Flue gas deep purification system adopting phase-change coagulation and charged processing integration

A flue gas deep purification and purification system technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as restricting ultra-low emission technology route selection and construction schedule, inability to provide temperature gradients, difficulties, etc. Achieve the effect of saving investment cost, simple operation and improving removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

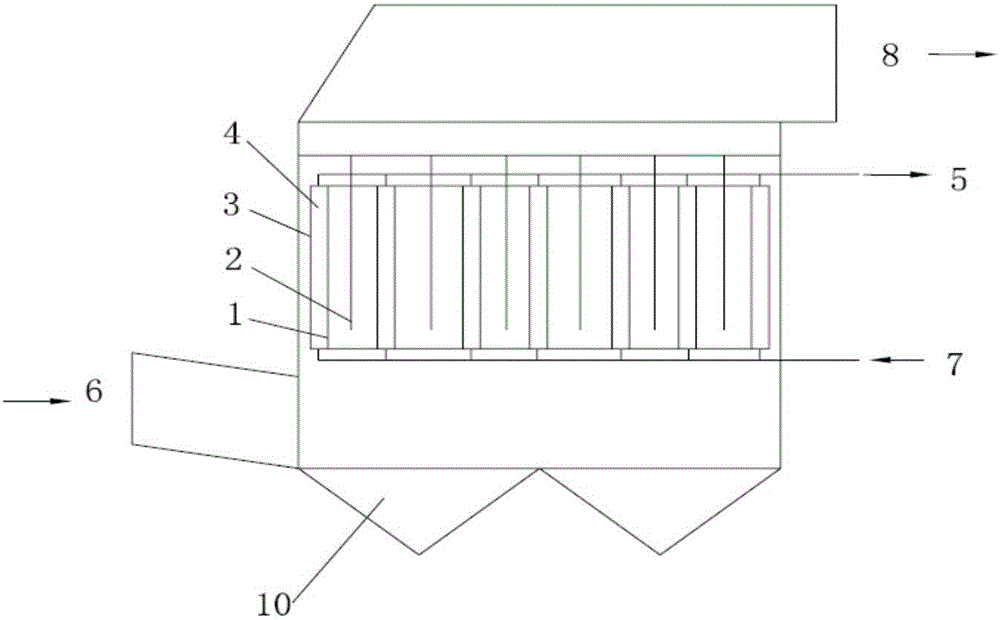

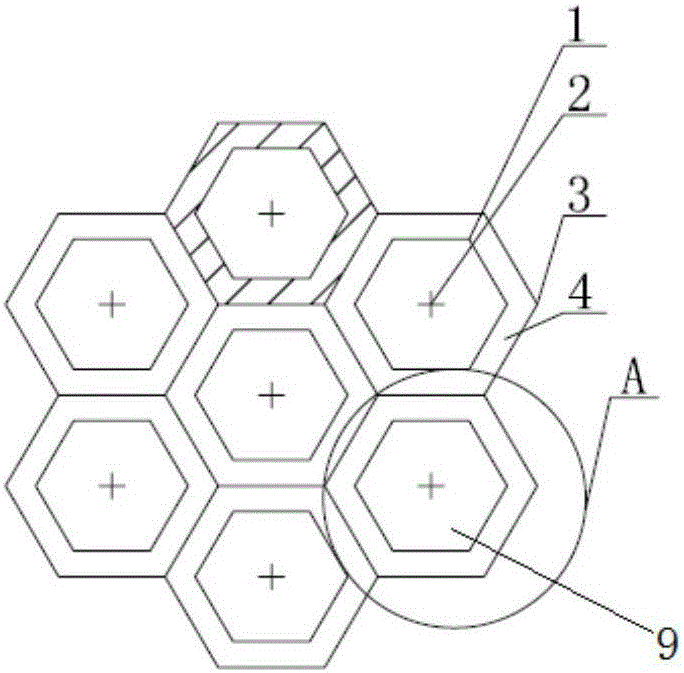

[0026] Such as figure 1 and figure 2 As shown, the flue gas deep purification system integrated with phase change condensation and charging includes a flue gas inlet, a flue gas outlet, a circulating cooling water outlet 5, a circulating cooling water inlet 7, multiple purification units A and a liquid collection tank 10, and the flue gas The inlet, the flue gas outlet, the circulating cooling water outlet 5 and the circulating cooling water inlet 7 are all connected to the purification unit A; the purification unit A is vertically arranged in the purification system, and the purification units A are fixed by welding or gluing along each side ; The sump 10 is set at the bottom of the purification system.

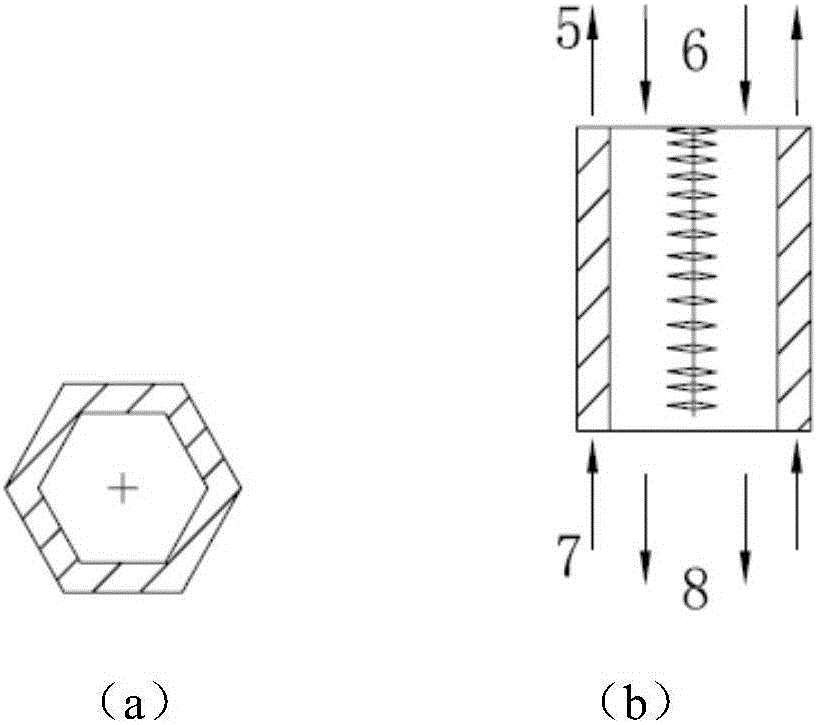

[0027] Such as image 3 As shown, the shape of each purification unit A is set to be hexagonal, square or circular. Each purification unit A includes an anode p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com