Pre-assembled pulley device with elastic ring and method of installing same

An elastic ring and pulley technology, applied in shaft installation, hoisting device, bearing assembly, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

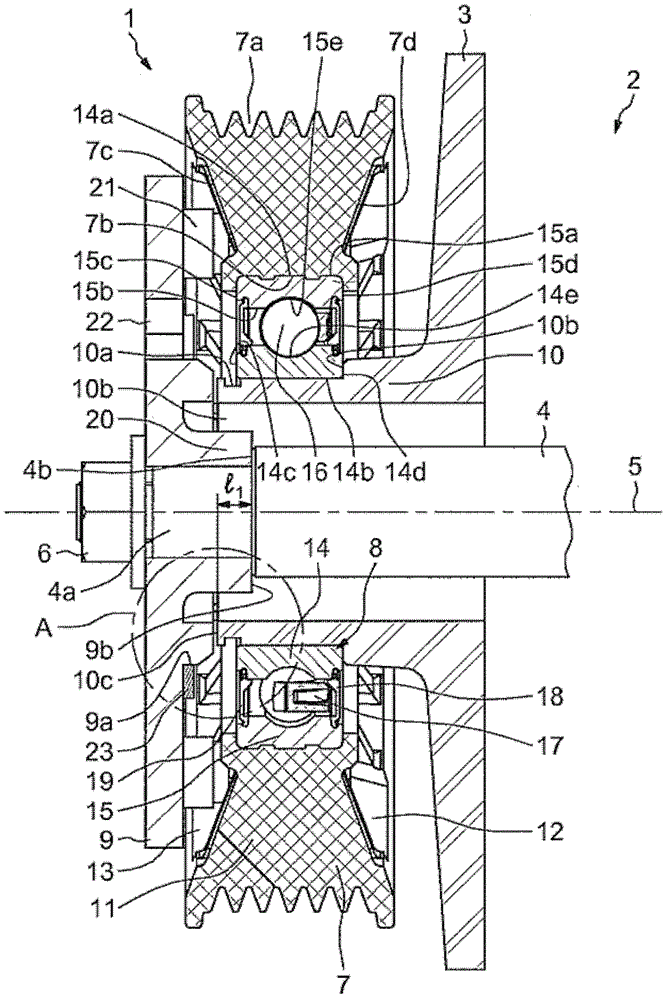

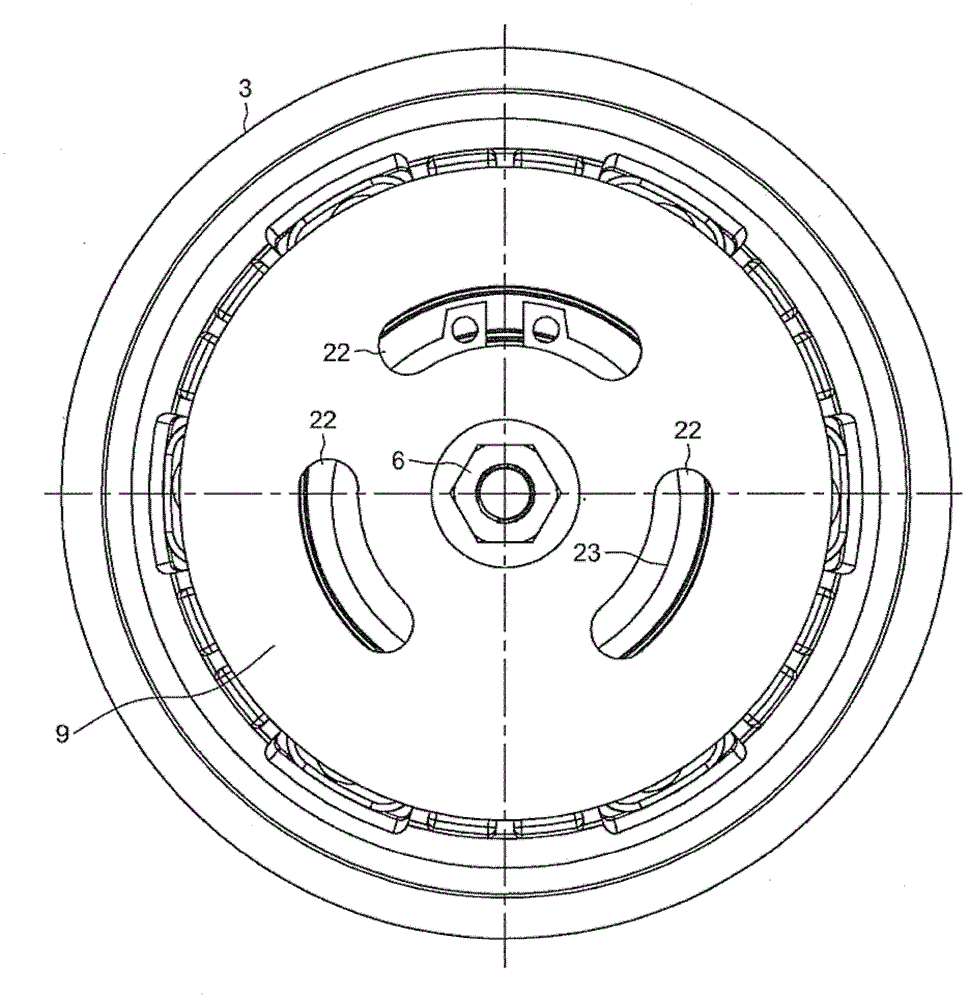

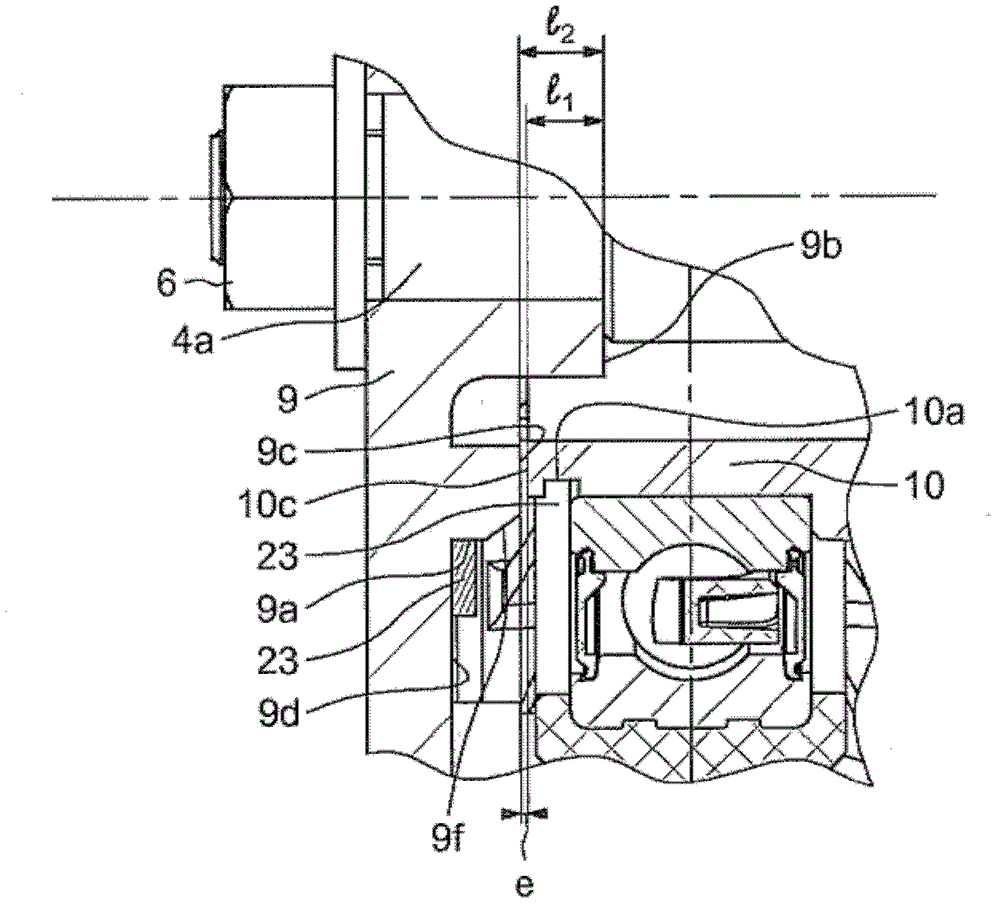

[0027] exist figure 1 and 2 In it, a pulley arrangement 1 is mounted on a compressor 2 comprising a non-rotating housing or shell 3 and a transfer spindle 4 rotatable about an axis 5 . The transfer mandrel 4 may be provided with a stepped end 4 a ending in a threaded portion so that it can interact with the nut 6 . This stepped end 4a, which is smaller in cross-section than the rest of the mandrel 4, is delimited by a shoulder 4b. The transfer mandrel 4 passes through the hollow shaft 10 of the housing coaxially with the transfer mandrel 4 . The shaft 10 of the housing has a radial end face 10c and a circumferential outer groove 10a adjacent to this end face 10c, that is to say the groove has an axial width greater than or equal to the distance between the end face 10c and the nearest edge of the groove 10a. The axial distance between the radial end face 10c of the shaft of the housing and the shoulder 4b of the mandrel 4 represents the algebraic distance l 1 ,Such as fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com