Device for coupling two tubes with pre-assembly

一种耦接装置、管子的技术,应用在管子/管接头/管件、套筒/插座连接、通过元件等方向,能够解决分离、移位或分离等问题,达到低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

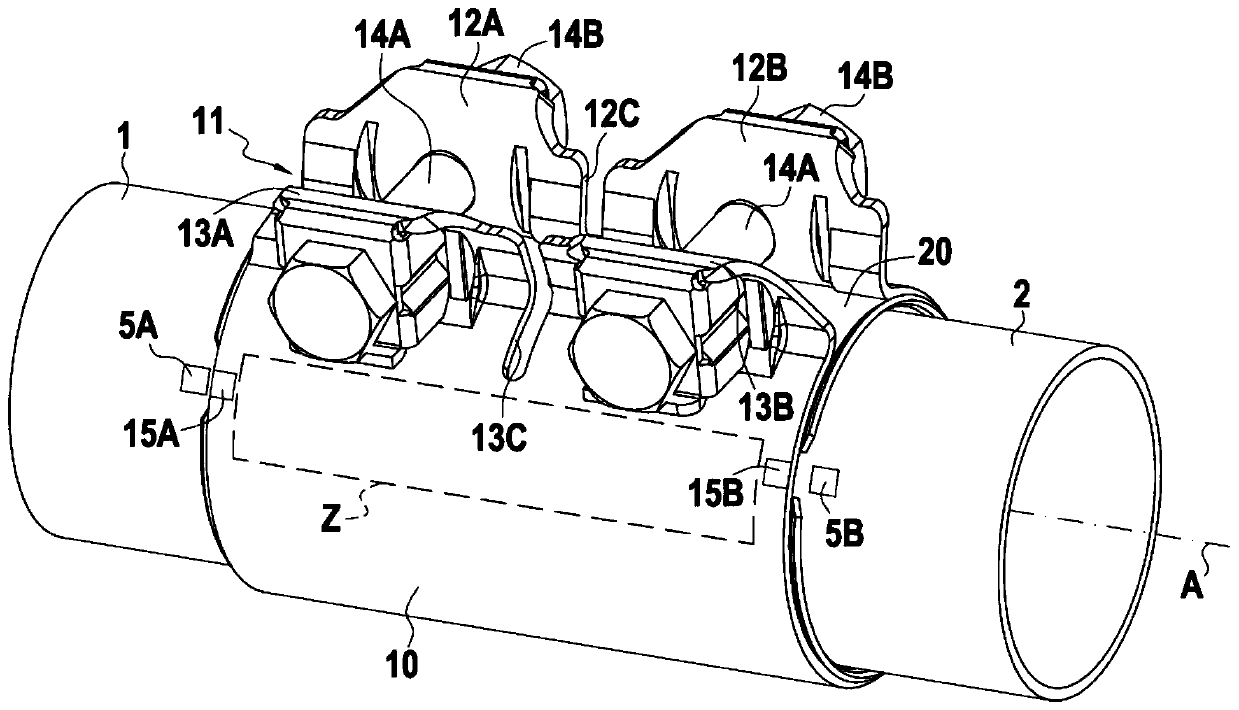

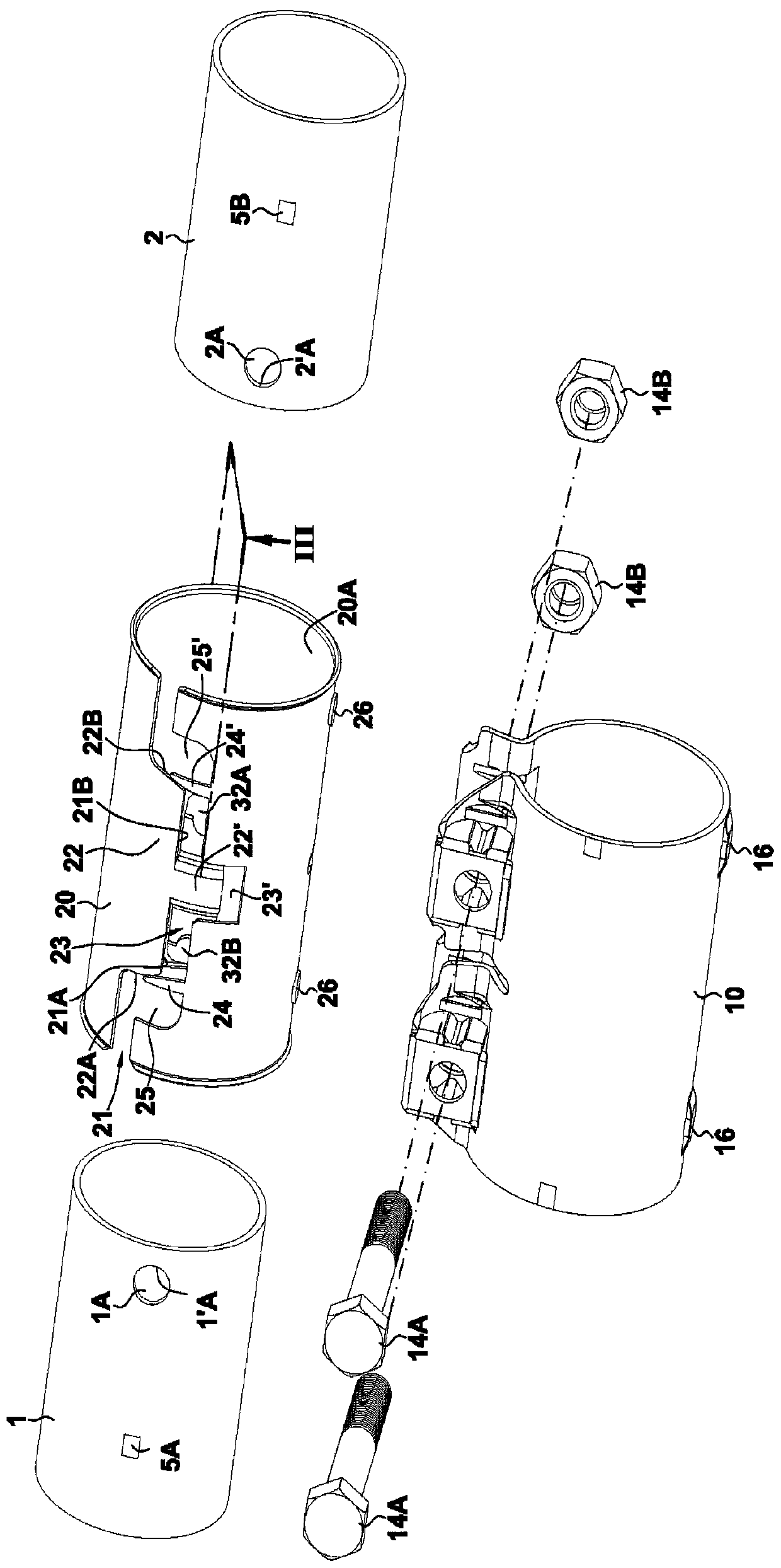

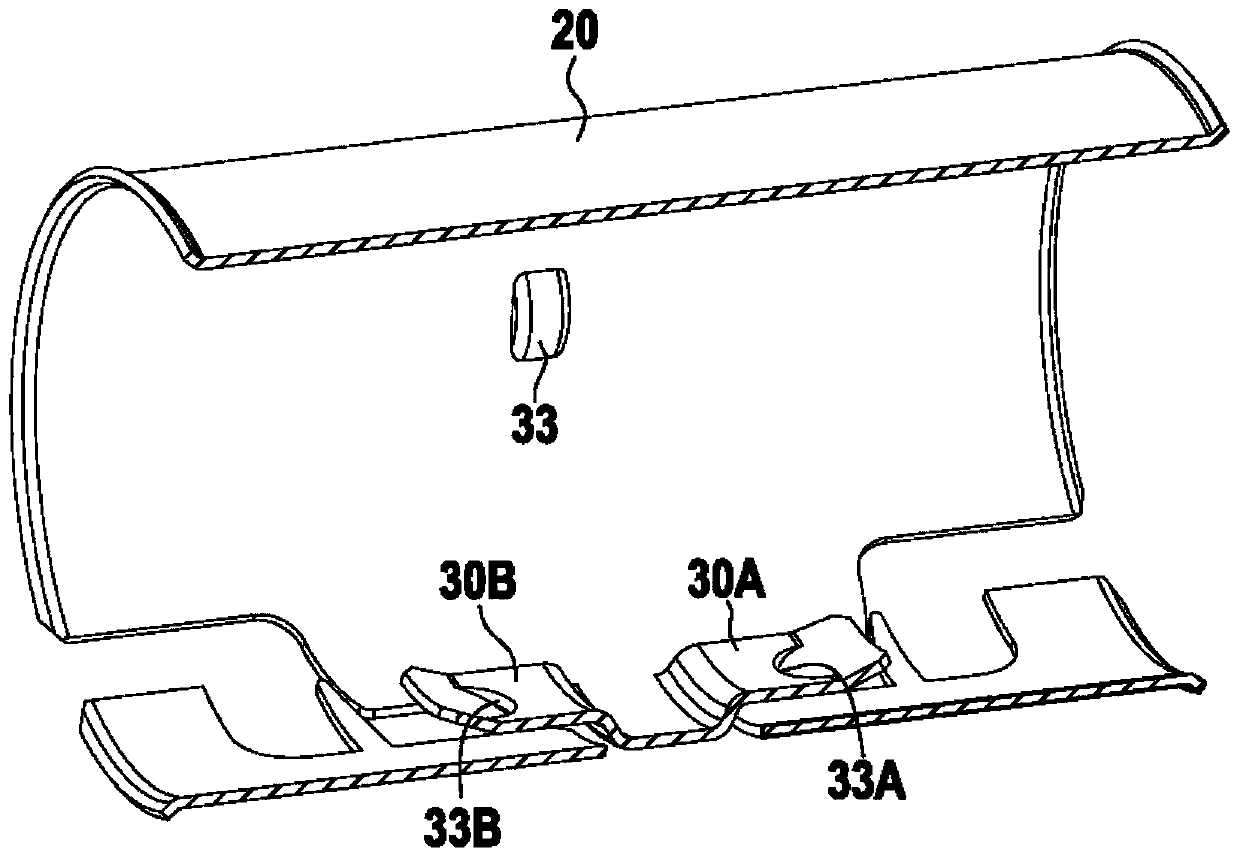

[0045] figure 1The ends of two tubes 1 and 2 are shown, aligned along their common axis A, which is also the general axis of the device (in particular, the clamping and sealing sleeves of the device) . The two pipes have substantially the same diameter and are coupled together by a coupling device comprising a clamping sleeve 10 and a sealing sleeve 20 inside the clamping sleeve 10 . For example, as described in application WO 00 / 75548, the sealing sleeve is split axially and thus has a radially turned axial groove 11 defined by the assembly lip. In order to achieve the clamping, the assembly lips facing each other can be brought together by fasteners, in particular by bolts cooperating with nuts. In this example, two fastening assemblies are provided, taking into account the axial length of the sleeve. Thus, the first assembly lip comprises two turned-out lugs 12A and 12B separated by a groove 12C which separates the lugs 12A and 12B from each other when they are drawn clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com