High-temperature desulfurization and denitrification flue gas dust removal system

A desulfurization, denitrification, and dust removal system technology, applied in the direction of gas treatment, dispersed particle filtration, combined devices, etc., can solve the problems of complex management and long process flow, and achieve the effects of simplified process flow, high dust removal efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

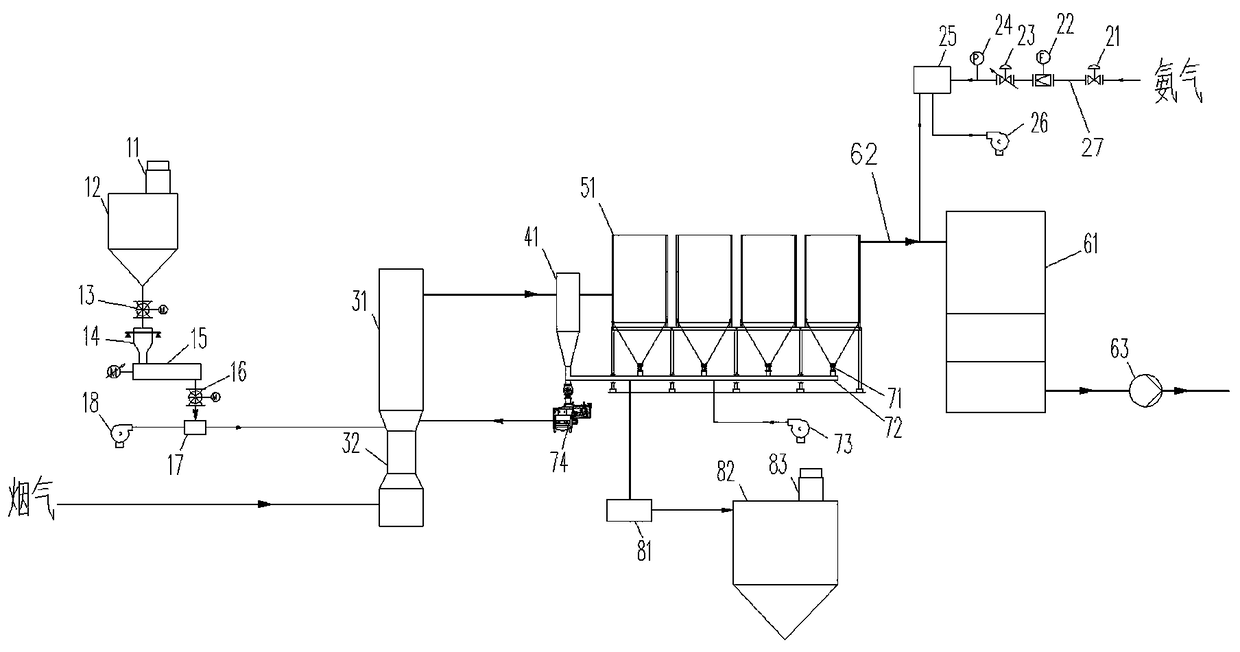

[0037] Such as figure 1 As shown, the present invention provides a high-temperature desulfurization and denitrification flue gas dust removal system, comprising:

[0038] a. Lime storage and transportation department,

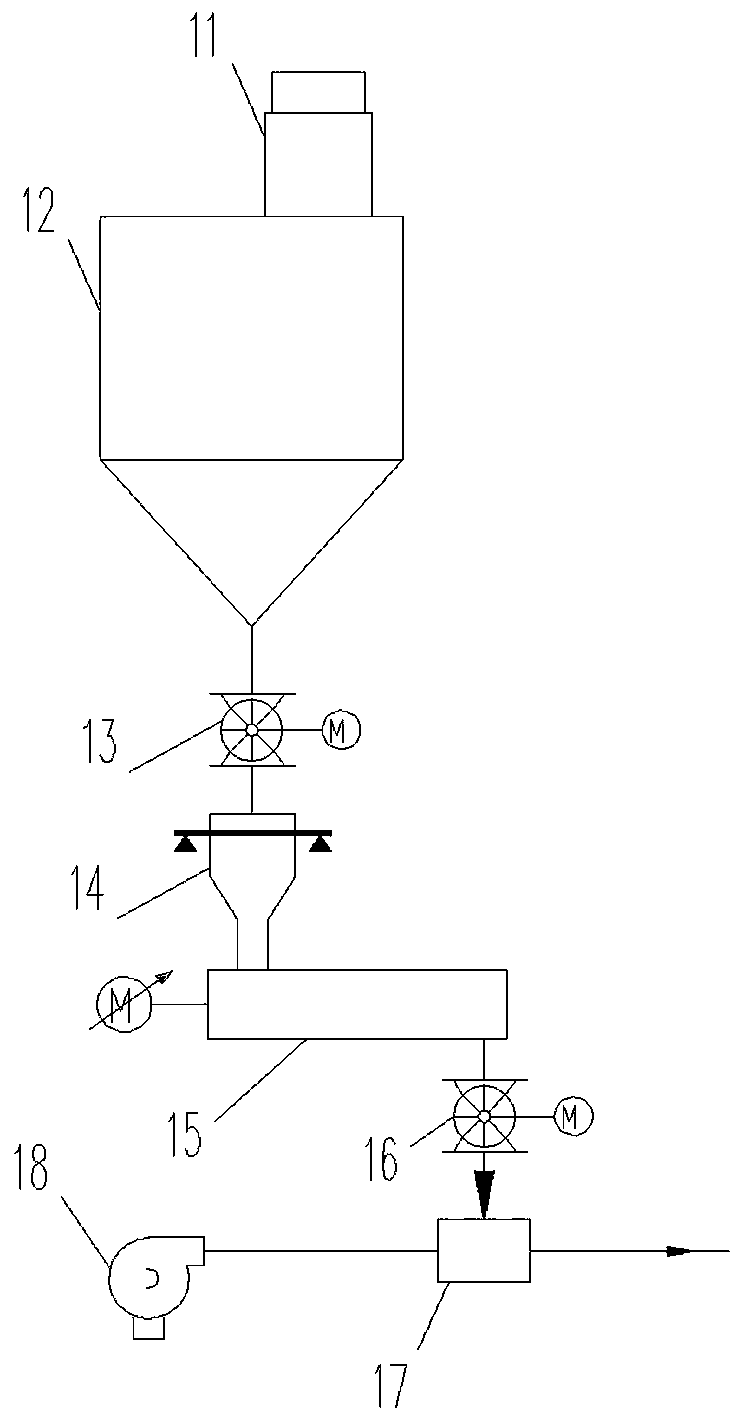

[0039] combine figure 2 As shown, the lime storage and transportation section includes a slaked lime storage bin 12, and the top of the slaked lime storage bin 12 is provided with a first dust collector 11; the bottom of the slaked lime storage bin 12 is provided with a first rotary valve 13. A weighing bin 14, a screw conveyor 15, a second rotary valve 16, and a gas-solid mixing bin 17 connected in sequence are provided; the two inlets of the gas-solid mixing bin 17 are respectively connected to the outlet of the conveying fan 18 and the second rotary valve 16;

[0040] b. Desulfurization settling part,

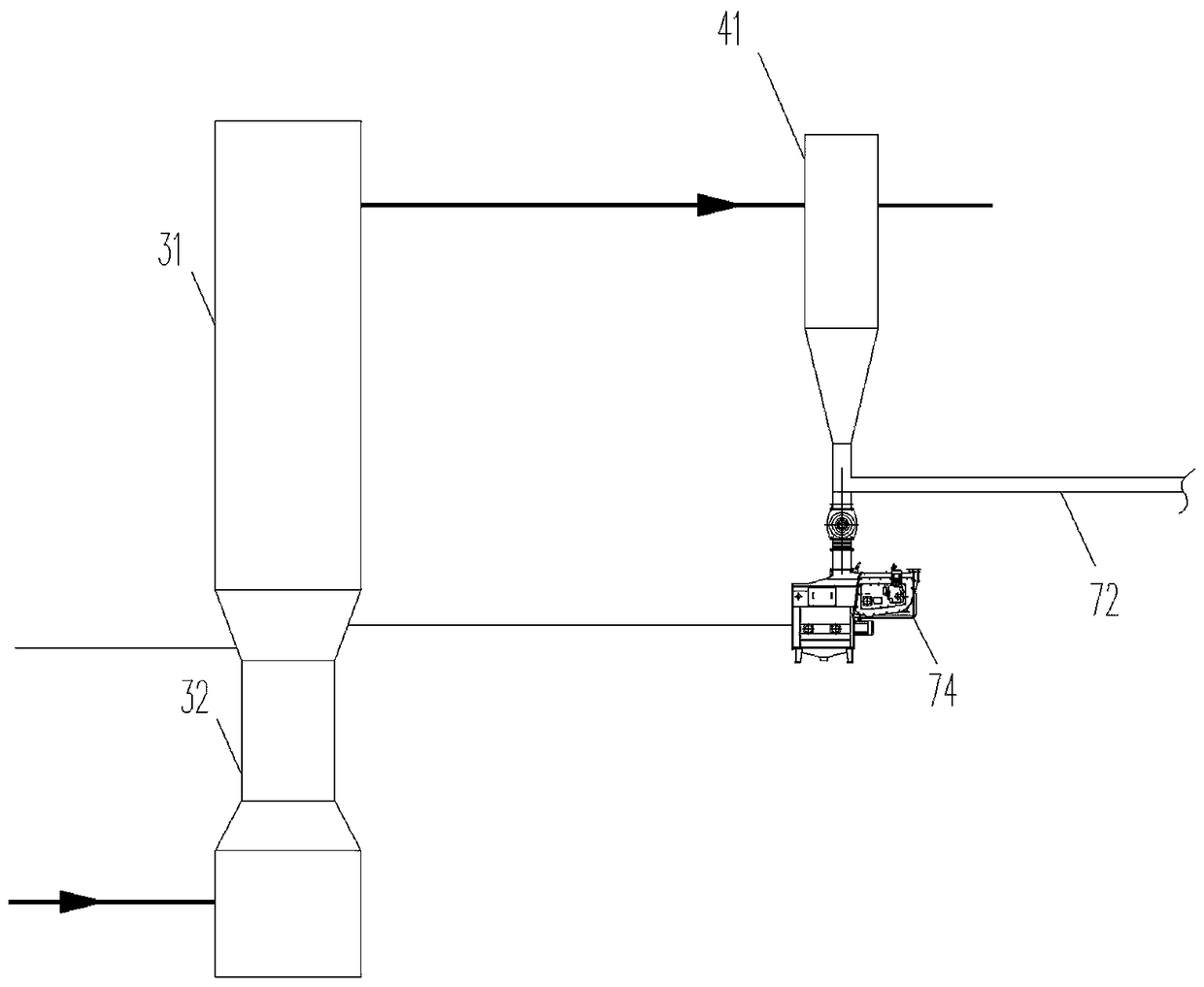

[0041] combine image 3 As shown, the desulfurization settling part includes a dry desulfurization tower 31 and a settling chamber 41. The dry desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com