Method used for eliminating white mist water vapour at flue gas discharge outlets

A flue gas emission and flue gas technology, which is applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of imperfect control measures, the device is corroded by flue gas, and the sulfur content of flue gas is increased. Good economic and environmental benefits, cost savings, and low system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

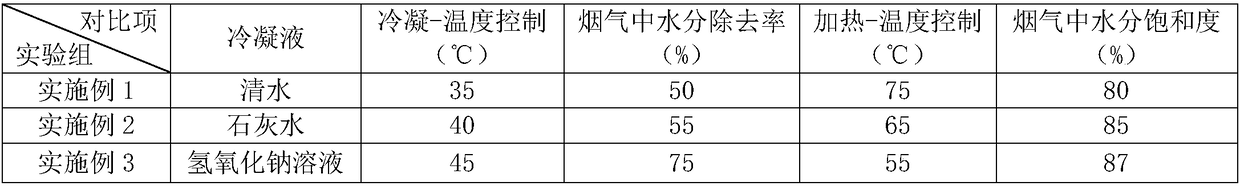

Embodiment 1

[0023] A method for eliminating white fog and water vapor at a flue gas discharge port, specifically comprising the following steps:

[0024] 1) The flue gas after wet desulfurization is connected to the condensation tower, and the condensed flue gas is sprayed with clean water as the condensate, and the temperature is controlled at 35°C to lower the temperature of the flue gas, precipitate condensed water, and remove the moisture in the flue gas .

[0025] 2) Introduce the flue gas from which condensed water has been precipitated into the demister, and further capture and remove the mist particles and slurry droplets entrained in the flue gas.

[0026] 3) The flue gas is introduced into the heating device to heat up the temperature, and the temperature is controlled at 75°C to reduce the moisture saturation in the flue gas, and change the state of the flue gas from a supersaturated state to an unsaturated state of flue gas, thereby reducing the flue gas for moisture saturati...

Embodiment 2

[0029] A method for eliminating white fog and water vapor at a flue gas discharge port, specifically comprising the following steps:

[0030] 1) The flue gas after wet desulfurization is connected to the condensation tower, and the condensed flue gas is sprayed with lime water as the condensate, and the temperature is controlled at 40°C to reduce the temperature of the flue gas, precipitate condensed water, and remove the water in the flue gas share. Lime water is selected as the condensate, and the sulfur oxides in the flue gas can be removed during the cooling process of the flue gas.

[0031] 2) Introduce the flue gas from which condensed water has been precipitated into the demister, and further capture and remove the mist particles and slurry droplets entrained in the flue gas.

[0032] 3) The flue gas is introduced into the heating device to heat up the temperature, and the temperature is controlled at 65°C to reduce the moisture saturation in the flue gas, and change t...

Embodiment 3

[0035] A method for eliminating white fog and water vapor at a flue gas discharge port, specifically comprising the following steps:

[0036] 1) The flue gas after wet desulfurization is connected to the condensation tower, and the condensed flue gas is sprayed with sodium hydroxide solution as the condensate, and the temperature is controlled between 45°C to lower the temperature of the flue gas, precipitate condensed water, and remove the flue gas. moisture in the air. Sodium hydroxide solution is selected as the condensate, and the sulfur-containing oxides in the flue gas can be removed during the cooling process of the flue gas.

[0037] 2) Introduce the flue gas from which condensed water has been precipitated into the demister, and further capture and remove the mist particles and slurry droplets entrained in the flue gas.

[0038] 3) Introduce the flue gas into the heating device to heat up the temperature, control the temperature at 55°C, reduce the moisture saturatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com