Dedusting and demisting device of spiral flow plate

A technology of demisting device and swirl plate, which is applied in the direction of separation method, dispersed particle separation, chemical instrument and method, etc., can solve the problem that the concentration of smoke and dust cannot meet the concentration of smoke and dust emission of coal-fired units, the high cost of wet electrostatic precipitator, installation, Arrangement and maintenance difficulties, etc., to achieve the effect of no risk of fouling and blockage, reduction of local disturbance, and uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

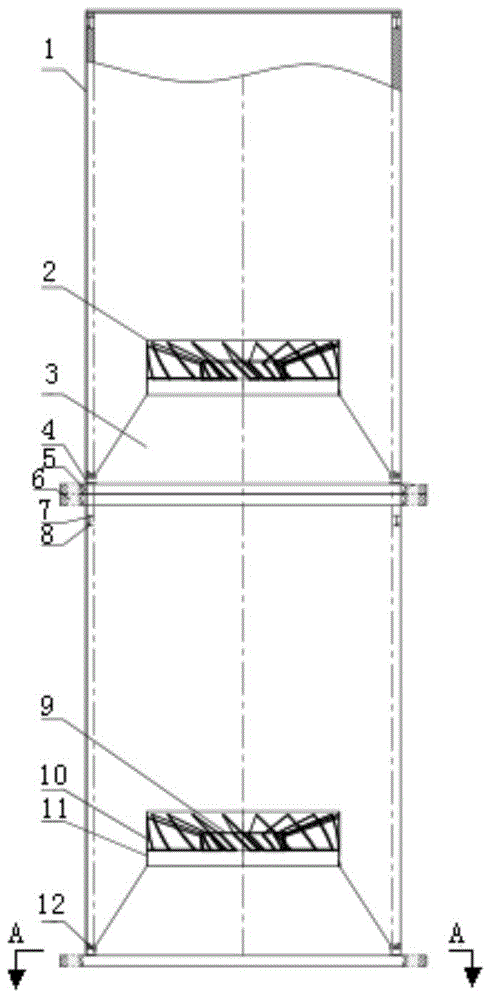

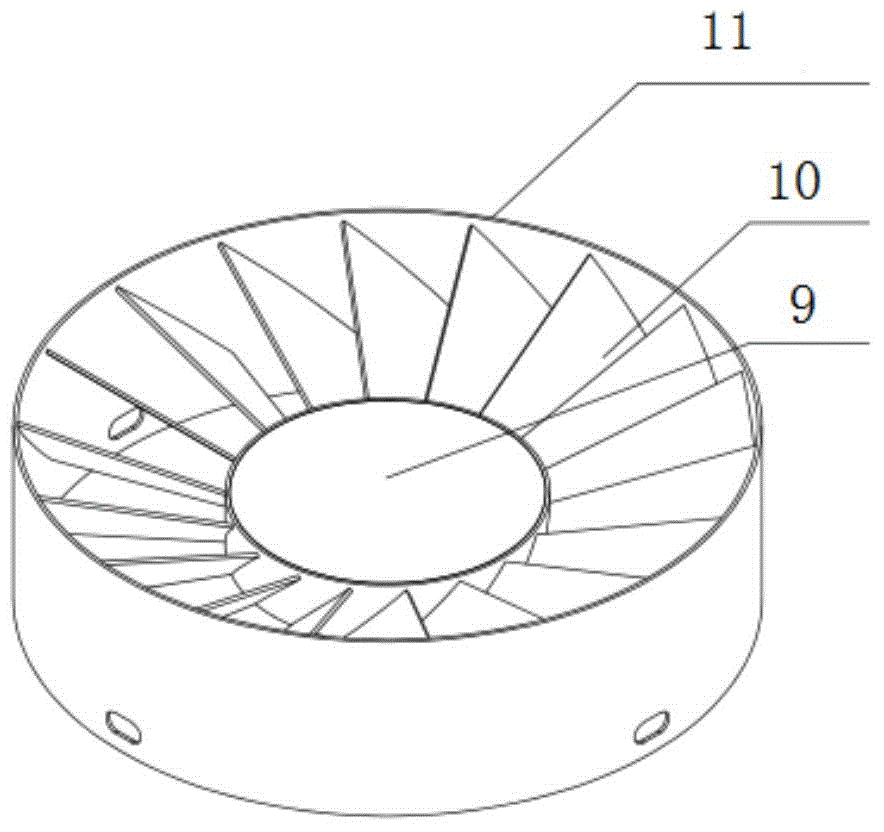

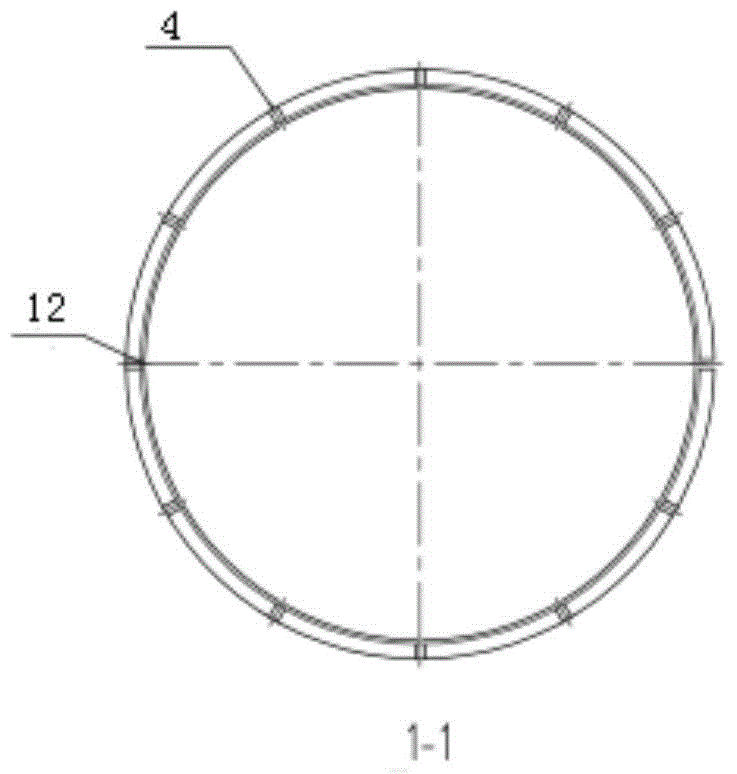

[0032] The swirl plate dedusting and demisting device of the present invention is installed above the spray layer in the desulfurization absorption tower, and the desulfurized saturated wet flue gas containing a large number of liquid droplets passes through the flow guide device from bottom to top before the flow section of the swirl. The diversion effect realizes the stability of the flue gas flow state. Then the small droplets reunite and grow into larger droplets during the collision process in the swirl. Using the separation inertia of the droplets and dust carried in the flue gas and the flue gas is different, the grown droplets are different from the particles in the flue gas. Dust particles are thrown onto the liquid film flowing on the inner wall of the cylinder to capture liquid droplets and smoke. The flue gas velocity before entering the sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com