Sound-wave-coupling rotational flow-rotation eliminating efficient dust removing and defogging device

A demisting device and swirl technology, applied in the field of flue gas purification, can solve the problems of low removal efficiency, small pressure loss, and high dedusting and demisting efficiency of dedusting and demisting devices, and achieve high dedusting and demisting efficiency, low energy consumption, Good dust removal and fog removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

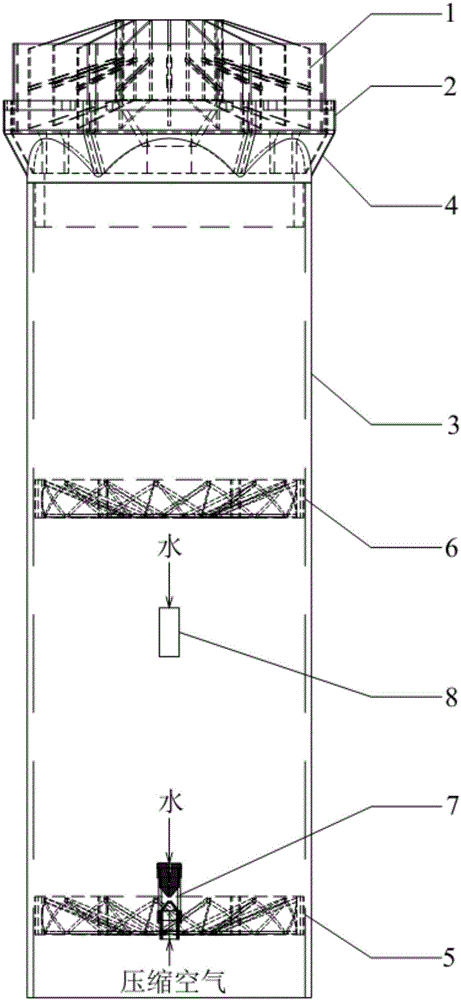

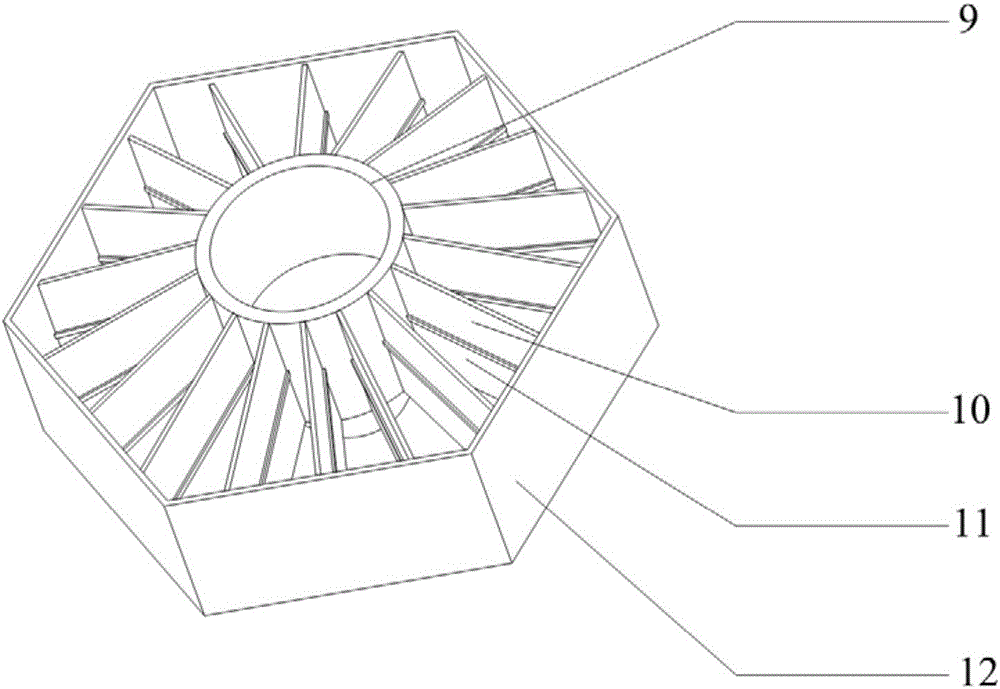

[0044] Such as figure 1 As shown in the figure, a sound-wave coupling cyclone-race-rotation high-efficiency dedusting and mist removal device is arranged above the spray layer in the desulfurization absorption tower, and includes multiple dust and mist removal units installed side by side. The dust removal and mist removal unit includes external The cylinder body, the first-stage centrifugal swirl plate 5 and the second-stage centrifugal swirl plate 6 arranged in parallel in the outer cylinder from bottom to top, and the racemic hydrophobic plate 1 obliquely arranged on the top of the outer cylinder, the first stage A sound wave generator 7 is arranged at the center of the centrifugal swirl plate 5 , and a flushing water injector 8 is arranged between the sound wave generator 7 and the second-stage centrifugal swirl plate 6 .

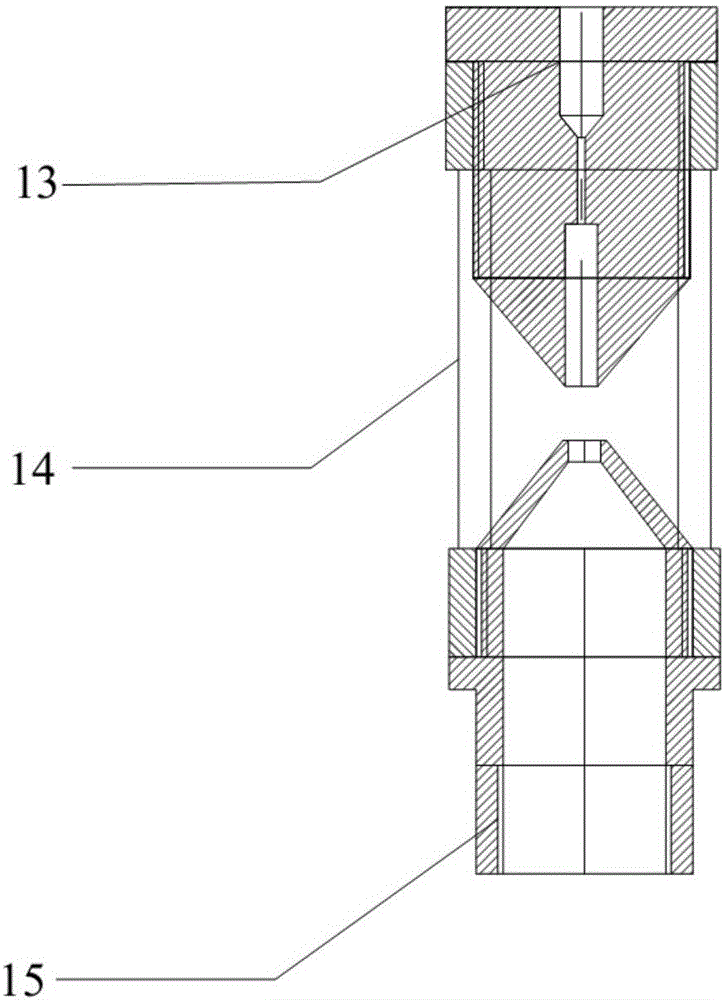

[0045] The acoustic wave generator 7 includes an airflow nozzle 15 whose bottom is fixedly connected to the first-stage centrifugal swirl plate 5 , a r...

Embodiment 2

[0054] In the present embodiment, the height of the acoustic wave generator 7 is 80 mm, and the diameter is 25 mm. The nozzle diameter of the air flow nozzle 15 is 5 mm, and the spray distance is 8 mm. The depth of the resonant cavity 13 is 20 mm. The overall height is 60mm.

[0055] All the other are with embodiment 1.

[0056] Using a test tower with an inner diameter of 700mm, the amount of flue gas used in the test is 2000m 3 / h, the flue gas temperature is 90°C, and the inlet droplet concentration is 250mg / Nm 3 , soot content is 75mg / Nm 3 . The measured demist efficiency is about 97%, the dust removal efficiency is 95%, and the total tower resistance is around 180Pa.

Embodiment 3

[0058] In the acoustic wave coupling swirling-descending high-efficiency dust and mist removal device of this embodiment, the ratio of the diameter of the acoustic wave generator 7 to the first-stage centrifugal swirl plate 5 is 1:20, and the nozzle of the airflow nozzle 15 in the acoustic wave generator 7 The ratio of the diameter to the spray distance is 0.2:1, the ratio of the outer diameter of the resonant cavity 13 to the spray distance is 2:1, the ratio of the depth of the resonant cavity 13 to the spray distance is 3:1, and the bottom of the resonant cavity 13 is provided with a flushing Water distribution port for continuous or intermittent addition of rinse water. In the working state, the injection volume of flushing water is 0.2m 3 / h.

[0059] The sound wave generator 7 adopts the jet power of compressed air or steam as the sound wave generation source, the distance between the air flow nozzle 15 and the resonant cavity 13 is 3mm, and in the working state, the flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com