Ultralow-emission, water-saving and smoke suppression synergistic advanced purification system and method thereof

A purification system and smoke elimination technology, which is applied in the field of resource and environment flue gas purification, can solve problems such as system fouling and blockage, unfavorable production and energy saving, and endangering production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

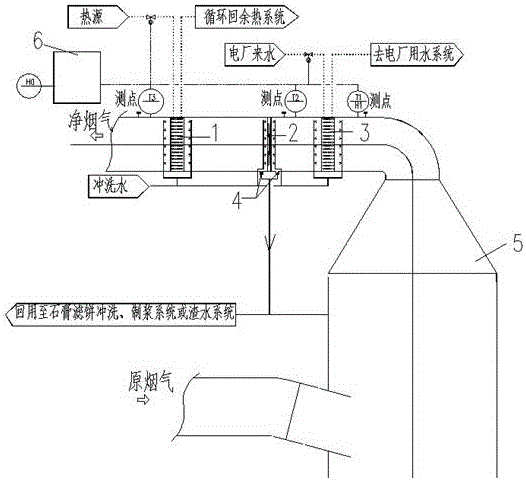

[0042] Such as figure 1 As shown, the multi-functional ultra-low emission water-saving and smoke-eliminating collaborative purification system of the present invention mainly includes four parts, which are respectively a micro-cooled phase change accelerator 1 and a multi-pollutant trap arranged in the flue at the outlet of the desulfurization tower. 2. Micro heat smoke eliminator 3 and corresponding flushing and drainage system. The distance between the micro-cooling phase change accelerator and the multi-pollutant trap is set to 10 m; the distance between the multi-pollutant trap and the micro-heat smoke eliminator is 10 m.

[0043] According to the positional relationship of each part, the flue gas at the outlet of the desulfurization tower 5 is sequentially treated by the slightly cold phase change accelerator 1, the multi-pollutant trap 2 and the flue gas slightly heat smoke eliminator 3, and then discharged through the chimney.

[0044] The flushing system includes pum...

Embodiment 2

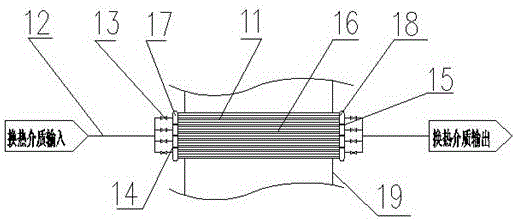

[0047] On the basis of Embodiment 1, the structure of the micro-cooled phase change accelerator and the micro-heat smoke eliminator in the system of the present invention is similar, and they are arranged in the flue 19, such as image 3 As shown, it mainly consists of a shell 11, an inlet medium flow pipe 12 and its (inlet) isolation shut-off valve 13, an inlet distribution box 14, a heat exchange pipe 16 passing through the flue perpendicular to the flue gas flow, and an outlet confluence Box 15, outlet medium flow line 12 and its (outlet) isolation shut-off valve; inlet distribution box 14 and outlet confluence box 15 are symmetrically arranged, and are divided into several small chambers, and each group of inlet and outlet chambers is correspondingly connected to a group of heat exchangers Pipeline 16, the corresponding inlet and outlet medium flow pipes and isolation shut-off valves to achieve independent control functions in different areas; the side walls of the flue gas...

Embodiment 3

[0049] The collaborative purification method for ultra-low emission of flue gas and smoke elimination of the present invention adopts the system processing process of Embodiment 2 as follows:

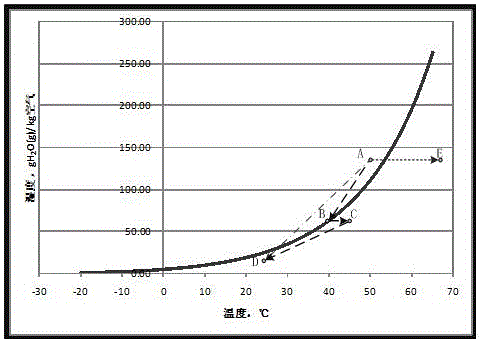

[0050] First measure the following data: the actual temperature T of the flue gas at the outlet of the desulfurization tower 1 , ambient air humidity H 0 , Flue gas humidity H at the outlet of desulfurization tower 1 , Determine the cooling economic cooling coefficient η, the value range is 0.05-1 (0.5 in this example), and the micro-thermal economic coefficient δ, the value range is 0-0.75 (0.35 in this example).

[0051] In the following formula: T 2 The flue gas temperature, T 3 It is the flue gas temperature that should be controlled after heating the micro heat smoke eliminator.

[0052] First, the desulfurization tower outlet T 1 The flue gas at ℃ is cooled to T by the micro-cooled phase change accelerator 2 ℃ Condensation, mist removal and dust removal treatment, after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com