Electric multiple unit chassis equipment pre-assembly tool and method

A technology of EMUs and pre-assembly, which is applied in the direction of manufacturing tools, workpiece clamping devices, hand-held tools, etc., and can solve the problems of large footprint of pre-assembly tooling, heavy workload of car model conversion accessories, and high work efficiency. To achieve the effect of facilitating the layout of production stations, improving the effective utilization rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

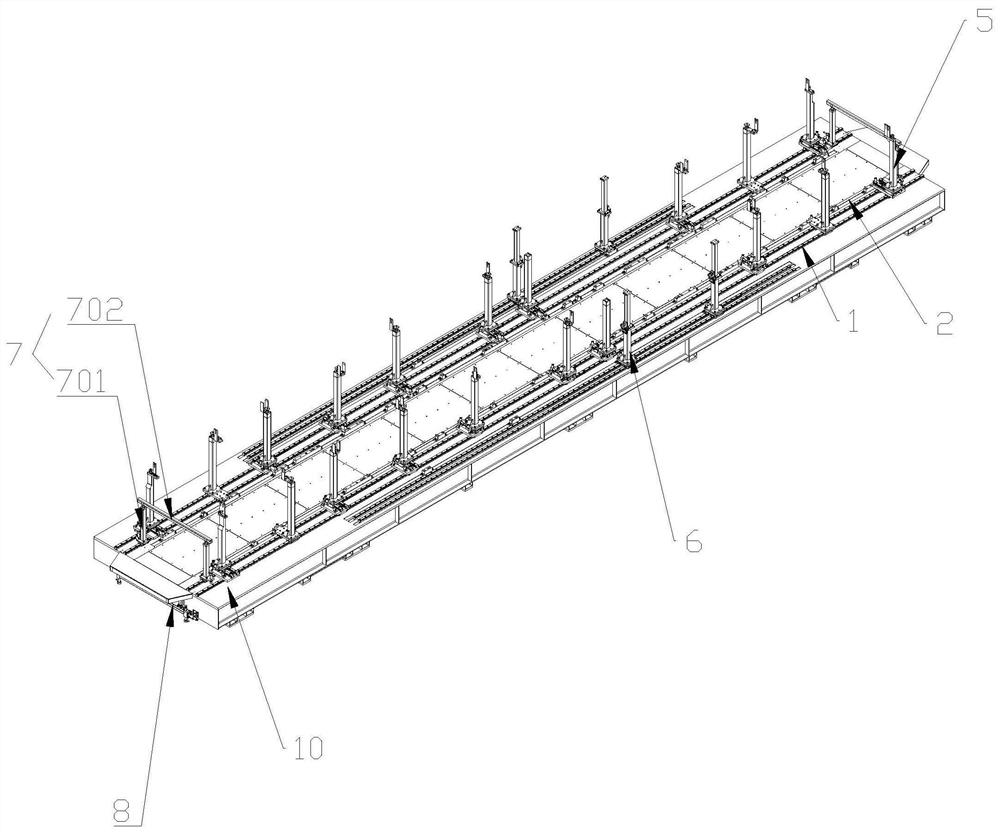

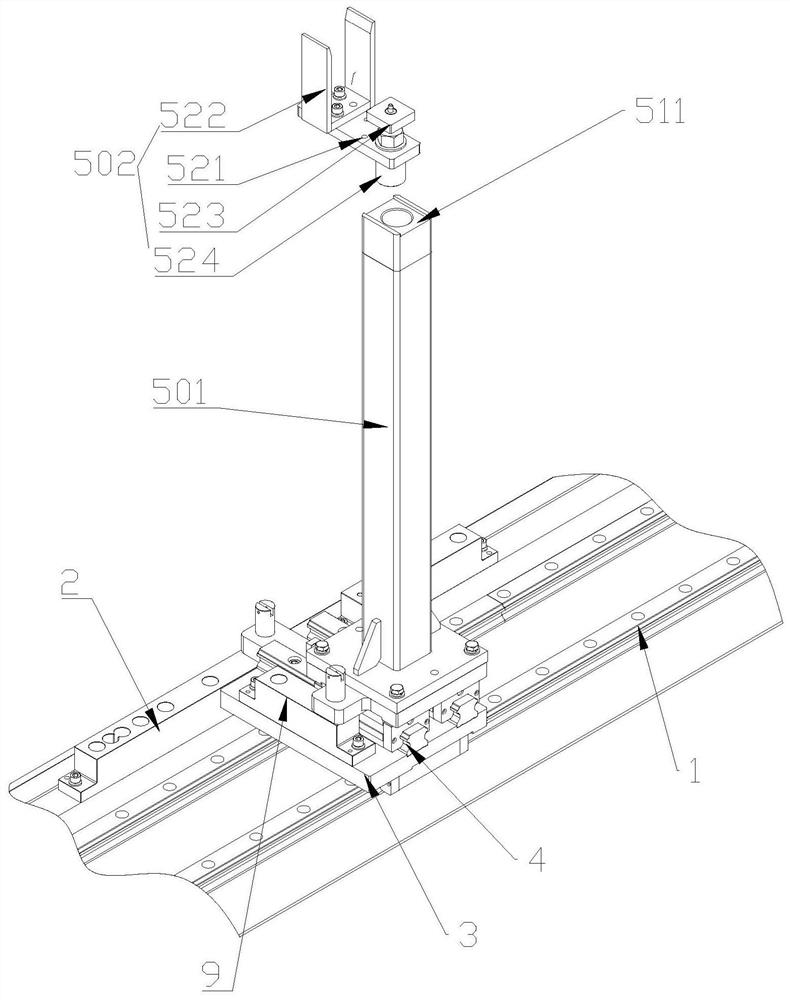

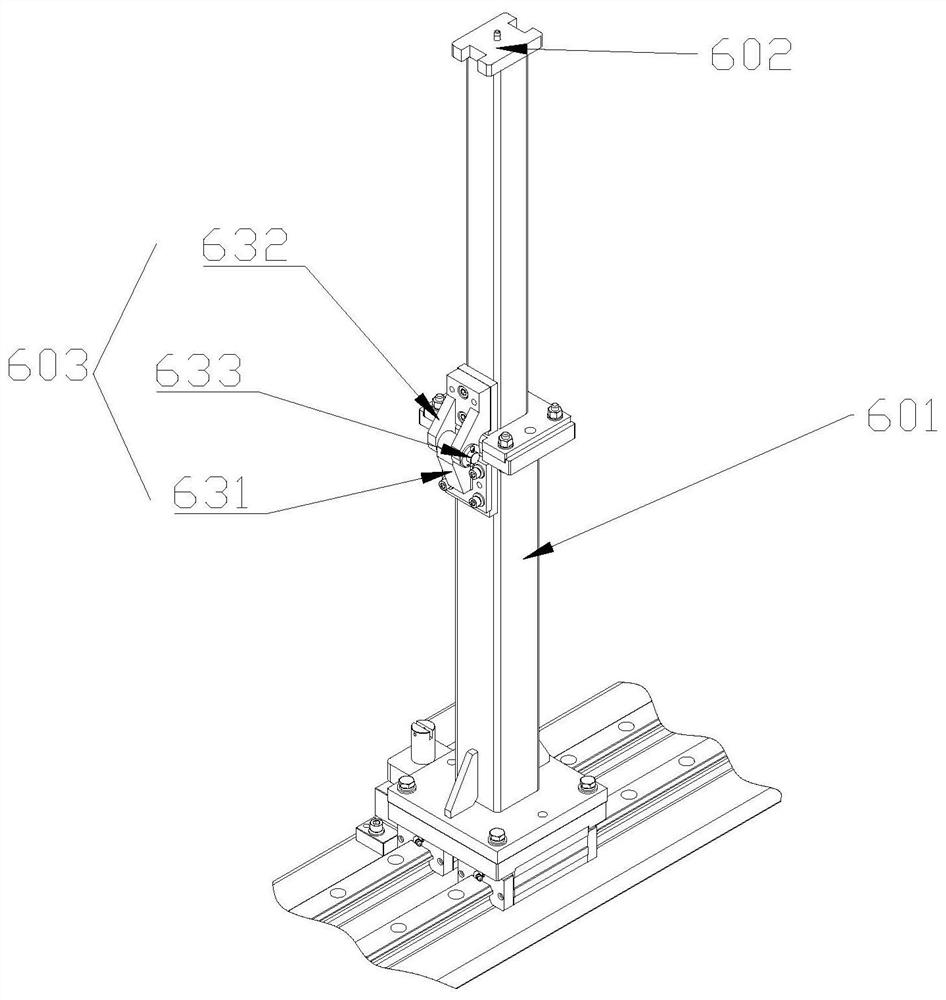

[0034] Such as Figure 1-Figure 6 As shown, a pre-assembly tooling for the underframe equipment of an electric train unit includes a rigid platform 10, a plurality of longitudinal linear slide rails 1 arranged in parallel on the rigid platform 10, a first positioning mechanism 5 and a first positioning mechanism 5 for moving along the longitudinal linear slide rails 1 Two positioning mechanisms 6, one side of the longitudinal linear slide rail 1 is provided with a plurality of longitudinal positioning blocks 2, the two ends of the longitudinal linear slide rail 1 are provided with a third positioning mechanism 7, and one end of the rigid platform 10 is also provided with a fine-tuning mechanism 8.

[0035] A longitudinal connection plate 3 moving along the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com