Fastening device, component comprising fastening device, and method for pre-assembling fastening device

A fixing device and fixing part technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of increasing pre-assembly time, pre-assembly workload, and increasing component costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

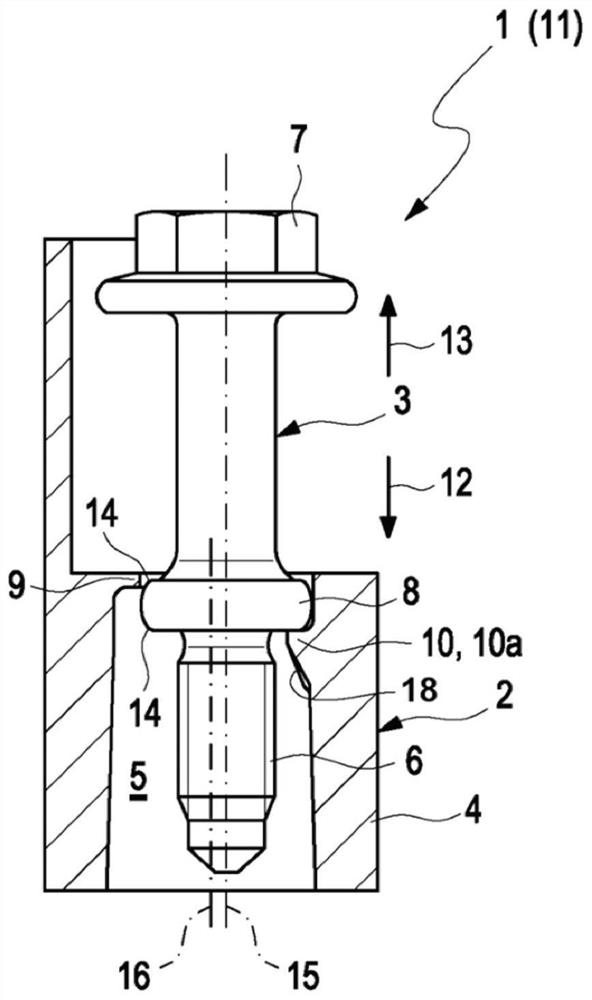

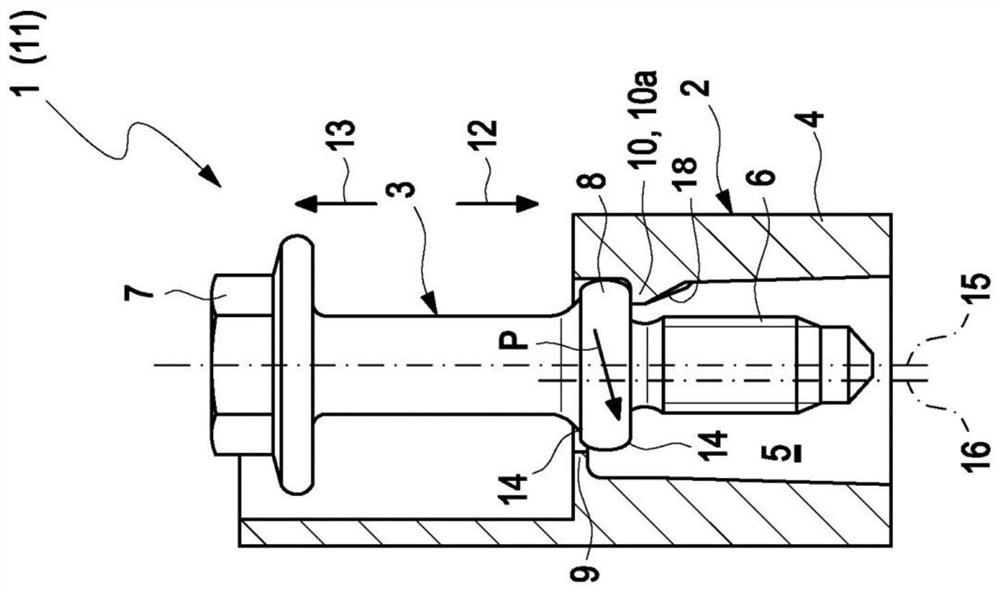

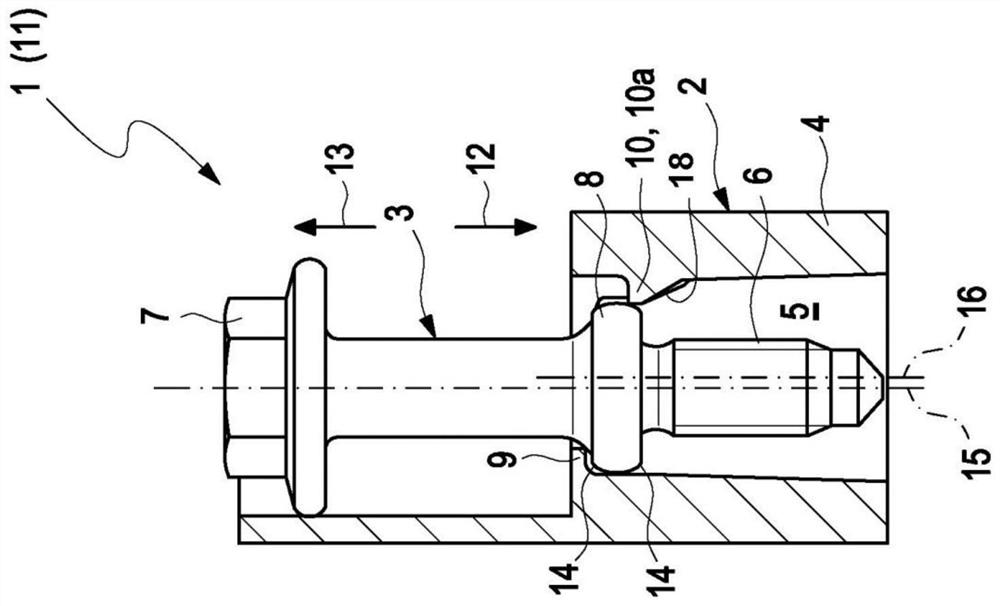

[0024] Figure 1 to Figure 4 A cross-sectional view of a fastening device 1 according to the invention is shown. Said fixing device 1 is provided for fixing a component 2 to a counterpart—not shown here. The fixing device 1 thus comprises a ring bolt 3 and a fixing part 4 of the part 2 . In the fixing portion 4 is formed a through hole 5 in which the ring bolt 3 is arranged. The ring bolt 3 thus has a thread 6 (only shown here), a bolt head 7 and a circumferential collar 8 formed between them. Formed in the through hole 5 are inner radial stop projections 9 and inner radial clamping projections 10 . The clamping projection 10 is positioned diametrically opposite to the stop projection 9 and is axially offset from the stop projection 9 .

[0025] The fastening device 1 is preassembled in the method 11 according to the invention. according to figure 1 , first insert the ring bolt 3 in the insertion direction 12 into the through hole 5 of the fastening part 4 until the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com