Pre-assembly process of roll-type membrane element and membrane element

A pre-assembled, rolled membrane technology, applied in the field of water treatment, can solve the problems of easy electrostatic charging, affecting the rolling quality of membrane elements, and damage to the PE material membrane, so as to improve the rolling efficiency, reduce friction and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

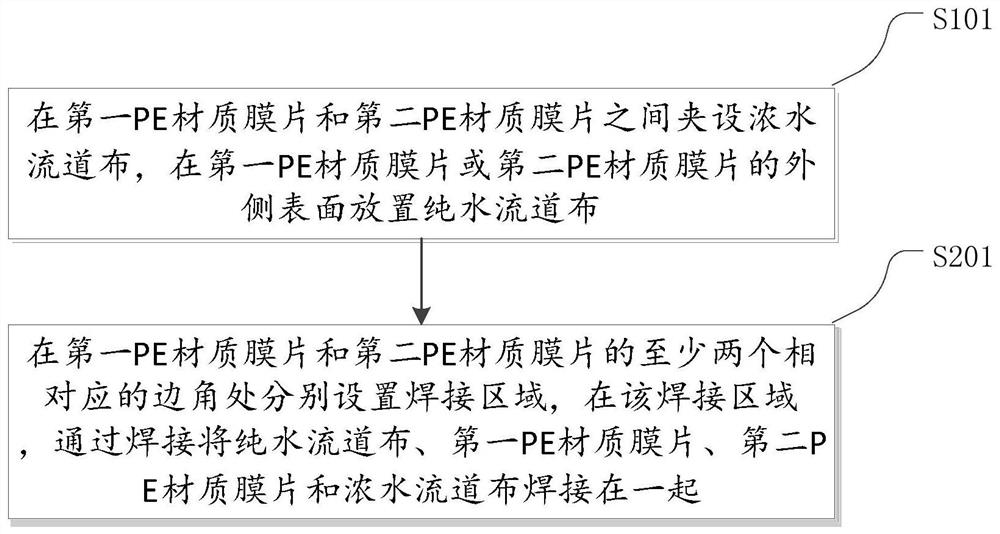

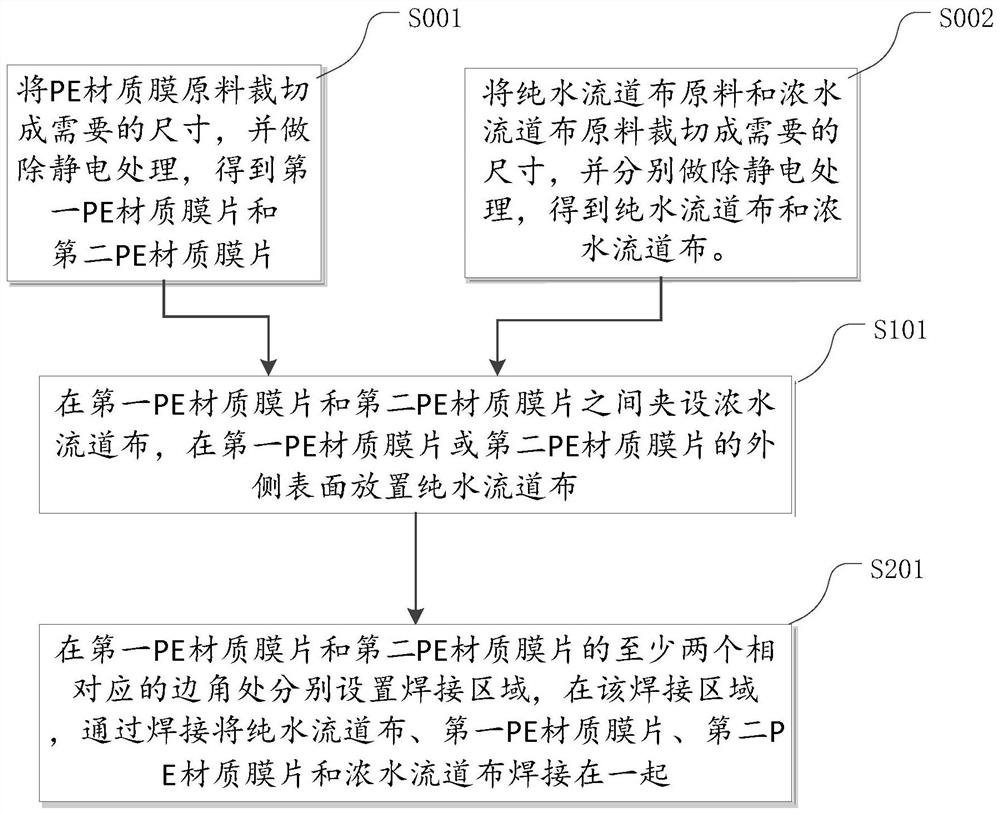

[0041] figure 1 It is a flow chart of the first pre-assembly process of the roll-type membrane element provided in the first embodiment of the present application.

[0042] Please refer to figure 1 , in this embodiment, the roll-type membrane element pre-assembly process is realized as follows:

[0043] Step S101: Desalination layers are respectively provided on the opposite surfaces of the first PE material diaphragm and the second PE material diaphragm, and a concentrated water flow is interposed between the first PE material diaphragm and the second PE material diaphragm Road cloth, placing pure water flow cloth on the outer surface of the first PE material diaphragm or the second PE material diaphragm;

[0044] Step S201: At least two corresponding corners of the first PE material diaphragm and the second PE material diaphragm, weld the pure water channel cloth and the first PE material diaphragm sheet, the second PE material diaphragm and the concentrated water channel...

no. 2 example

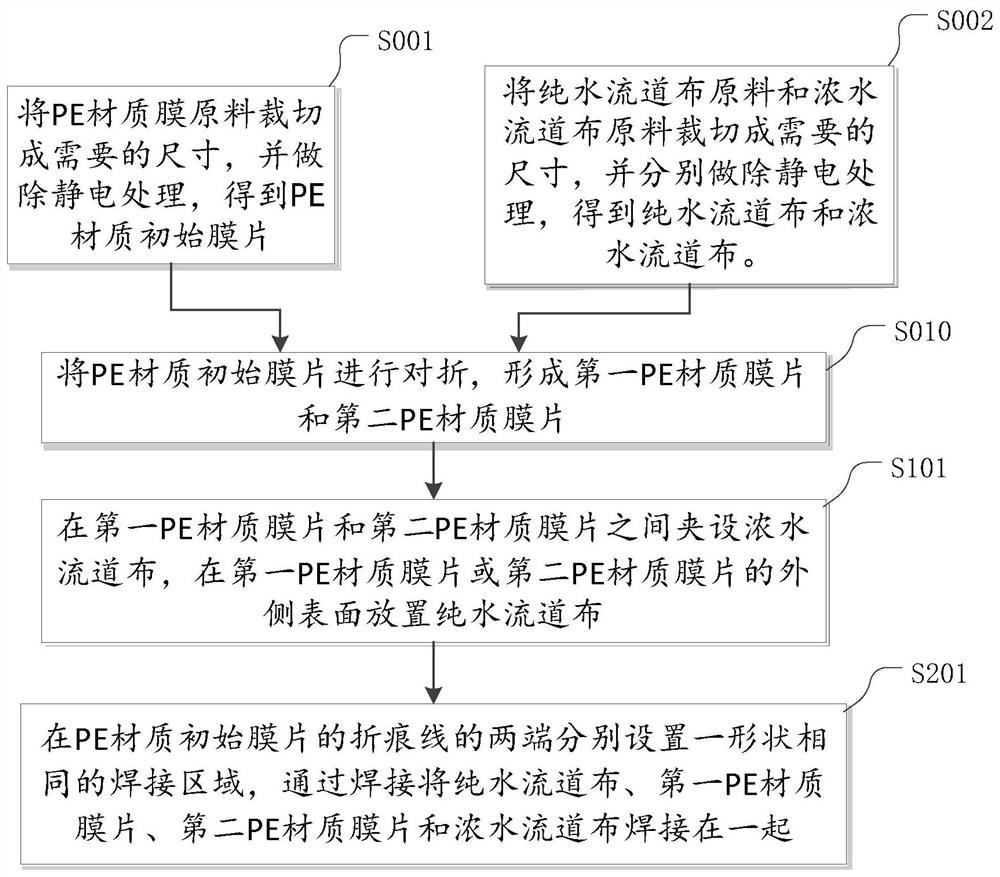

[0061] image 3 A flow chart of the pre-assembly process of the roll-type membrane element provided in the second embodiment of the present application;

[0062] Please refer to image 3 , in this embodiment, the roll-type membrane element pre-assembly process is realized as follows:

[0063] Step S001: cutting the PE material film raw material into the required size, and performing static removal treatment to obtain the initial PE material film;

[0064] Step S002: Cut the raw materials of the pure water runner cloth and the concentrated water runner cloth into required sizes, and perform static removal treatment respectively to obtain the pure water runner cloth and the concentrated water runner cloth;

[0065] In step S001 and step S002, the static electricity removal equipment of the cutting machine used is the same as that of the first embodiment, and will not be repeated here.

[0066] Step S010: Folding the initial PE material membrane in half to form a first PE mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com