Pre-assembled fitting group and fitting assembly for a window or a door

A technology of pre-assembly and accessories, which is applied in door/window accessories, wing leaf suspension devices, wing leaf parts, etc., can solve the problems of increased workload and cost, high cost of assembly work, and difficulty in moving accessories, etc., to achieve reduction The effect of work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

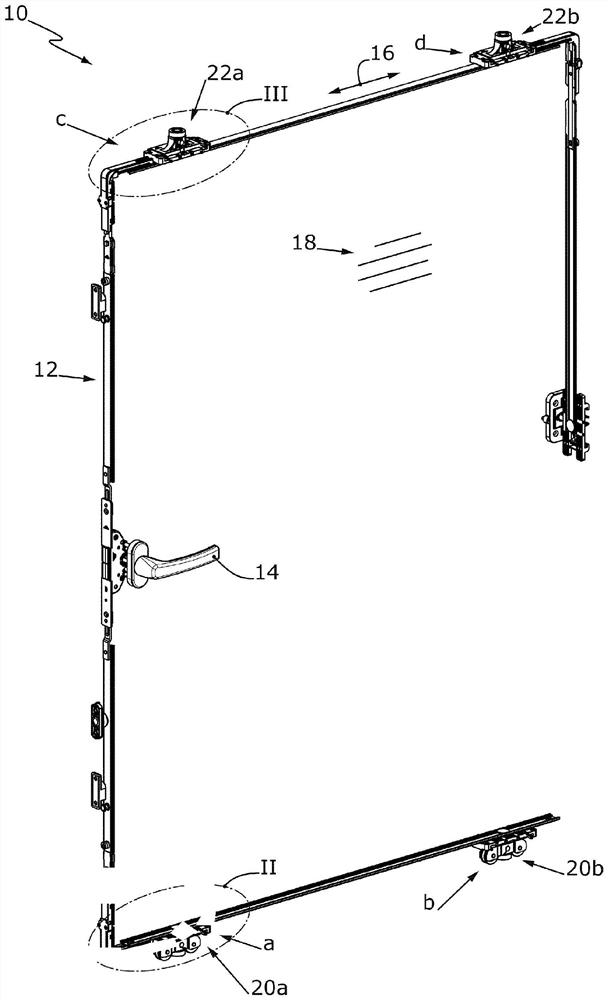

[0043] figure 1 There is shown a fitting assembly 10 , shown as a shifting assembly, having an actuation mechanism 12 designed as a circumferential drive rod fitting operable via an actuation handle 14 . Actuating mechanism 12 is attached to Figure 8 with 9 (a) window or door as shown, and extends circumferentially 16 along the slot. Groove circumferentially 16 in the main plane 18 of the window or door (only in figure 1 shown in ) extended. In the illustrated embodiment, the displacement assembly 10 has two points a, b with roller assemblies 20a, 20b and two points c, d with support assemblies 22a, 22b, wherein the rollers The sub-assemblies 20a, 20b and the support assemblies 22a, 22b, respectively, are laterally displaceable relative to the slot circumference 16. As shown in FIG.

[0044] Also visible on the right side upright is a locking assembly whose locking elements are also displaceable laterally relative to the groove circumference.

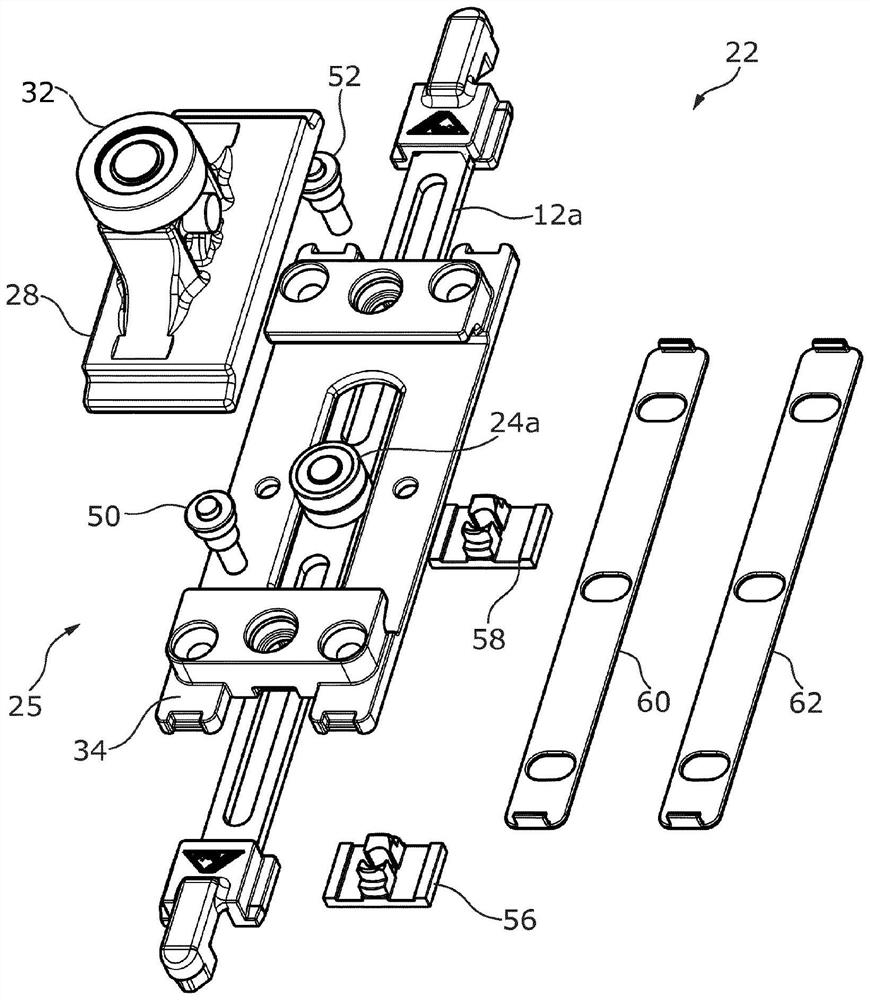

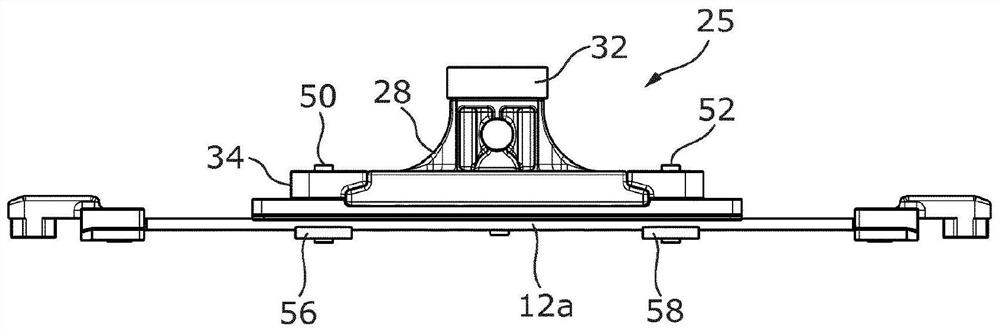

[0045] figure 2 shows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com