Device and method for removing pollutants in flue gas

A pollutant and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of neglecting the synergistic dust removal function of the desulfurization system, high investment in flue gas treatment, and inability to meet the requirements of ultra-low emissions. Achieve the effect of inhibiting the generation of SO3, reducing investment and operating costs, and improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

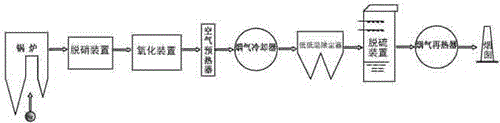

[0052] Such as Figure 1~Figure 3 As shown, this specific embodiment provides a device for removing pollutants in flue gas, including a boiler, and the flue gas of the boiler passes through a denitration device, an oxidation device, an air preheater, a flue gas cooler, and a low-temperature dust collector in sequence. , desulfurization device and flue gas reheater, and then discharged from the chimney.

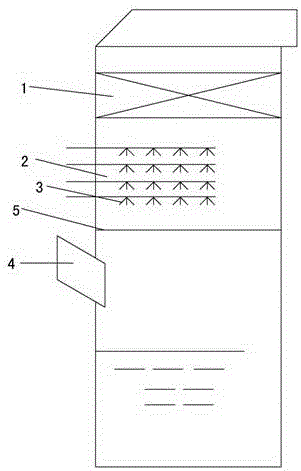

[0053] The desulfurization device includes a desulfurization tower, the top of the desulfurization tower is provided with a high-efficiency demister 1, and a number of spray layers 2 for spraying water are provided under the high-efficiency demister 1, and each of the spray A number of nozzles 3 are arranged on each layer 2, and a flue gas inlet 4 is arranged in the middle of the desulfurization tower; a flue gas uniform distribution device 5 is arranged between the top of the flue gas inlet 4 and the spray layer 2 on the lowermost layer.

[0054] The spray layer is 2 layers....

Embodiment 2

[0070] Embodiment 2: as Figure 1~Figure 3 As shown, this specific embodiment provides a device for removing pollutants in flue gas, including a boiler, and the flue gas of the boiler passes through a denitration device, an oxidation device, an air preheater, a flue gas cooler, and a low-temperature dust collector in sequence. And desulfurization device, and then discharged from the chimney.

[0071] The desulfurization device includes a desulfurization tower, the top of the desulfurization tower is provided with a high-efficiency demister 1, and a number of spray layers 2 for spraying absorption liquid are provided under the high-efficiency demister 1, and each spray A number of nozzles 3 are arranged on the spray layer 2, and a flue gas inlet 4 is arranged in the middle of the desulfurization tower; a flue gas uniform distribution device 5 is arranged between the top of the flue gas inlet 4 and the spray layer 2 on the lowermost layer .

[0072] The spray layer is 4 layers...

Embodiment 3

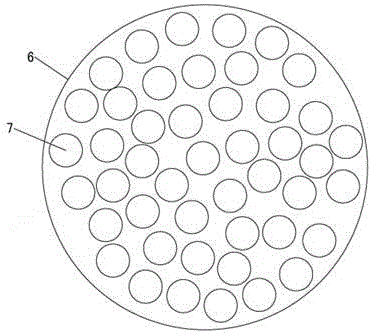

[0087] Embodiment 3: as Figure 1~Figure 3 As shown, the difference between this embodiment and embodiment 1 is that the spray layer is 3 layers; the area of all the small holes 7 accounts for 40% of the area of the flat plate 6; the cooling temperature of the flue gas cooler is 85 ℃; the strong oxidant is sodium hypochlorite solution; the auxiliary agent is calcium chloride solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com