Smoke ultra-low emission purification equipment of coal-fired industrial boiler

An industrial furnace and coal-fired technology, applied in emission prevention, combustion methods, gas treatment, etc., can solve problems such as high pollutant emission intensity, backward combustion methods, and variable coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

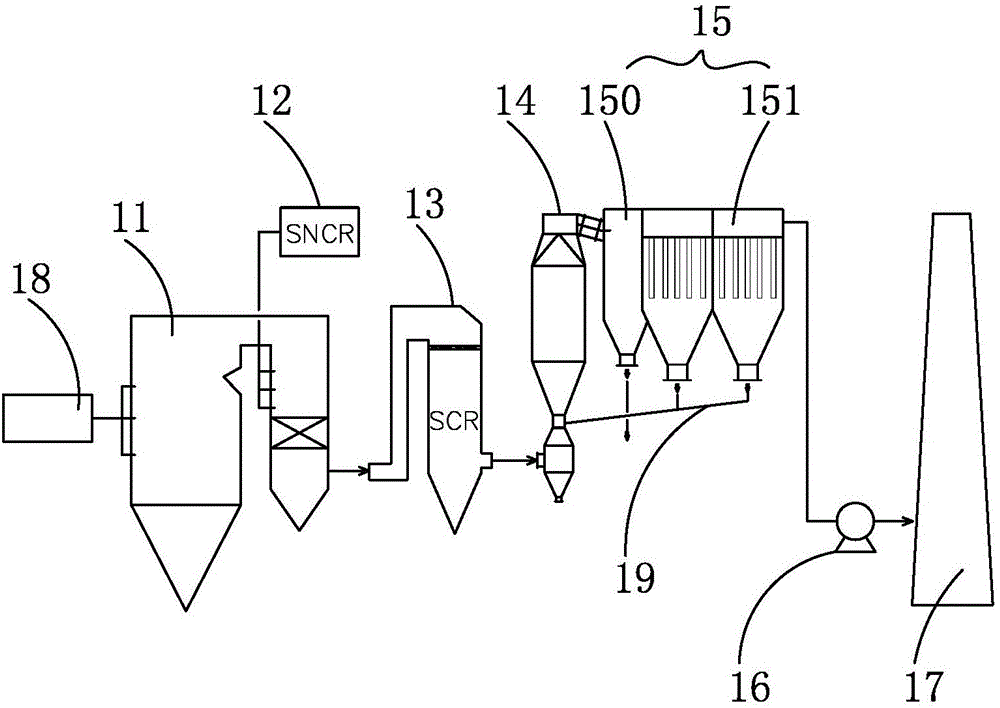

[0024] Such as figure 1 Shown is an ultra-low emission purification equipment for coal-fired industrial furnace flue gas. The SNCR denitration equipment 12 connected with the boiler 11, the SCR denitration equipment 13 connected with the flue gas outlet flue of the boiler 11, the semi-dry desulfurization equipment connected with the SCR denitration equipment 13, and the dust removal equipment connected with the semi-dry desulfurization equipment, The dust removal equipment is connected to the clean air outlet to discharge to the chimney 17, and the dust removal equipment and the chimney 17 are connected through an induced draft fan 16. The flue gas is desulfurized by calcium spraying in the furnace first, then denitrated by SNCR coupled with SCR, desulfurized by semi-dry method, and then discharged after dust removal. In this example:

[0025] According to the furnace temperature and structural conditions of coal-fired industrial boilers, especially the wide-area and large-s...

Embodiment 2

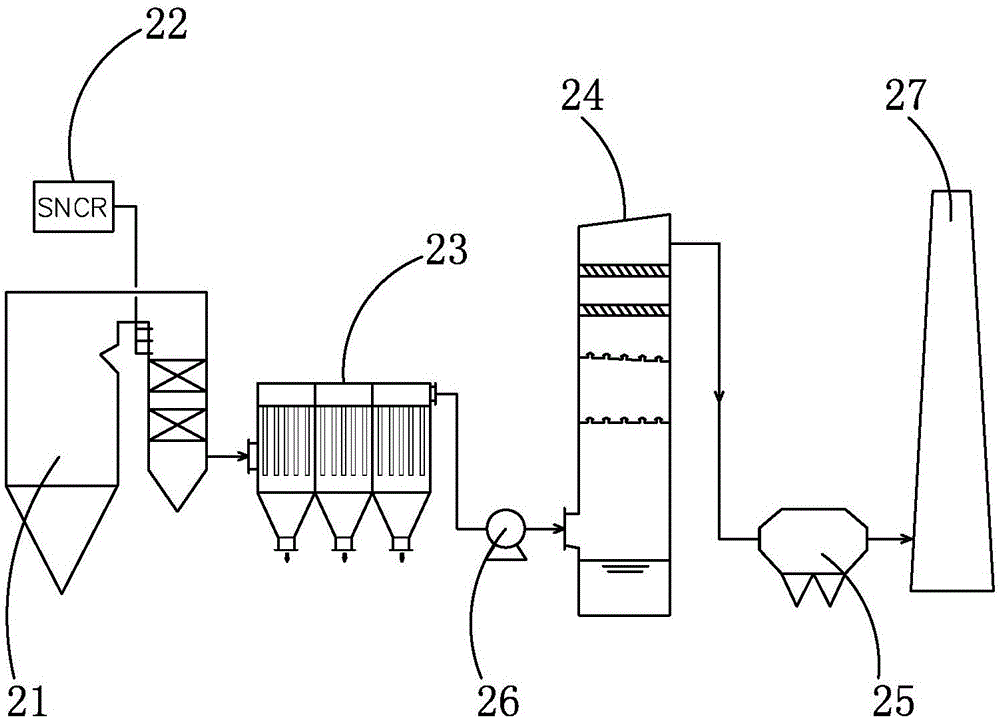

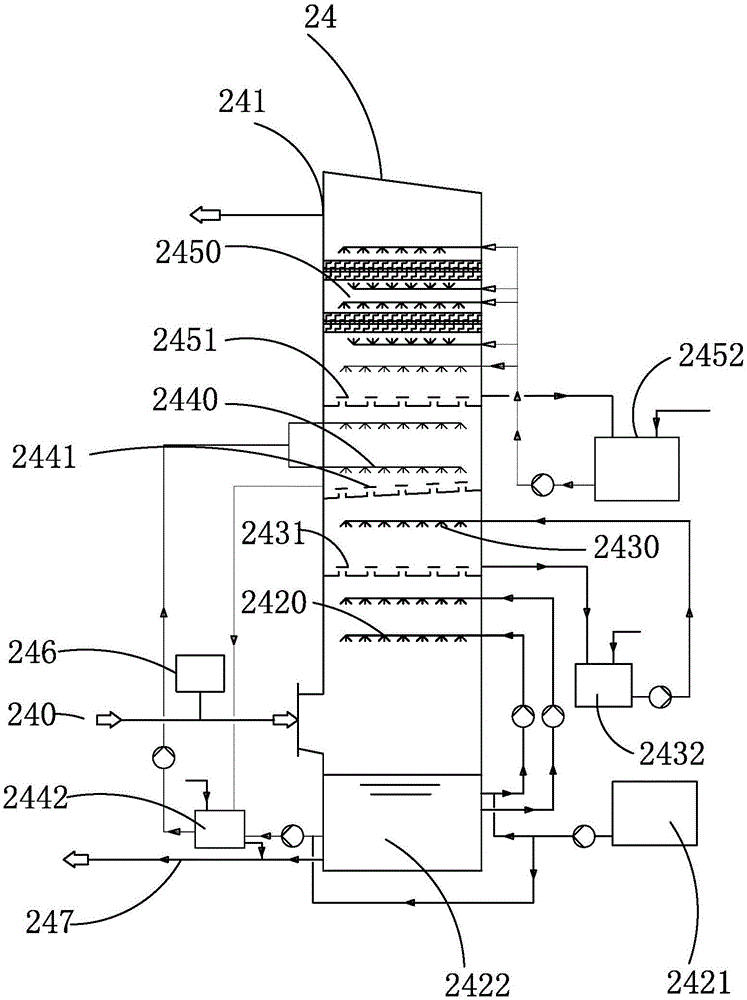

[0035] Such as figure 2 Shown is an ultra-low emission purification equipment for coal-fired industrial furnace flue gas. The dust collector equipment 23 connected with the dust collector equipment 23, the wet desulfurization and denitrification equipment connected with the dust collector equipment 23, the demist equipment 25 connected with the wet desulfurization and denitrification equipment, the demist equipment 25 is connected to the clean gas outlet to discharge to the chimney 27, and the dust collector equipment 23 It is connected with the desulfurization and denitrification equipment through the induced draft fan 26. After the flue gas is denitrated by SNCR, it is discharged after dust removal, desulfurization, further denitrification and demisting. In this example:

[0036] In view of the low and unstable furnace flue gas temperature of small and medium-sized coal-fired industrial boilers, SNCR denitrification equipment 22 adopts medium-temperature SNCR denitrificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com