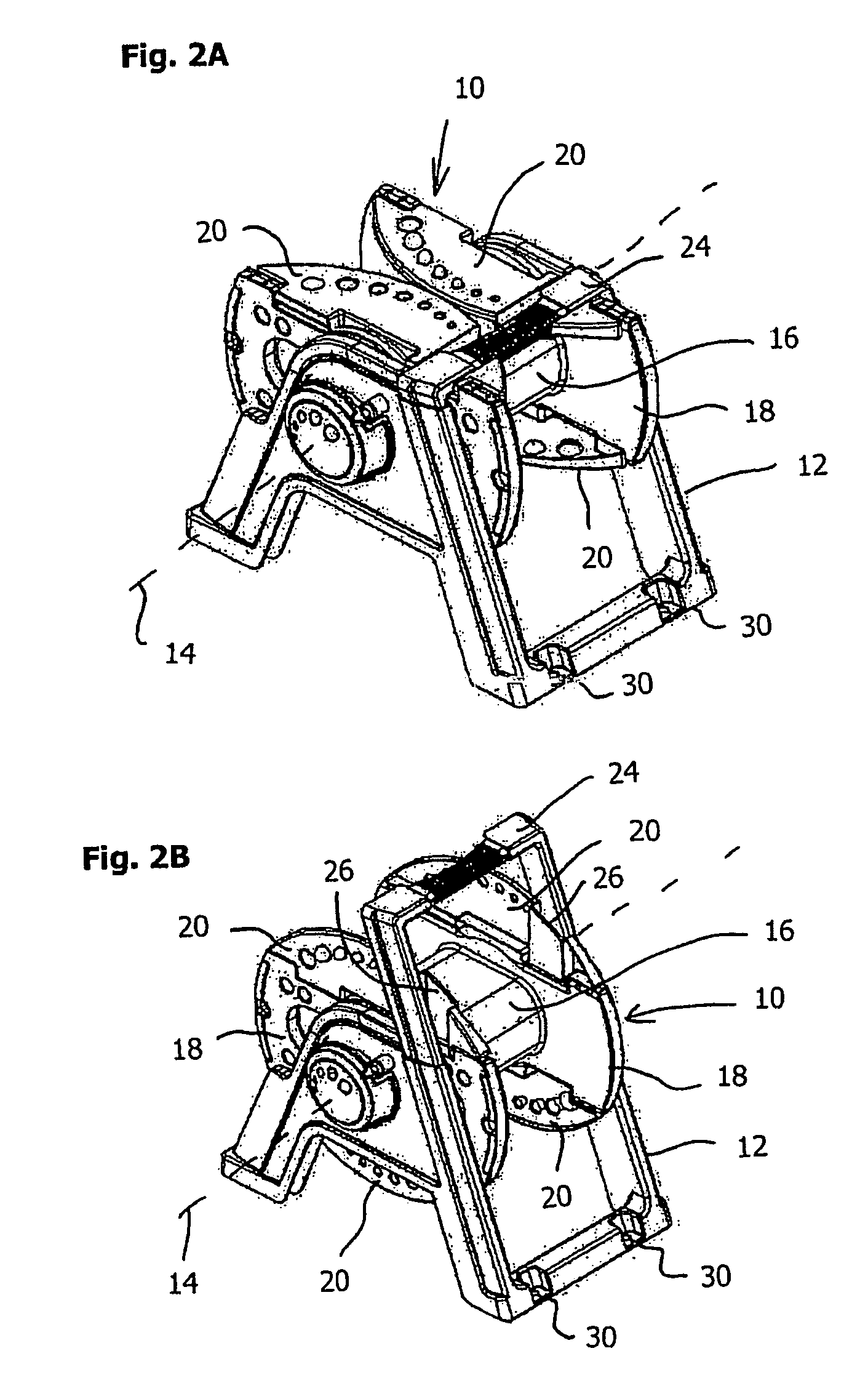

Add-on housing

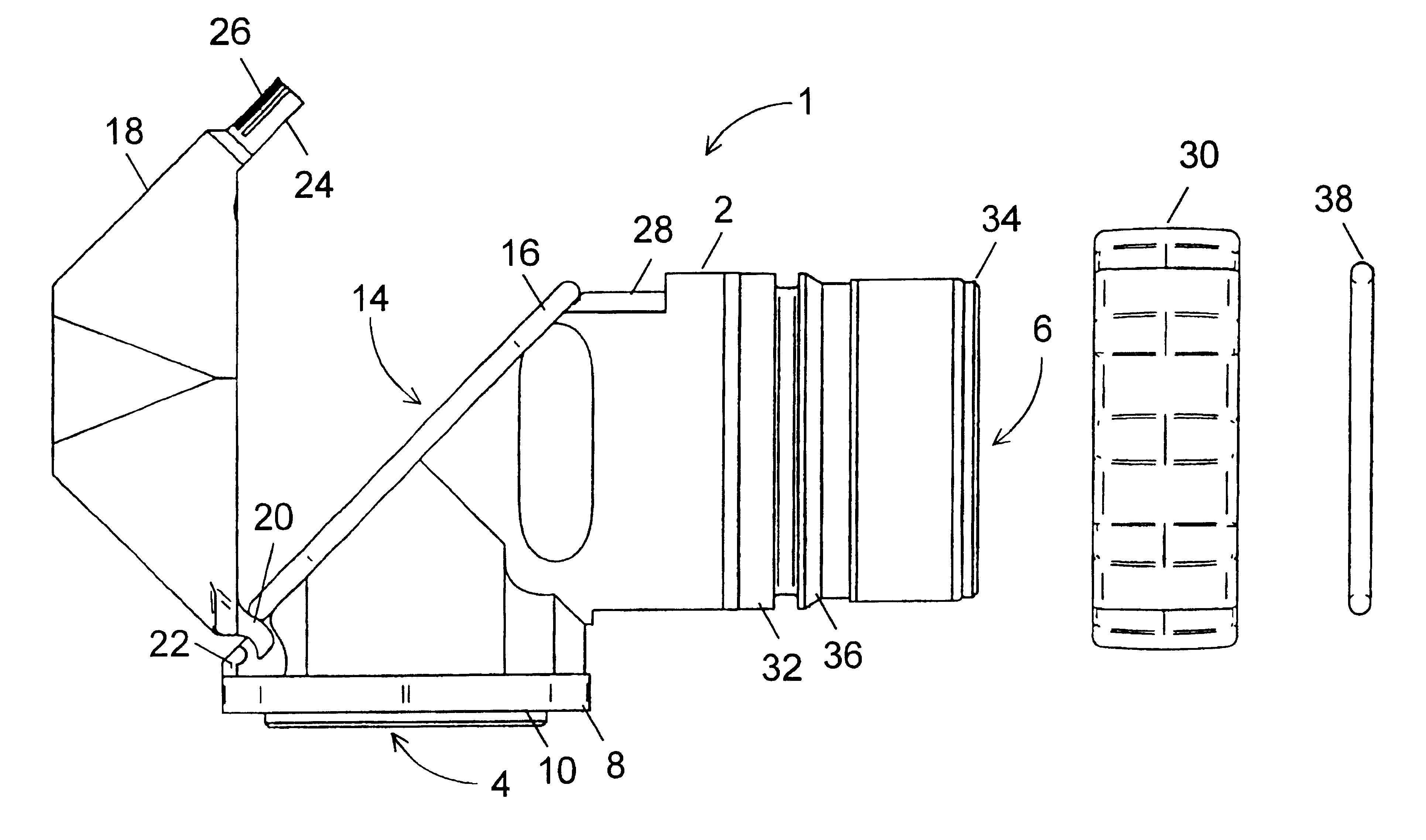

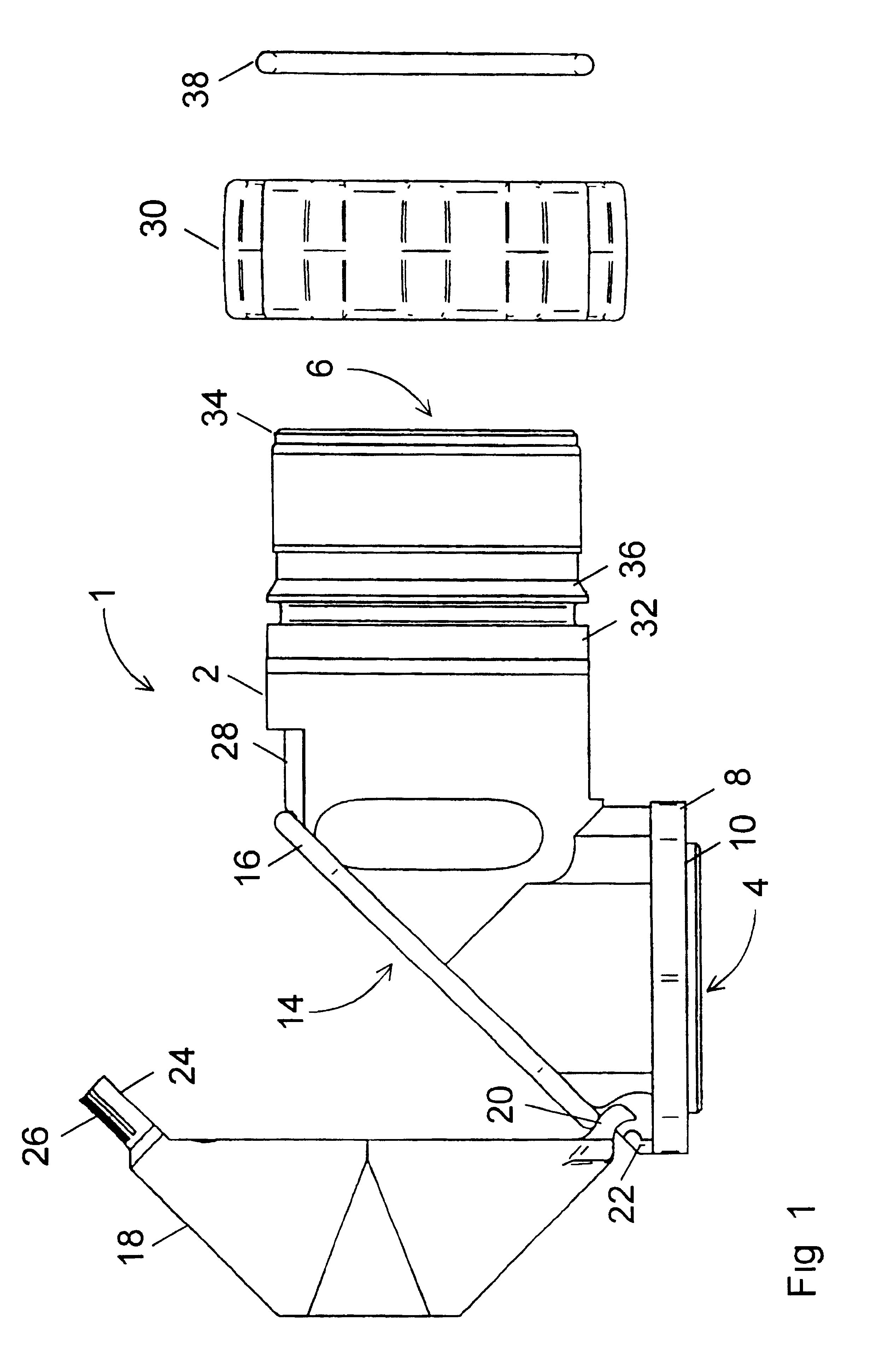

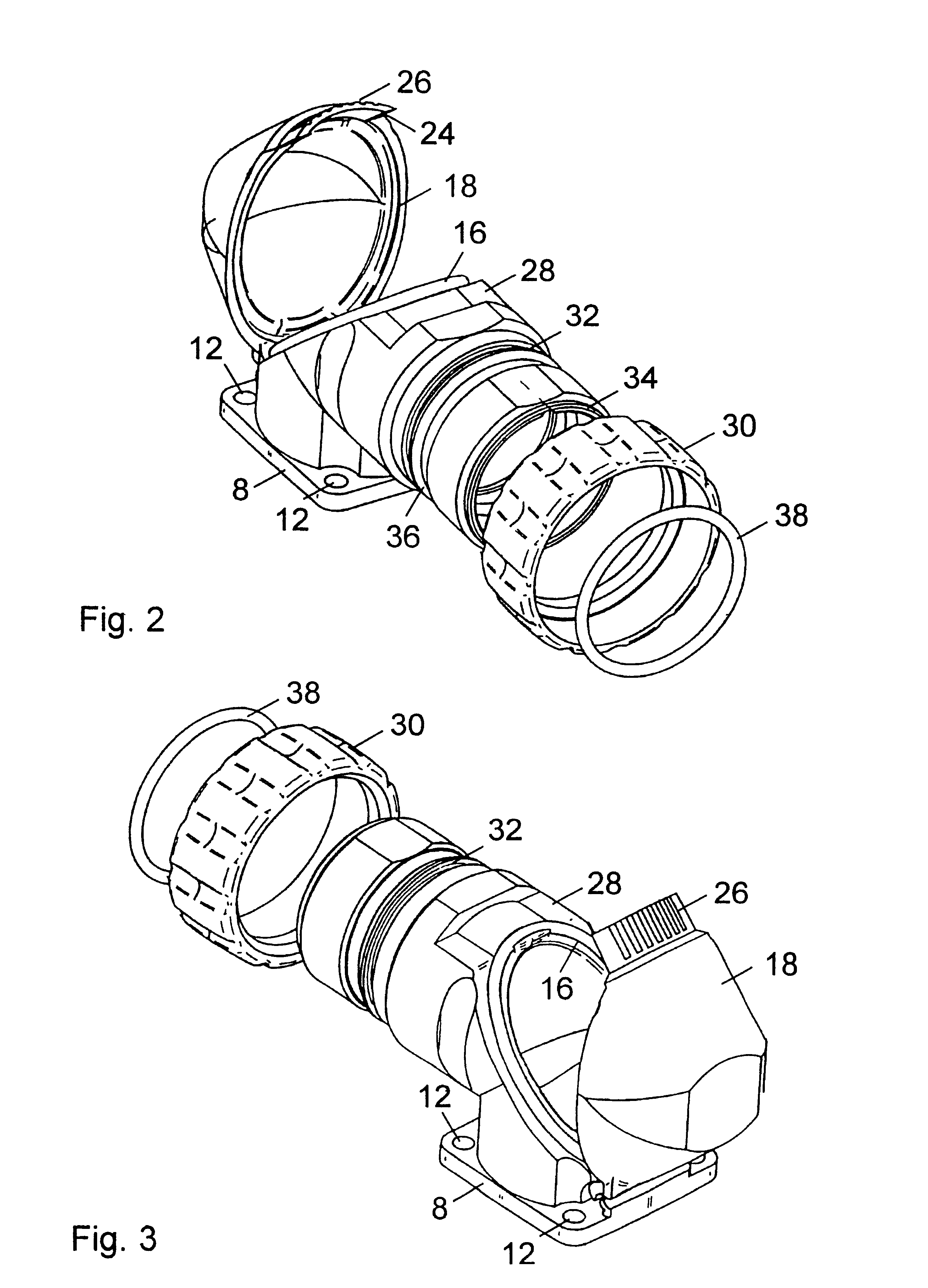

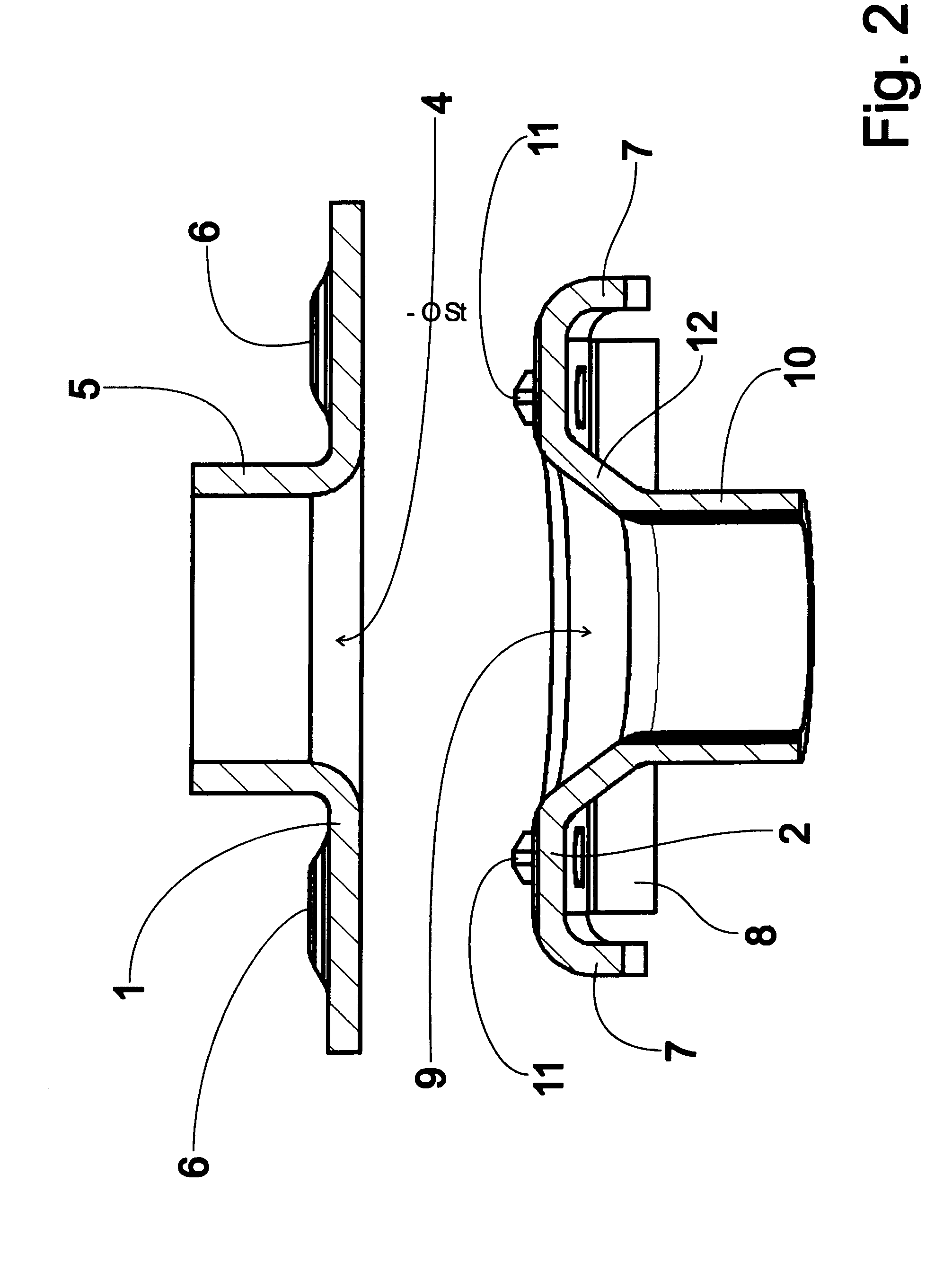

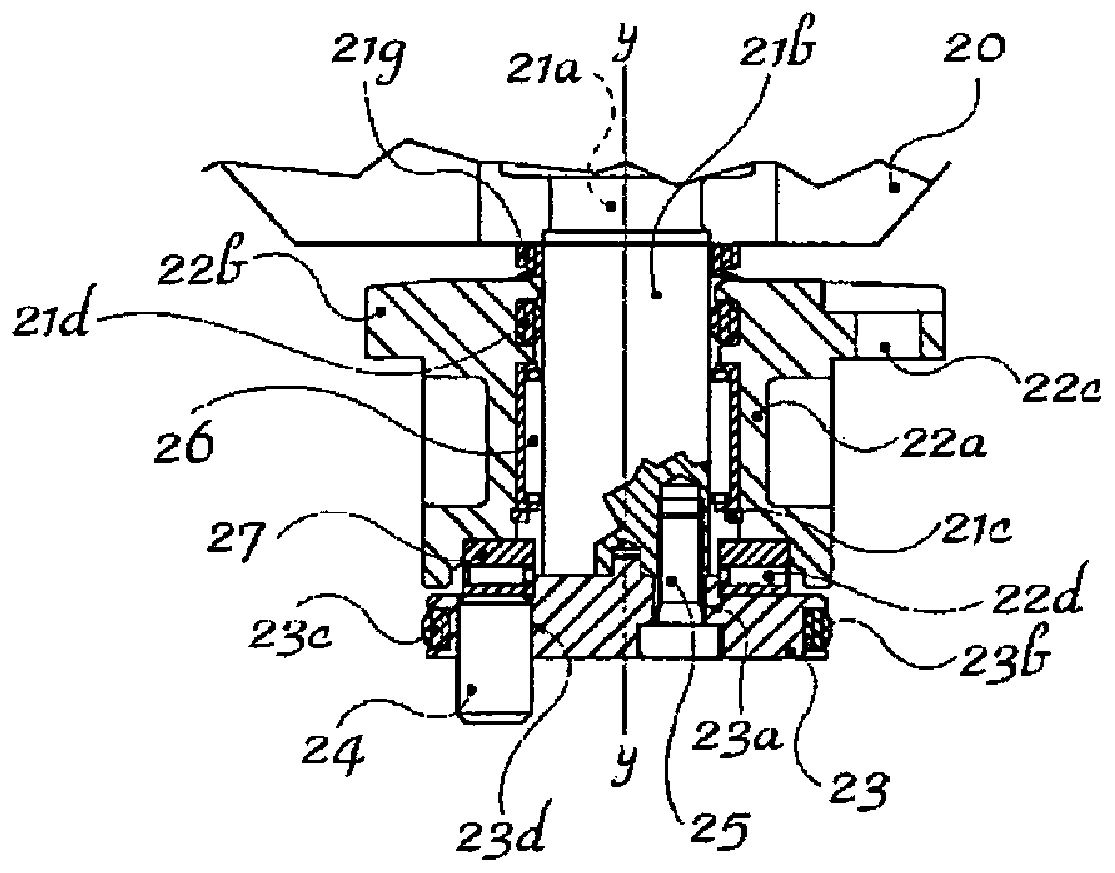

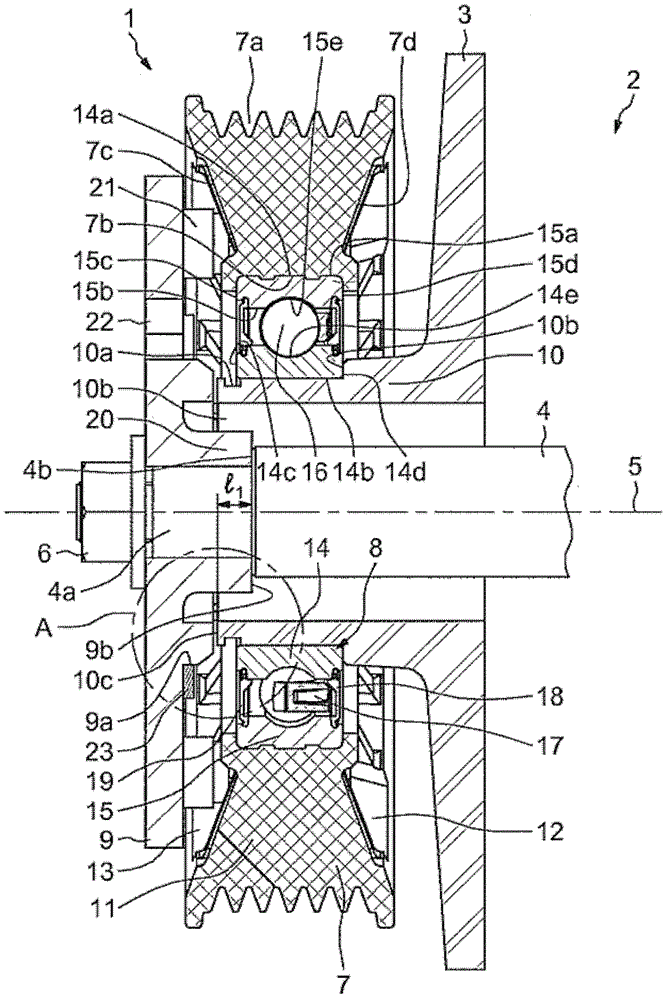

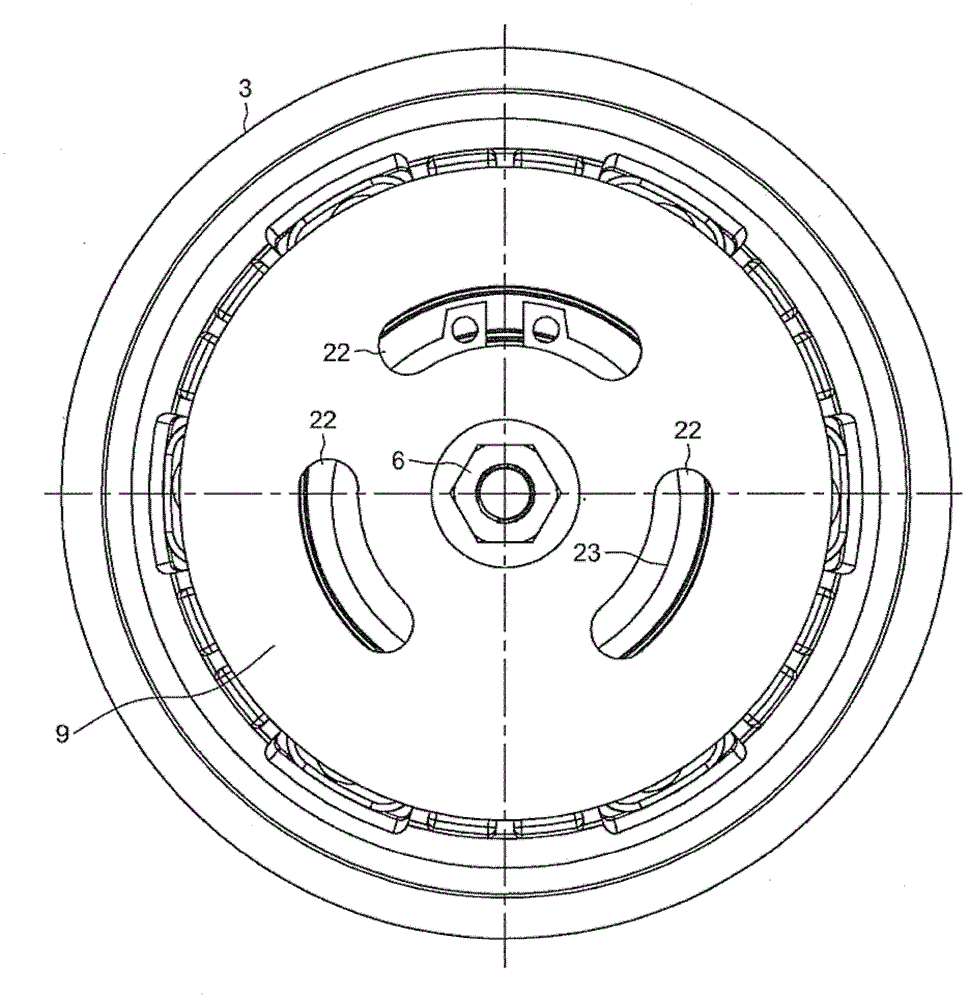

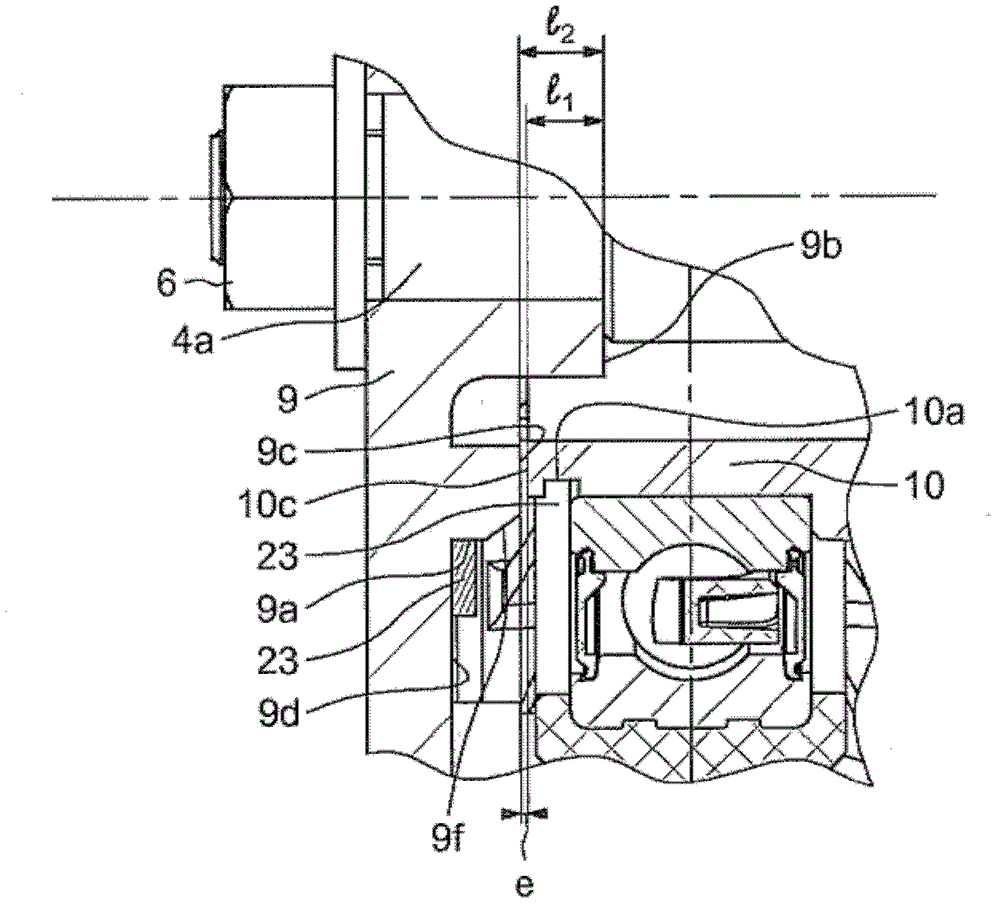

InactiveUS6593531B2Easily pre-assembledEasy accessCasings/cabinets/drawers detailsPipe units with cleaning aperturesFlangeStructural engineering

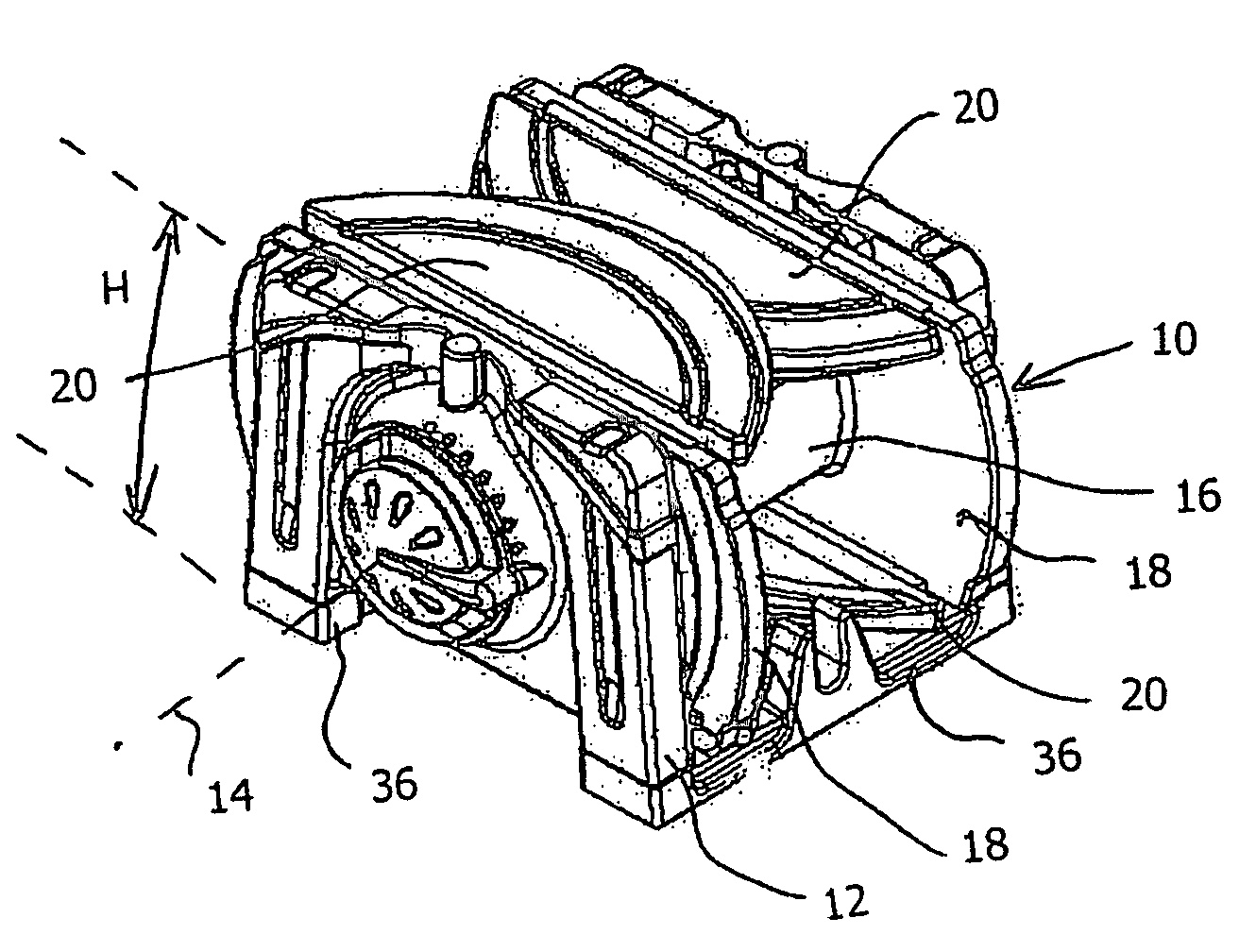

The present invention relates to a mounting housing for example or circular connectors. For a convenient pre-assembly of the mounting housing it includes an access opening which can be closed by a cover. The cover is hooked in a housing body of the mounting housing on one side and is secured at the housing body via a retaining nut, with the cover in conjunction with a seal arranged in the area of the access opening sealing same. In addition, a vibration protection is provided in that the cover includes a contoured area which in the screwed on condition is urged by the retaining nut against a corresponding area of the housing body. The mounting housing also includes a mounting flange which is formed at the housing body in such a manner that an installation and removal of the mounting housing at corresponding mounting surfaces is possible after the pre-assembly of the mounting housing.

Owner:CONTACT

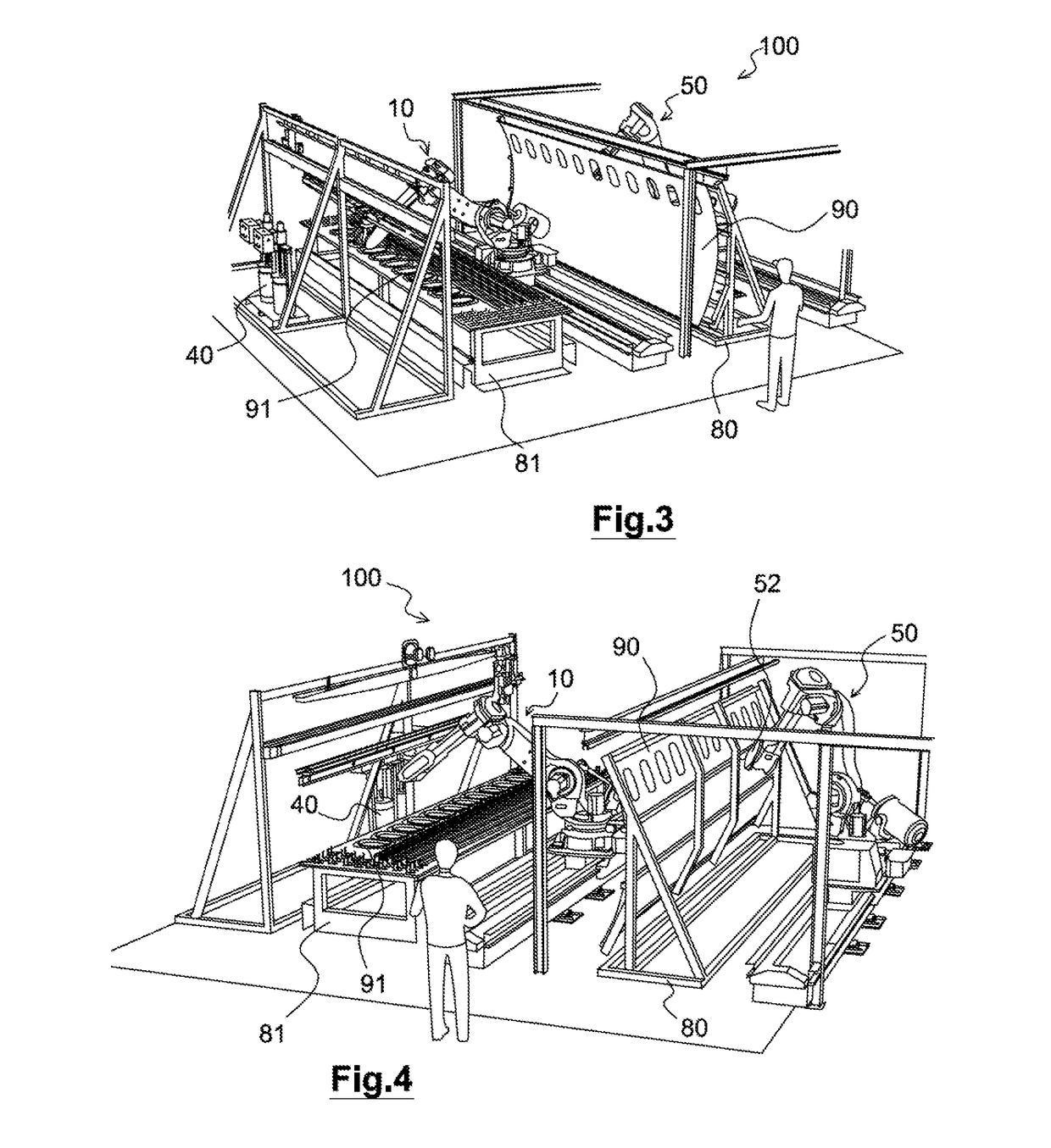

Method for Assembling Motor Vehicles

ActiveUS20140082918A1Simple and easy-to-assemble connectionImprove the level ofFlexible coversWrappersPre-RC assemblyMotorized vehicle

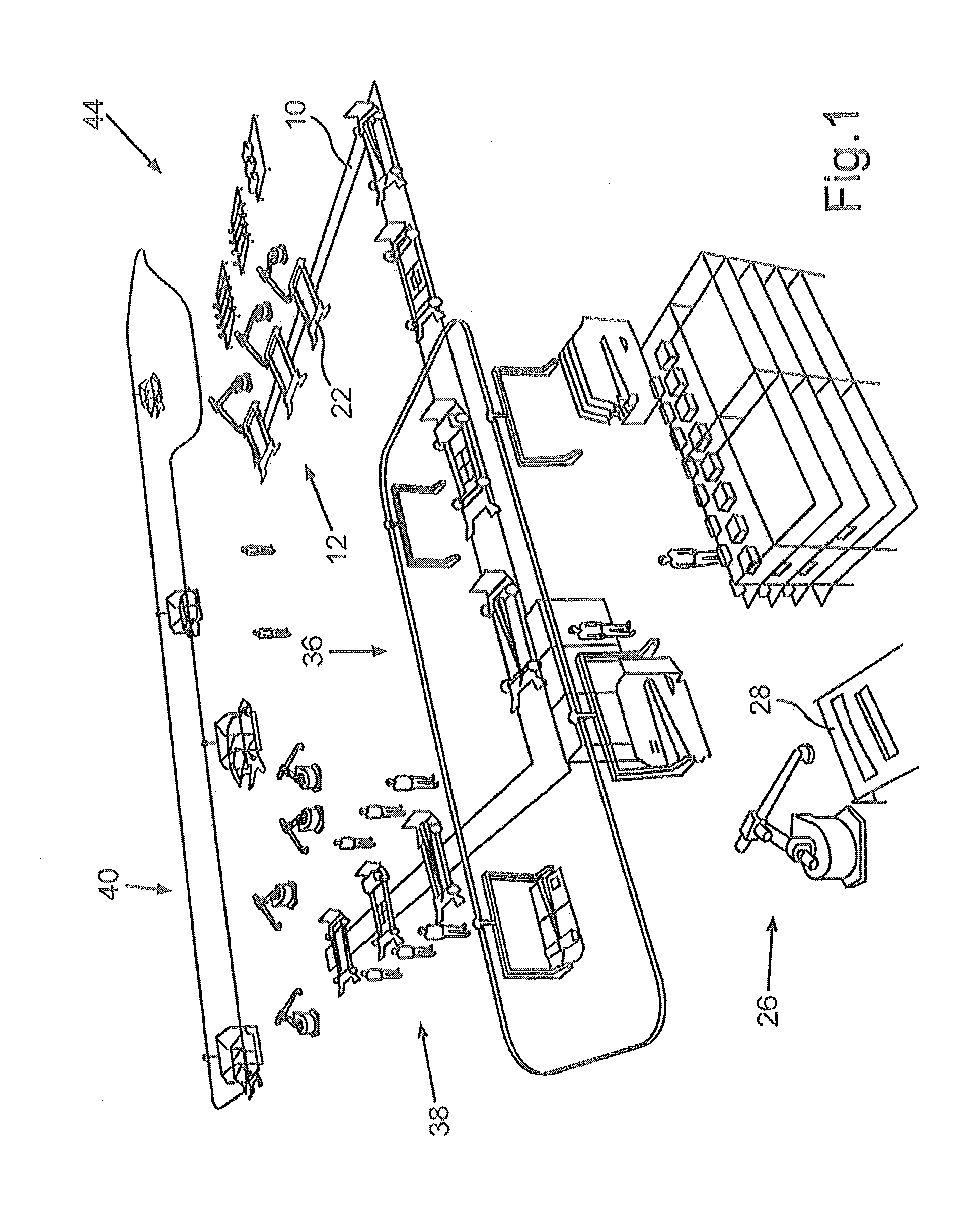

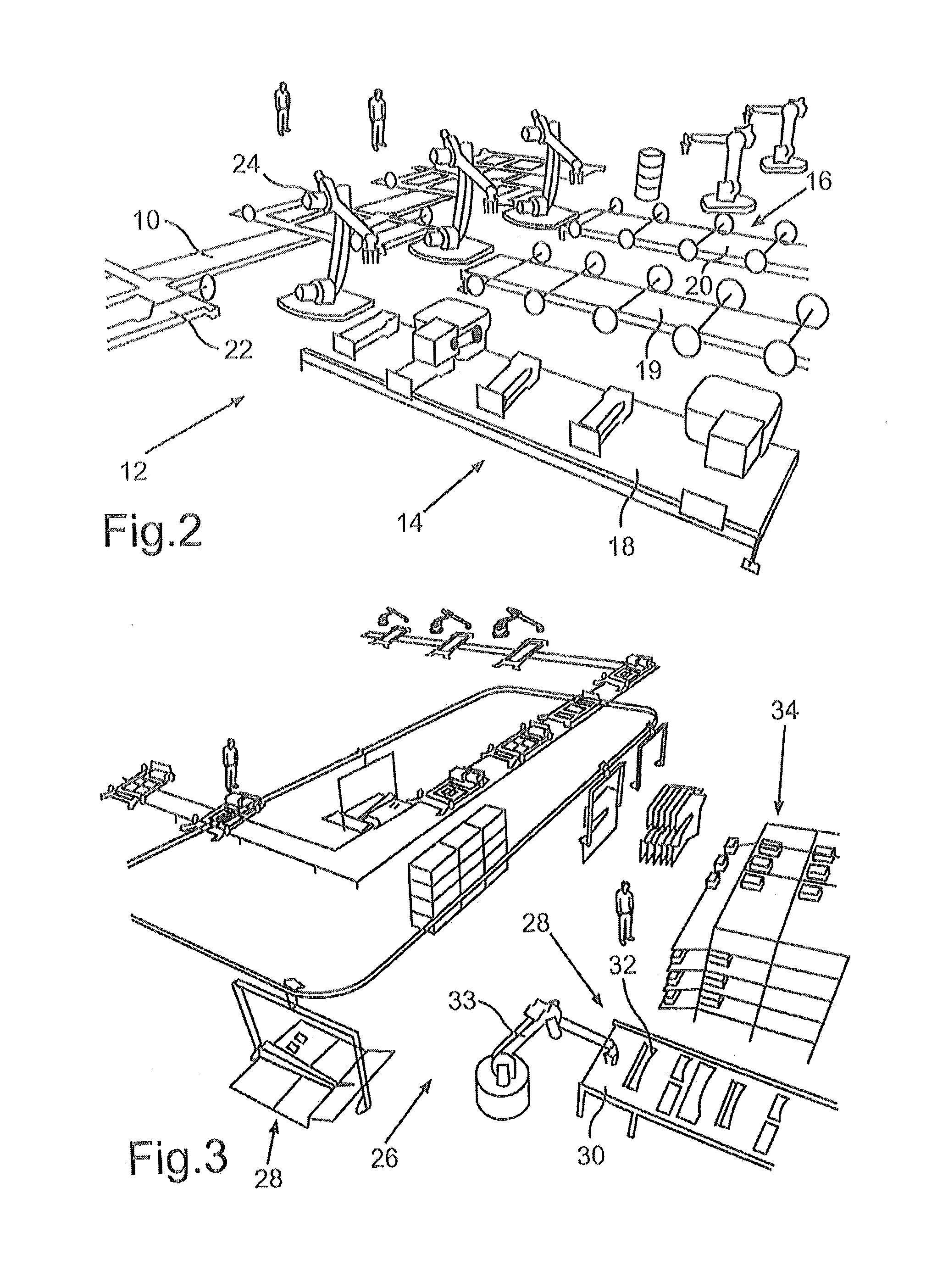

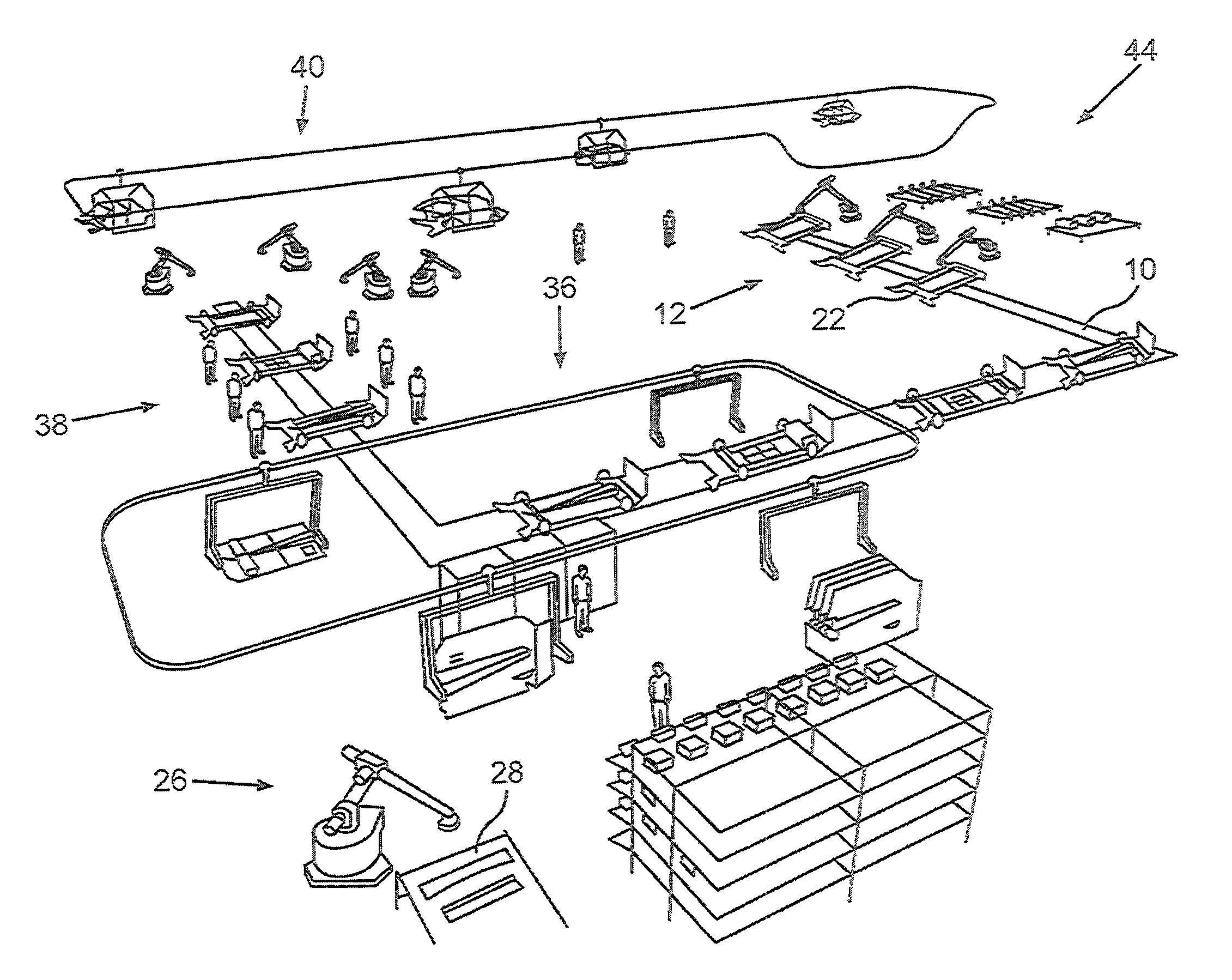

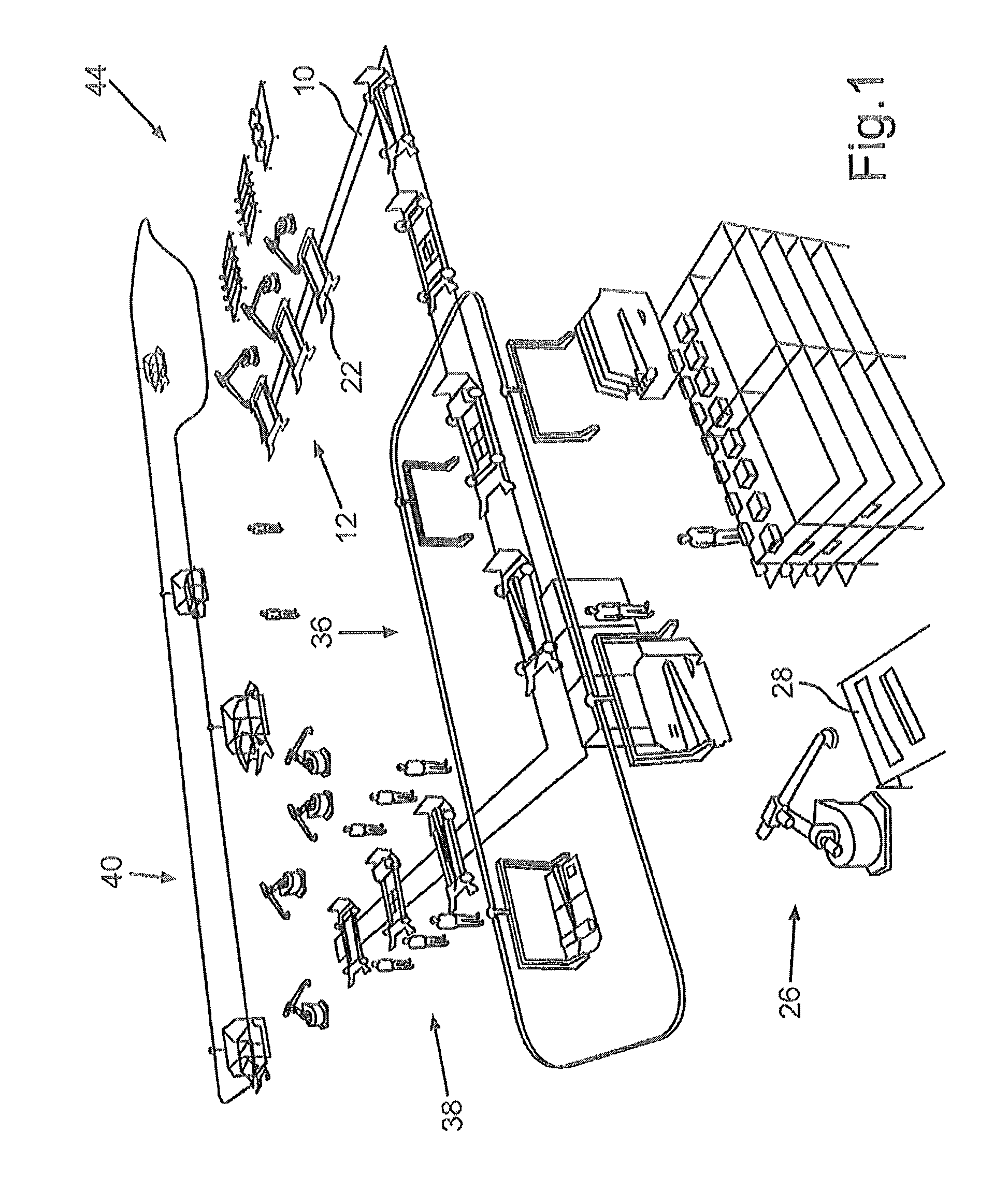

A method for assembling motor vehicles in which a drive train, chassis and floor module are pre-assembled and then connected to a shell of the motor vehicle. The floor module is pre-assembled in a first pre-assembly process and the drive train and the chassis are pre-assembled in a second pre-assembly process. The floor module, the drive train and the chassis are combined and then connected to the shell of the motor vehicle.

Owner:DAIMLER AG

Stackable hose reel with folding flanges

A hose-reel assembly includes a reel with foldable flange portions to allow compact shipping and storage in a pre-assembled state. The reel is rotatably mounted on a support frame which either stacks with similar frames or has selectively deployable legs to allow packaging of the assembly in a rectangular box of height less than the reel diameter.

Owner:HYDRO INDS TYNAT

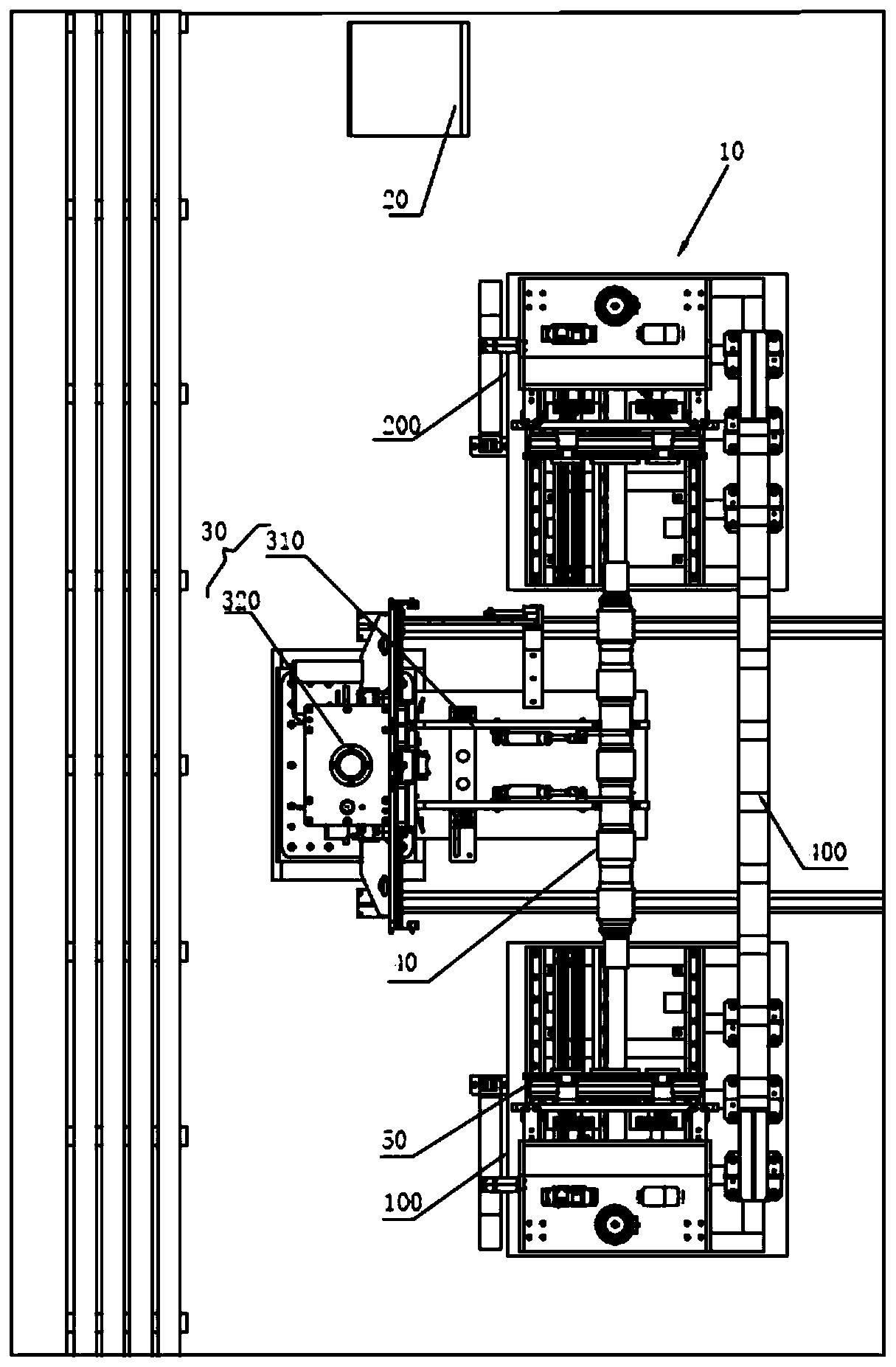

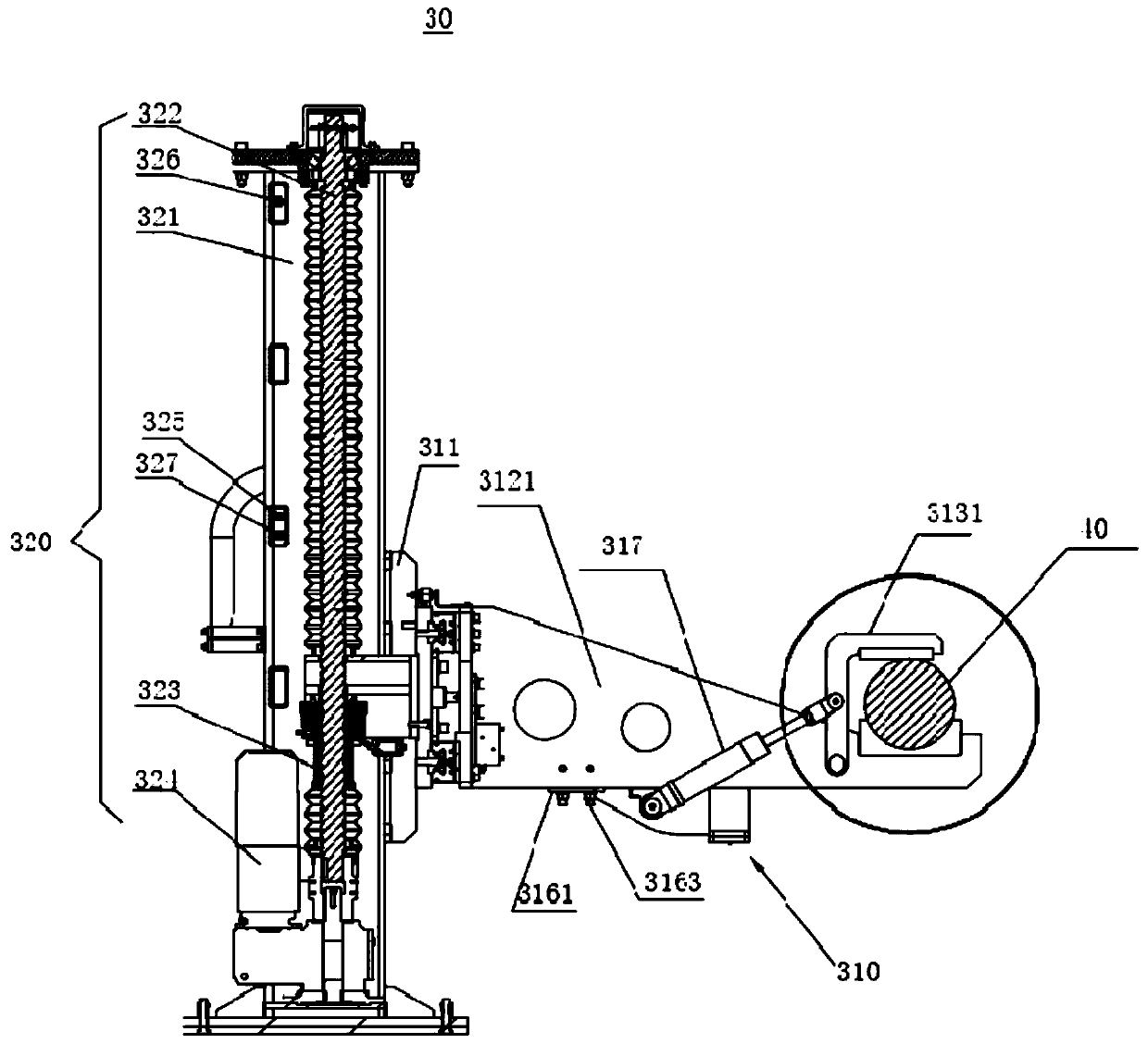

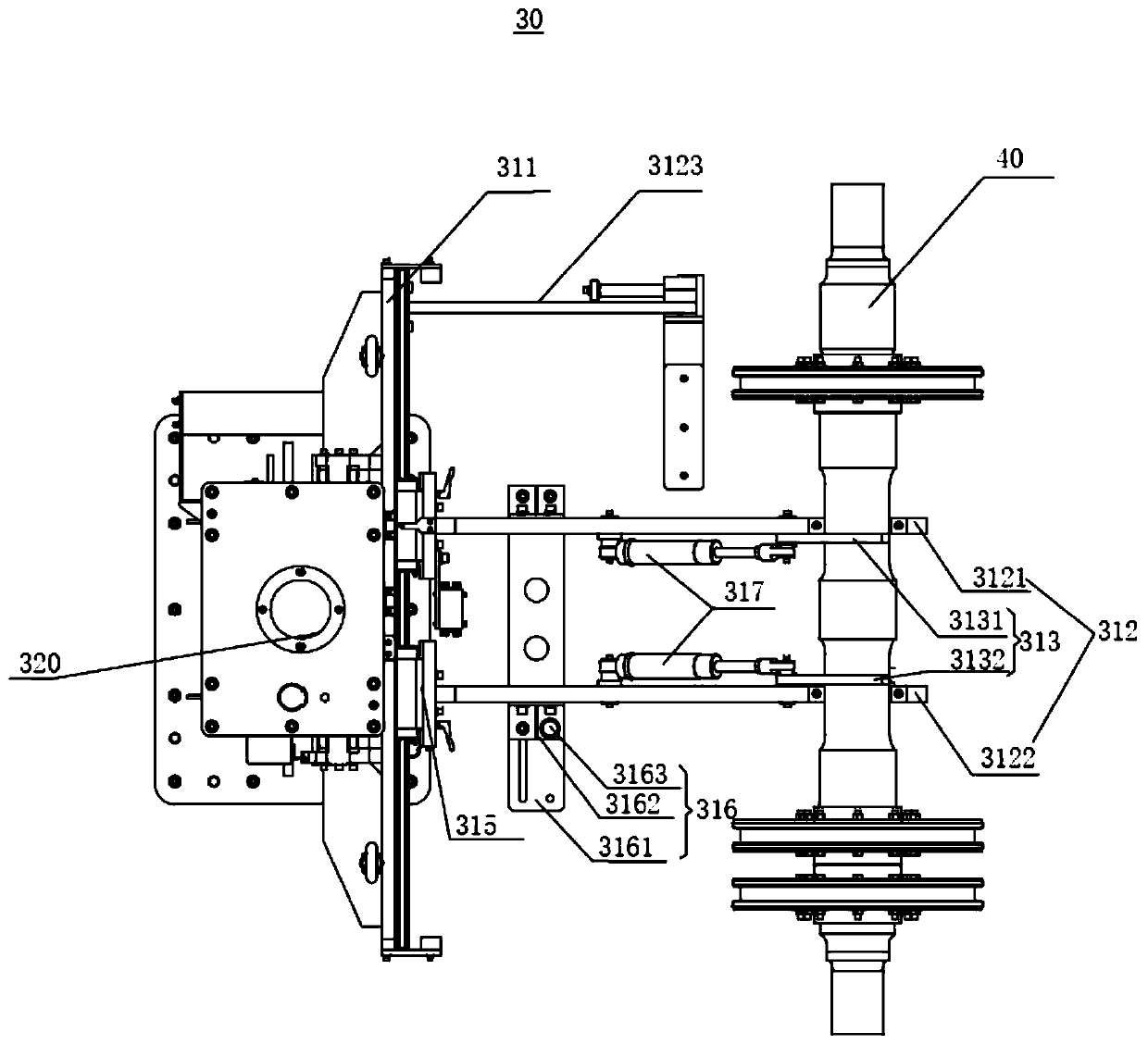

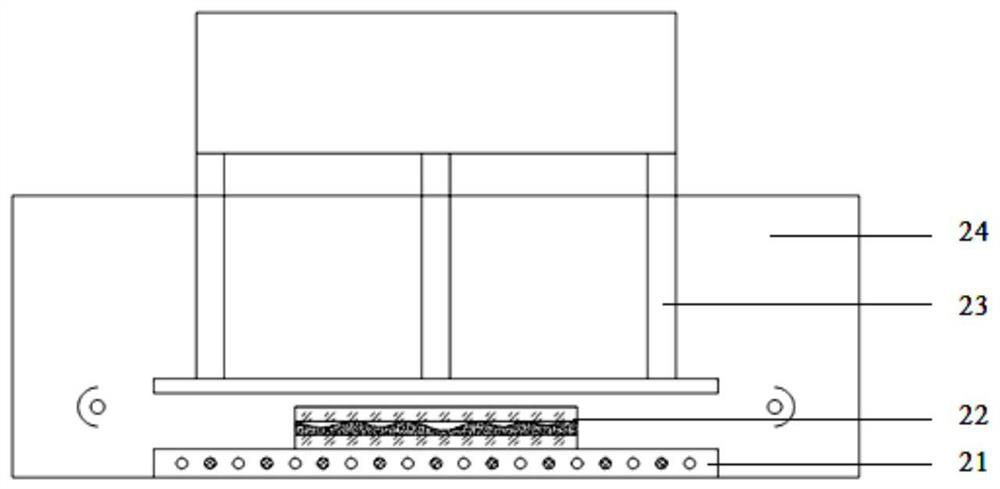

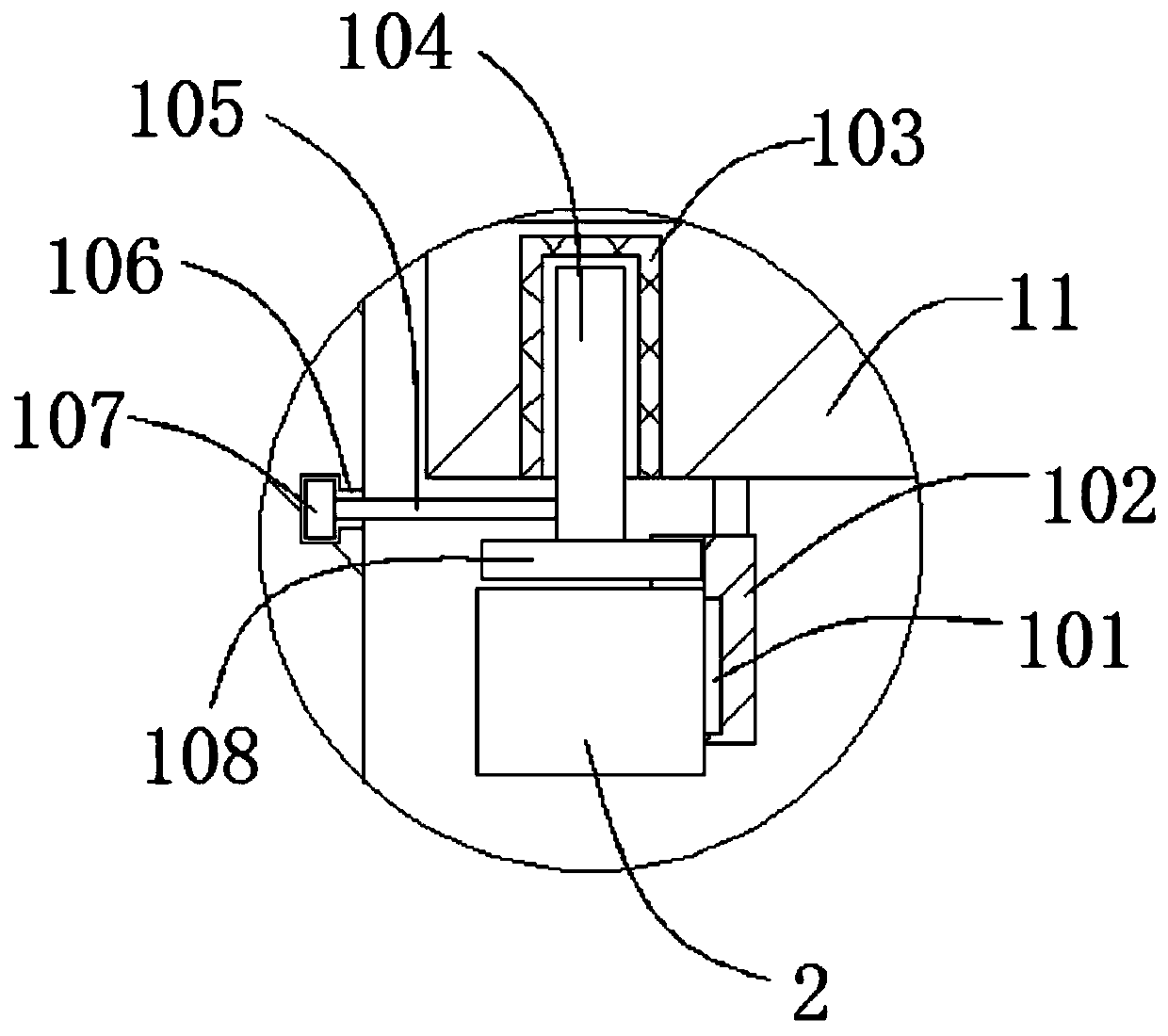

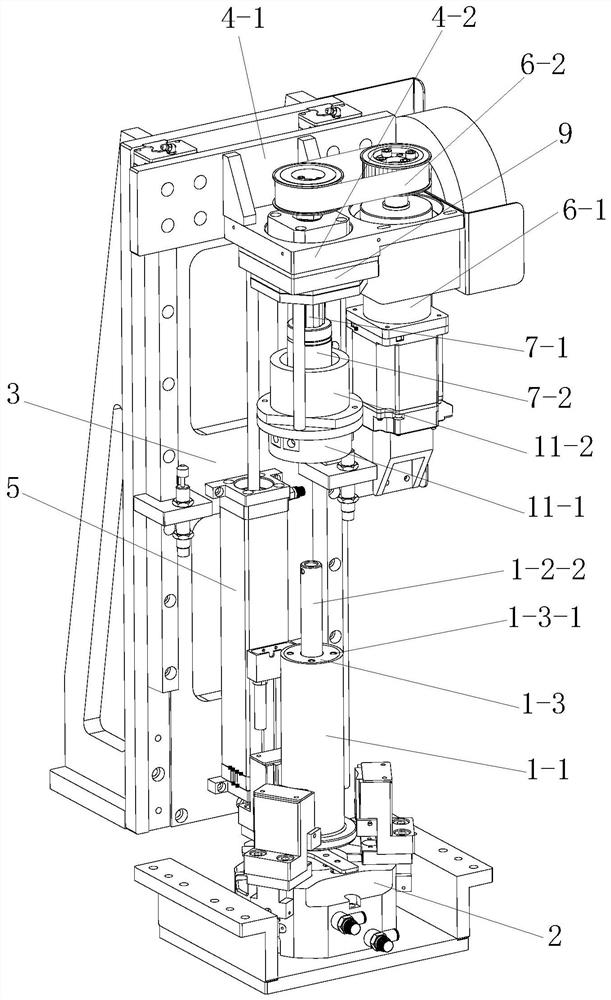

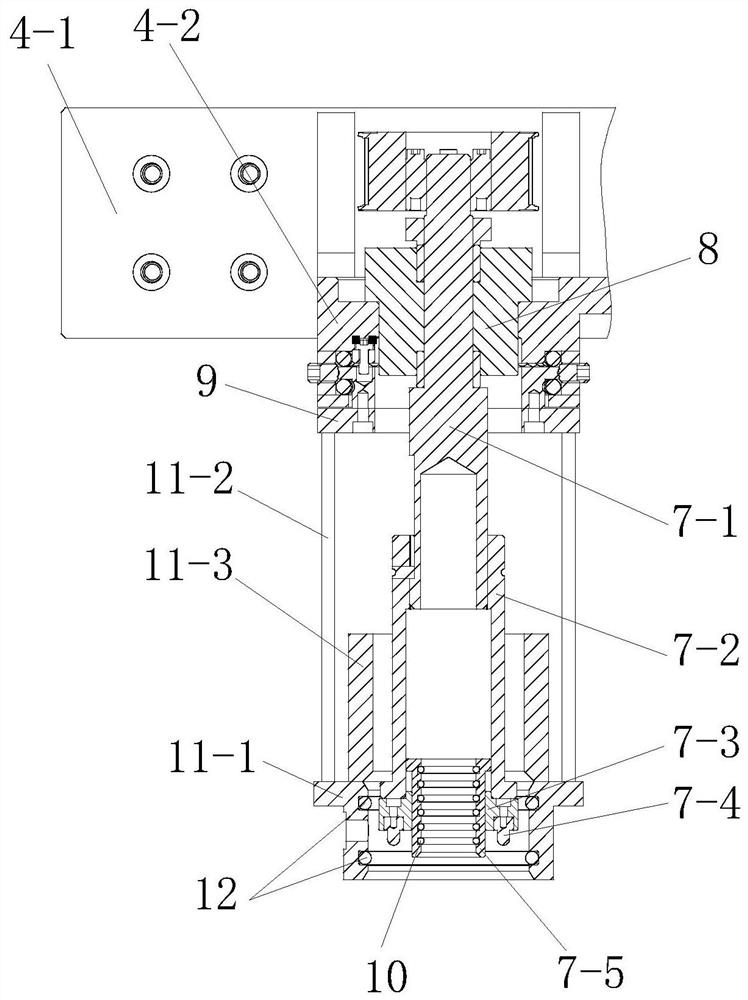

Wheel pair pre-assembling equipment and wheel pair pre-assembling system

PendingCN111002006AImprove applicabilityImprove practicalityMetal working apparatusBrakeControl system

The invention relates to wheel pair pre-assembling equipment and a wheel pair pre-assembling system. The wheel pair pre-assembling equipment comprises a pre-pressing device, a vehicle shaft receivingdevice and a master control system, wherein the pre-pressing device is used for placing a to-be-assembled wheel or brake disc, the vehicle shaft receiving device is used for placing a to-be-assembledvehicle shaft, and the master control system is in communication connection with the pre-pressing device and the vehicle shaft receiving device and is used for controlling the pre-pressing device and / or the vehicle shaft receiving device to work according to the information of the wheel or the brake disc and the vehicle shaft so as to adjust at least one of the position of the wheel or the brake disc and the position of the vehicle shaft, so that the centering of the wheel or the brake disc and the center of the vehicle shaft is achieved. The wheel pair pre-assembly equipment provided by the invention can be suitable for pre-assembly of vehicle shafts and wheels or brake discs with different types and sizes.

Owner:BEIJING SHEENLINE GRP CO LTD

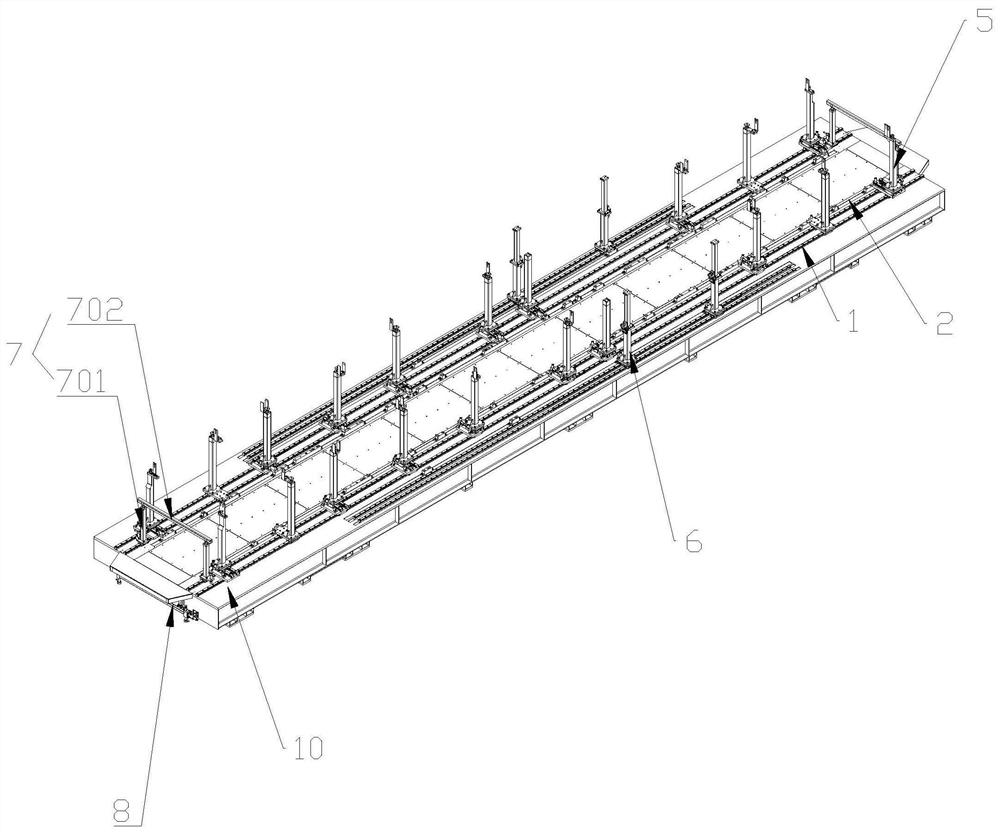

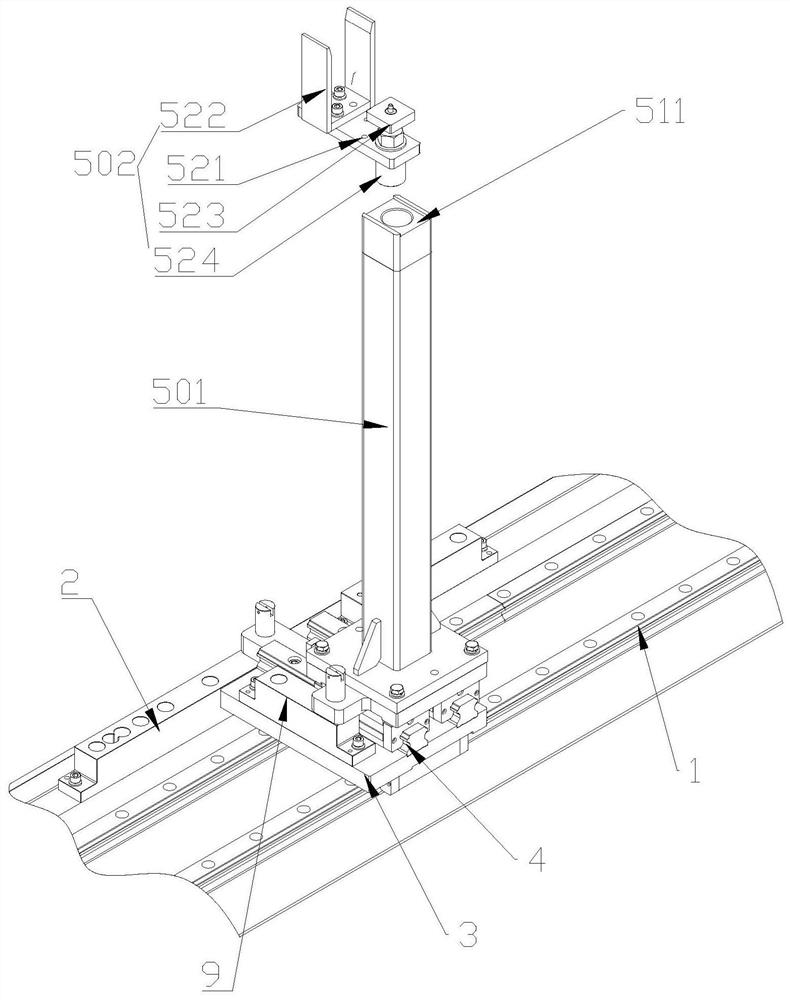

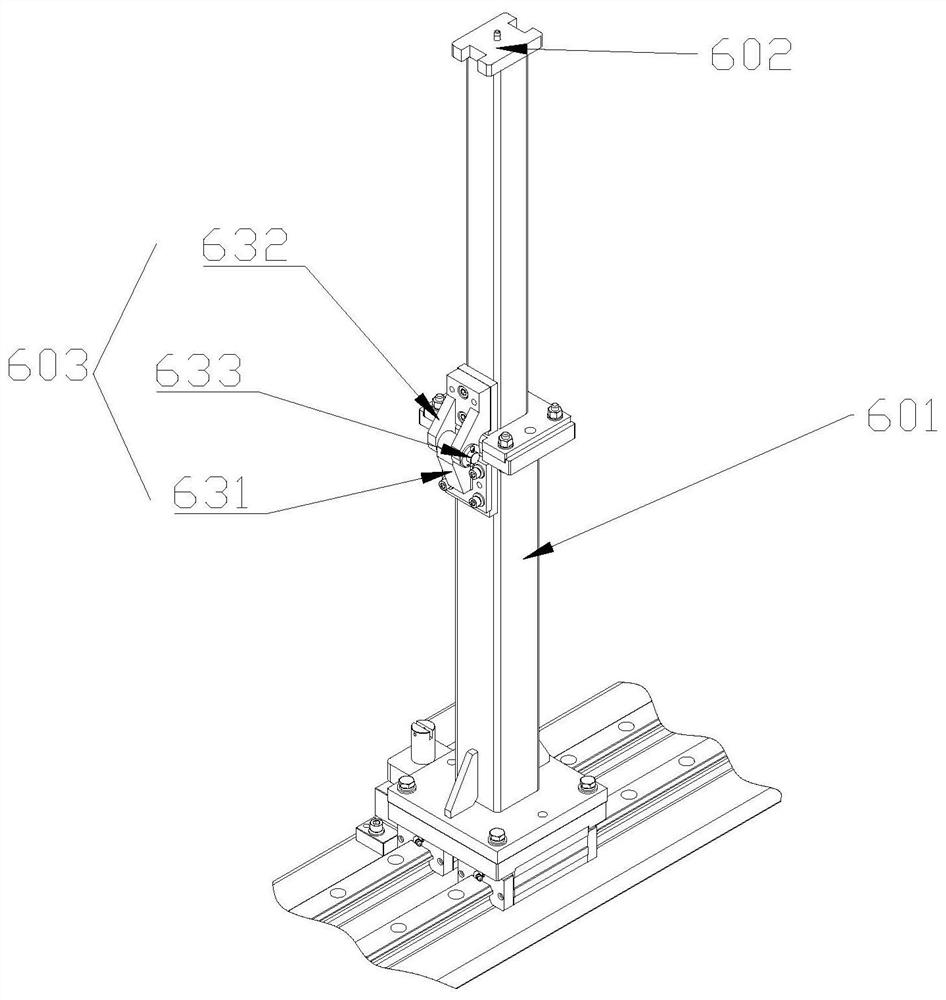

Electric multiple unit chassis equipment pre-assembly tool and method

PendingCN111975706AQuick conversionReduce in quantityWork holdersMetal-working hand toolsControl engineeringPre-RC assembly

The invention discloses an electric multiple unit chassis equipment pre-assembly tool. The electric multiple unit chassis equipment pre-assembly tool comprises a rigid platform, a plurality of longitudinal linear sliding rails parallelly arranged on the rigid platform, a first positioning mechanism and a second positioning mechanism, wherein the first positioning mechanism and the second positioning mechanism move along the longitudinal linear sliding rails. A plurality of longitudinal positioning blocks are arranged on one sides of the longitudinal linear sliding rails, and third positioningmechanisms are arranged at the two ends of the longitudinal linear sliding rails. Longitudinal connecting plates moving along the longitudinal linear sliding rails are arranged between the first positioning mechanism and the longitudinal linear sliding rails, transverse linear sliding rails are arranged on the longitudinal connecting plates, and the first positioning mechanism moves along the transverse linear sliding rails. A fine adjustment mechanism is further arranged at one end of the rigid platform, and the problems that the floor space of the chassis equipment pre-assembly tool is large, vehicle model conversion attachments are more, the workload is large and the working efficiency is low are solved. The invention further discloses an electric multiple unit chassis equipment pre-assembly method. A modular assembly method is adopted, and the electric multiple unit chassis equipment pre-assembly method has the characteristics of fast assembly and scattered processes.

Owner:BOMBARDIER SIFANG QINGDAO TRANSPORTATION

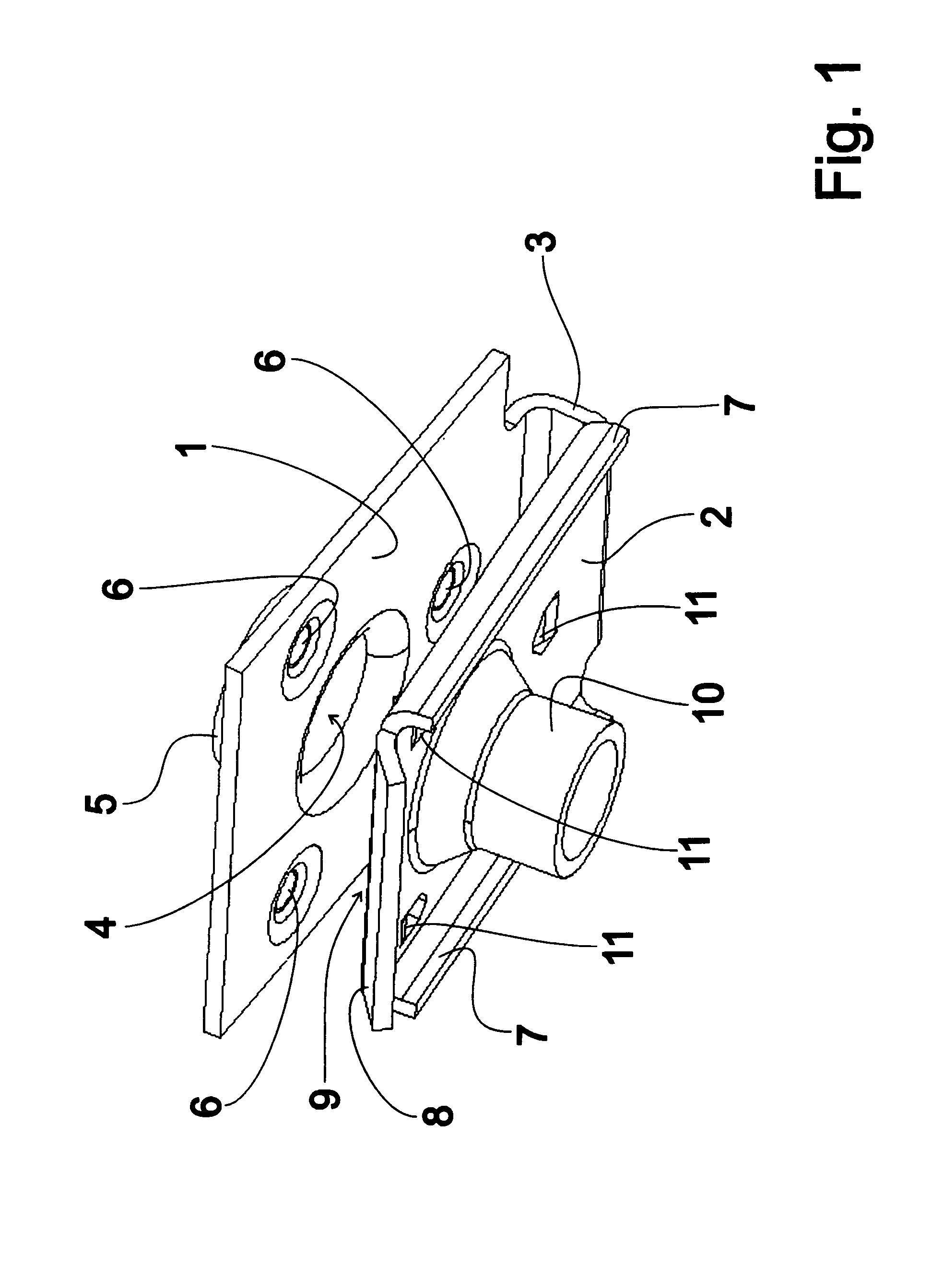

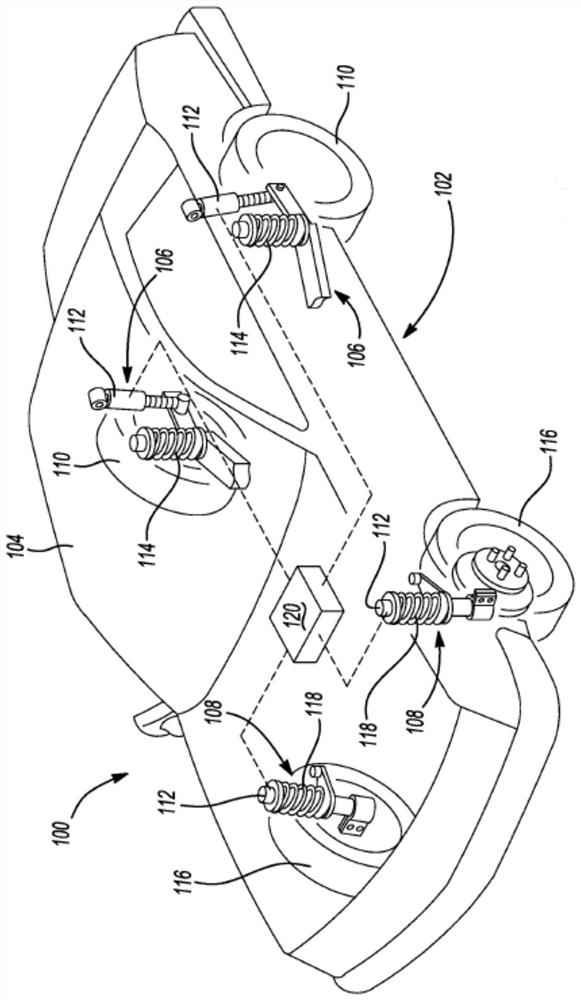

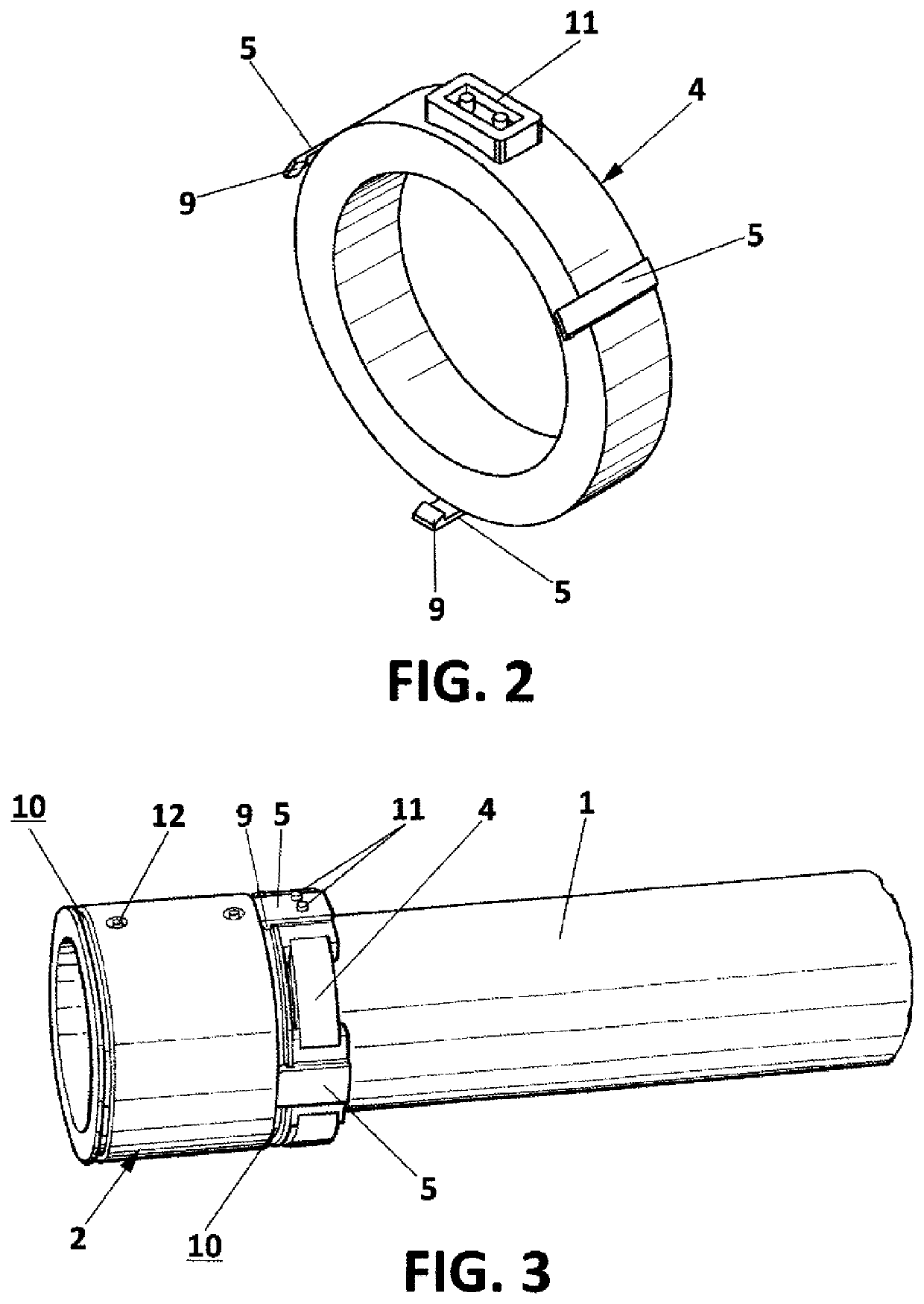

Fastening Clamp

ActiveUS20100000058A1Reduce the overall heightSnap fastenersLocking fastenersEngineeringScrew thread

A fastening clamp for connecting a carrier part (13) and an add-on part (14) has a plug-through leg (1), with a plug-through sleeve (5), and a threaded leg (2), which is connected to a thread unit (10). The plug-through sleeve (5) extends away from the threaded leg (2) and has an effective overall height which is greater than the thickness of an add-on part (14). Engagement elements (11) are present on that side of the thread leg (2) which is directed towards the plug-through leg (1). In a pre-assembly arrangement, the legs (1, 2) are spaced apart by a distance which is large enough to allow a carrier part (13) to be positioned between the legs (1, 2) such that it is essentially free of engagement with the engagement elements (11), in which case, once a screw has been screwed into an end position, the engagement elements (11) thus engage with the carrier part (13) such that the fastening clamp is connected in a non-displaceable manner to the carrier part (13). This achieves a certain degree of positioning freedom on the carrier part (13) and, for tolerance-compensating purposes, movement of the add-on part (14).

Owner:A RAYMOND & CO

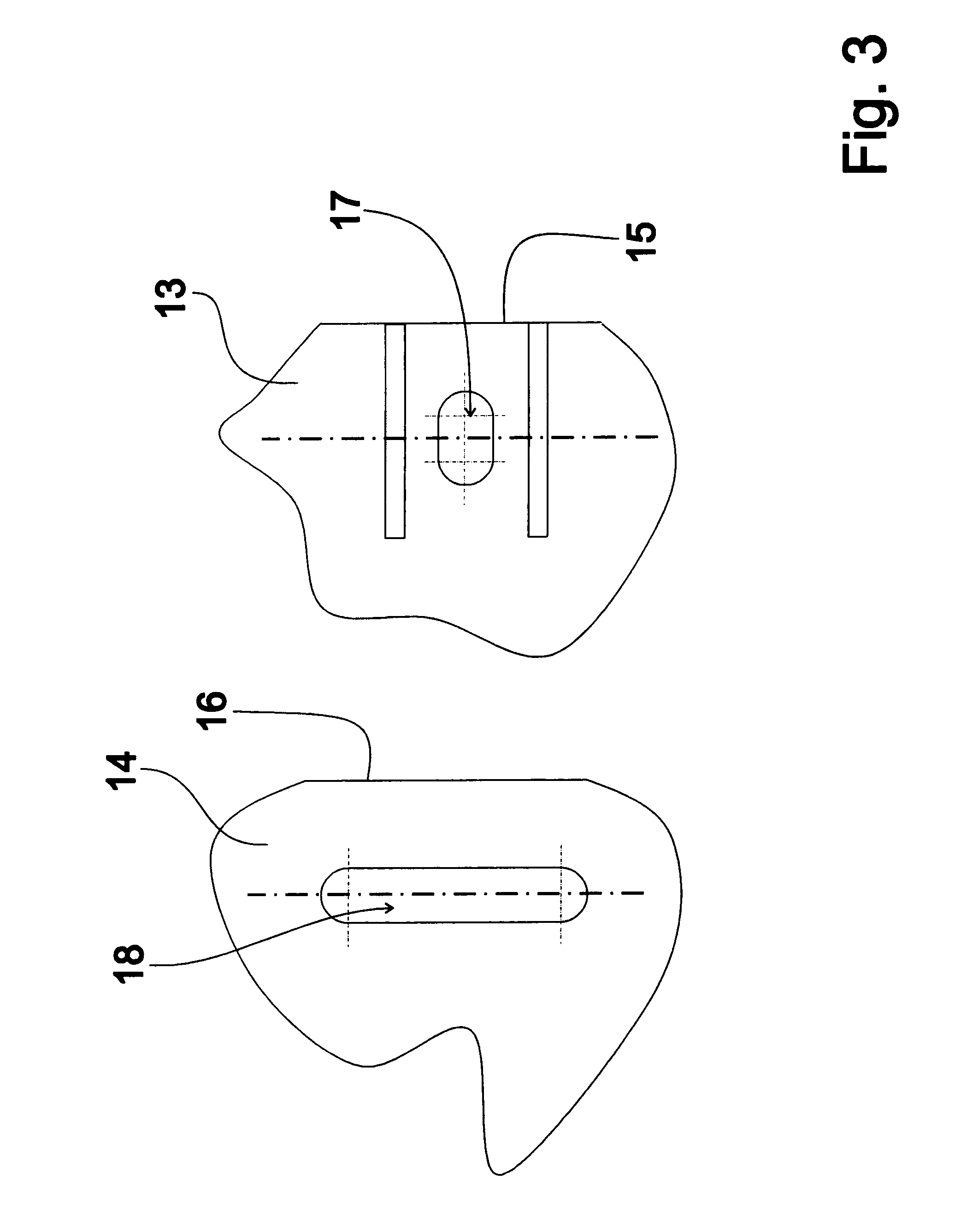

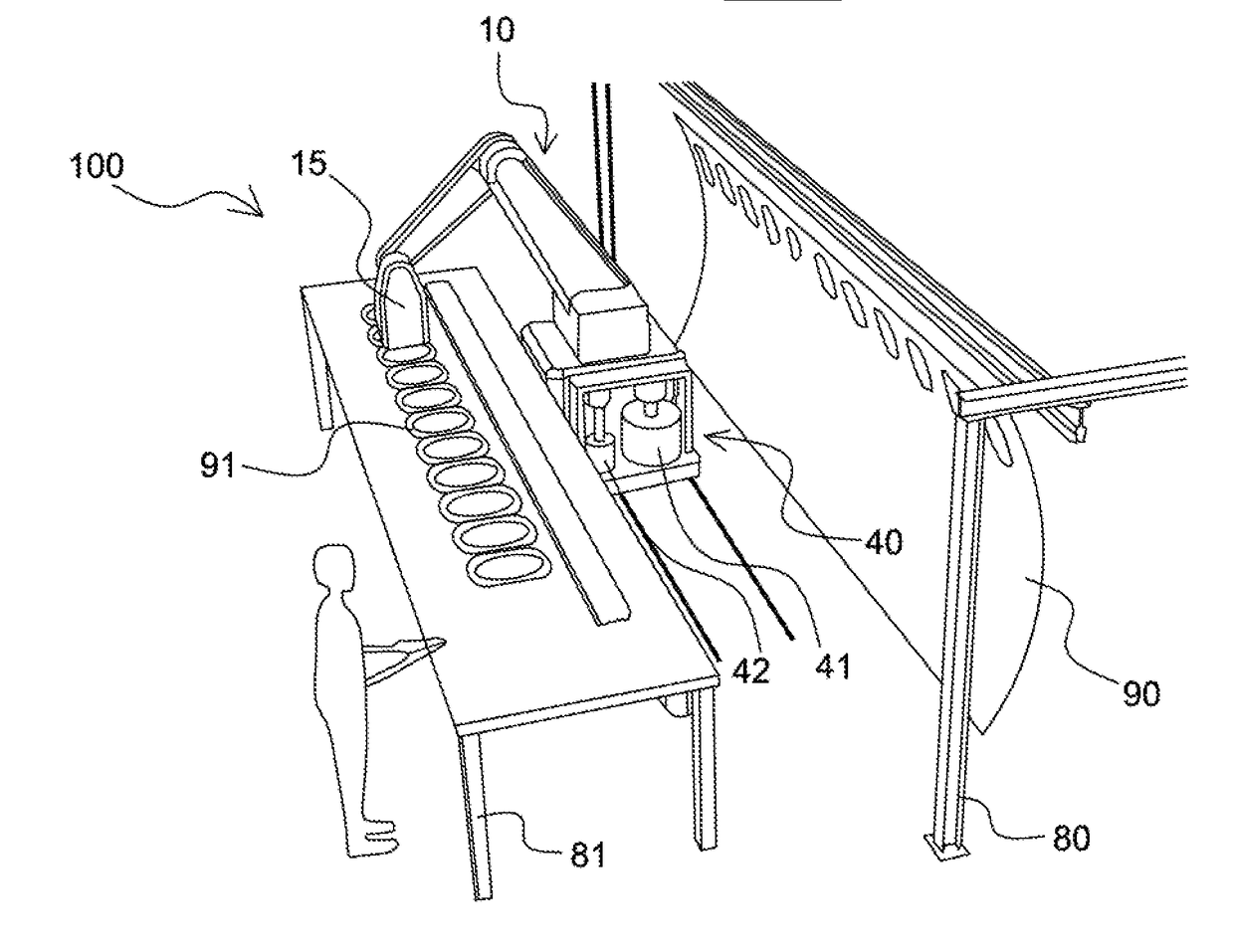

Device for pre-assembling parts, with the interposition of mastic, and pre-assembly method

InactiveUS20170120507A1Improve productivityRapid depositionProgramme-controlled manipulatorAircraft assemblyPre-RC assemblyMechanical engineering

The invention relates to a method for pre-assembling parts with the insertion of mastic, including surface preparation carried out by spraying cold plasma produced by a plasma gun carried by a preparation robot, onto the surfaces of the parts to be brought into contact, and deposition of fresh mastic on the prepared surfaces of at least one part, carried out using the preparation robot.

Owner:STELIA AEROSPACE

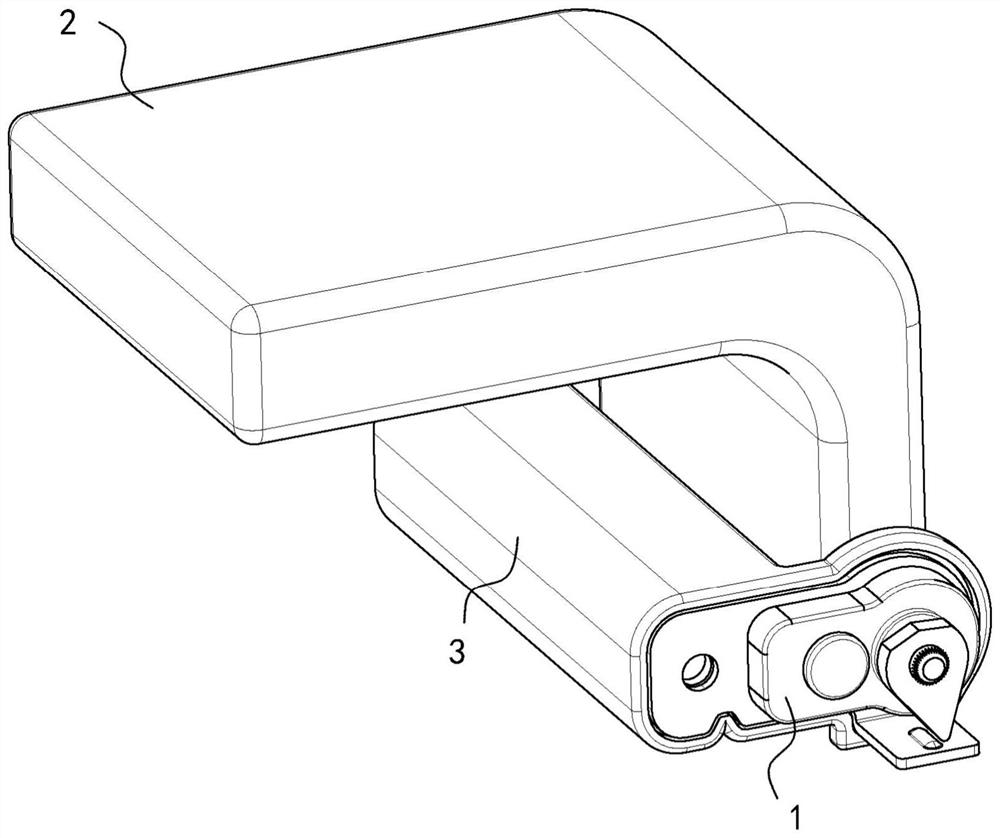

Pre-assembled hinge module and hinge system

The invention discloses a pre-assembly type hinge module and a hinge system, and the pre-assembly type hinge module comprises a mounting plate which is fixed to one of a first part and a second part; a shaft defining a pivot axis and fixed to the other of the first member and the second member; at least one torque element fixed to the mounting plate and frictionally engaged with the shaft; the cam is fixed on the shaft and can rotate together with the shaft; the limiting piece is fixed to the mounting plate or integrally formed with the mounting plate, when the cam rotates to the position in contact with the limiting piece, the limiting piece can stop the cam and provide stop resistance for further rotation of the cam, and under the action of overcoming the stop resistance, the cam can rotate to cross the limiting piece. The hinge module can improve the stability of a product at a specific stop position.

Owner:SOUTHCO MFG & TECH SHENZHEN CO LTD

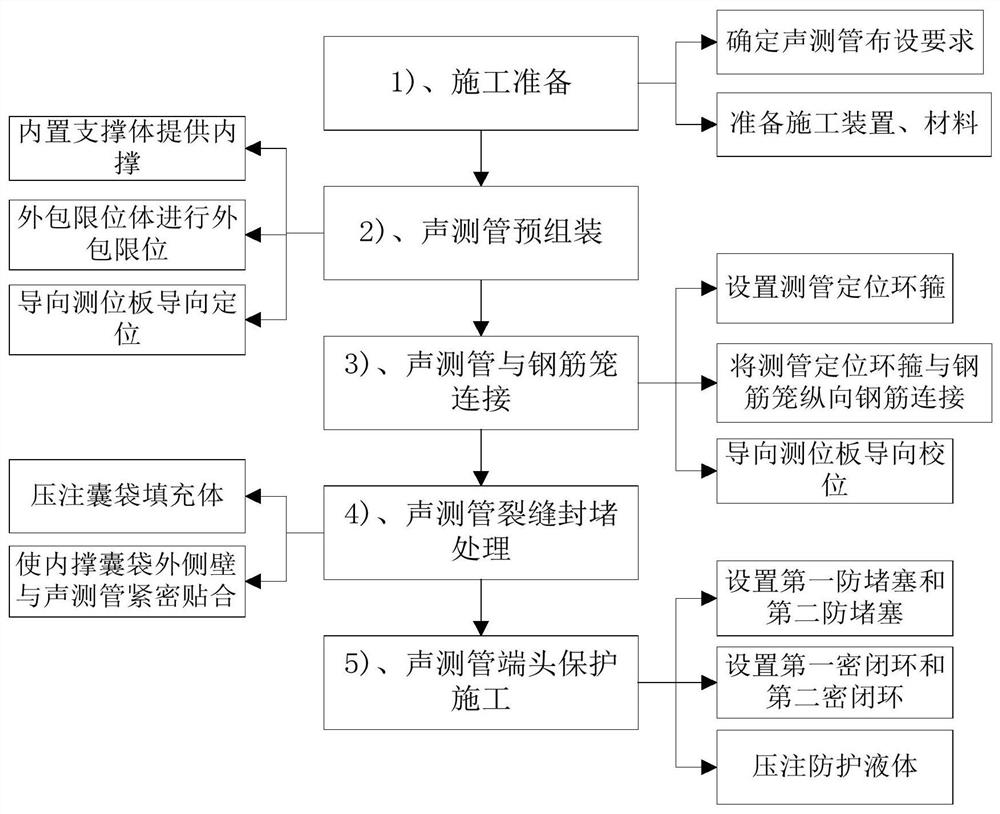

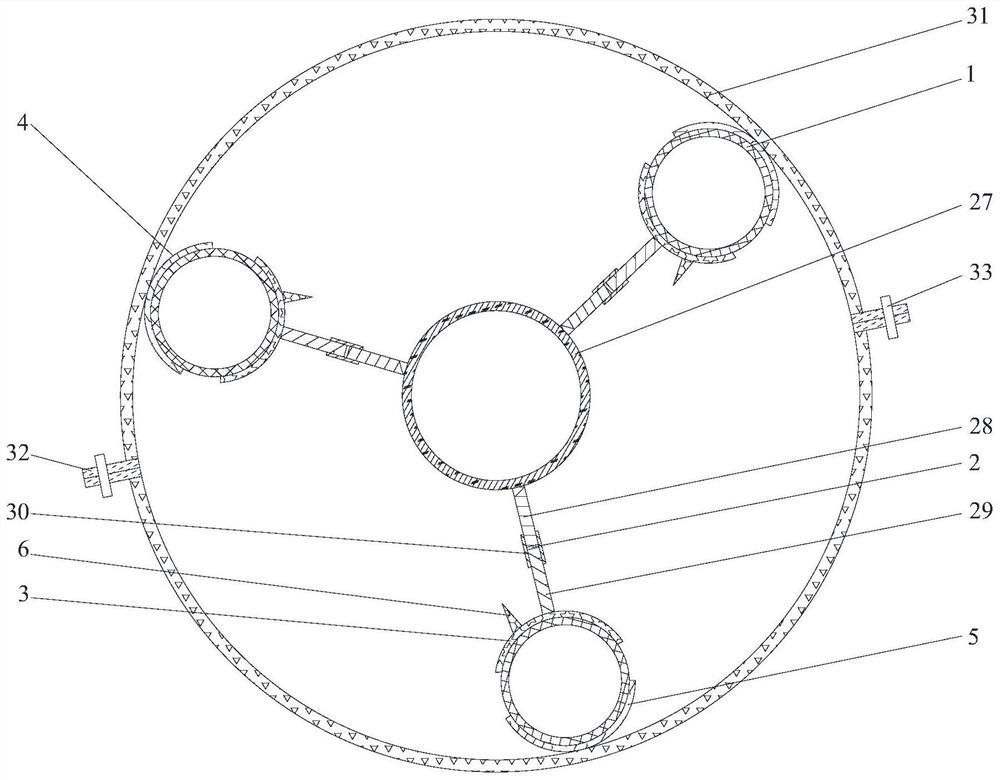

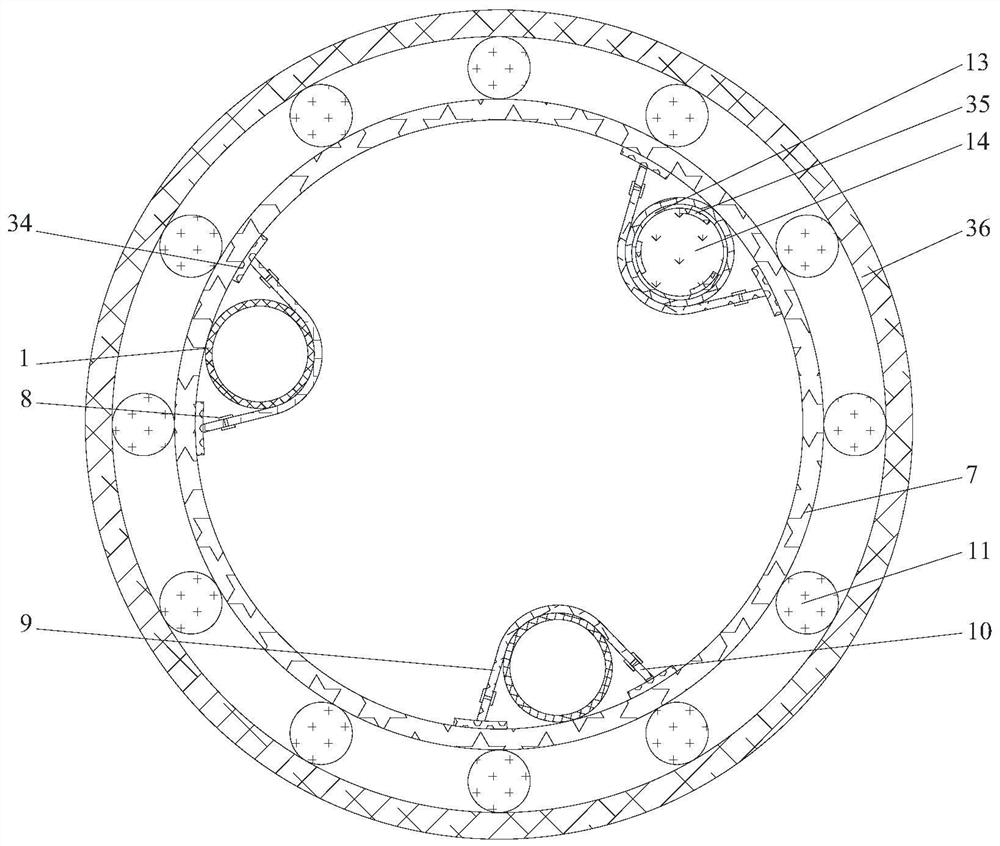

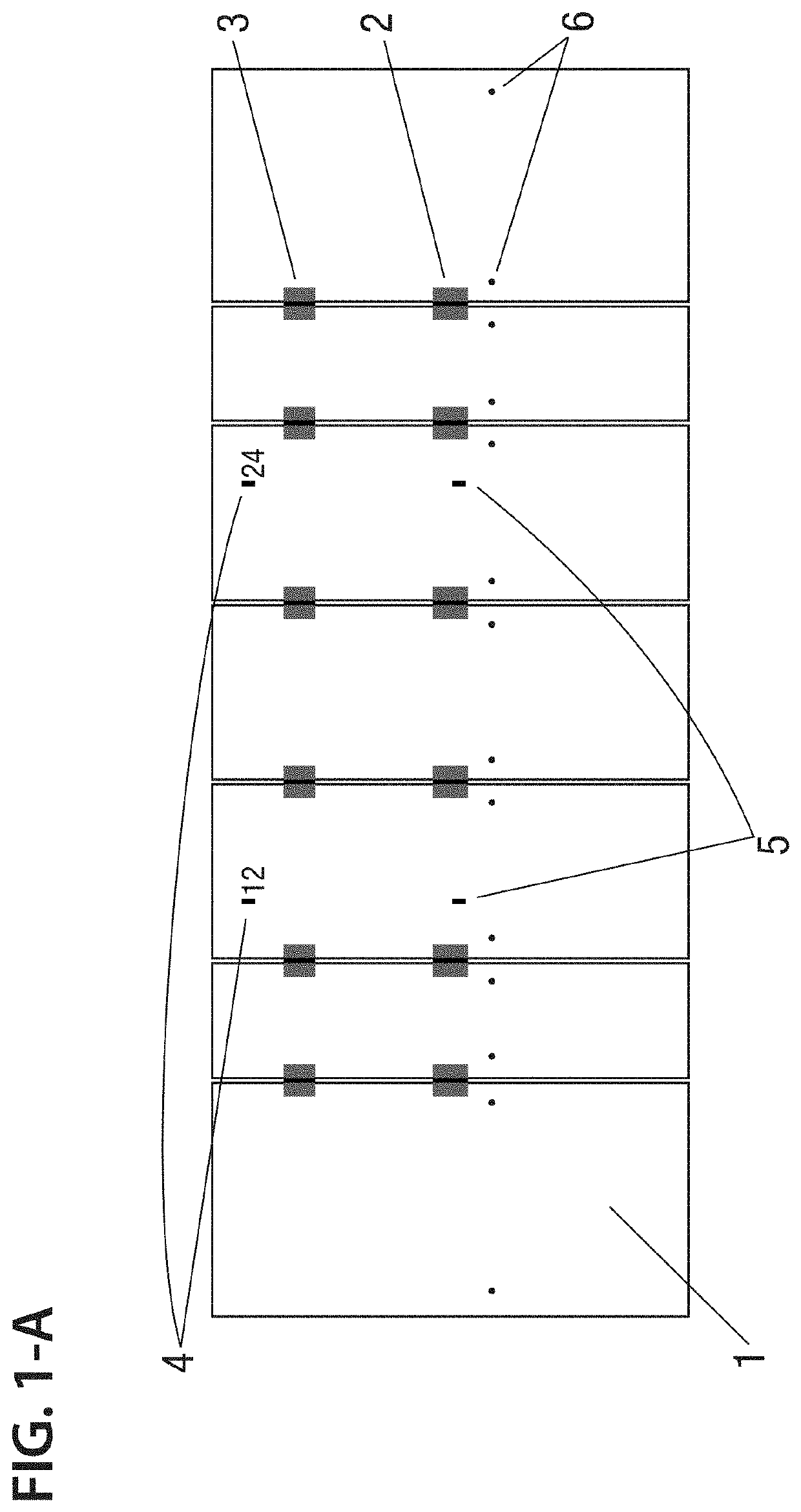

The construction method of the installation structure of the foundation pile acoustic measuring tube

ActiveCN110878564BRealize multi-angle controlAvoid damageFoundation testingSound detectionClassical mechanics

The invention relates to a construction method for a foundation pile acoustic tube installation structure, which comprises the following steps: 1) construction preparation; 2) pre-assembly of the acoustic tube; 3) connection of the acoustic tube and a reinforcement cage; 4) treatment of cracks in the acoustic tube ; 5) Protective construction of acoustic tube ends. The beneficial effects of the present invention are as follows: the present invention can limit the plane position of the acoustic measuring tube with the help of the built-in support body and the outer limiting body, and can measure and control the axial position of the acoustic measuring tube with the help of the guide positioning plate, so as to realize the sound detection and control. The multi-angle control of the spatial position of the measuring tube; the present invention is provided with a connecting splint, a tie positioning rib and an outsourcing positioning rib between the acoustic measuring tube and the measuring tube positioning hoop, and can be connected and fastened by the positioning rib bolts, reducing the The difficulty of connection construction of the acoustic measuring tube and the damage to the acoustic measuring tube caused by the connection construction are eliminated; the present invention arranges an inner support bladder in the cracked section of the acoustic measuring tube, and injects the bladder filling body in the inner support bladder, so that the acoustic measurement can be realized. Fast closed filling of the tube lumen, preventing concrete from entering the acoustic tube.

Owner:安徽建工路港建设集团有限公司

Pre-Assembled Ventilated Shingle Set

PendingUS20200248459A1Great panel strengthQuick installationRoof covering using tiles/slatesCovering/liningsClassical mechanicsStructural engineering

An assembly, and method for constructing the assembly, that provides a much faster and more precise shingle installation with required keyway spacing and offsets, and with built-in ventilation that improves the performance of the shingles and protects the wall assembly. Also providing a pleasing distribution of shingle widths with no apparent patterns.

Owner:LINK VISUAL COMM LLC

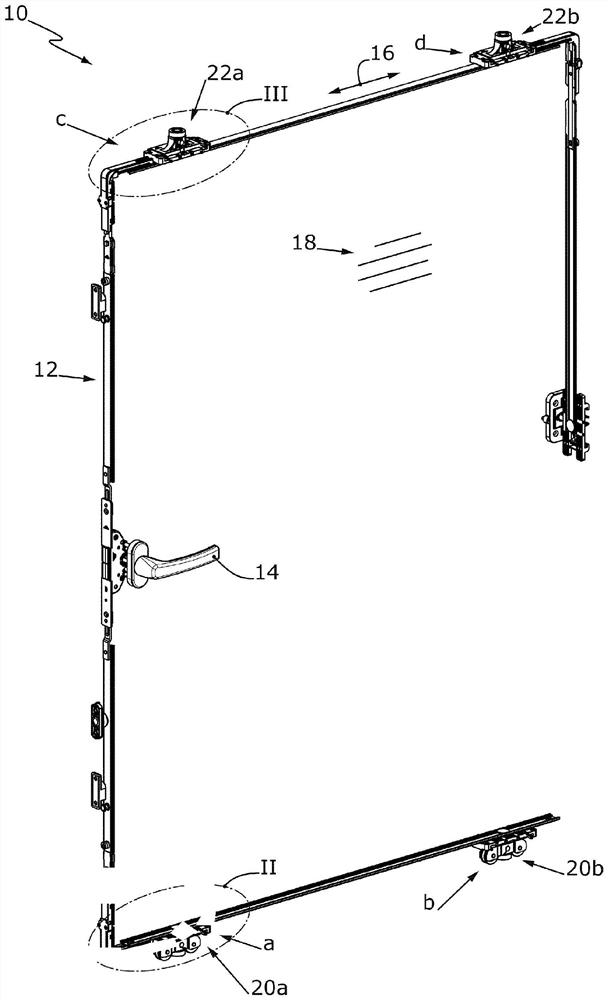

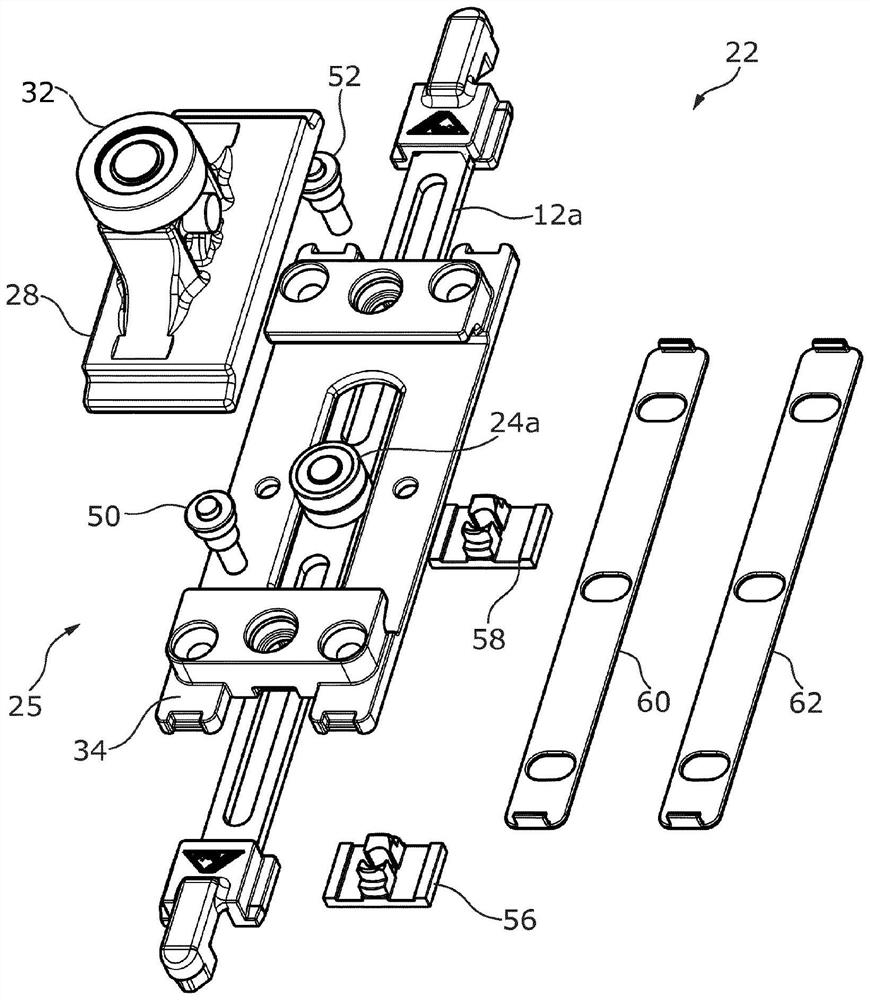

Pre-assembled fitting group and fitting assembly for a window or a door

ActiveCN112384675ANo loss of stabilityReduce work costsWing suspension devicesClassical mechanicsEngineering

Owner:ROTO FRANK FENSTER & TURTECHNOLOGIE GMBH

Method for assembling motor vehicles

A method for assembling motor vehicles in which a drive train, chassis and floor module are pre-assembled and then connected to a shell of the motor vehicle. The floor module is pre-assembled in a first pre-assembly process and the drive train and the chassis are pre-assembled in a second pre-assembly process. The floor module, the drive train and the chassis are combined and then connected to the shell of the motor vehicle.

Owner:DAIMLER AG

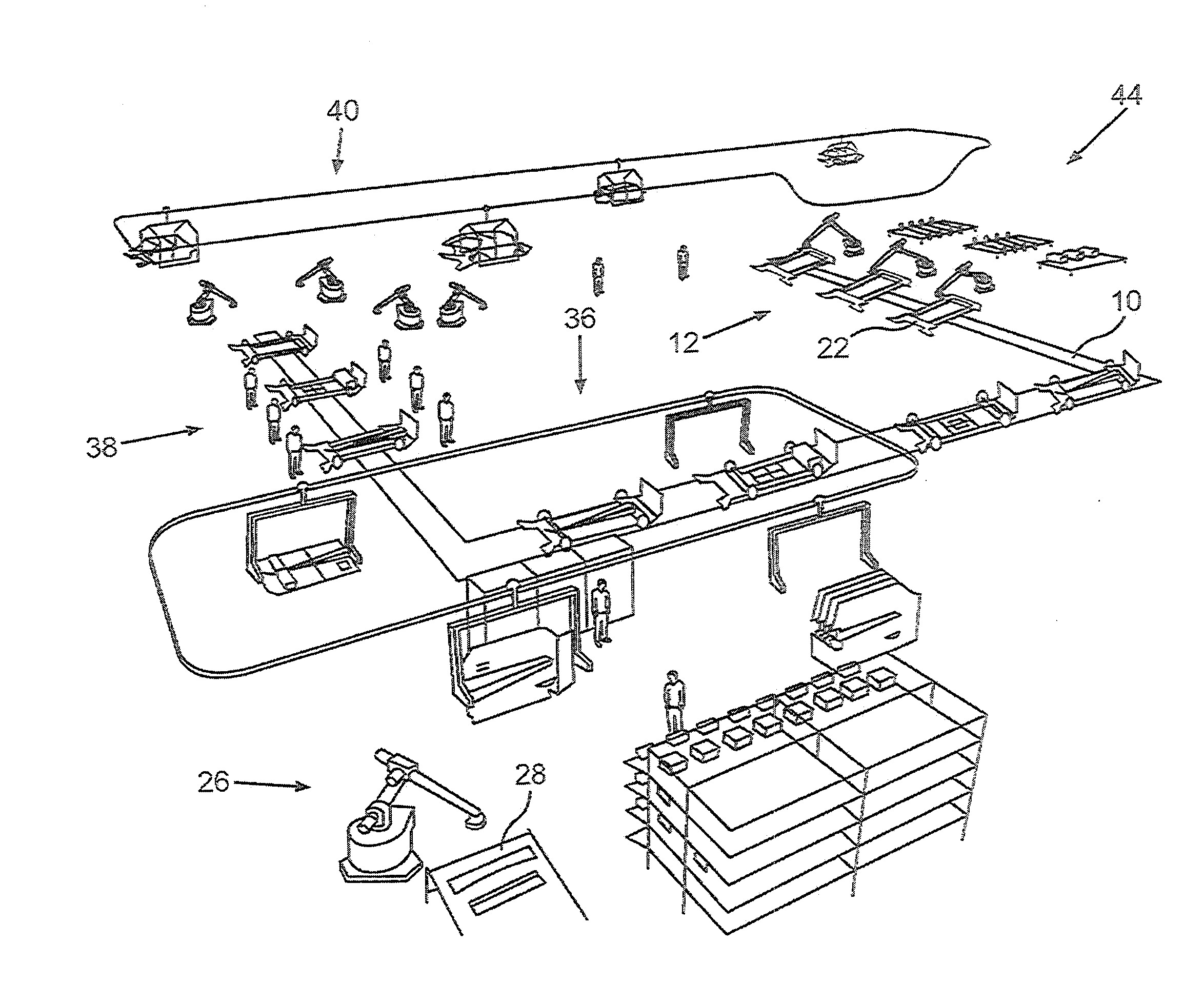

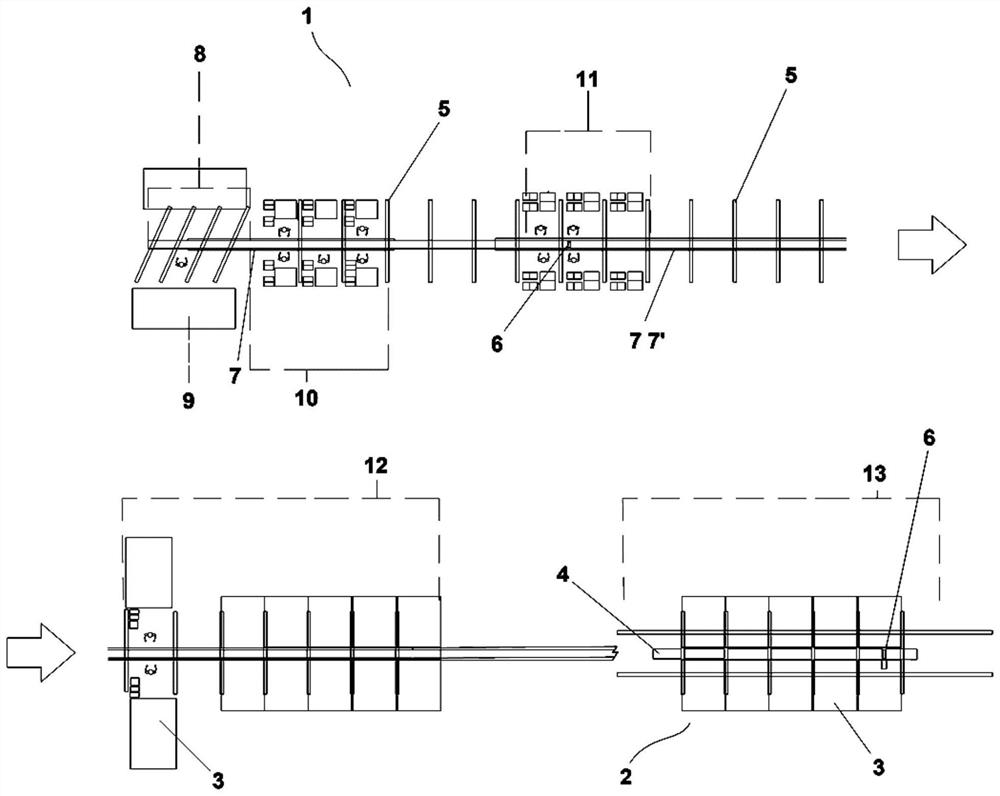

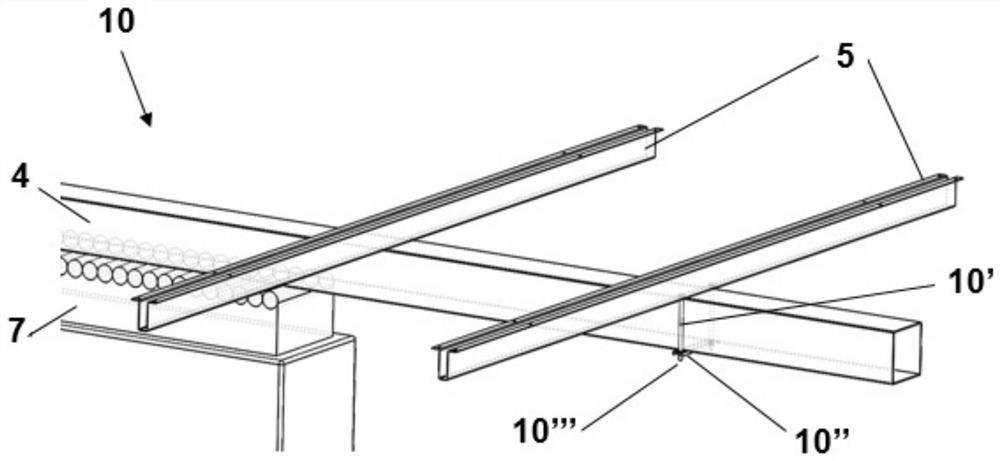

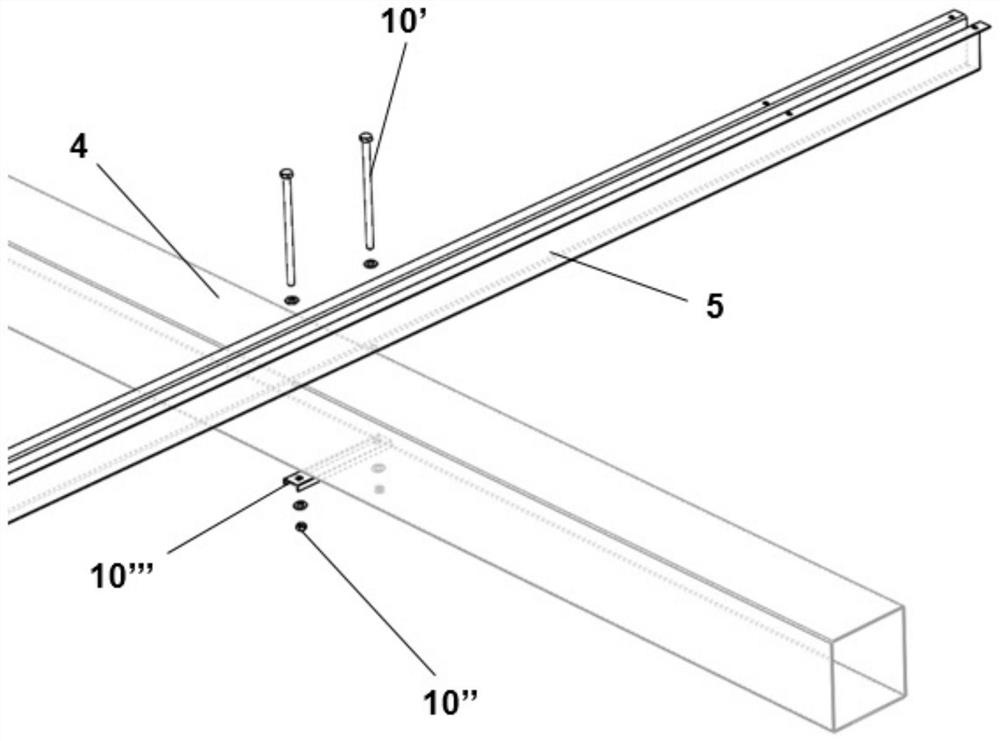

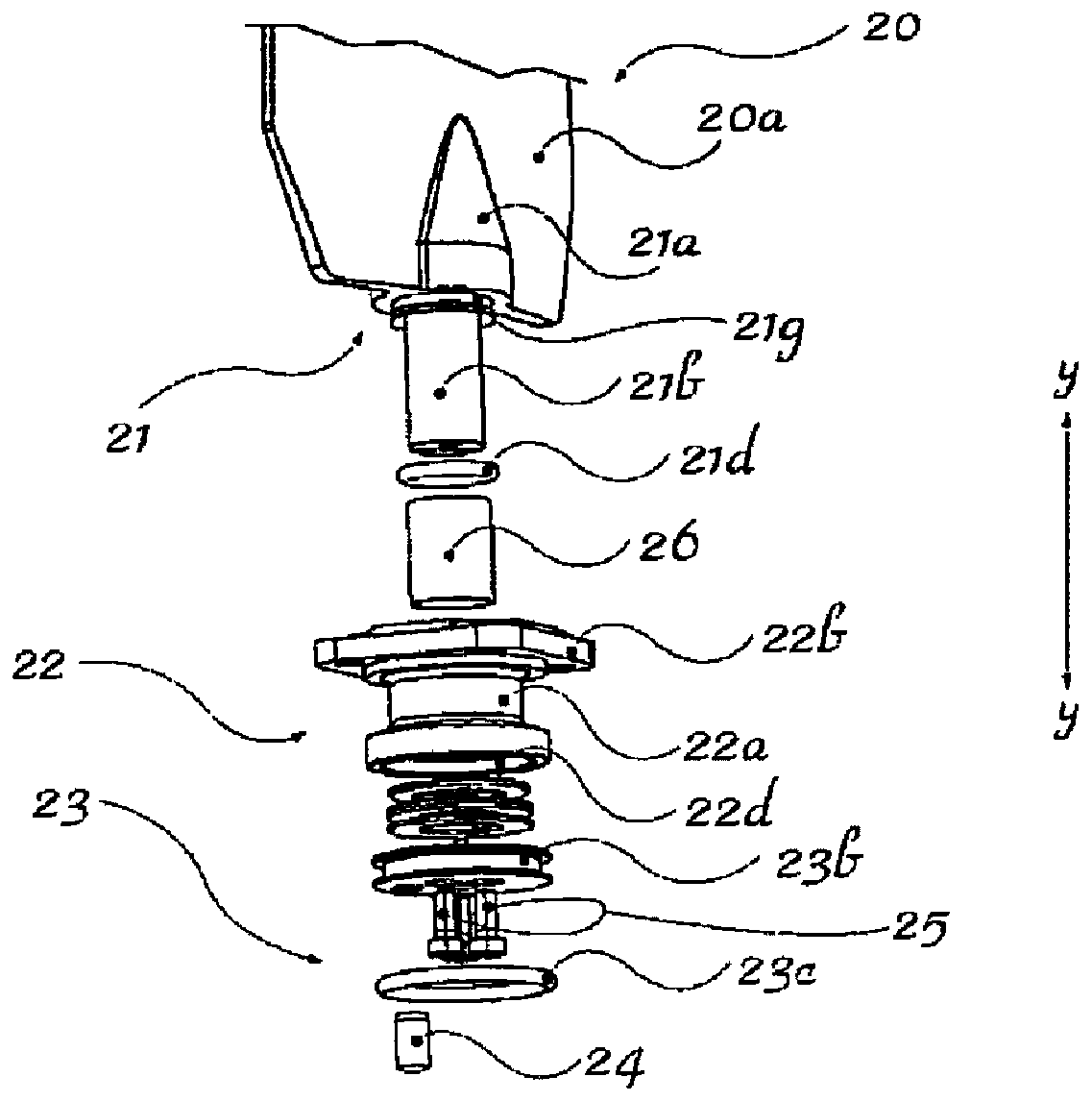

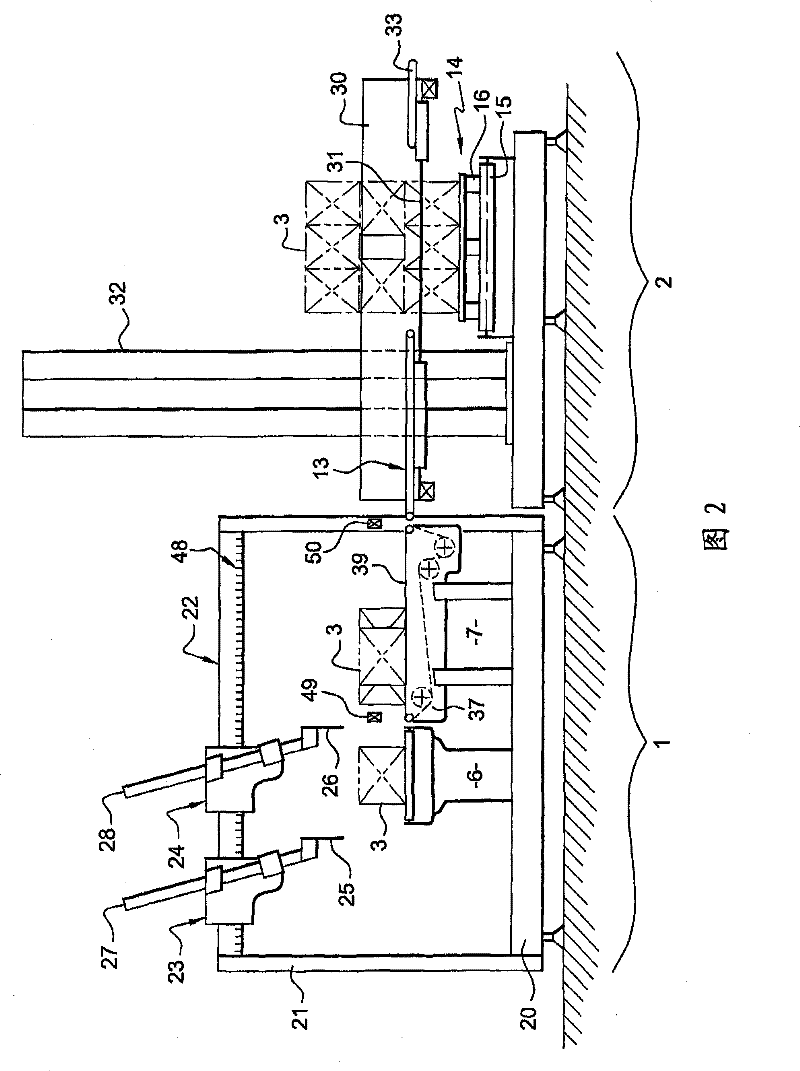

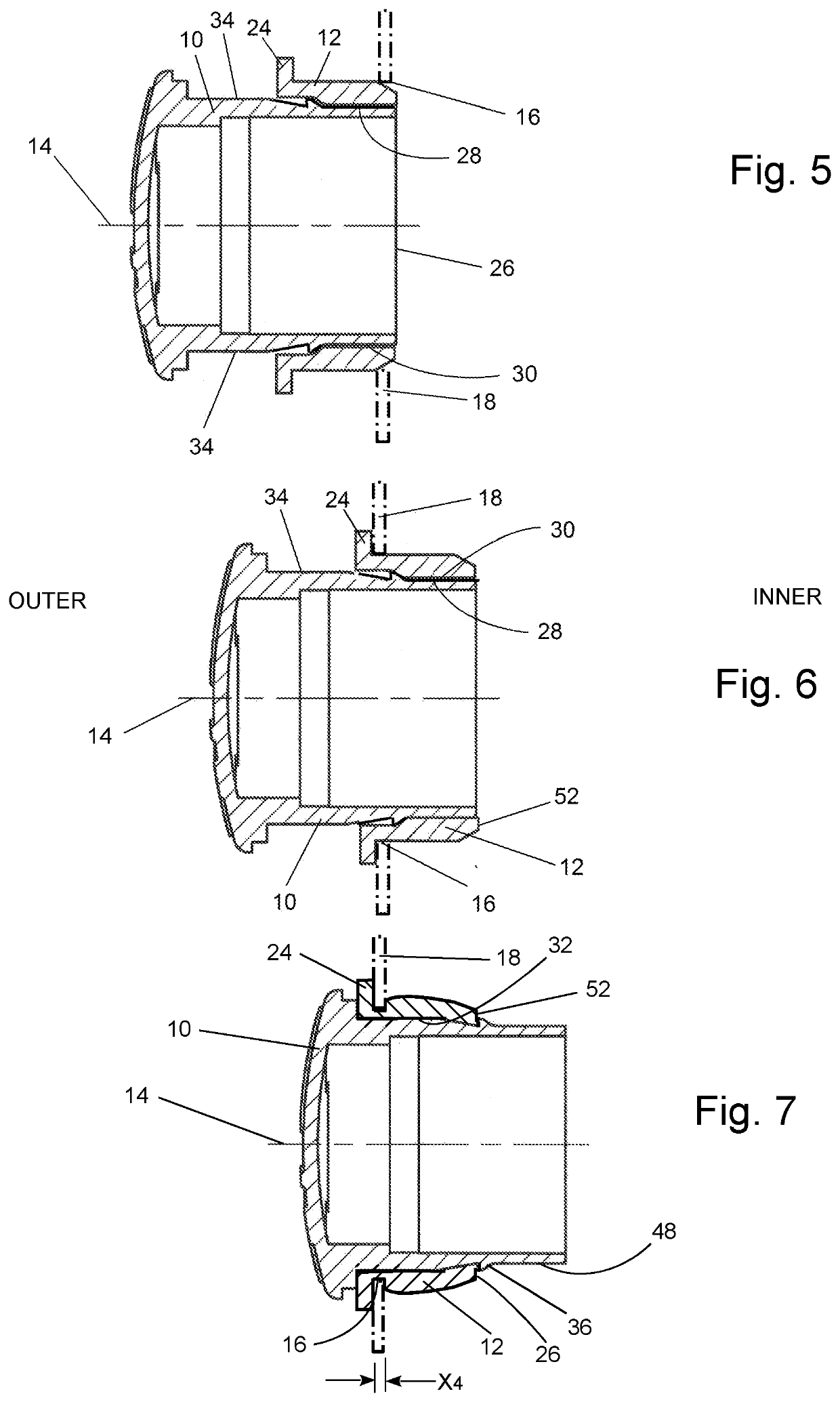

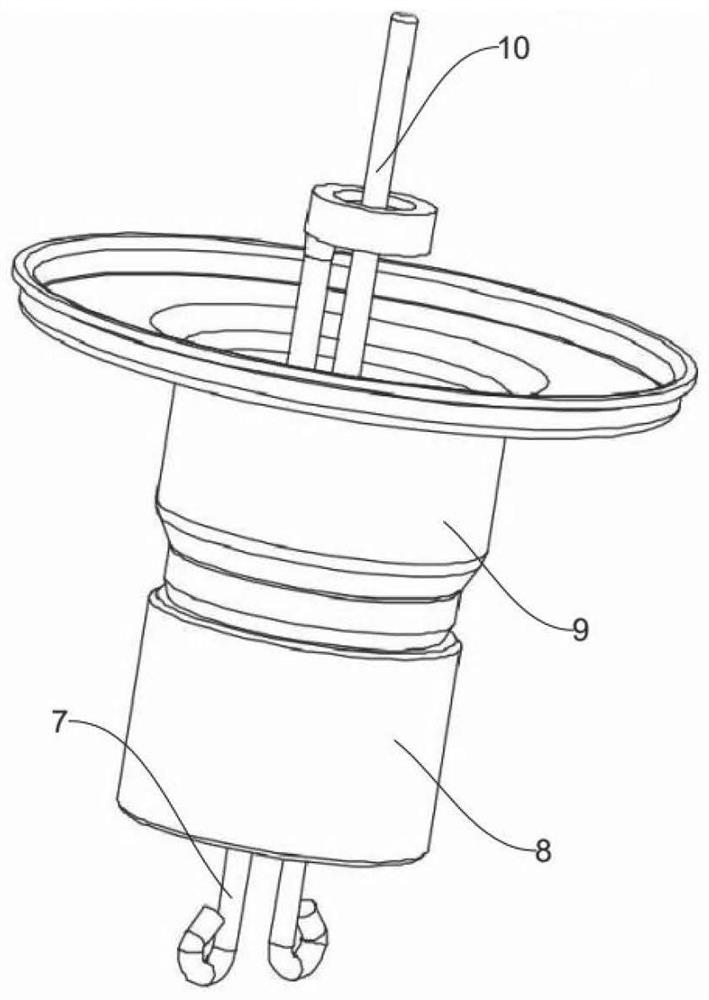

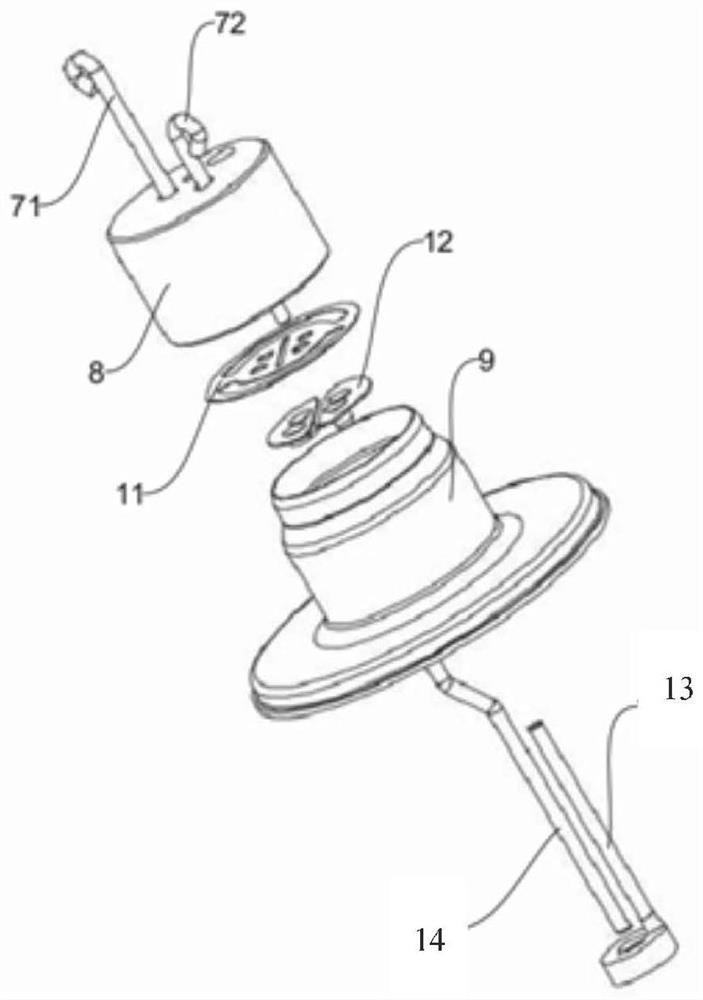

Pre-assembly device for photovoltaic solar tracker and related pre-assembly method

InactiveCN113120585ASave assembly timeEasy to storePhotovoltaic supportsSolar heating energyPhotovoltaic solar energyEngineering

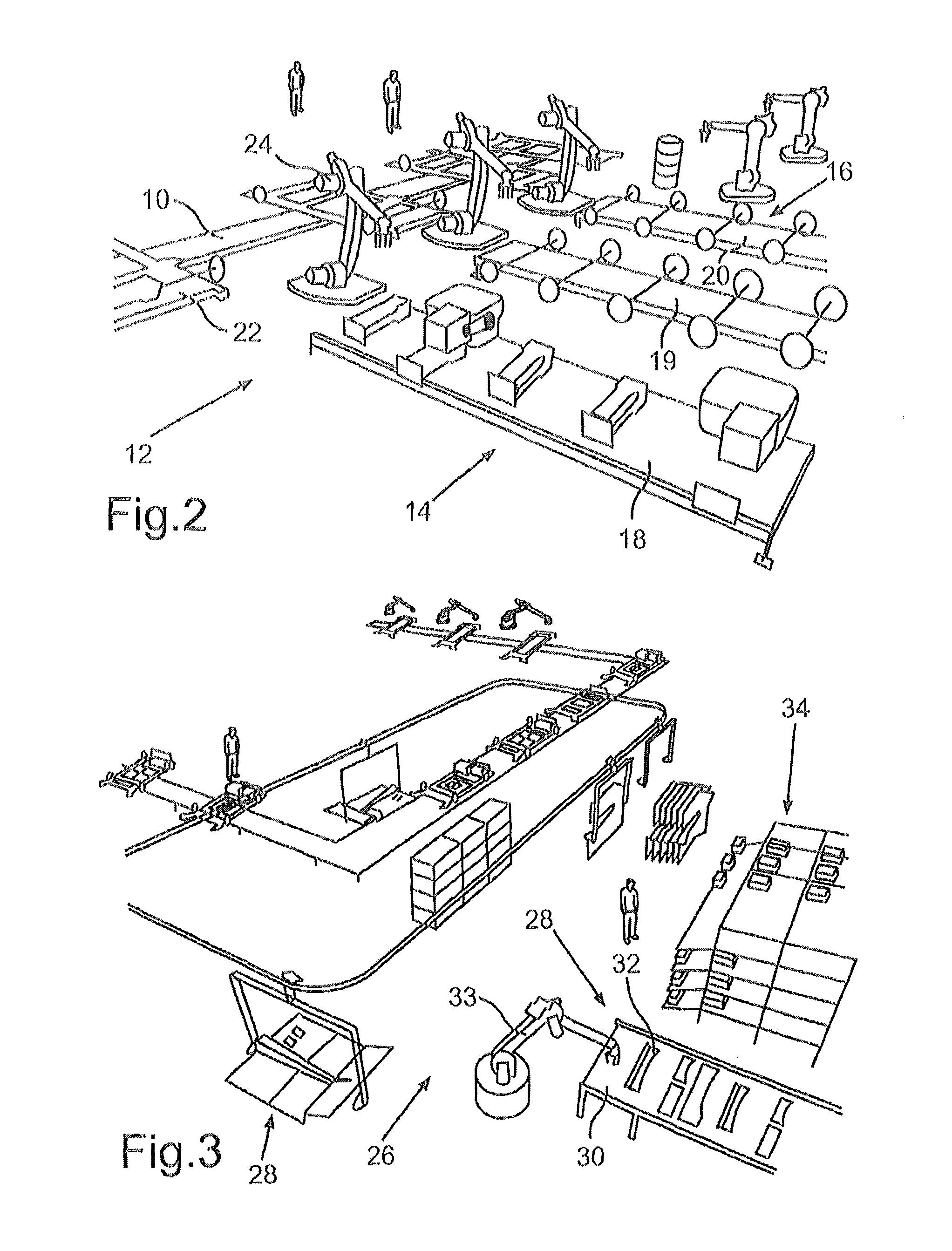

The invention relates to a pre-assembly device (1) for pre-assembling a unit (2) of a solar tracker; wherein the unit (2) comprises a set of photovoltaic panels (3) arranged on a structure formed by a main shaft (4) and a plurality of purlines (5). Advantageously, the device (1) comprises a transport line (7, 7 ') for transporting the components of the unit (2), near which at least the following pre-assembly sections are arranged: a section equipped with receiving means for receiving the components of the unit (2), and an unloading area (8) thereof; a fitting portion (10) for fitting the purline (5) to the shaft (4); a mounting portion (12) for mounting the photovoltaic panel (3) on the purline (5); and an end portion for pre-assembling and stockpiling (13) the units (2) in the support structure (13 '). The invention also relates to a pre-assembly method for pre-assembling units (2) comprising the use of said device (1).

Owner:ESASOLAR ENERGY SYST SL

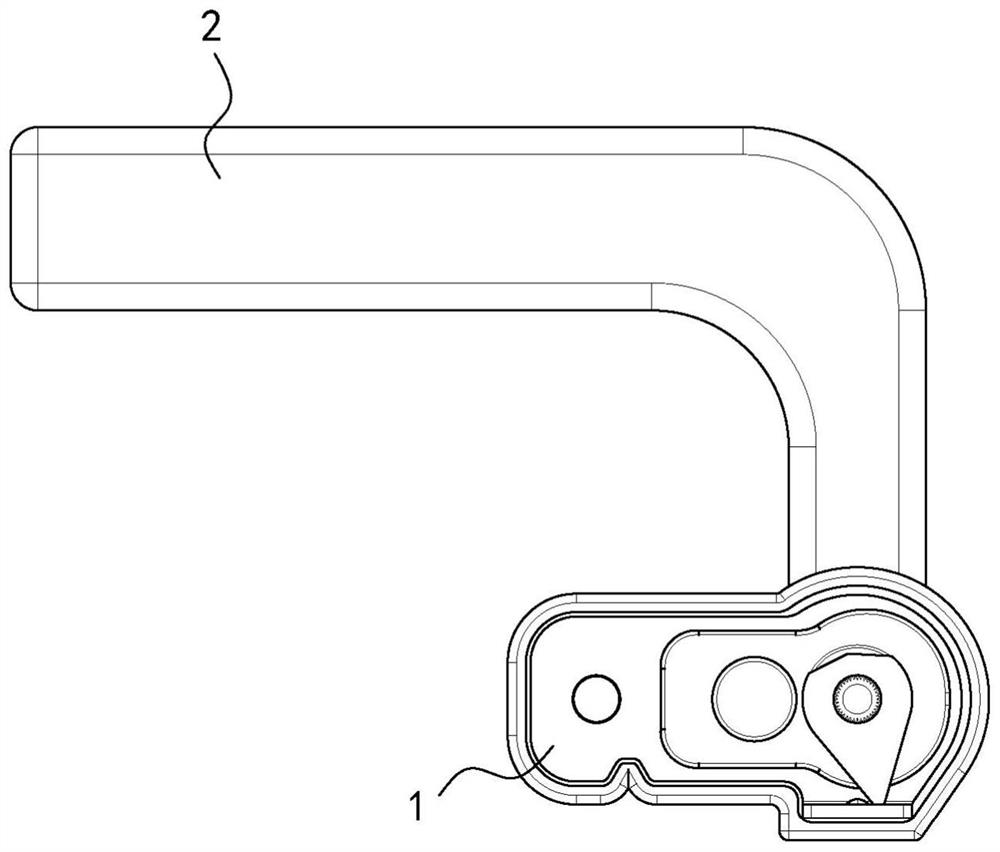

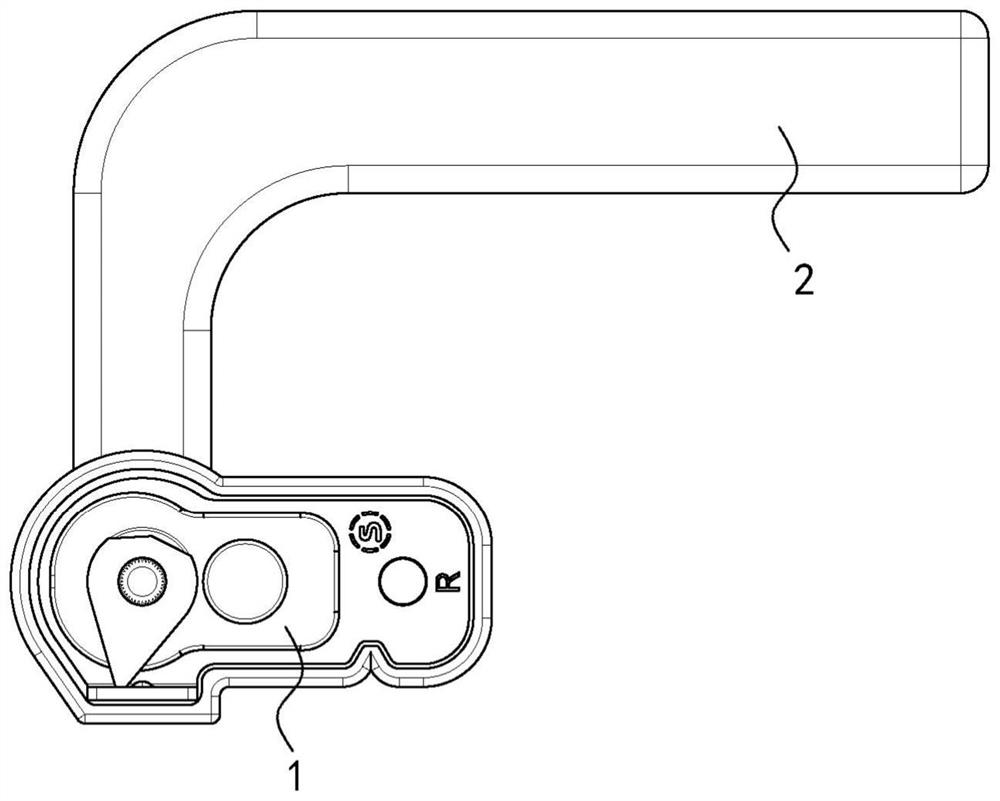

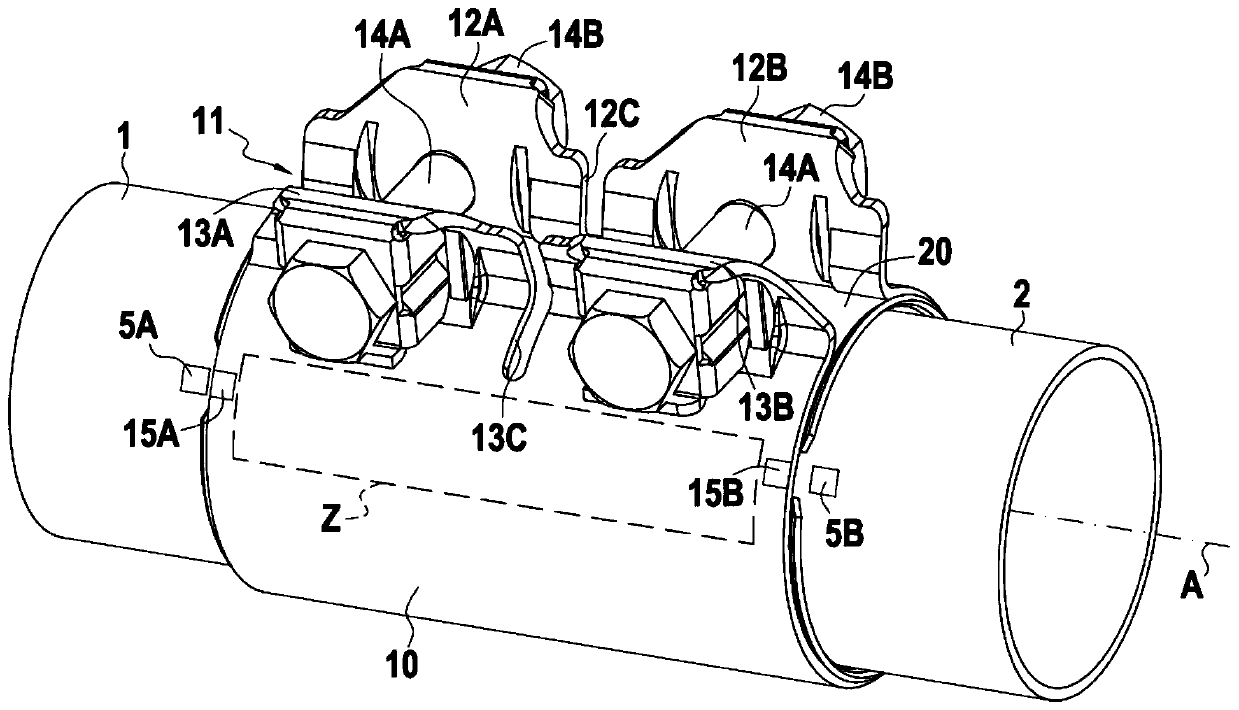

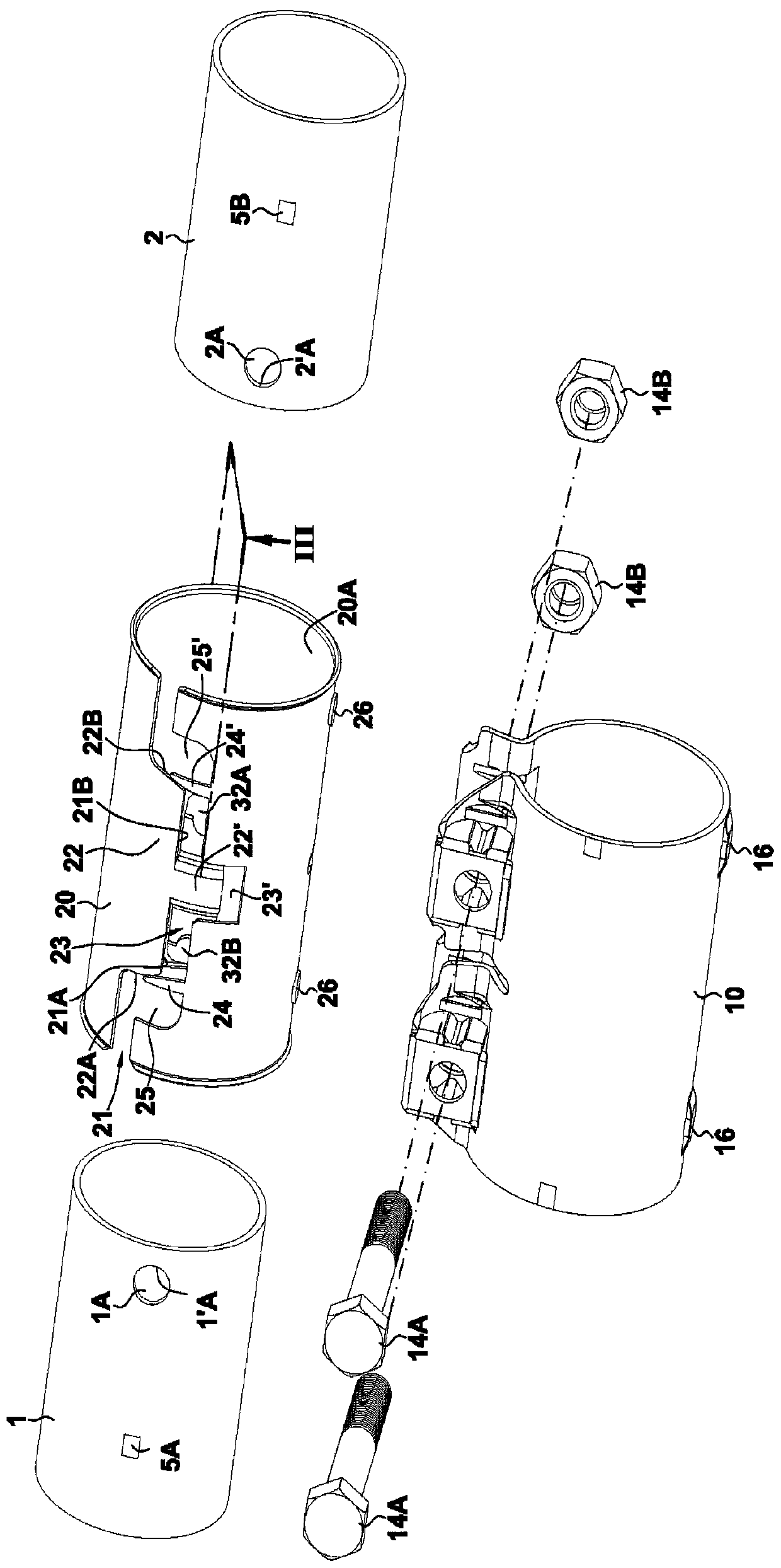

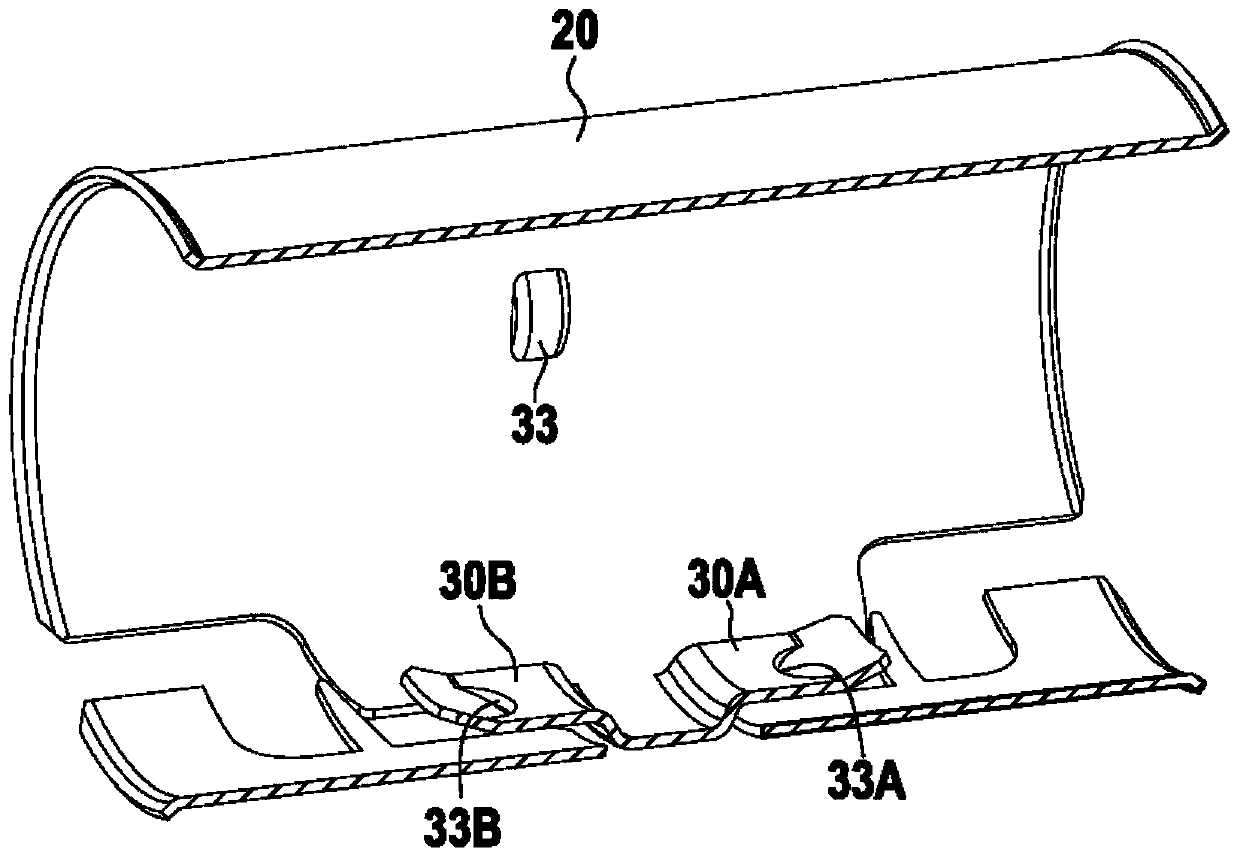

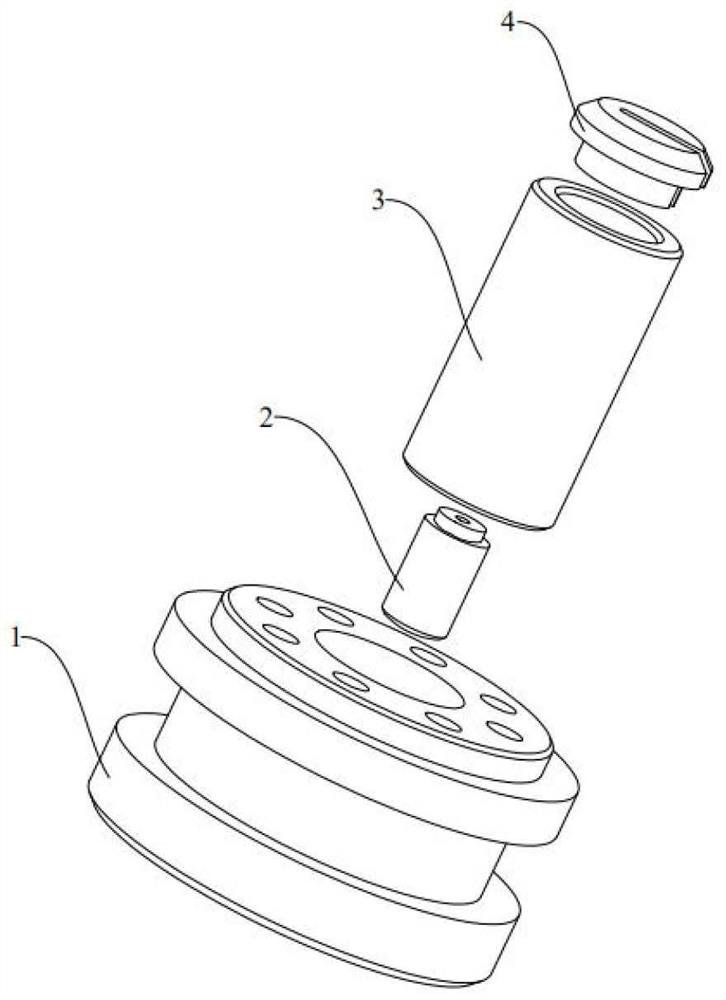

Device for coupling two tubes with pre-assembly

ActiveCN110268185AAvoid destructionAvoid risk of damageSleeve/socket jointsEngineeringPre-RC assembly

Owner:CAYO CORP

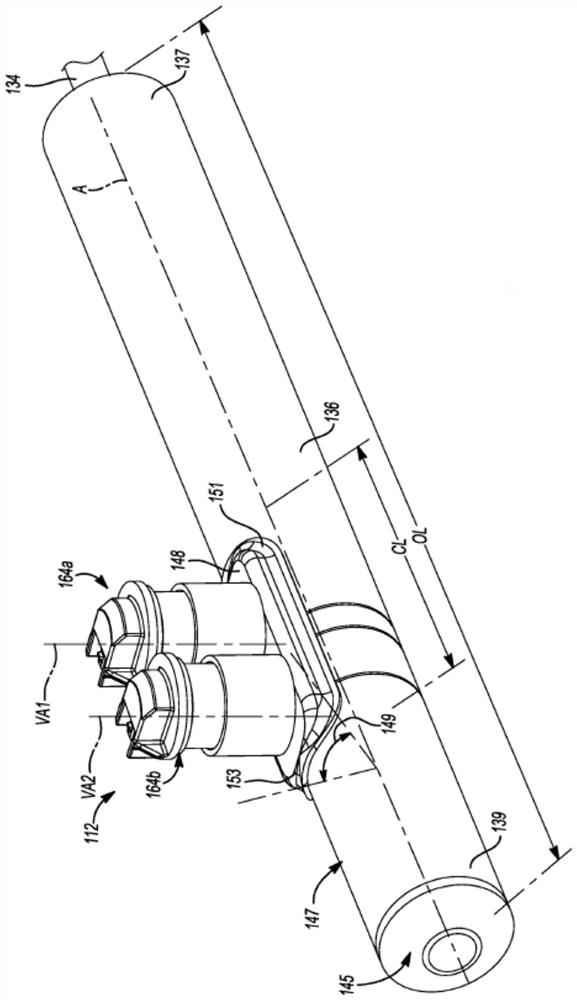

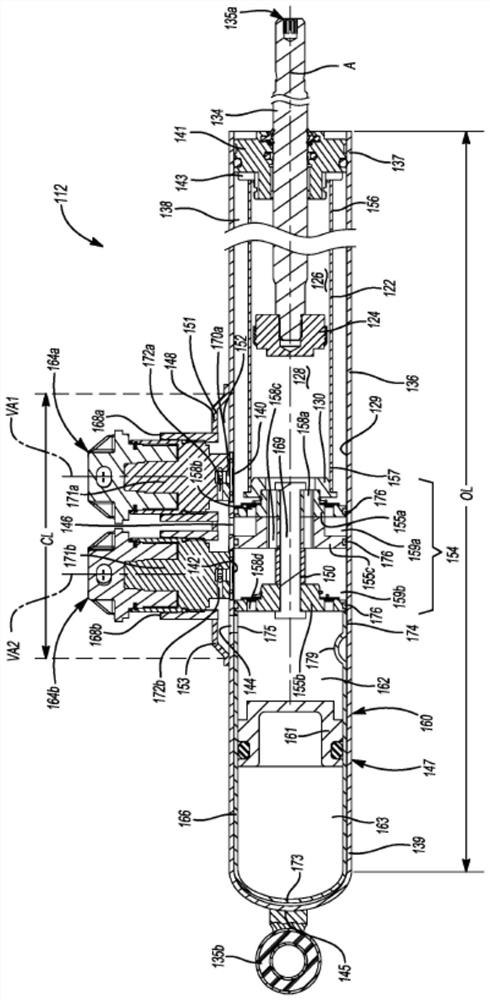

Pre-assembled piston accumulator device

ActiveCN113661342ADoes not affect sealing surfacesExcellent manufacturing efficiencyAuxillary drivesSpringsFluid transportEngineering

A damper with inner and outer tubes and a piston disposed within the inner tube to define first and second working chambers is disclosed. A fluid transport chamber is positioned between the inner and outer tubes. A collector chamber is positioned outside the outer tube. An intake valve assembly, abutting one end of the inner tube, is positioned inside the outer tube. An accumulator insert with an open end abutting the intake valve assembly is positioned inside the outer tube. The accumulator insert includes an accumulator sleeve, a floating piston, and a pressurized chamber. The floating piston is disposed inside the accumulator sleeve and the pressurized chamber is positioned between the floating piston and a closed end of the accumulator sleeve. An accumulation chamber is positioned between the intake valve assembly and the floating piston and the accumulator sleeve includes one or more apertures arranged in fluid communication with the collector chamber.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

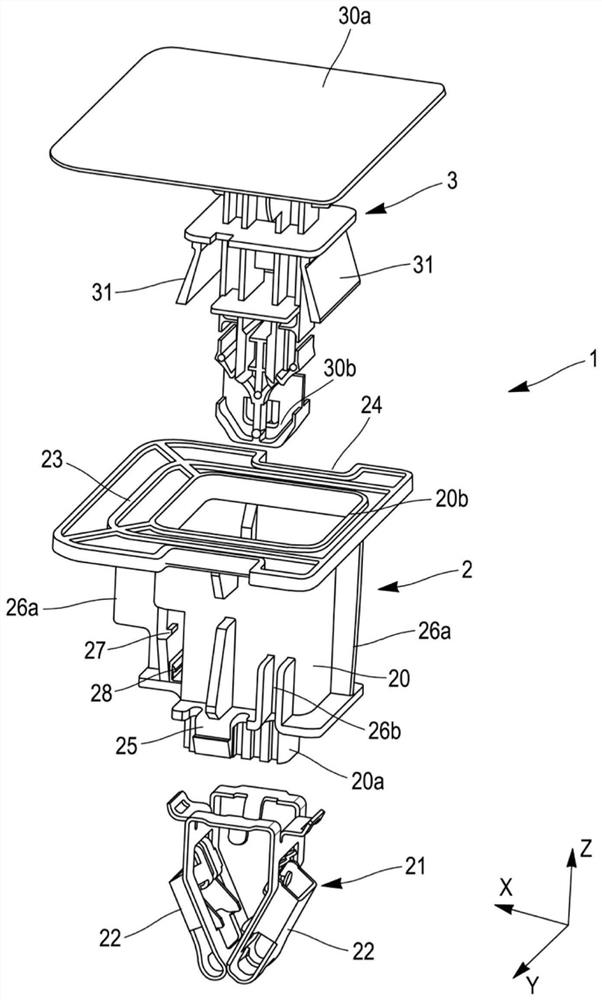

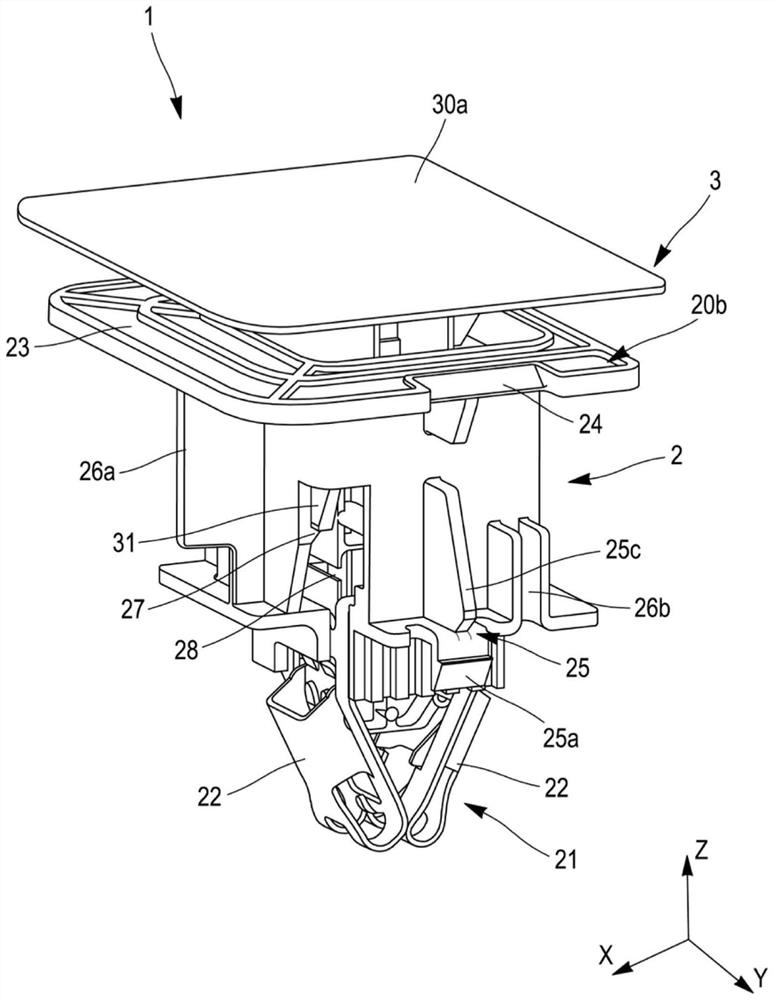

Device for attaching two elements allowing its pre-assembly

The invention relates to a device for attaching two elements allowing its pre-assembly. Specifically, the invention relates to a fixing device (1) for fixing an assembly comprising at least a first element and a second element, and each element of the assembly is provided with an opening intended to be placed opposite one another. The fixing device comprises a holding cage (2) and a pin (3). The holding cage (2) comprises a protruding flexible clip (21) having two legs (22) intended to engage through the openings of the first and the second elements to retain the assembled elements to one another; and a device (25) for keeping the holding cage (2) to the first element. The pin (3) is arranged in the holding cage (2) and has a first end (30a) to receive an external assembly force and a second end (30b). The fixing device (1) also comprises a selective coupling device (31) for the pin (3) and the cage (2).

Owner:A RAYMOND & CO

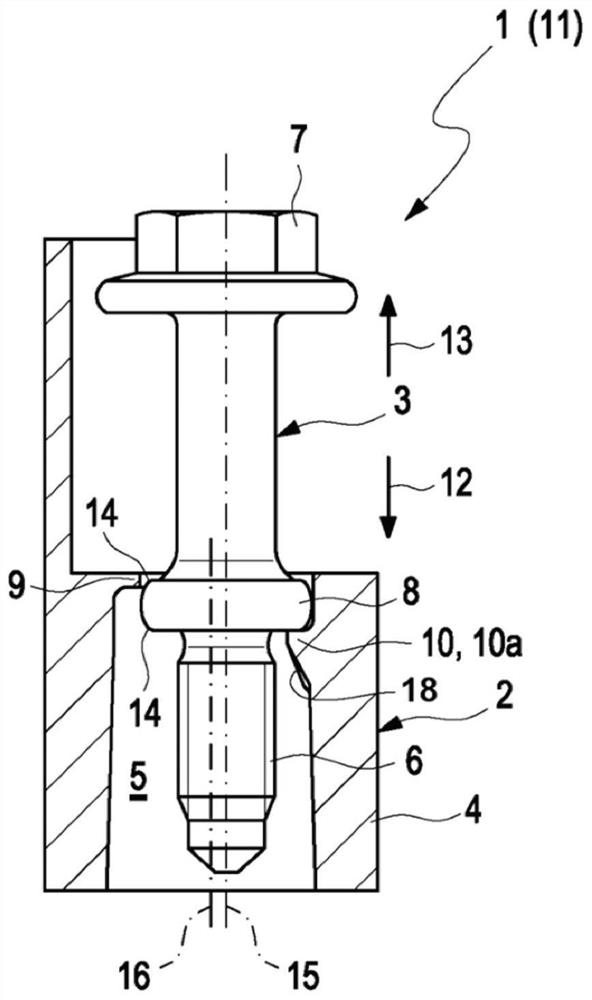

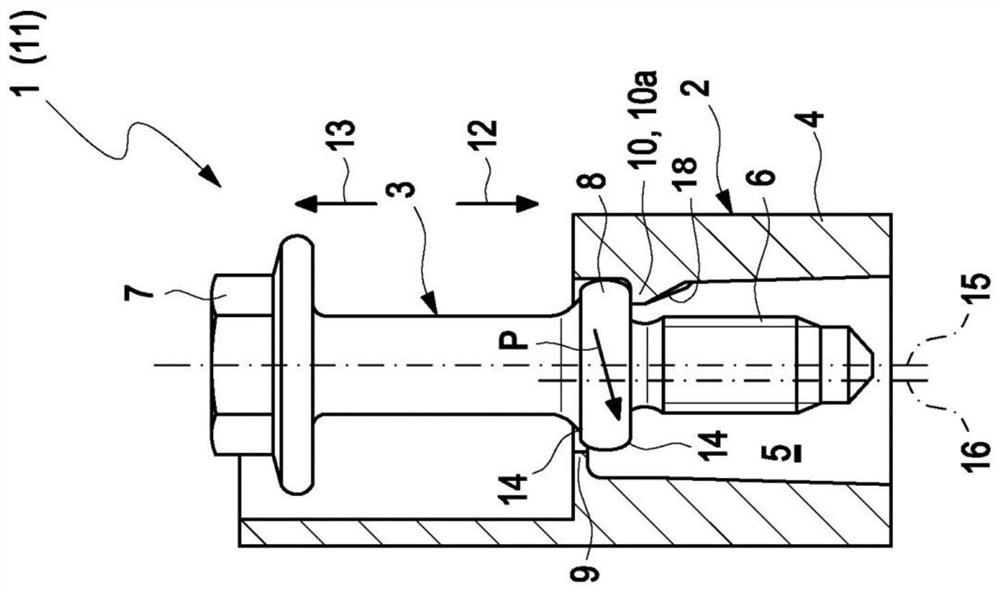

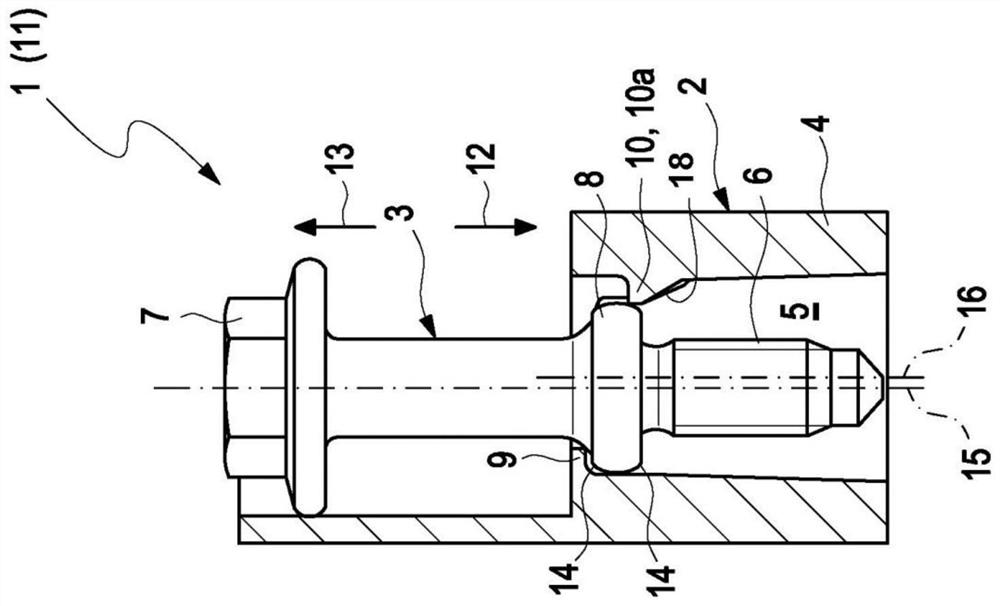

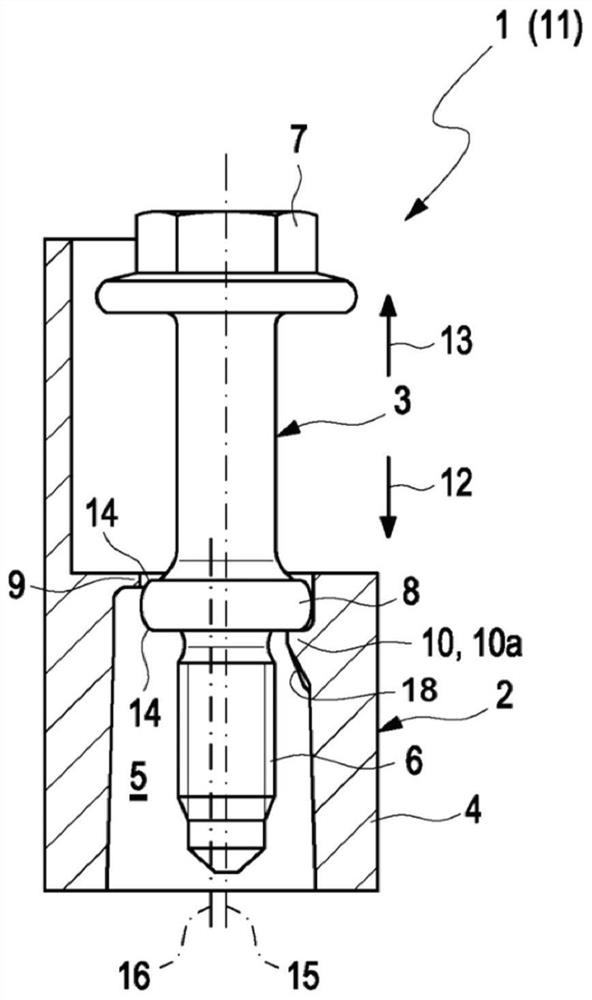

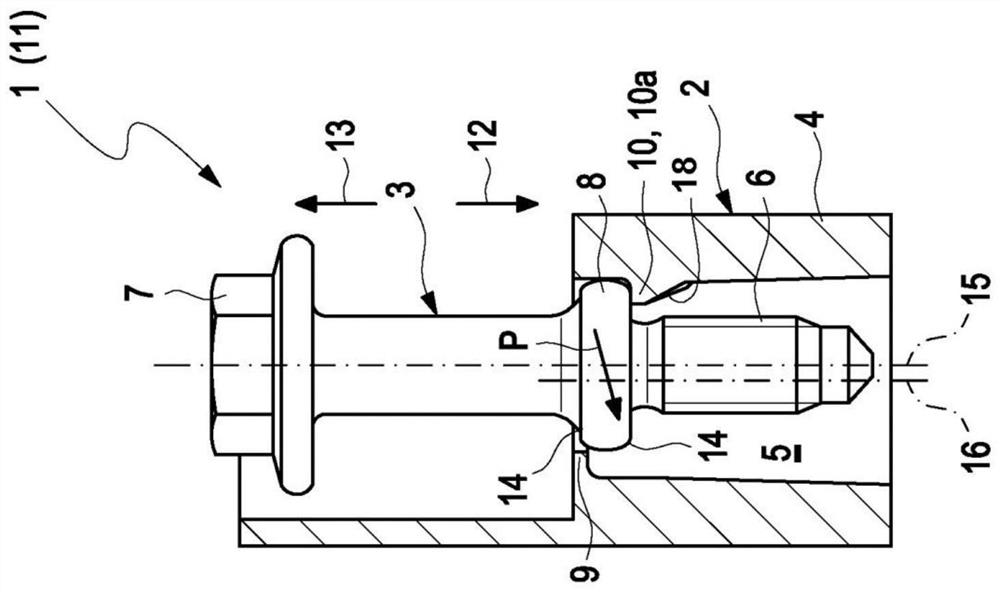

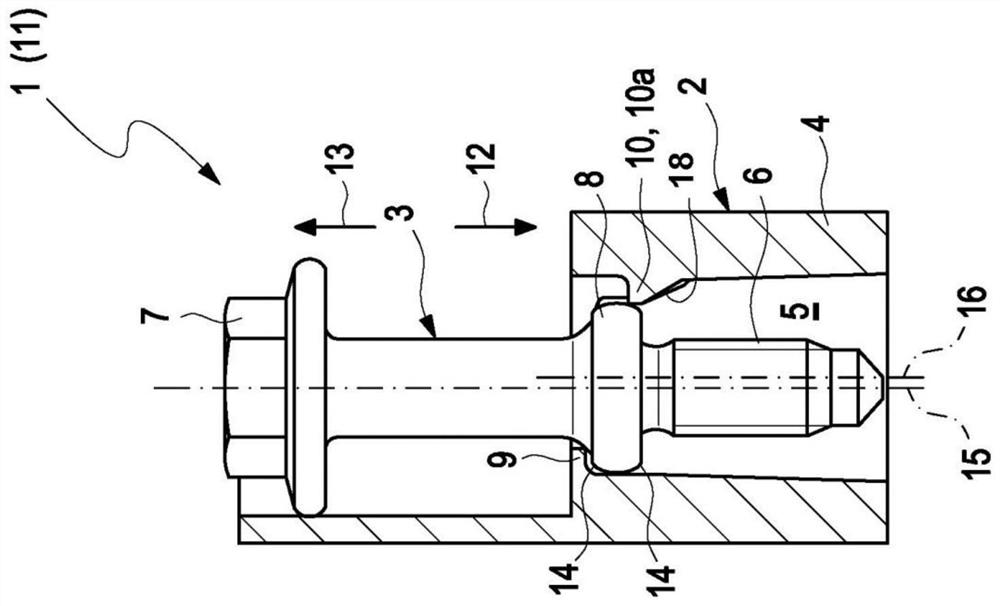

Fastening device, component comprising fastening device, and method for pre-assembling fastening device

The invention relates to a fastening device (1) for securing a component to a counter piece (2). The fastening device (1) includes a collar screw (3) having a thread (6), a screw head (7), and a circumferential collar (8) formed therebetween. The fastening device (1) also includes a fastening section (4) of the counter piece (2) in which a through hole is formed, said through hole comprising an inner radial stop projection. The collar screw may be inserted into the through hole in the insertion direction, and, in a pre-assembly state, the collar may be axially supported on the stop projectionin a pull-out direction. According to the invention, a clamping projection is formed in the through hole, located inside, radially opposite the stop projection, and axially offset from the stop projection in the insertion direction. In the pre-assembly state, the collar may be axially supported on the clamping projection in the insertion direction, and the collar screw may be clamped between the stop projection and the clamping projection. The invention also relates to a component comprising a fastening device, and a method for pre-assembling a fastening device.

Owner:MAHLE INT GMBH

Preassembled blades of a fan for cooling coolant in a machine/vehicle and a fan provided with said blades

Owner:BARUFFALDI

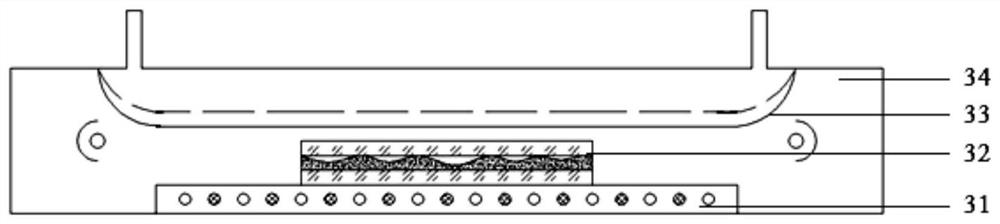

A sealing method of flat vacuum glass

A method for sealing flat vacuum glass, comprising: in a vacuum chamber, heating a pre-assembled part including flat glass, a sealing material and a support, and simultaneously evacuating the vacuum chamber to remove gas inside the pre-assembled part , and then apply pressure perpendicular to the horizontal direction of the glass to the pre-assembled parts to achieve sealing, and finally cool and solidify to obtain a sealed flat vacuum glass. This method is a one-step process. Pressure is applied in the vacuum chamber to make the material flow to form a stable structure and heat to seal, so that the sealing and vacuuming can be carried out at the same time. Compared with the traditional technology, the production efficiency is improved. When the sealing material is softened, the hot pressing process is used to make the material flow to a certain extent to form a stable structure that avoids stress concentration, and the yield is higher than that of traditional technology.

Owner:深圳理大科技产业有限公司

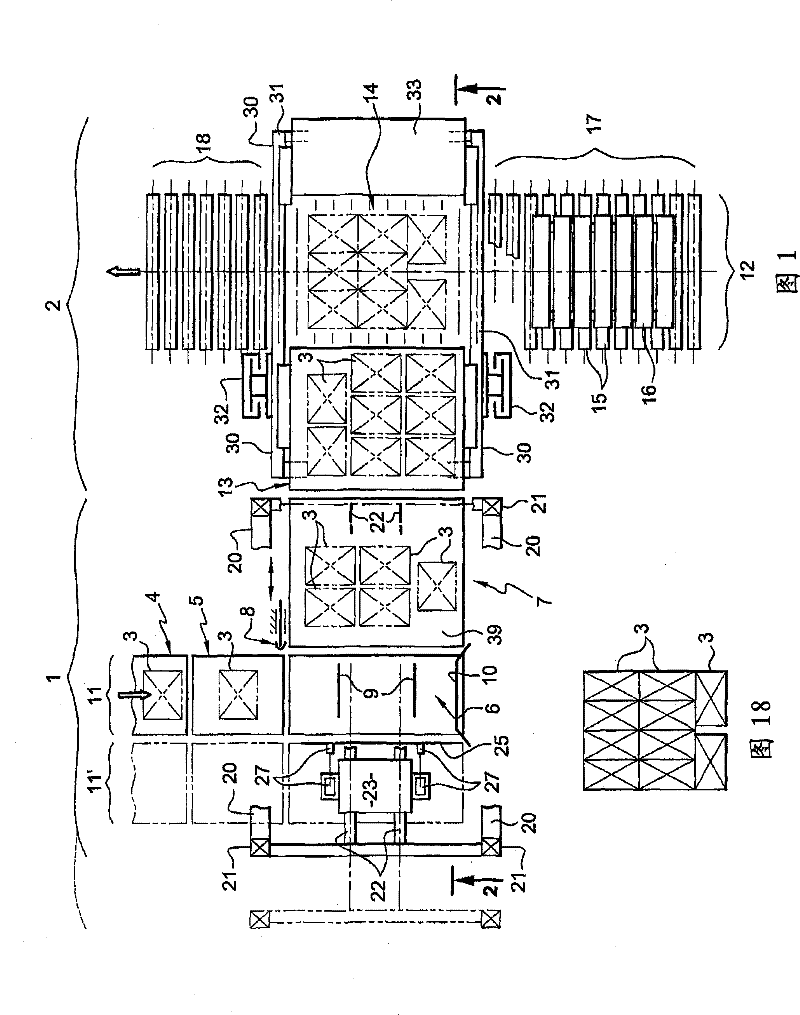

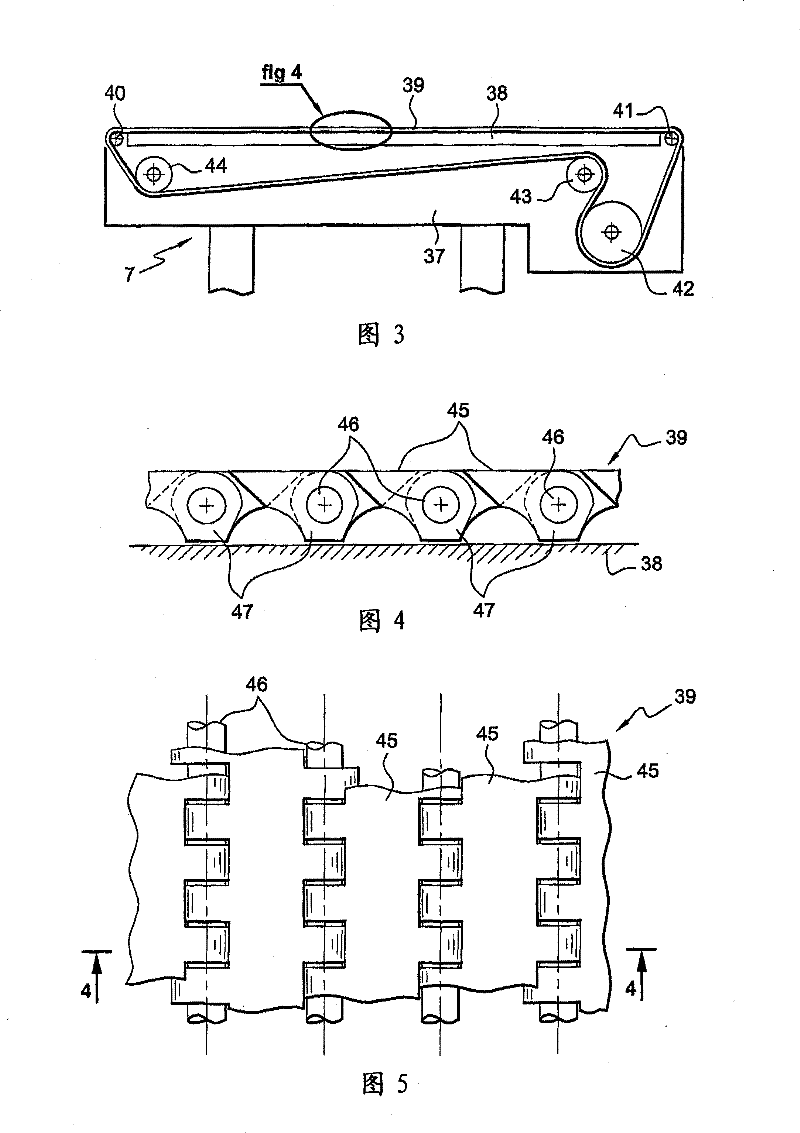

Method and installation for assembling palletizable products

InactiveCN101384488BImprove stabilityEnough gripPackagingStacking articlesEngineeringStructural engineering

The invention concerns a method which consists in cyclically: transferring a first row of products (3) between the station for preparing said products (6) and the pre-assembly station (7), at a speed V; transferring similarly a second row of products (3) onto said pre-assembly table (7), and in order to manage the docking of said second row with the row of products already set on said pre-assembly table (7), moving said set row at a speed v selected between zero and V, depending on the type or products (3); transferring, as the case may be, another row of products (3) onto the table (7), and, when the number of rows is reached to obtain said layer, transferring said layer onto the setting table (13) of the palletizing station (14). The installation comprises transfer means consisting of pushers (25) and (26) mobile between different stations, driven at suitable speeds. The invention also concerns, at the pre-assembly station (7), a modular endless belt which is supported and moves on a slider bed, said belt being mobile, driven at a speed which is related to that of the pushers (25) and (26).

Owner:SIDEL PARTICIPATIONS SAS

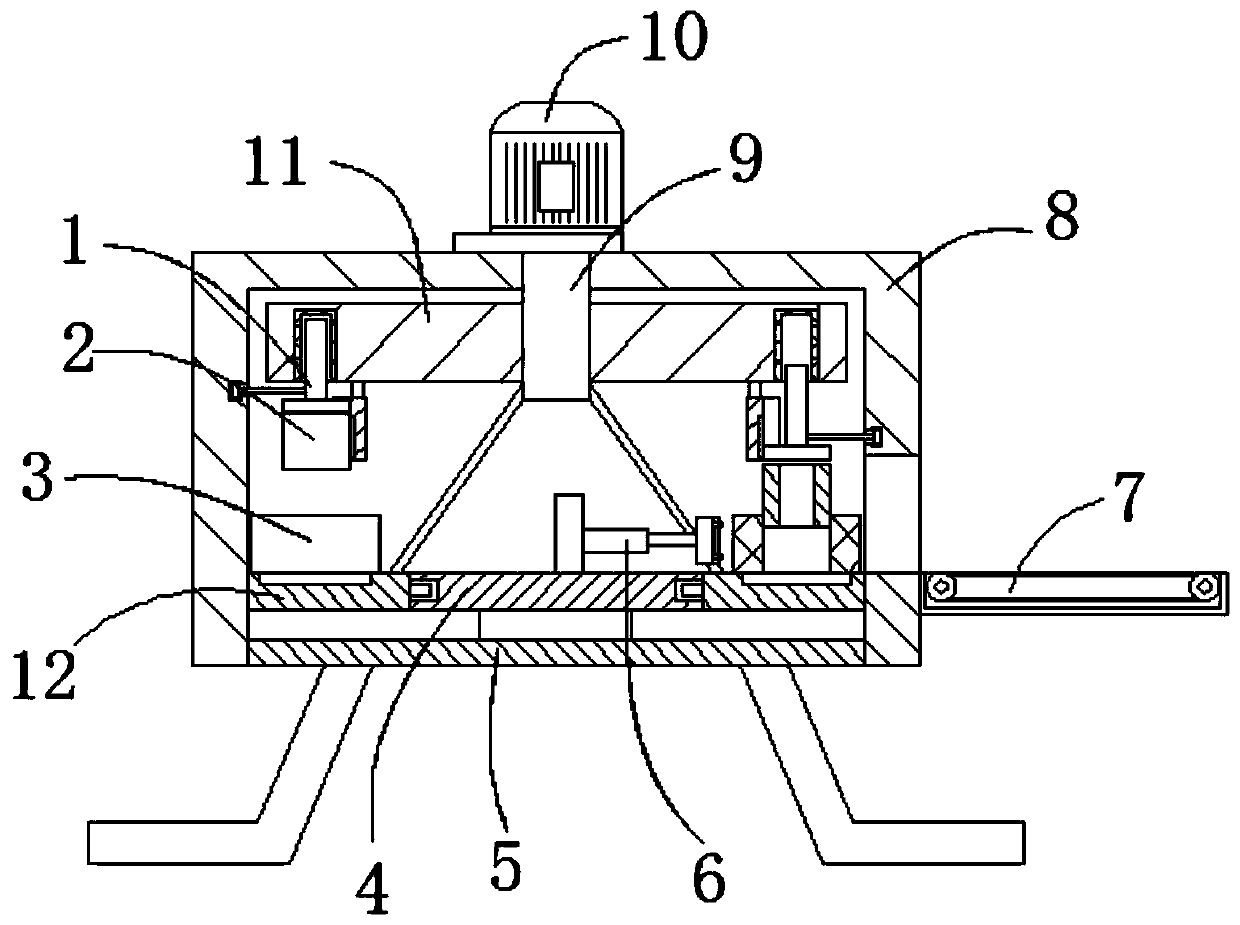

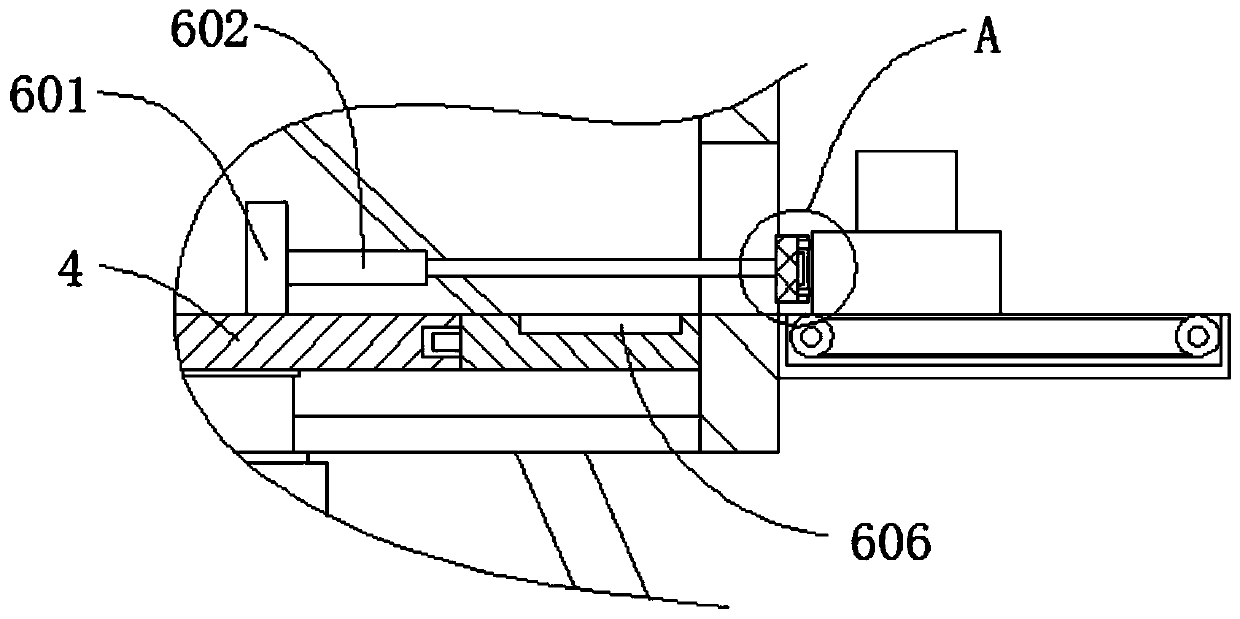

Roller shaft sleeve pre-assembly production equipment

InactiveCN110977388AQuick installationRealize automatic feeding functionMetal working apparatusButt jointPre-RC assembly

The invention discloses a roller shaft sleeve pre-assembly production equipment and belongs to the field of roller pre-assembly. According to an existing shaft sleeve butt joint process, inaccurate butt joint is likely to be brought about; when a shaft sleeve is pressed in a later period, the shaft sleeve deviates easily; and as a result, the percent of pass of roller assembly is low. According tothe technical schemes of the invention, the roller shaft sleeve pre-assembly production equipment comprises a lower rotary disc, an upper rotary disc, a shaft sleeve butt joint mechanism located on the edge of the lower side face of the upper rotary disc, and a discharging mechanism located on the upper side face of a fixing table; the shaft sleeve butt joint mechanism comprises a limiting plate,a magnet block, a pushing plate and a guide rail groove; the limiting plate is welded and fixedly connected to the edge of the lower end face of the upper rotary disc through a supporting rod; the magnet block is embedded in the surface of one side of the limiting plate; the pushing plate is welded and fixed to the bottom end face of a guiding rod; the guide rail groove is formed in the inner wall of an outer frame; and a guiding wheel is connected into the guide rail groove in a sliding manner. With the roller shaft sleeve pre-assembly production equipment of the invention adopted, a rollerand a shaft sleeve can be pre-assembled; assembling precision is high; the rapid press fit of the roller and the shaft sleeve in a later period is facilitated; and the percent of pass of roller assembling is increased.

Owner:CHANGXING QIKAI MECHANICAL EQUIP CO LTD

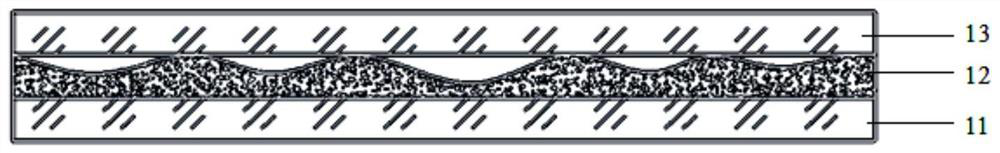

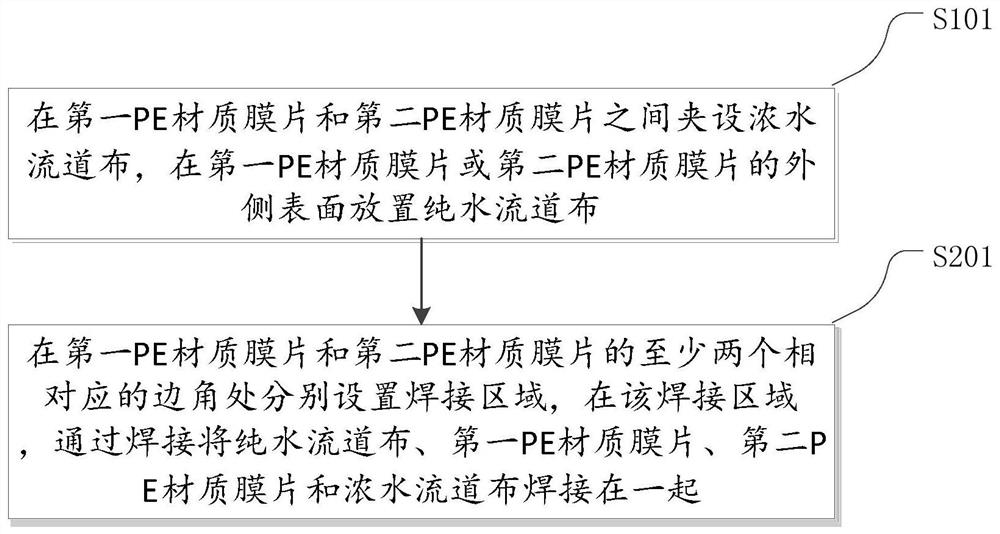

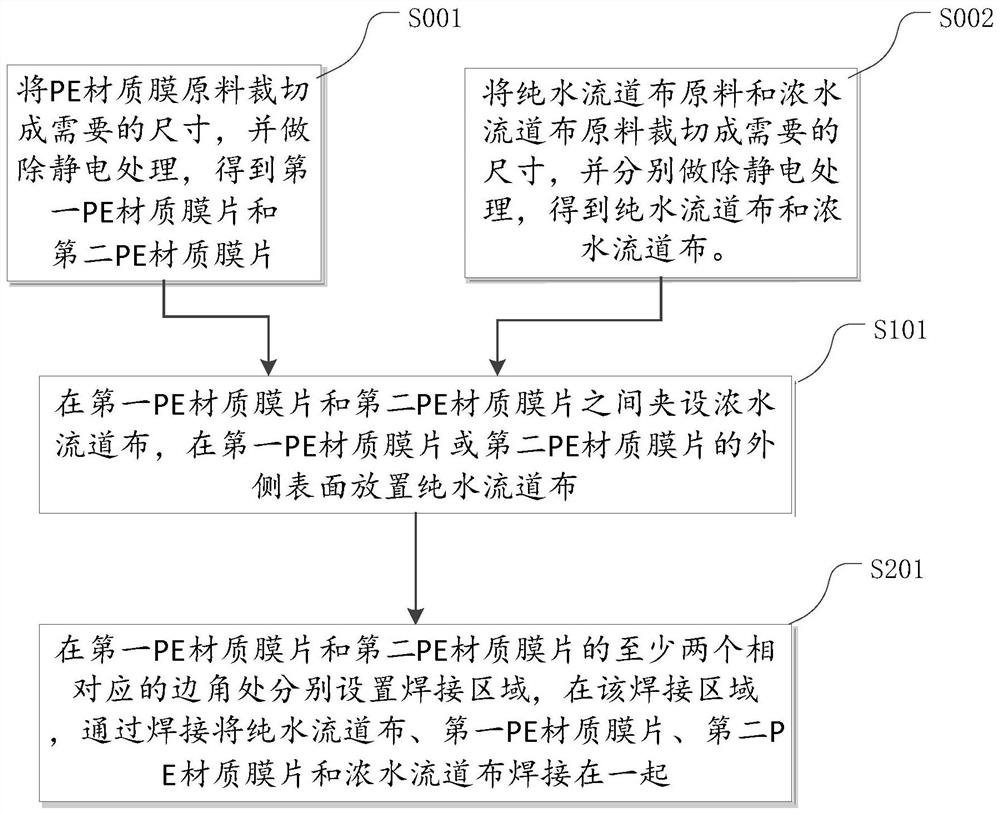

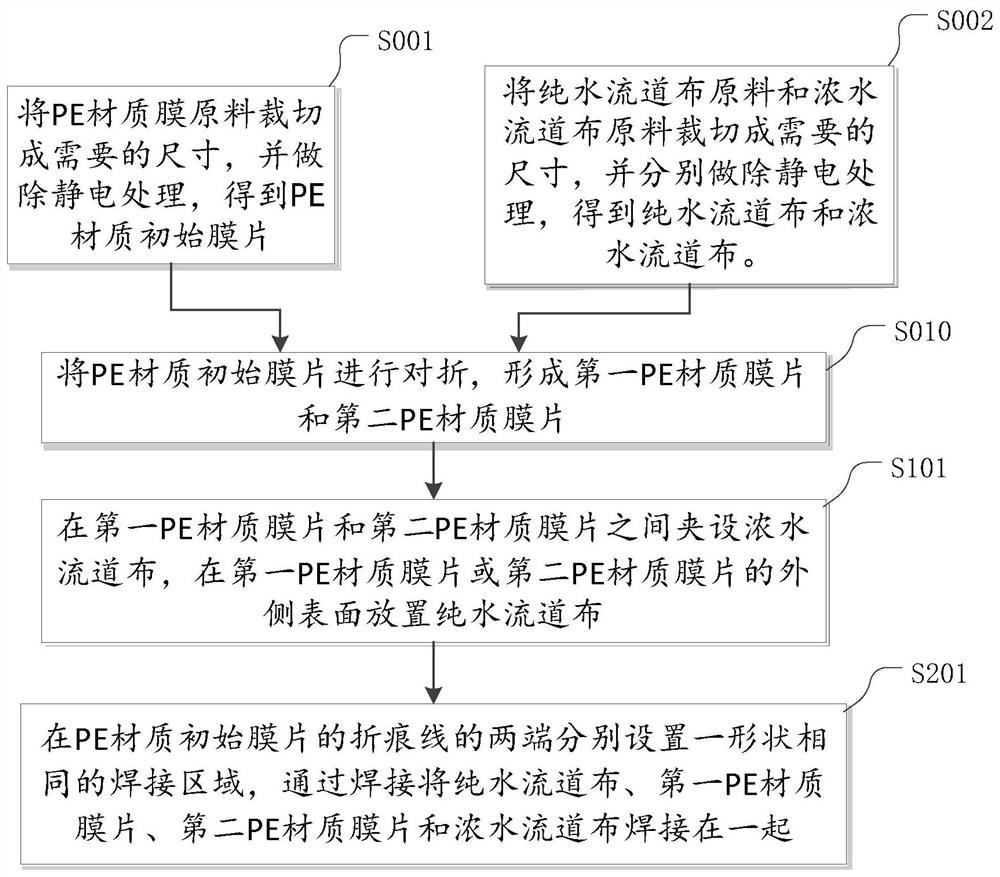

Pre-assembly process of roll-type membrane element and membrane element

PendingCN111644068AAvoid damageQuality improvementSemi-permeable membranesEngineeringWater processing

The invention relates to the technical field of water treatment, in particular to a roll-type membrane element pre-assembly process and a membrane element. The method comprises the following steps that concentrated water runner cloth is clamped between a first PE membrane and a second PE membrane, and pure water runner cloth is placed on the outer side surface of the first PE membrane or the outerside surface of the second PE membrane; and the pure water runner cloth, the first PE material membrane, the second PE material membrane and the concentrated water runner cloth are welded together. The membrane element is prepared by adopting the roll-type membrane element pre-assembly process. The PE membrane, the pure water runner cloth and the concentrated water runner cloth are welded and pre-assembled, wherein the step of placing the pure water runner cloth in the membrane element rolling process is omitted; therefore, on one hand, the rolling efficiency of the water treatment roll typemembrane element of the PE membrane is improved, on the other hand, damage to the PE membrane in the rolling process is reduced, and the quality of the membrane element is improved.

Owner:BEIJING ORIGIN WATER FILM TECH

Fixture, component with fixture and method of pre-assembling fixture

The invention relates to a fixing device (1) for fixing a component (2) to a counterpart. The fixing device (1) comprises a ring bolt (3) having a thread (6), a bolt head (7) and a circumferential collar (8) formed between them. The fixing device (1) also comprises a fixing portion (4) of the part (2), in which a through hole is formed including a radial stop protrusion located inside. The ring bolt is inserted into the through-hole in the insertion direction, and in the pre-assembled state, the collar of the ring bolt is supported axially in the pulling-out direction on the stop projection of the through-hole. According to the invention, a clamping projection is formed in the through hole, which is located inside, diametrically opposite to the stop projection and axially offset from the stop projection in the insertion direction. In the pre-assembled state, the collar is supported axially in the insertion direction on the clamping projection, so that the collar bolt is clamped between the stop projection and the clamping projection. The invention also relates to a component comprising a fixing device and a method for pre-assembling the fixing device.

Owner:MAHLE INT GMBH

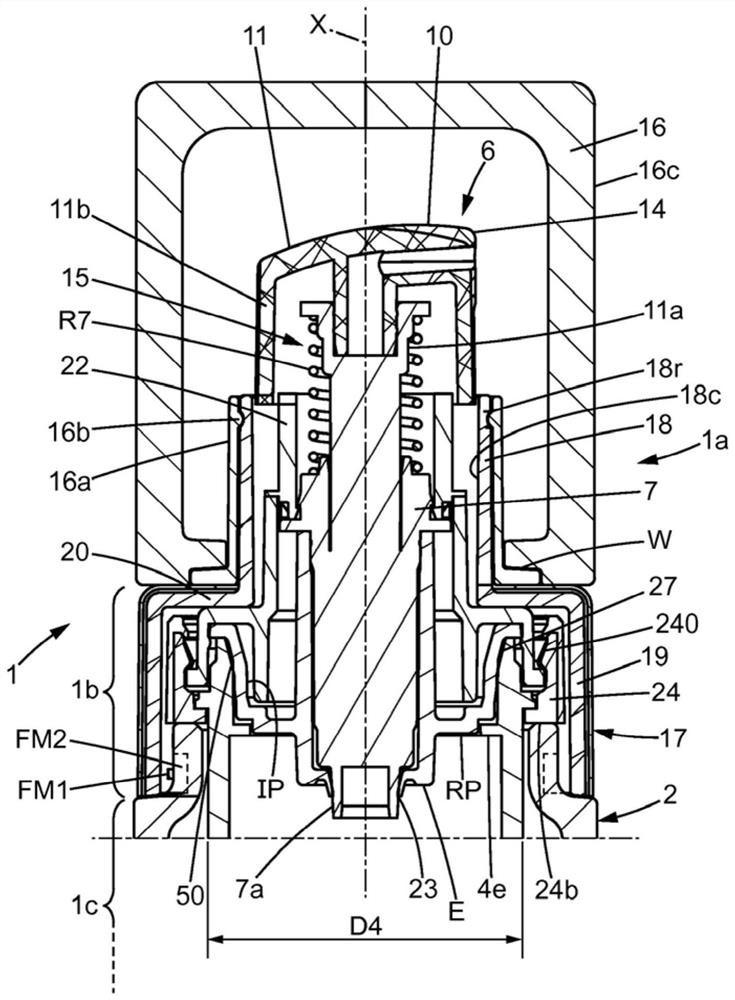

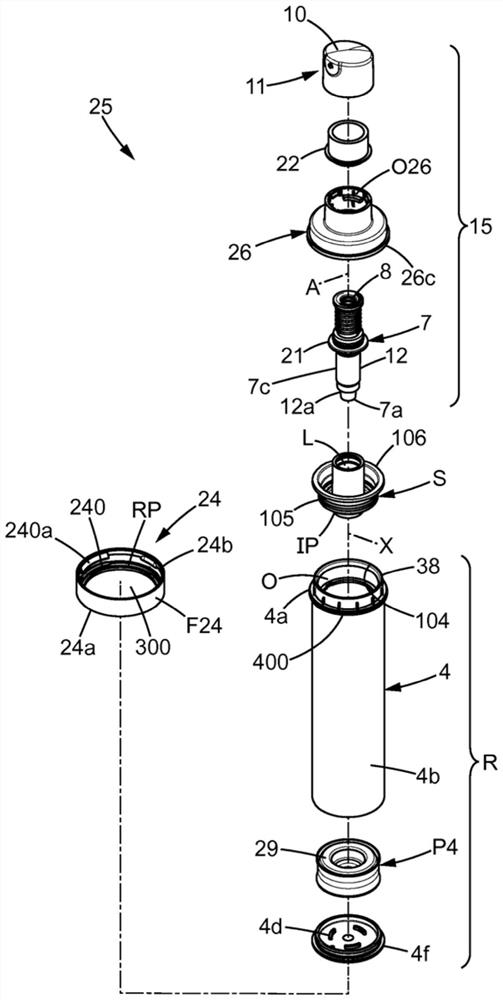

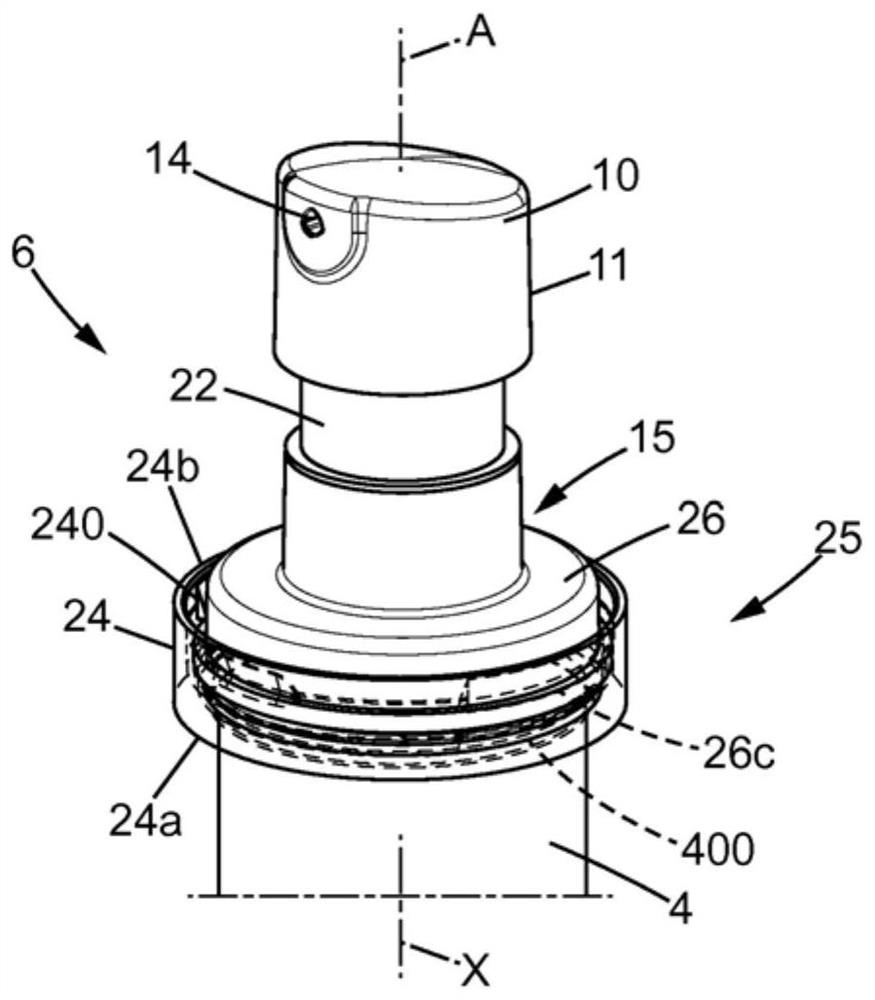

Device for packaging fluid product and dispensing product in doses, including reusable bottle

The invention relates to a device (1) for packaging and dispensing a product, comprising a pre-assembled inner unit (25) to be mounted in a hollow body (2), with a dispensing head (6) which is surrounded by an upper connector (17) that can be attached to the body detachably. The inner unit comprises a reservoir, and the head sealingly closes the opening of the reservoir. A peripheral holder ring (24) of the inner unit holds the reservoir and the head together. The connector (17) connects to the body by means of a locking action achieved by the relative pivoting between the connector (17) and the body (2), without interference with the ring (24). An actuating portion of a dose metering pump of the head is accessible on the top via a duct of the connector, while a tubular outer portion (107) of the connector covers the zone, where it is attached to the body, while axially extending along the outer wall of the body.

Owner:波切特公司

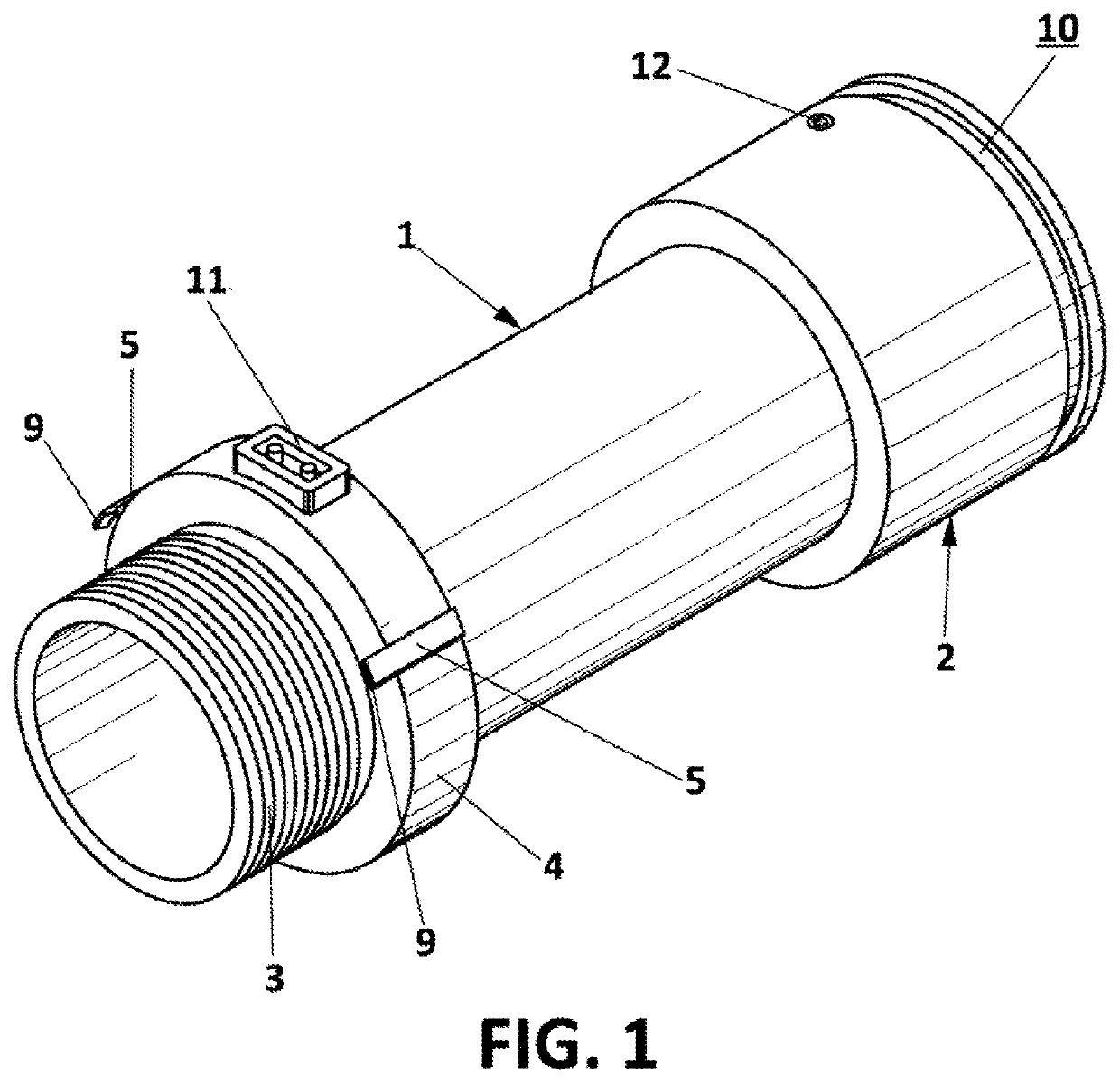

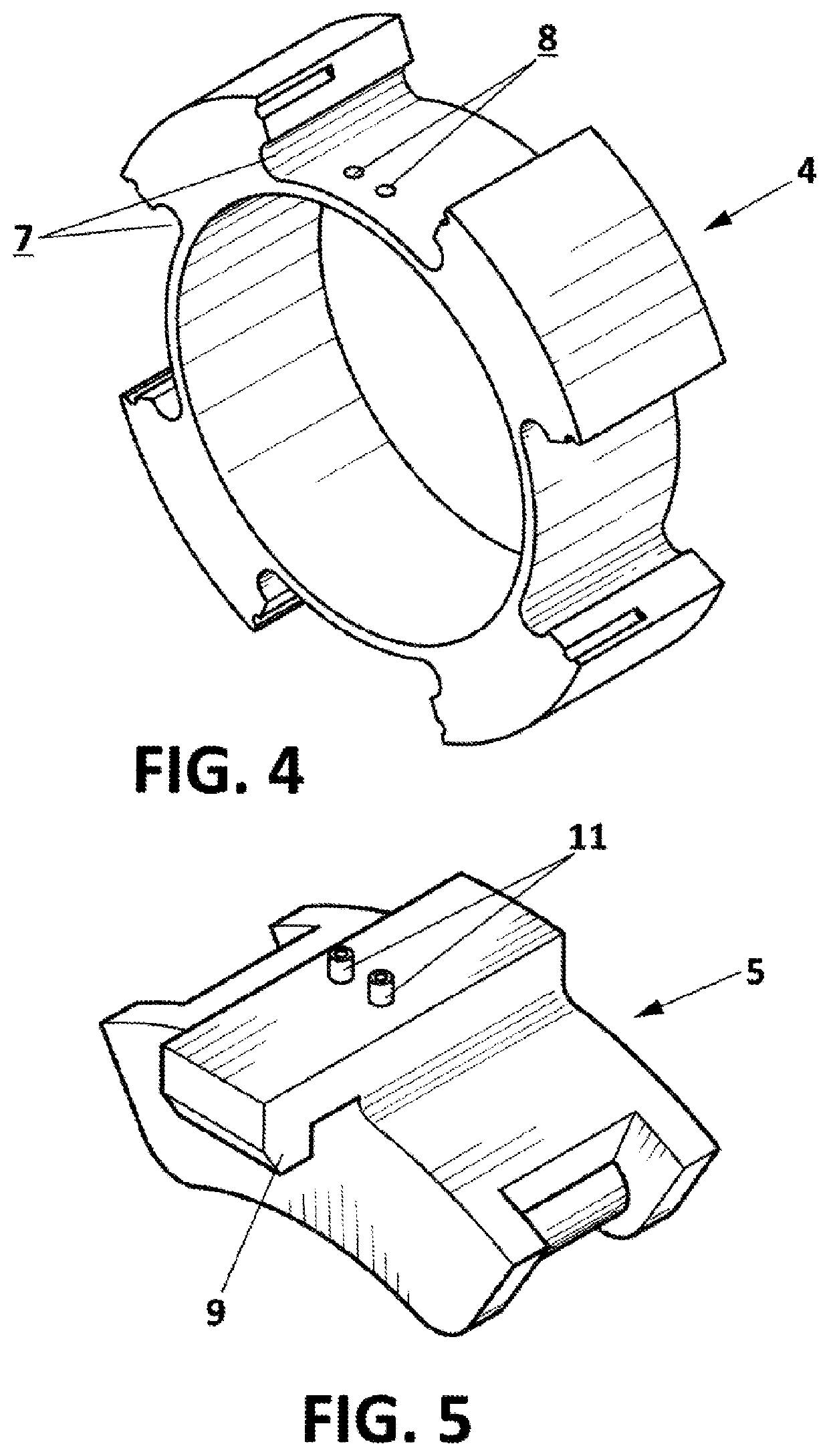

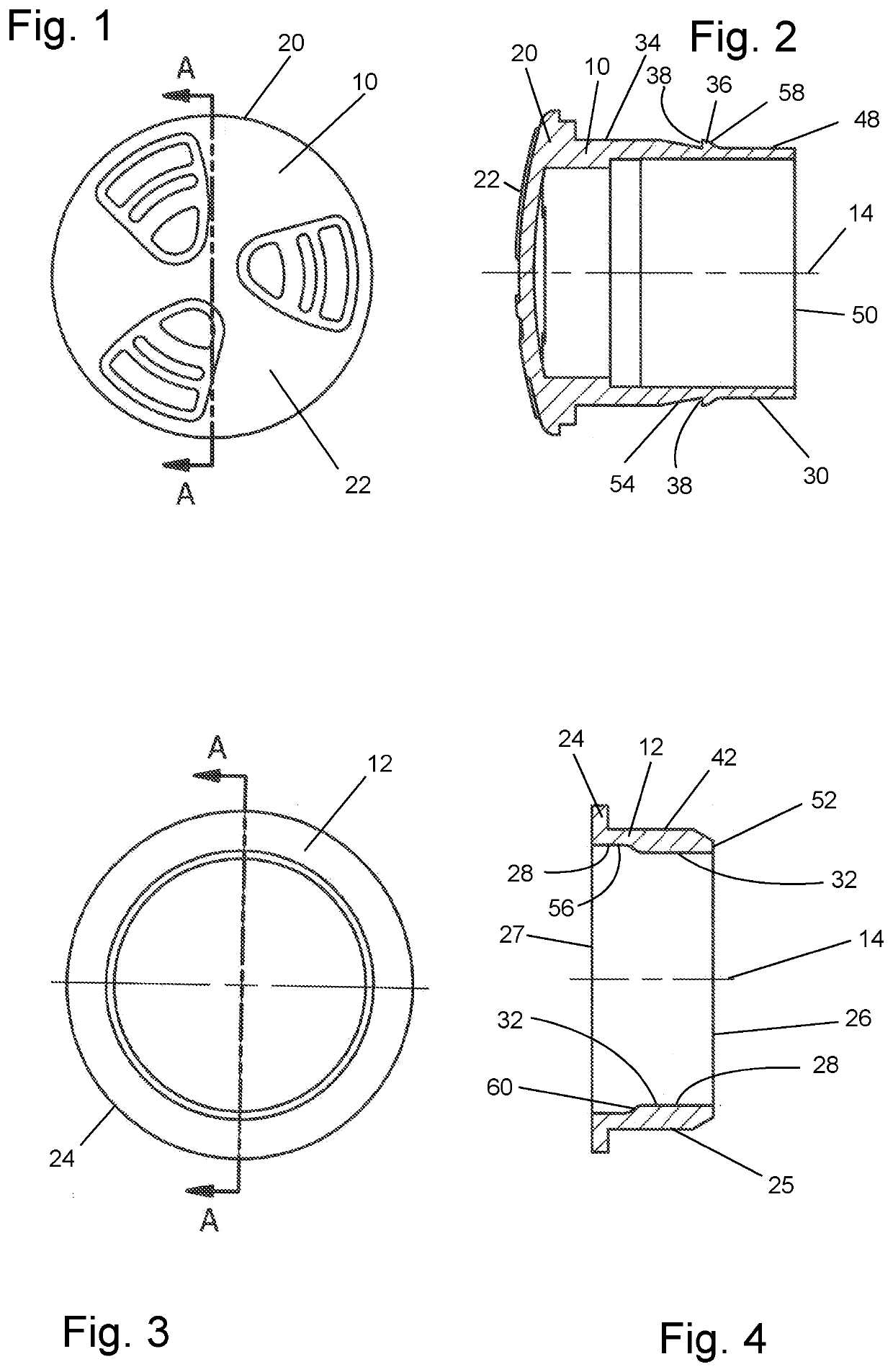

Connection device for pipe elements

ActiveUS11506320B2Easy to adjustGreat pressure and safetyPipe connection arrangementsNon-disconnectible pipe-jointsPipe fittingClassical mechanics

Owner:ABN PIPE SYST

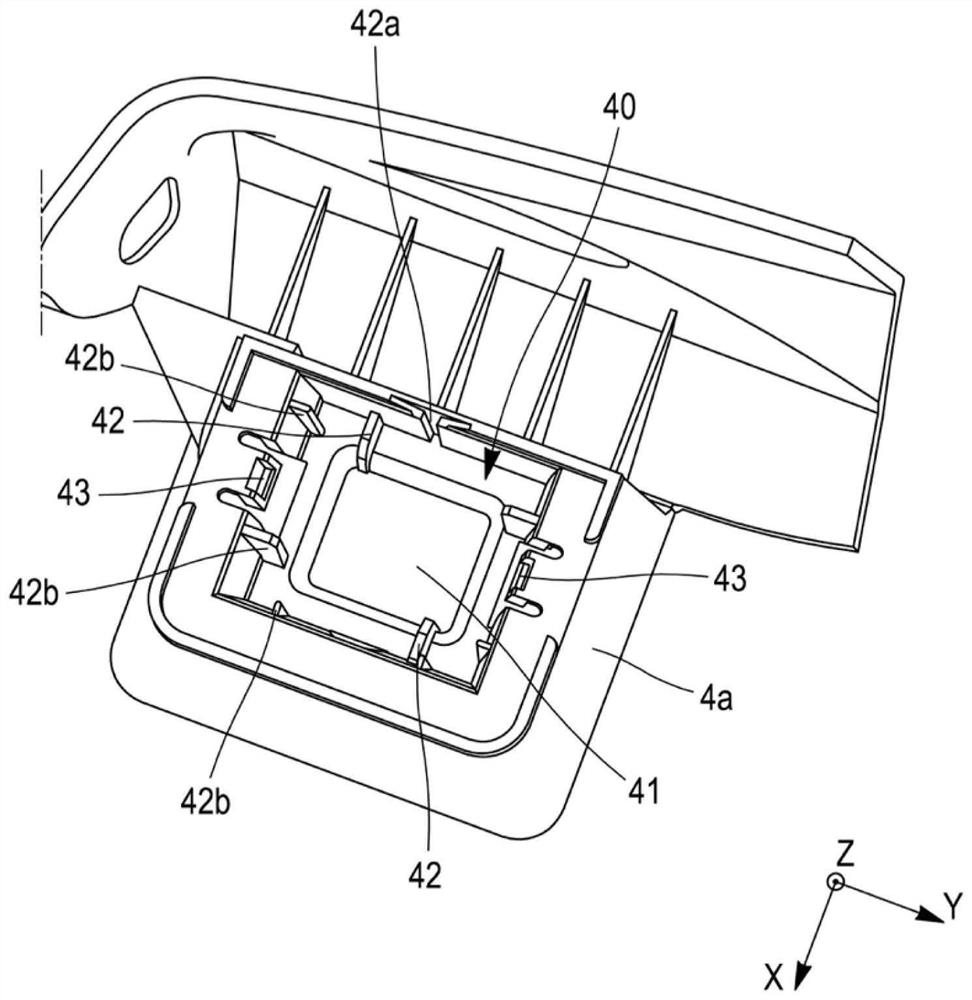

Panel mount for mounting signalling and control devices on control panels

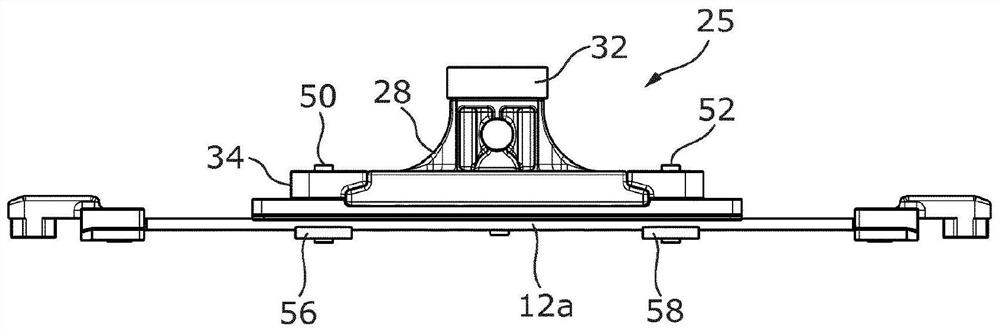

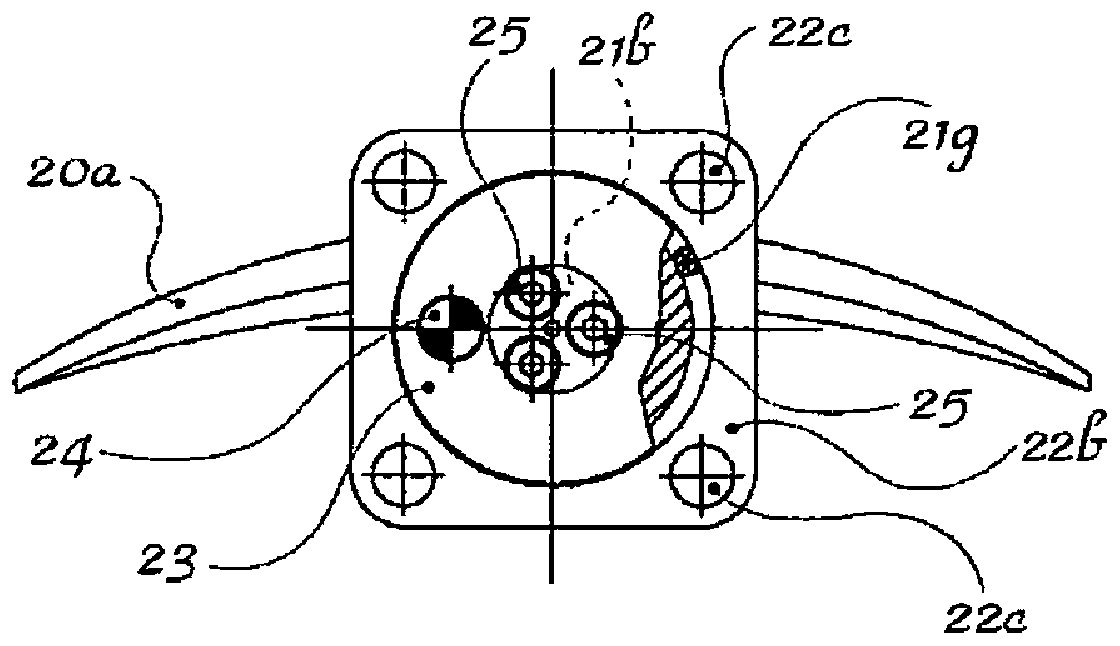

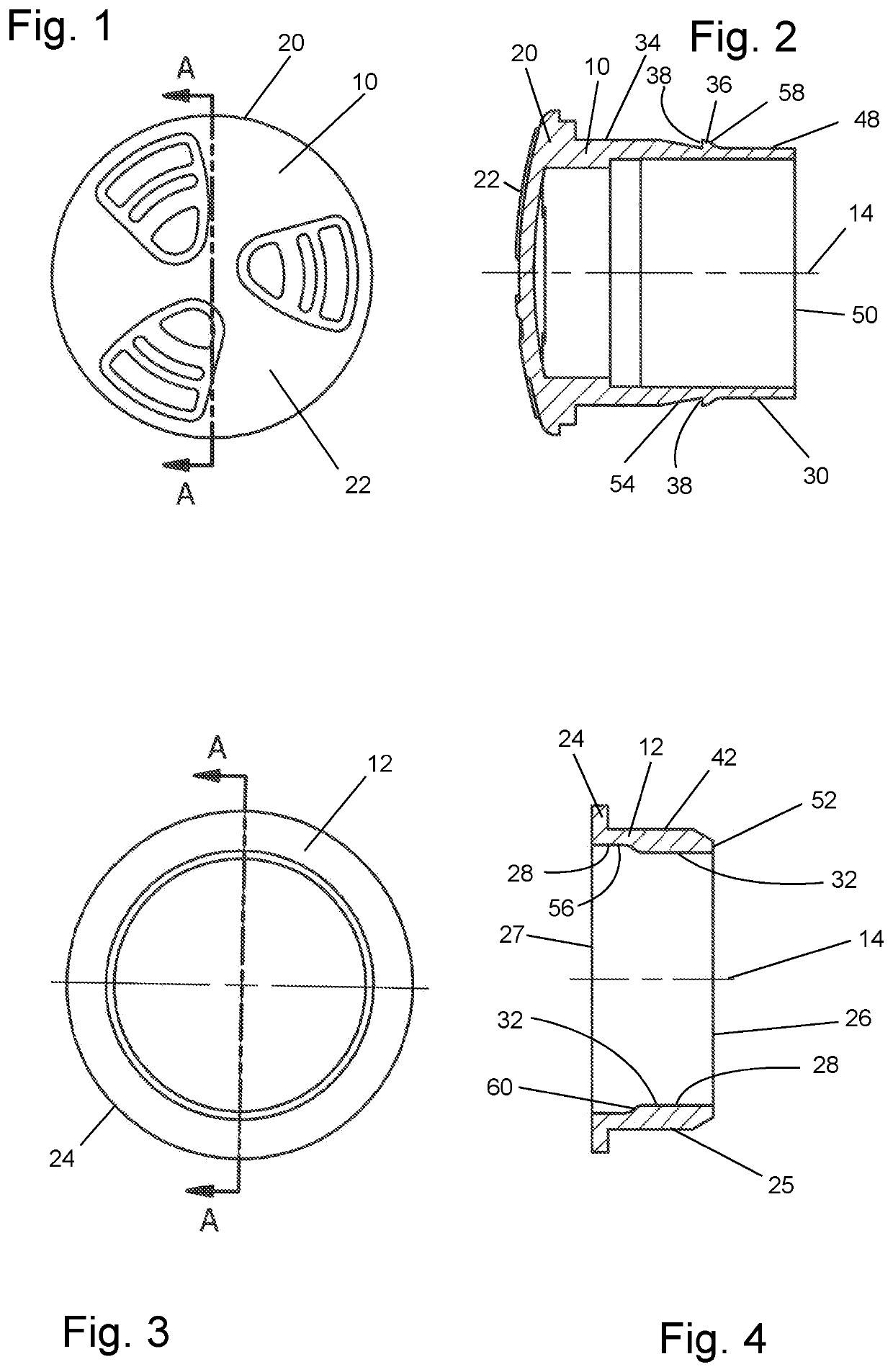

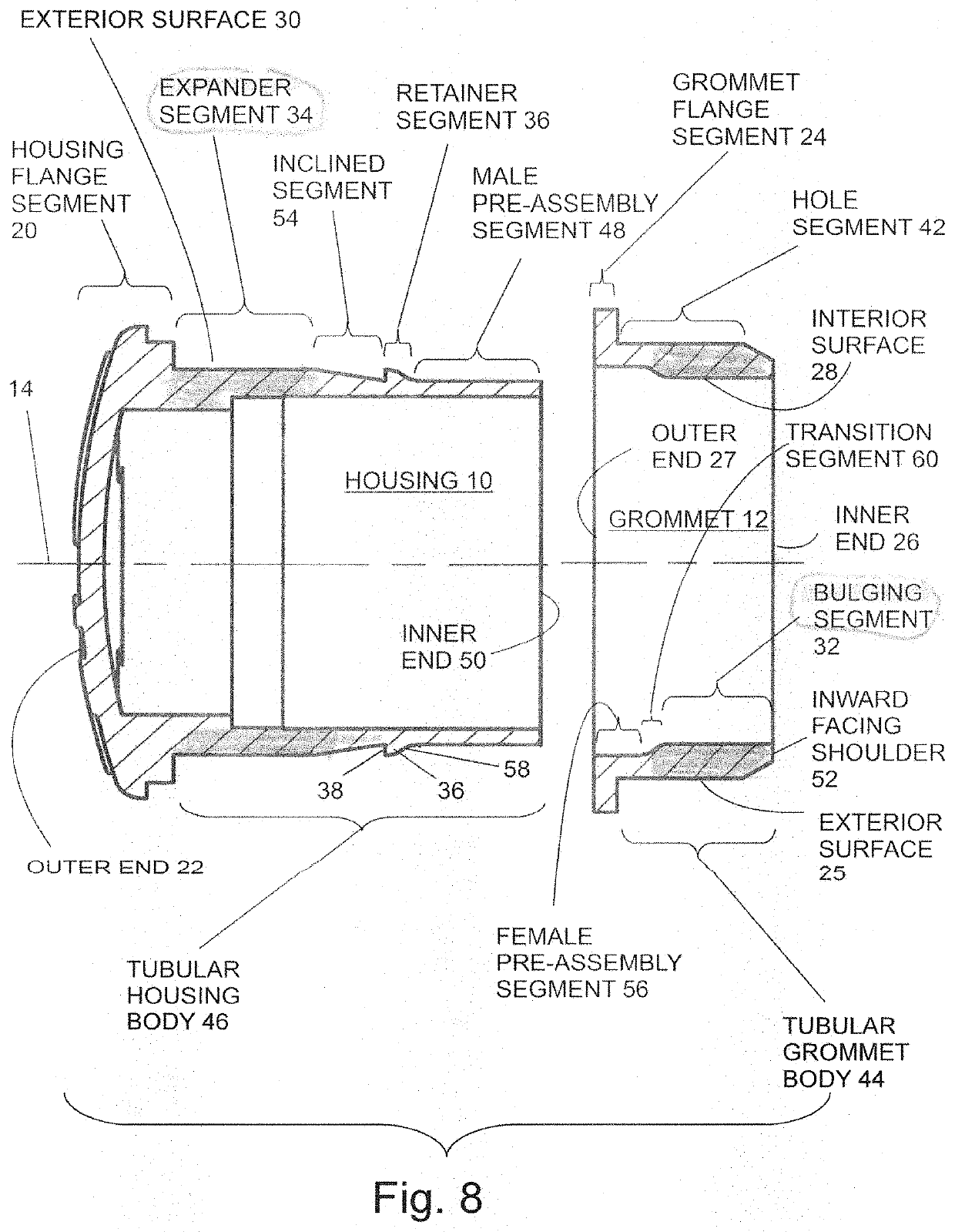

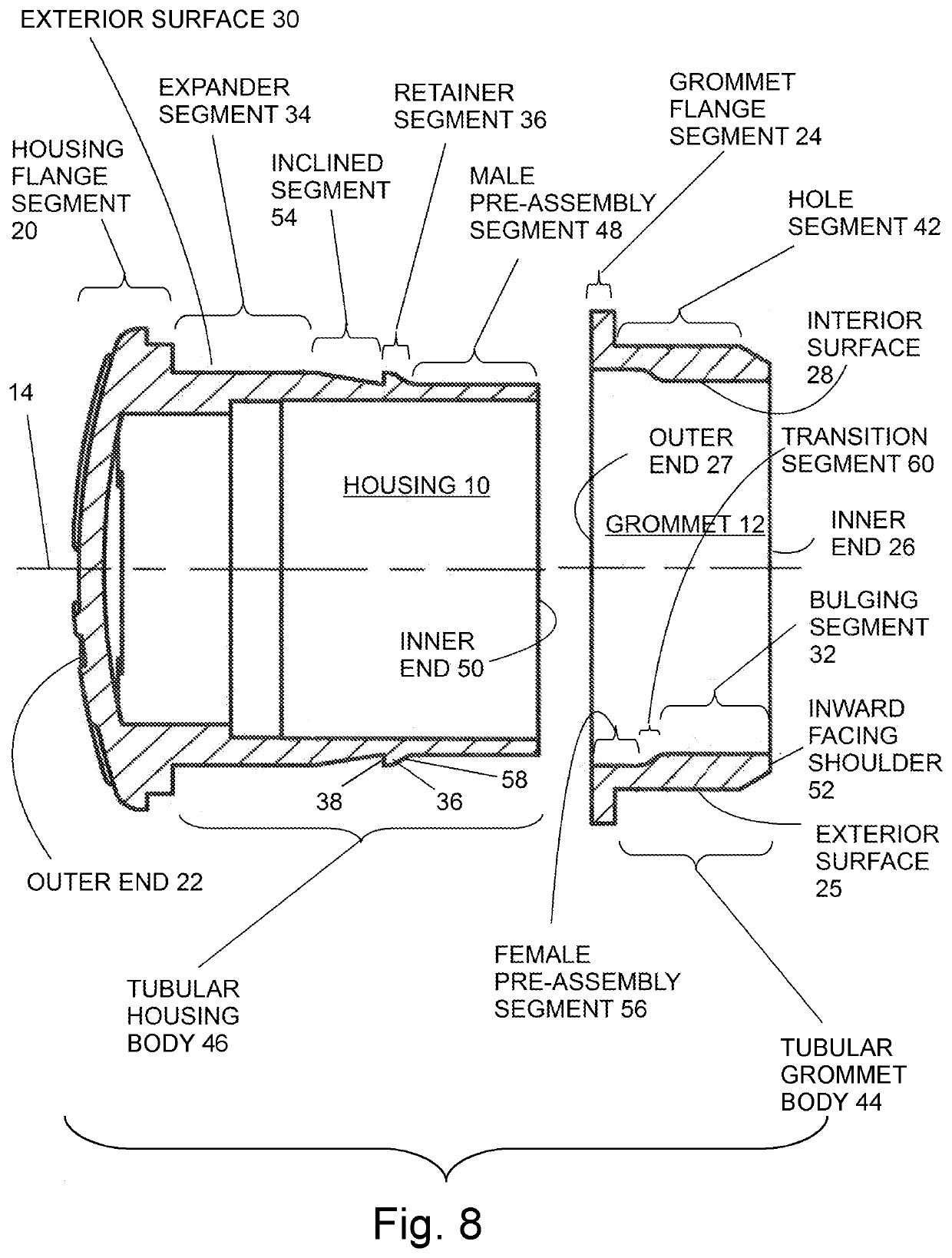

ActiveUS20210305795A1Low costQuickly and easily and completelySubstation/switching arrangement detailsClassical mechanicsGrommet

A panel mount for supporting an electronic device at a hole in a control panel and mountable with access to only the front of the panel. It has a housing that slides into a tubular elastomeric grommet. During installation, an expander segment of the housing slides within a bulging segment of the grommet to expand the grommet inward of the hole and for retaining the components within the hole. A tubular male pre-assembly segment on the exterior surface of the tubular housing permits the housing to be pre-inserted partially into the grommet without expanding any part of the grommet radially outward in preparation for inserting the assembled housing and grommet into the panel hole. A withdrawal lock prevents the housing from sliding axially out of the grommet after installation. The withdrawal lock includes a shoulder formed on the grommet and a shoulder formed on the housing.

Owner:FLOYD BELL

A kind of assembly process of magnetron cathode assembly

ActiveCN112238274BImprove assembly efficiencyImprove yield rateSoldering auxillary devicesEngineeringPre-RC assembly

The invention provides a magnetron cathode assembly assembly process, including the following steps: S1: pre-assembly between pre-assembled parts and molds; S2: welding, demoulding; S3: leak detection; S4: installation of filaments, upper ends cap, and weld and fix the filament and upper end cap; S5: filament carbonization; S6: resistance detection, titanium powder coating; wherein, the pre-installed parts include lower end cap, long lead wire, reflector, K side tube, solder plate, support Body, terminal assembly; the mold includes an upper mold and a lower mold. The upper mold and the lower mold are set so that the cathode assembly will not be deformed during welding, thereby ensuring the structural accuracy of the cathode assembly, and then through the setting of the upper and lower fixtures of the leak detector, the cathode assembly can be inspected When leaking, it has higher sensitivity and detection accuracy. The cathode assembly assembly process formed by the above mold is used to ensure the assembly accuracy of the magnetron cathode assembly and improve the product qualification rate.

Owner:GUANGDONG GALANZ MICROWAVE OVEN & ELECTRICAL APPLIANCES MFG +1

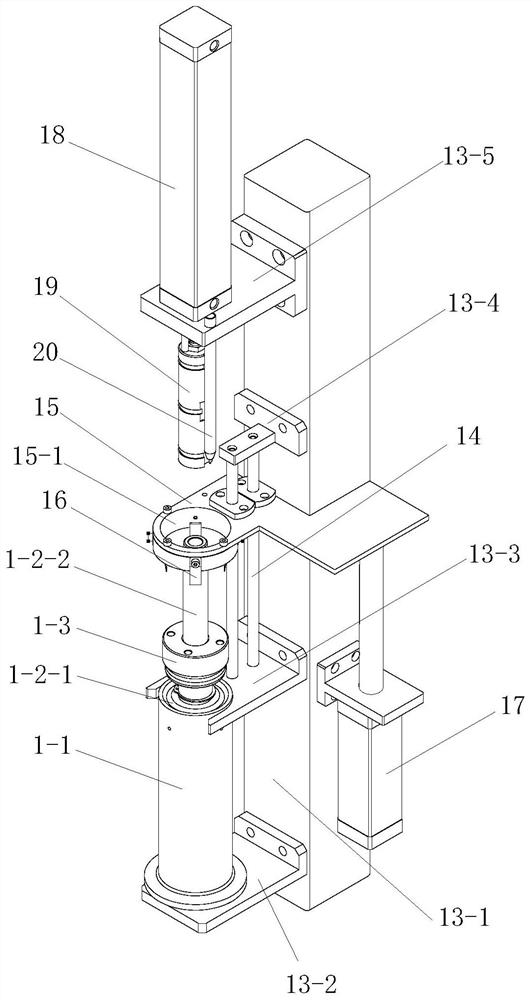

Retarder disassembling and assembling device and method

ActiveCN113459033AImprove the level of indoor maintenanceGuaranteed repair qualityMetal-working hand toolsStructural engineeringPre-RC assembly

The invention discloses a retarder disassembling and assembling device and method. The disassembling and assembling device comprises a split disassembling and assembling mechanism, a pre-assembling mechanism and an overall disassembling and assembling mechanism, wherein the overall disassembling and assembling mechanism comprises a clamp holder, a first support, a sliding support and a screwing assembly; and the pre-assembling mechanism comprises a second support, a guide rod, a positioning plate and a press-fitting assembly. The disassembling and assembling method comprises the following steps of I, disassembly of a retarder: 101, disassembling an oil cylinder body and a piston rod assembly by using the overall disassembling and assembling mechanism; 102, disassembling the piston rod assembly through the split disassembling and assembling mechanism; and II, assembling of the retarder: 201, assembling the piston rod assembly by using the split disassembling and assembling mechanism; 202, pre-assembling the retarder by using the pre-assembling mechanism; and 203, conducting final assembling of the retarder through the overall disassembling and assembling mechanism. According to the retarder disassembling and assembling device and method, the indoor maintenance level of the retarder can be improved, the labor intensity can be greatly reduced, the maintenance quality of the retarder can be ensured, and the equipment quality problem caused by human factors can be avoided.

Owner:XIAN DUOWEI COMM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com