A sealing method of flat vacuum glass

A technology for vacuum glass and flat glass, applied in the field of flat vacuum glass sealing, can solve the problems of low yield, many types of equipment, structural failure, etc., to achieve high yield, improve production efficiency, and avoid stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

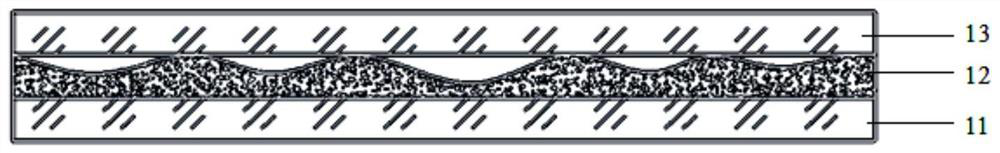

[0081] Use 3mm thick float sodium calcium glass as the glass substrate; use tinned copper strip as the sealing metal material, its width is 5mm, thickness is 0.4mm, coating thickness is 40μm, and the specific tinning material is SnAg3.5; The high-temperature sintering type connecting silver paste is a metallized layer, which is applied to the sealing position by screen printing, and fixed by sintering at 700°C for 60s (with glass tempering) to form a metallized layer with a thickness of 20 μm and a width of 6 mm; 304 stainless steel is turned into 0.4mm high, 0.8mm diameter non-chamfered cylinders as support columns, and arranged into a matrix with a spacing of 40mm by automatic machinery.

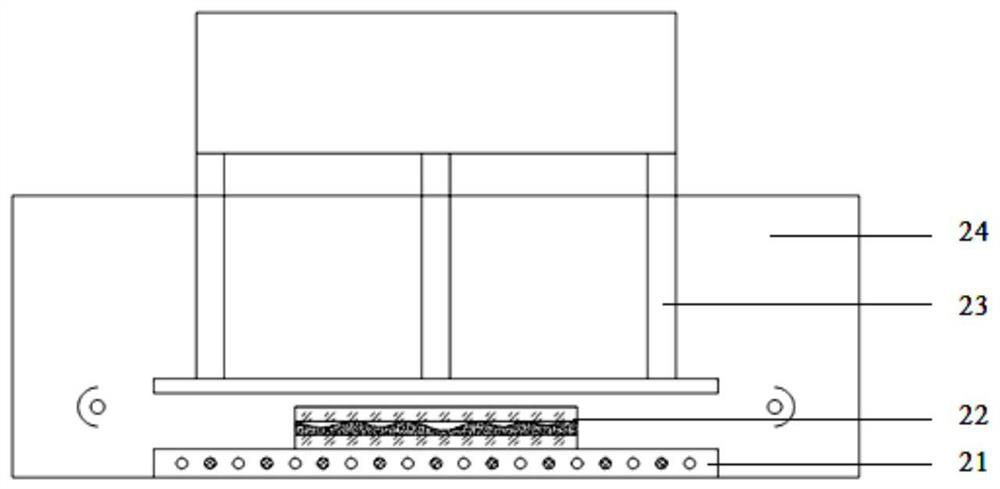

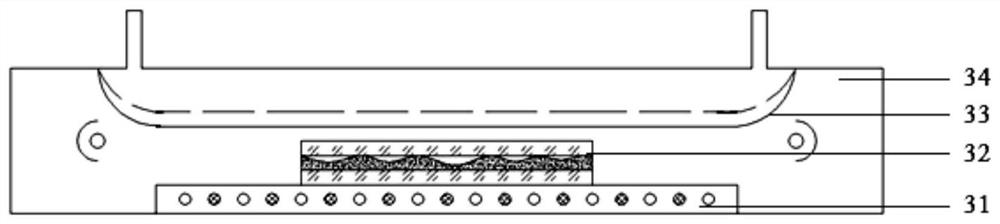

[0082] Then carry out manual pre-assembly, and the wavy tinned copper strips formed by assembly have a gap of no more than 0.05mm and are randomly arranged. It is then sent into a vacuum processing chamber that is compressed with air bags. The vacuum chamber is made of 304 stainless steel...

Embodiment 2

[0086] Use 5mm thick float soda lime glass as the glass substrate; use tin-lead (SnPb40Ag1) metal material to make high-density square frame preforms with a width of 4mm and a thickness of 0.5mm; use high-temperature sintered silver-containing paste Material (for the metallization layer, applied to the sealing position by screen printing to form a wet film with a width of 6mm and a thickness of 20 microns, and dried at 150°C for 10 minutes, then sintered at 700°C for 3 minutes (with glass tempering) Fixed to form a metallized layer with a thickness of 14 μm and a width of 6 mm; 304 stainless steel is used to turn and process a non-chamfered cylinder with a height of 0.4 mm and a diameter of 0.8 mm as a supporting column, and arrange it into a matrix with a spacing of 40 mm by automatic machinery.

[0087] Then pre-assembled to form a structure of glass-metallized layer-pre-assembled part-metalized layer-glass to ensure the flatness of the pre-assembled part, and set a horizonta...

Embodiment 3

[0091] Use 5mm thick float soda lime glass as the glass substrate; use low melting point glass powder (85wt%) to mix terpineol (14.5wt%) and ethyl cellulose (0.5wt%) to make a viscous slurry through a three-roll mill material. Apply the paste to the sealing area around the glass plate to form a wet film with a width of 6mm and a thickness of 0.6mm. Then, 304 stainless steel was turned into a non-chamfered cylinder with a height of 0.4mm and a diameter of 0.8mm as a support column, which was arranged into a matrix with a pitch of 40mm by automatic machinery, and the upper cover glass was aligned and combined.

[0092] Set horizontal limit fixtures on the outside of the combined glass to avoid glass movement caused by air flow during the vacuuming process. It is then sent into a vacuum processing chamber that is compressed with air bags. The vacuum chamber is made of 304 stainless steel, equipped with a mechanical pump and a molecular pump unit for vacuuming, and the ultimate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com