White smoke removing system and technology capable of accurately controlling corrosion

A precise control, white smoke technology, applied in fixed tubular conduit components, tubular components, lighting and heating equipment, etc., can solve the problems of high energy consumption and corrosion in the white smoke treatment process, avoid gypsum rain phenomenon, and avoid clogging problems , The effect of reducing acid dew point corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

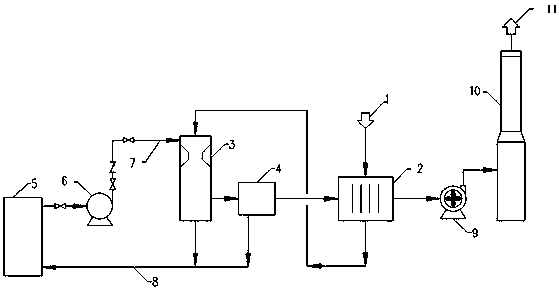

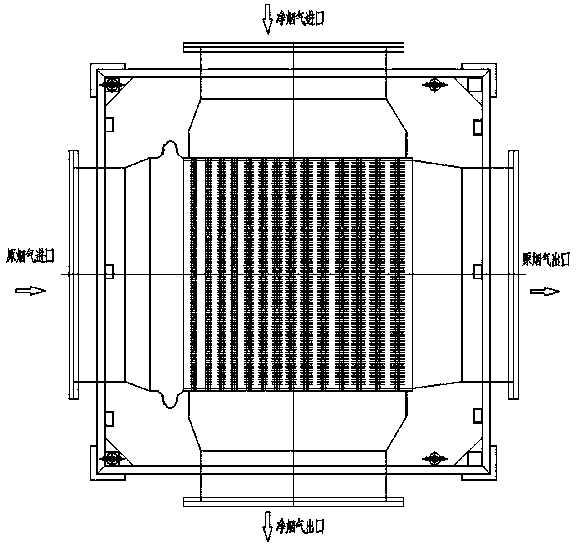

[0032] Such as figure 1 As shown, a white smoke removal system with precise corrosion control, in this system, the desulfurization raw flue gas 1 is connected to the hot side inlet of the gradient fin temperature-controlled heat exchanger 2 through the raw flue gas pipeline, and the gradient fin temperature control After passing through the desulfurization tower, the hot side outlet of the heat exchanger 2 is connected to the flue gas inlet of the high-efficiency combined double-swirl scrubber 3, and the flue gas outlet of the combined double-swirl scrubber 3 is connected to the gradient fin temperature-controlled heat exchanger 2 The inlet of the cold side is connected through the clean flue gas pipeline, and there is a wire mesh demister 4 in the middle, and the outlet of the gradient fin temperature-controlled heat exchanger 2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com