Preassembled blades of a fan for cooling coolant in a machine/vehicle and a fan provided with said blades

A cooling fan, pre-assembled technology, applied in the field of fan blades, can solve the problems of oscillation, undesired blades, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

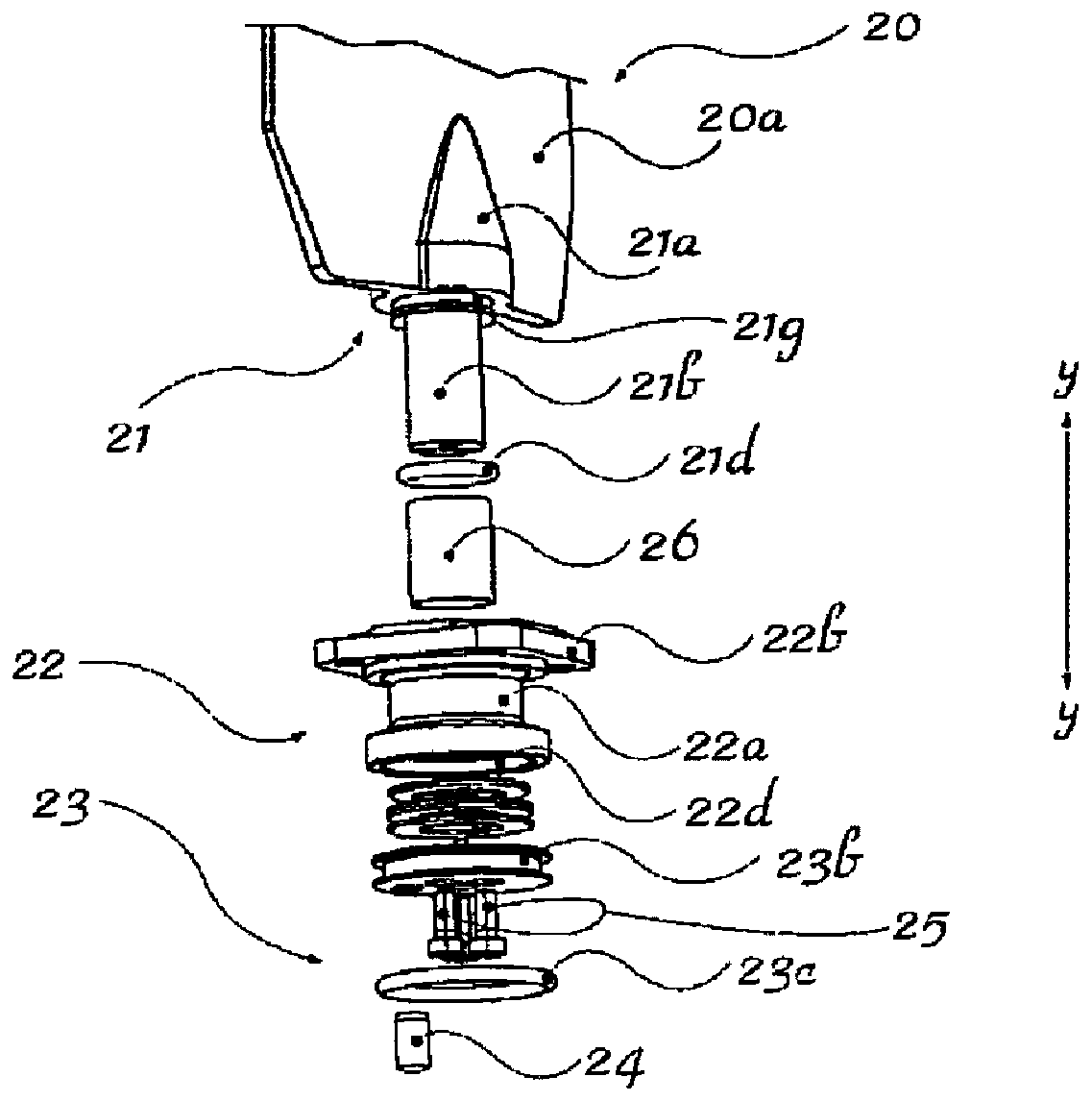

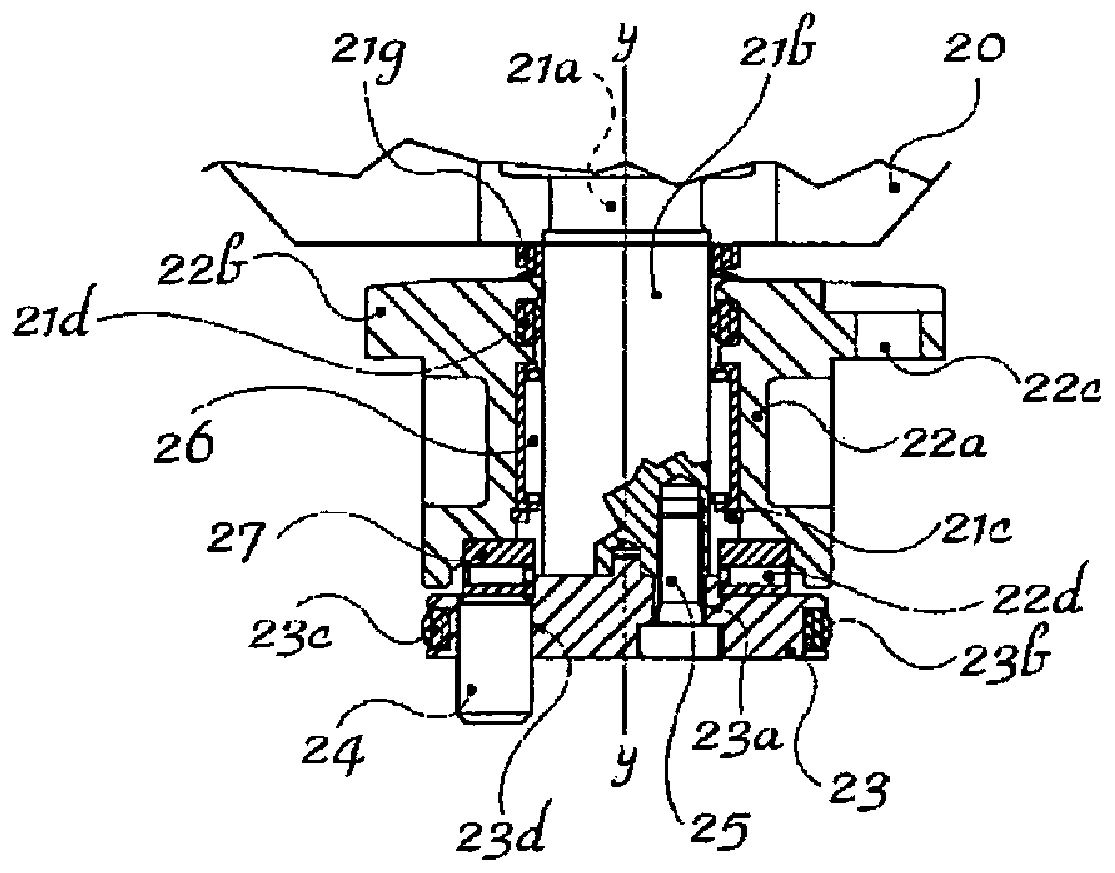

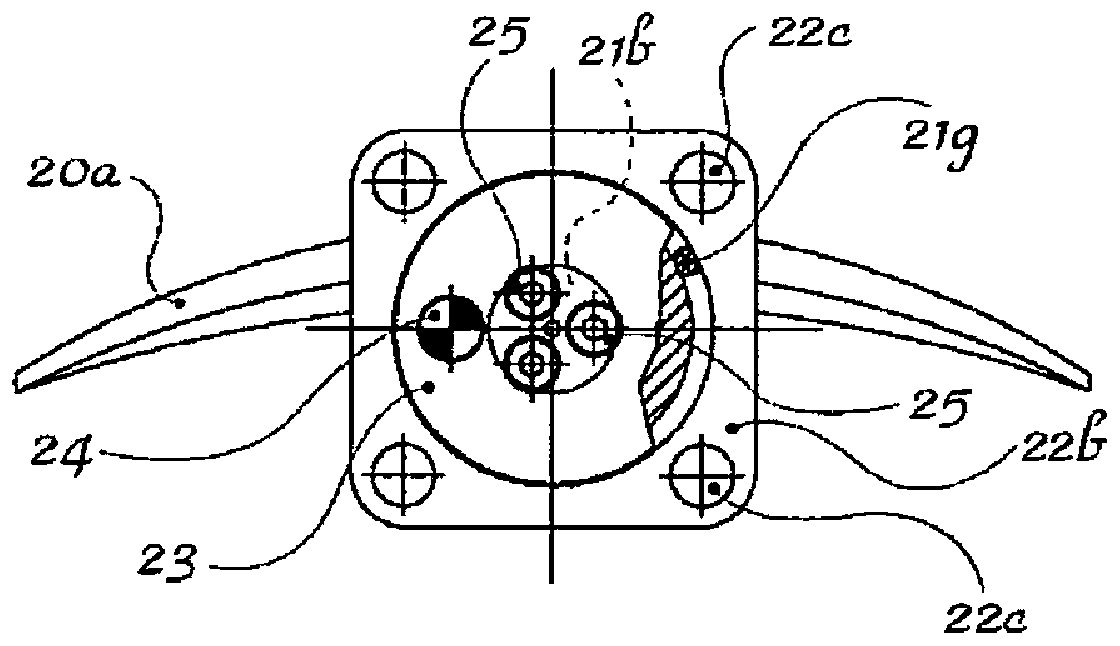

[0037] Such as figure 1 As shown, for ease of description and without limitation, a longitudinal axis X-X (corresponding to the axis of rotation of the fan 10) and a radially transverse axis Y-Y are assumed and—cf. Figure 6 Arrow "A" in the vehicle indicates the direction of travel of the vehicle - the front (corresponding to the position of the radiator 1) and the rear (corresponding to the position of the heat engine 2 of the vehicle), the fan 10 is arranged behind the radiator 1 and the engine 2 and the fan comprises a hub 111 which is preferably closed at the front by a cover portion 111b.

[0038] The hub 111 is locked axially to a pulley 3 for driving the fan in rotation, which pulley is connected to the shaft of the heat engine 2 by a suitable driven belt 3a.

[0039]The pulley 3 is mounted on a pair of bearings 3b, 3c which are keyed to a fixed support element which in the example described comprises a tubular sleeve 5 passed through Fixed to the base of the engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com