Catalyst for treating escape of ammonia gas as well as preparation method and application of catalyst

A technology of catalysts and composite catalysts, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems that it is difficult to meet the ultra-low emission standards of NH3, cannot be used directly, and the temperature of flue gas is low. Ease of large-scale production, wide application range, and high N2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

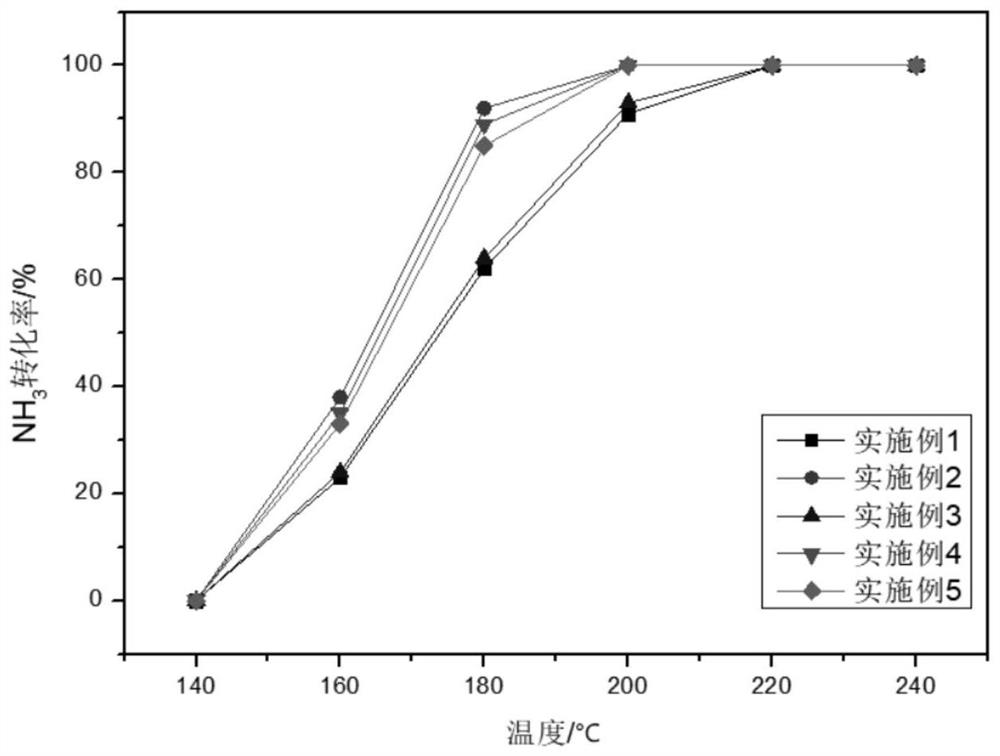

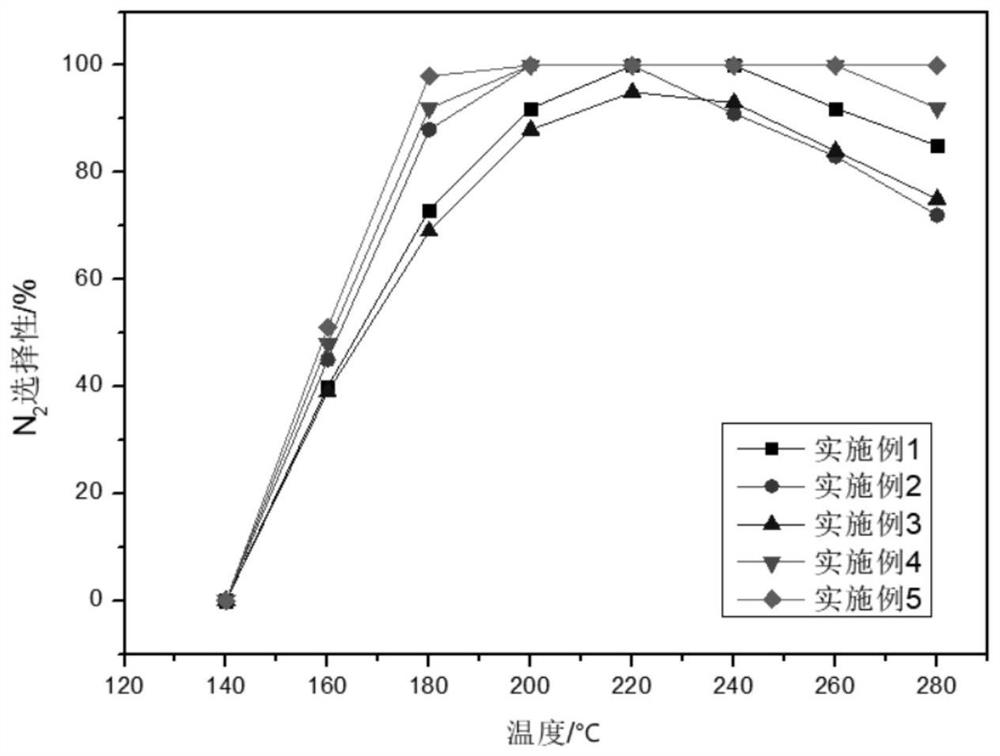

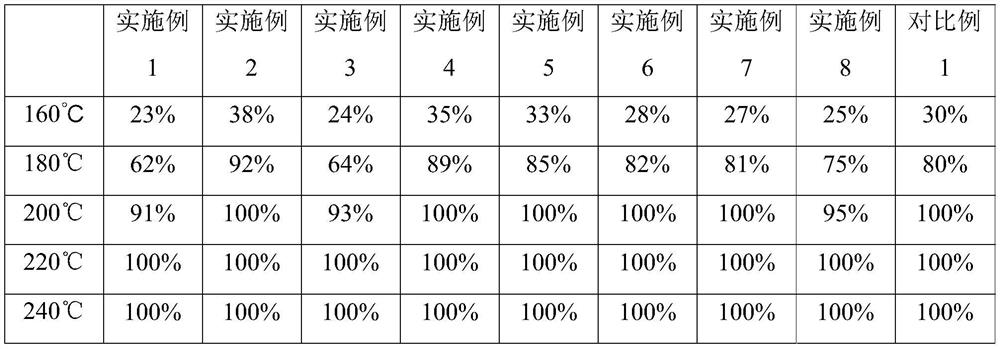

[0035] Prepare 0.02mol / L of H 2 PtCl 6 solution, pour 80 mL of deionized water into a beaker, and then add anatase TiO 2 20g, turn on magnetic stirring, set the speed to 500r / min, stir for 20min, and then add H 2 PtCl 6 Solution 5.13mL, Co(NO 3 ) 6H 2 O 6.98g, continue to stir for 3h; transfer the beaker to a spray dryer and dry at 120°C for 7h; grind the dried powder and place it in a muffle furnace, at a heating rate of 5°C / min in air The temperature was raised from room temperature to 500 °C under the atmosphere, and the powder was calcined for 3 hours. The powder obtained after calcination was the treated NH 3 escape catalyst.

Embodiment 2

[0037] Prepare 0.02mol / L of H 2 PtCl 6 solution, pour 80 mL of deionized water into a beaker, and then add CeO 2 20g, turn on magnetic stirring, set the speed to 500r / min, stir for 20min, and then add H 2 PtCl 6 Solution 5.13mL, Co(NO 3 ) 6H 2O 6.98g, continue to stir for 3h; transfer the beaker to a spray dryer and dry at 120°C for 5h; grind the dried powder and place it in a muffle furnace, at a heating rate of 5°C / min in air The temperature was raised from room temperature to 500 °C under the atmosphere, and calcined for 3 hours. The powder after calcination was treated with NH 3 escape catalyst.

Embodiment 3

[0039] Prepare 0.02mol / L of H 2 PtCl 6 solution, pour 80 mL of deionized water into a beaker, and then add Al 2 O 3 20g, turn on magnetic stirring, set the speed to 500r / min, stir for 20min, and then add H 2 PtCl 6 Solution 5.13mL, Co(NO 3 ) 6H 2 O 6.98g, continue to stir for 3h; transfer the beaker to a spray dryer and dry at 120°C for 6h; grind the dried powder and place it in a muffle furnace, at a heating rate of 5°C / min in the air The temperature was raised from room temperature to 500 °C under the atmosphere, and calcined for 3 hours. The powder after calcination was treated with NH 3 escape catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com