Device and method for glass granulation and waste heat recovery of molten smelting slag

A technology of smelting and waste heat recovery, which is applied in the steam generation method using heat carrier, glass forming, glass manufacturing equipment, etc., can solve the problems of ineffective recovery, waste heat resources waste of smelting smelting slag, waste of resources, etc., to achieve The system has a short processing cycle, a high degree of equipment automation, and the effect of effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

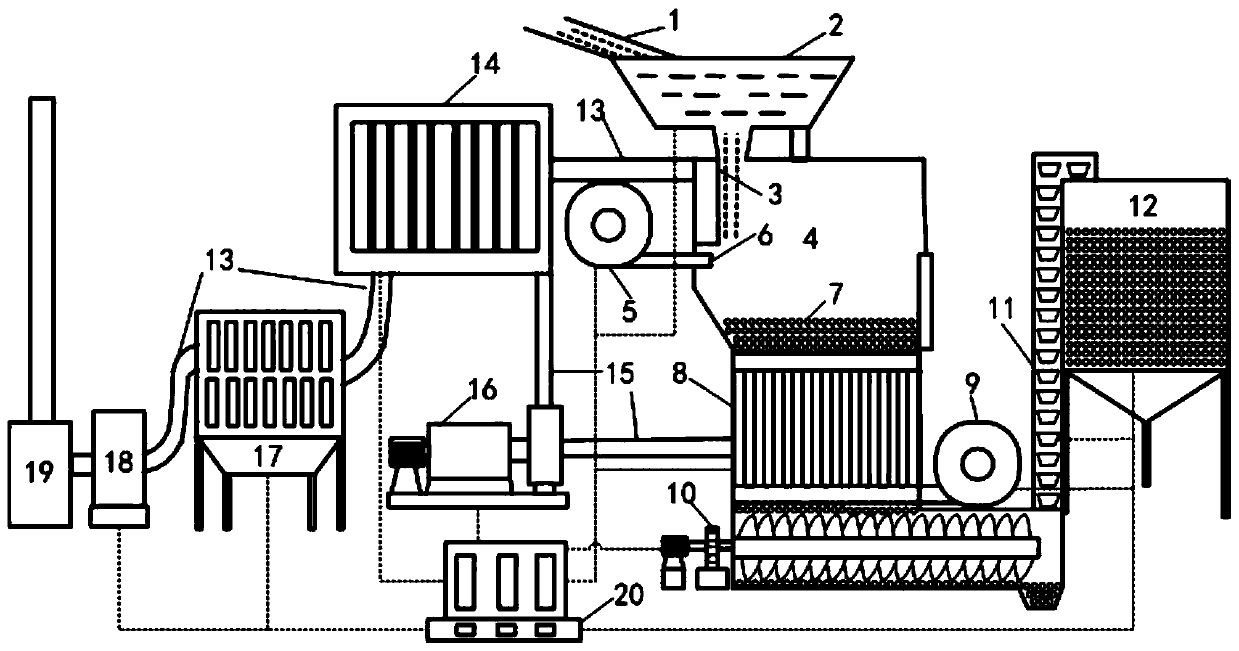

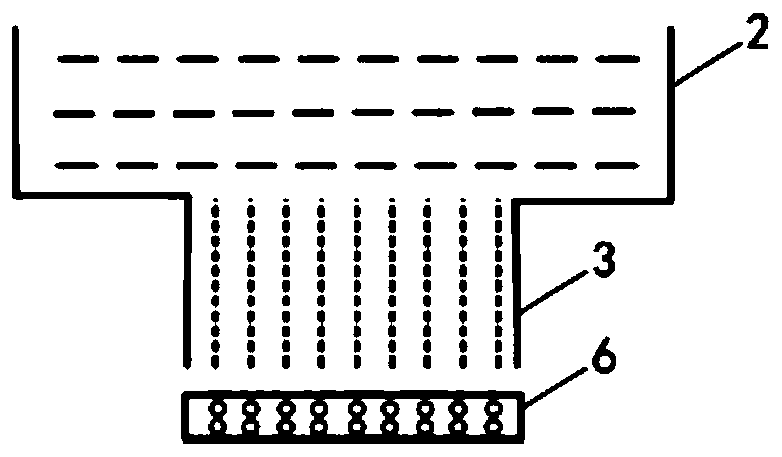

[0035] A glass granulation and waste heat recovery treatment device for molten smelting slag as attached figure 1As shown, it includes: chute 1, tundish 2, diversion tank 3, granulation chamber 4, granulation fan 5, blast tank 6, tubular heat exchanger 8, cooling fan 9, screw discharger 10, The hoist is preferably a bucket elevator 11, a finished product warehouse 12, a plate heat exchanger 14, a first steam pipe 15, a second steam pipe 15, a generator set 16 and a purification discharge device; the chute 1 is connected to the tundish 2 for The molten smelting slag flows into the tundish 2 through the chute 1, and the tundish 2 is connected to the granulation chamber 4 through the diversion groove 3, and is used to flow the molten smelting slag in the tundish 2 into the granulation chamber 4 through the diversion groove 3 Inside, the granulation chamber 4 and the granulation blower 5 are connected through the blowing groove 6, and are used to blow the cold air generated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com