Preparation method and application of modified anti-corrosion super-hydrophobic integrated coating

A technology of super-hydrophobic and anti-corrosion materials, applied in anti-corrosion coatings, coatings, etc., can solve the problem of not meeting the service requirements of advanced equipment protection, and achieve the effects of economically feasible anti-corrosion super-hydrophobicity, improving dispersibility, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

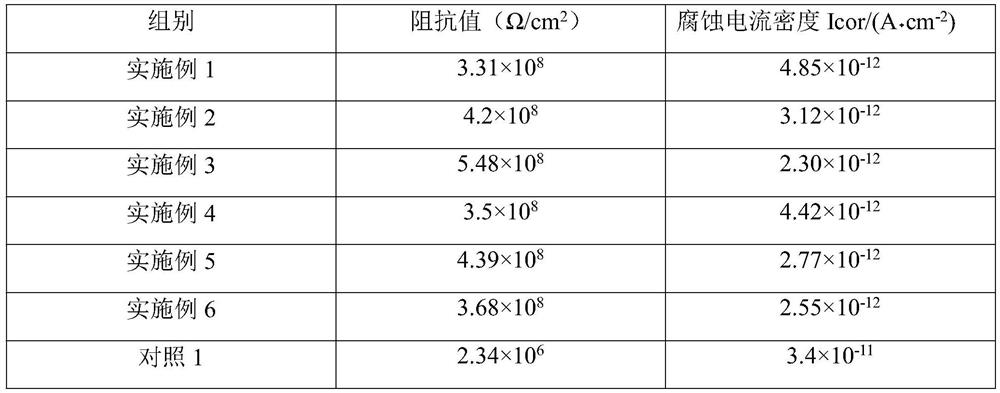

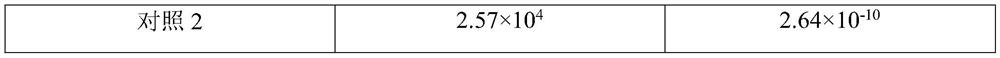

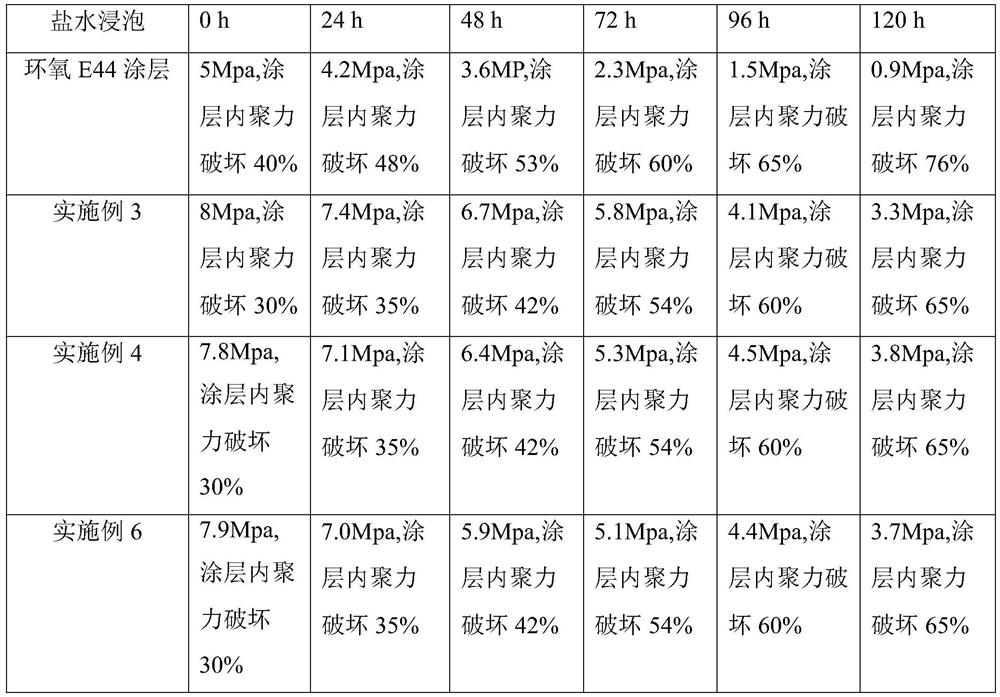

Examples

Embodiment 1

[0063] Embodiment 1 A kind of preparation method of modified anticorrosion superhydrophobic integrated coating comprises the following steps:

[0064] (1) Preparation of graphene-titanium dioxide composite:

[0065] S11. Weigh 0.1 g of graphene and disperse it in 80 mL of organic solvent (absolute ethanol), and disperse it ultrasonically for 2 hours to obtain a graphene dispersion;

[0066] S12. Weigh 10mL of tetrabutyl titanate, 60mL of absolute ethanol and 10mL of deionized water to form a mixed solution, fully stir for 20min at room temperature with a magnetic stirrer at 200rpm, and slowly add glacial acetic acid dropwise to the stirred solution to adjust the pH to 5.5 , to slow down the hydrolysis process to obtain a hydrolysis solution;

[0067] S13. Mix the graphene dispersion and the hydrolysis solution, mechanically stir it at room temperature for 1.5 hours, put it into a polytetrafluoroethylene reaction kettle, and conduct a solvothermal reaction at 140° C. for 8 hou...

Embodiment 2

[0079] Embodiment 2 A kind of preparation method of modified anticorrosion superhydrophobic integrated coating comprises the following steps:

[0080] (1) Preparation of graphene-titanium dioxide composite:

[0081] S11. Weigh 0.15g of graphene and disperse it in 80mL of organic solvent (absolute ethanol), and ultrasonically disperse it for 2h to obtain a graphene dispersion;

[0082] S12. Weigh 15mL of tetrabutyl titanate, 90mL of absolute ethanol and 15mL of deionized water to form a mixed solution, fully stir for 20min at room temperature with a magnetic stirrer at 300rpm, and slowly add glacial acetic acid dropwise to the stirred solution to adjust the pH to 5.6 , to slow down the hydrolysis process to obtain a hydrolysis solution;

[0083] S13. Mix the graphene dispersion with the hydrolysis solution, stir mechanically at room temperature for 1.5 h, put it into a polytetrafluoroethylene reaction kettle, and conduct a solvothermal reaction at 180° C. for 12 h; after cooli...

Embodiment 3

[0095] Embodiment 3 A kind of preparation method of modified anticorrosion superhydrophobic integrated coating comprises the following steps:

[0096] (1) Preparation of graphene-titanium dioxide composite:

[0097] S11. Weigh 0.2g graphene and disperse it in 80mL organic solvent (absolute ethanol), and ultrasonically disperse it for 2h to obtain a graphene dispersion;

[0098] S12. Weigh 20mL of tetrabutyl titanate, 120mL of absolute ethanol and 20mL of deionized water to form a mixed solution, fully stir for 20min at room temperature with a magnetic stirrer at 300rpm, and slowly add glacial acetic acid dropwise to the stirred solution to adjust the pH to 6.0 , to slow down the hydrolysis process to obtain a hydrolysis solution;

[0099] S13. Mix the graphene dispersion with the hydrolysis solution, stir mechanically at room temperature for 1.5 hours, put it into a polytetrafluoroethylene reaction kettle, and conduct a solvothermal reaction at 180° C. for 6 hours; after cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com