Fixture, component with fixture and method of pre-assembling fixture

A fixing device and fixing part technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of increasing pre-assembly time, pre-assembly workload, and increasing component costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

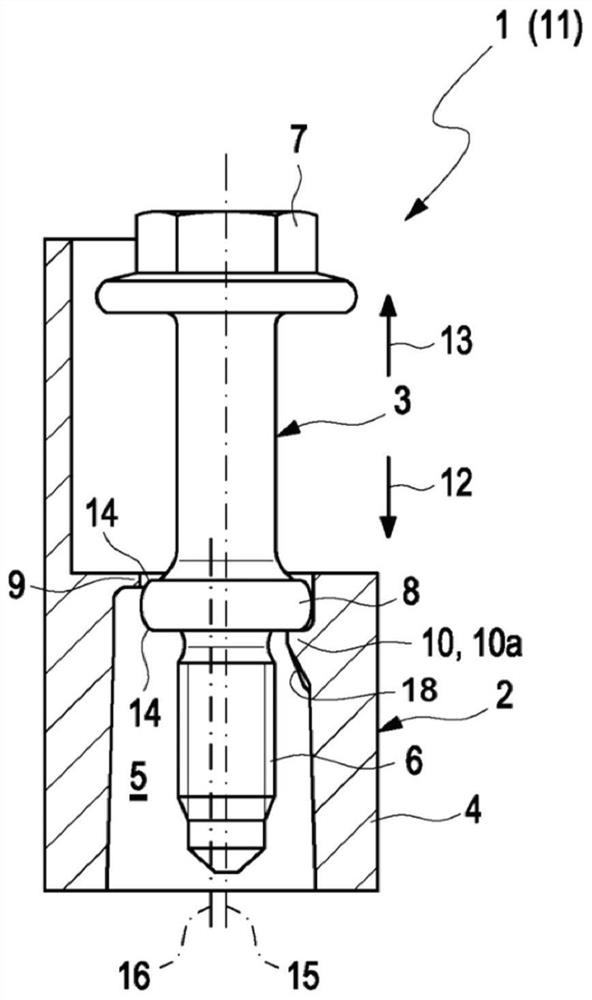

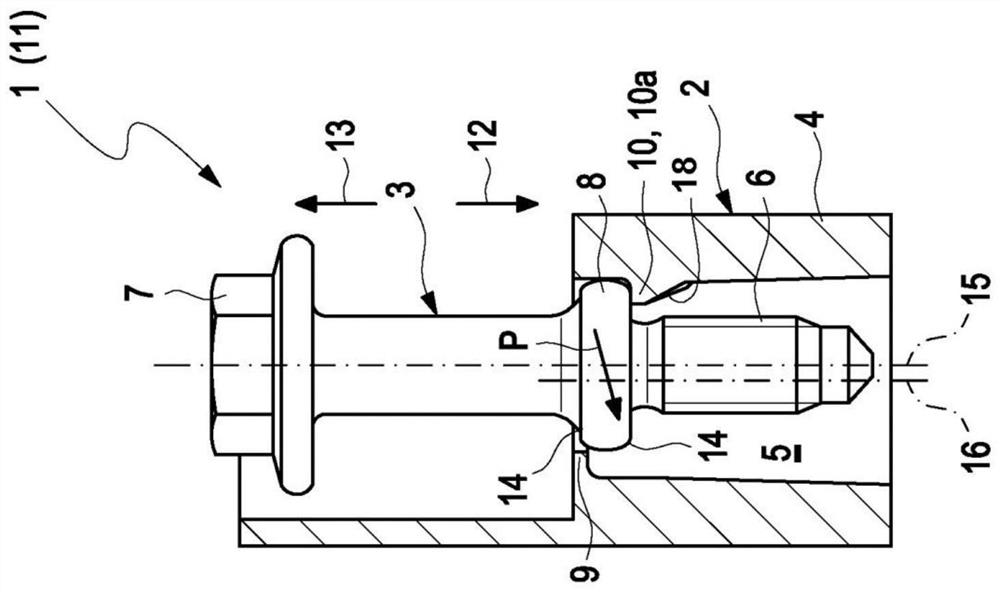

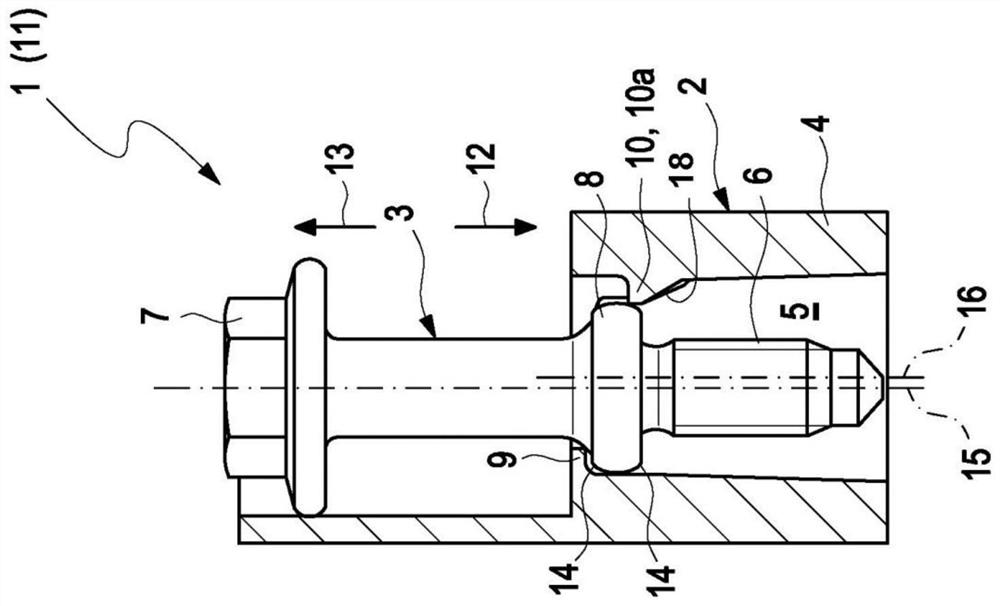

[0024] Figure 1 to 4 A cross-sectional view of the fixing device 1 in accordance with the present invention is shown. The fixing device 1 is provided as securing the member 2 to a pairing member - not shown here. The fixing device 1 thus includes a fixing portion 4 having a ring bolt 3 and a member 2. A through hole 5 is formed in the fixing portion 4, and a ring bolt 3 is arranged in the through hole. Belt bolt 3 thus has a thread 6 (shown in this only), the bolt head 7 and the circumferential collar 8 formed thereon. An inner radial stop protrusion 9 and an internal radial clamp projection 10 are formed in the through hole 5. The clamping projection 10 is positioned relative to the stop projection 9, and offset from the stop projection 9 in the axial direction.

[0025] The fixing device 1 is pre-assembled in accordance with the method 11 according to the present invention. according to figure 1 First, the bond bolt 3 is inserted into the through hole 5 of the fixing portion 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com