Composite dioxygen oxidizing and denitrifying process method and device

A process method and compound hydrogen peroxide technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of increasing investment in dust removal systems, high requirements for flue gas quality, and high initial investment costs, and achieve fast denitrification treatment. , The effect of short flue gas residence time, reducing investment and operating burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a compound hydrogen peroxide oxidation denitrification process, including the steps of: configuring a denitrification agent according to the weight ratio of sodium chlorite and sodium hypochlorite at a ratio of 3:1. Then mix the denitration agent and water to prepare a denitration solution. The obtained denitrification liquid is mixed with the untreated nitrate-containing flue gas for denitrification reaction.

[0050] In another preferred improved embodiment, before performing the denitration reaction, the flue gas containing nitrate to be treated is firstly subjected to dust removal treatment.

[0051] In another preferred improved embodiment, the mass concentration of the denitration agent in the denitration solution is 25%. The denitrification solution with a mass concentration of 25% can achieve better denitrification efficiency while controlling the input cost of denitrification agent. According to NO in flue gas containing nitrate to be...

Embodiment 2

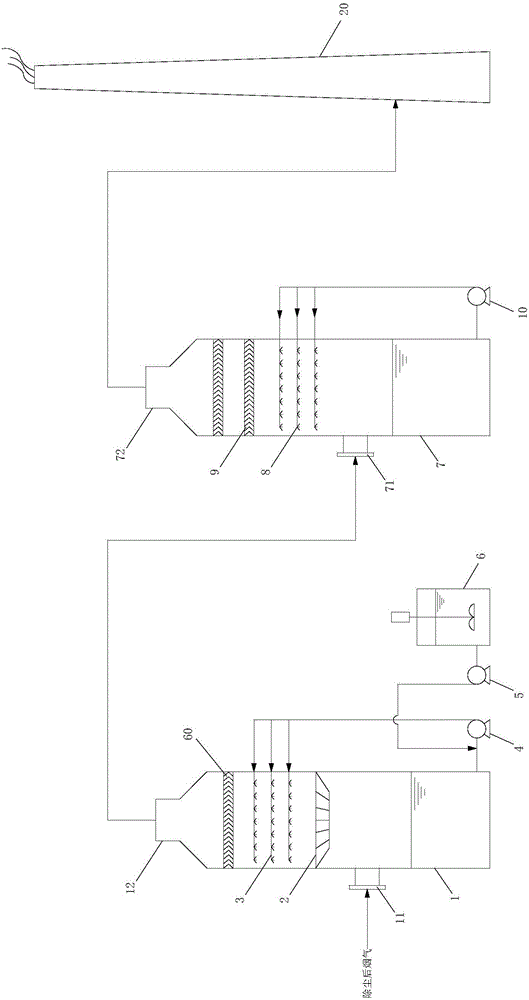

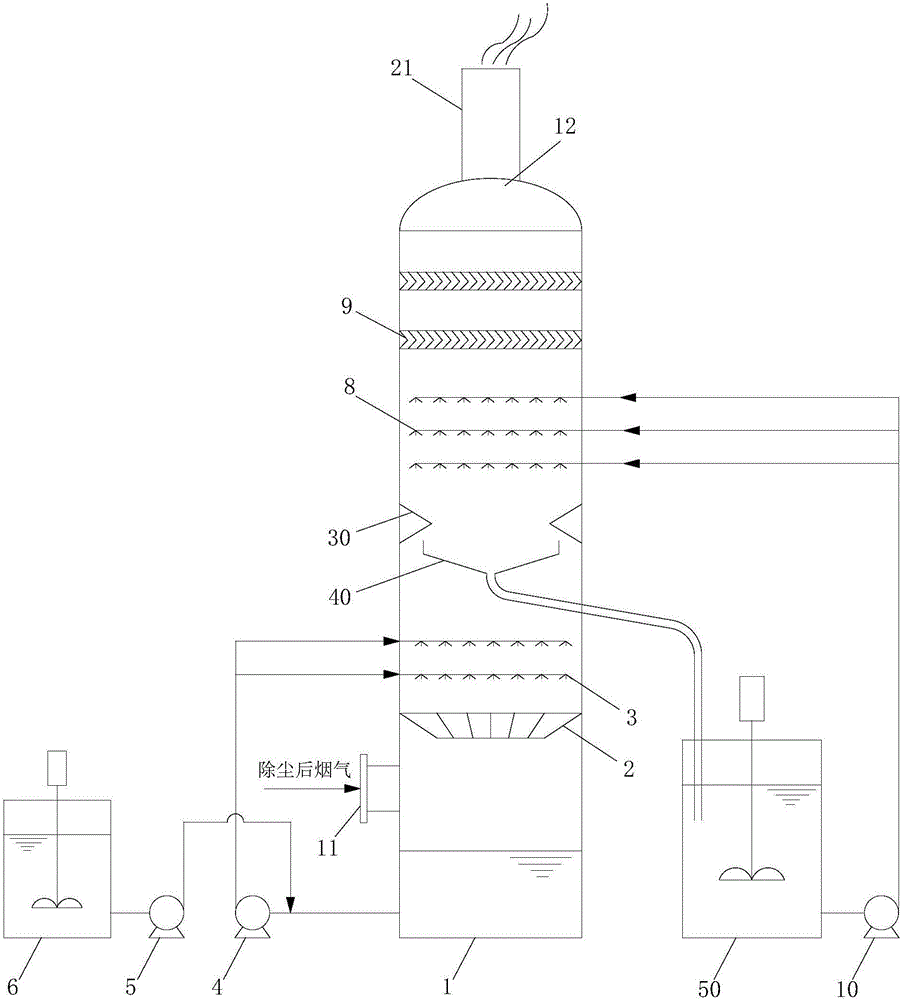

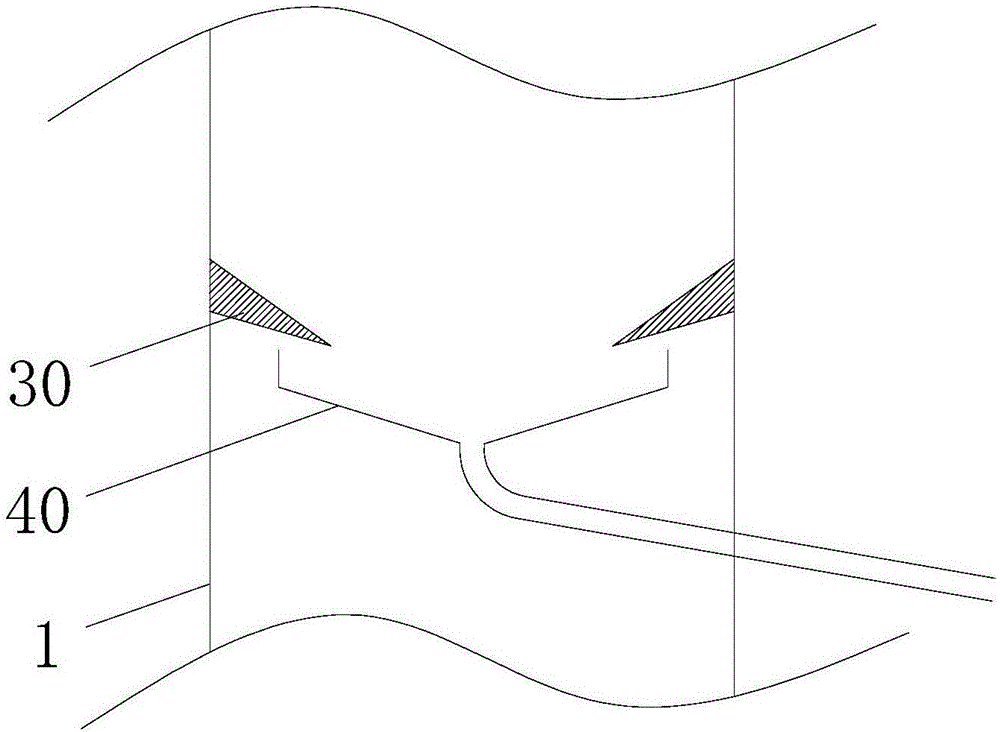

[0054] This embodiment provides a compound hydrogen peroxide oxidation denitrification device, including a denitrification tower 1, a first atomization spray system 3, a first plate type demister 60, a first circulating pump 4, a metering pump 5 and a denitration agent solution storage tank 6; the lower part of the side wall of the denitrification tower 1 is provided with a denitrification tower air inlet 11, and the top of the denitrification tower 1 is provided with a denitrification tower gas outlet 12; the first atomization spray system 3 is located in the denitrification tower Tower 1, and is located between the denitrification tower inlet 11 and the denitrification tower outlet 12; the first flat plate demister 60 is located inside the denitration tower 1, and is located in the first fog between the chemical spray system 3 and the gas outlet 12 of the denitrification tower; the liquid inlet of the first circulation pump 4 communicates with the bottom of the denitration to...

Embodiment 3

[0060] This embodiment provides a compound hydrogen peroxide oxidation denitrification device, including a denitrification tower 1, a first atomization spray system 3, a first circulation pump 4, a metering pump 5 and a denitrification agent solution storage tank 6; the denitrification tower 1 The lower part of the side wall is provided with a denitrification tower air inlet 11, and the top of the denitrification tower 1 is provided with a denitrification tower gas outlet 12; the first atomization spray system 3 is located inside the denitrification tower 1, and is located in the between the air inlet 11 of the tower and the gas outlet 12 of the denitrification tower; the liquid inlet of the first circulation pump 4 communicates with the bottom of the denitration tower 1, and the liquid outlet of the first circulation pump 4 is connected to The pipe is connected with the first atomizing spray system 3; the liquid outlet of the metering pump 5 is connected with the liquid inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com