Phase change-based flue gas end dehydration fine dust removal device

A technology for fine dust removal and flue gas, which is applied in the field of air pollution control, can solve the problems of water consumption, low heat exchange efficiency, heavy absorption tower weight, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

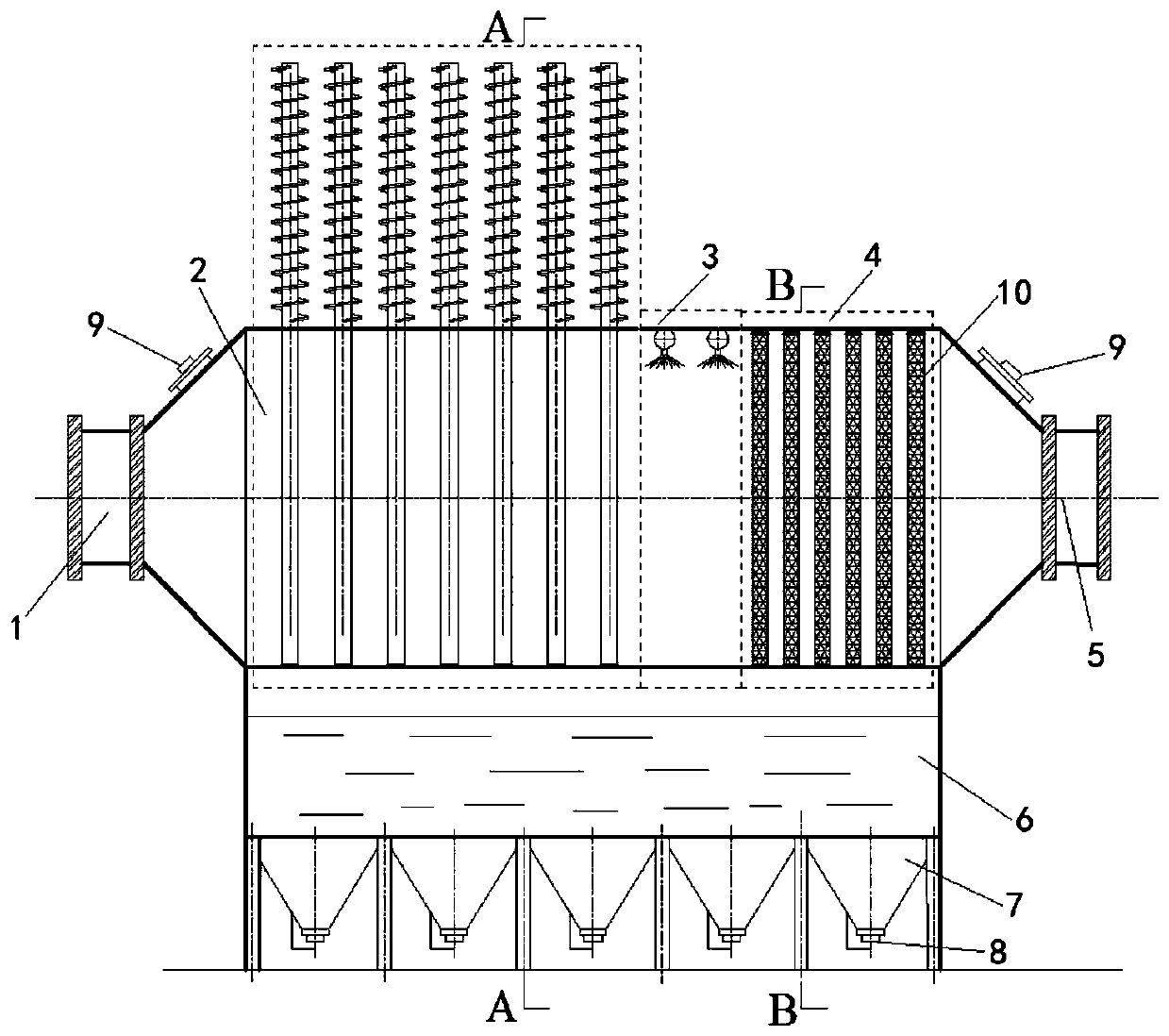

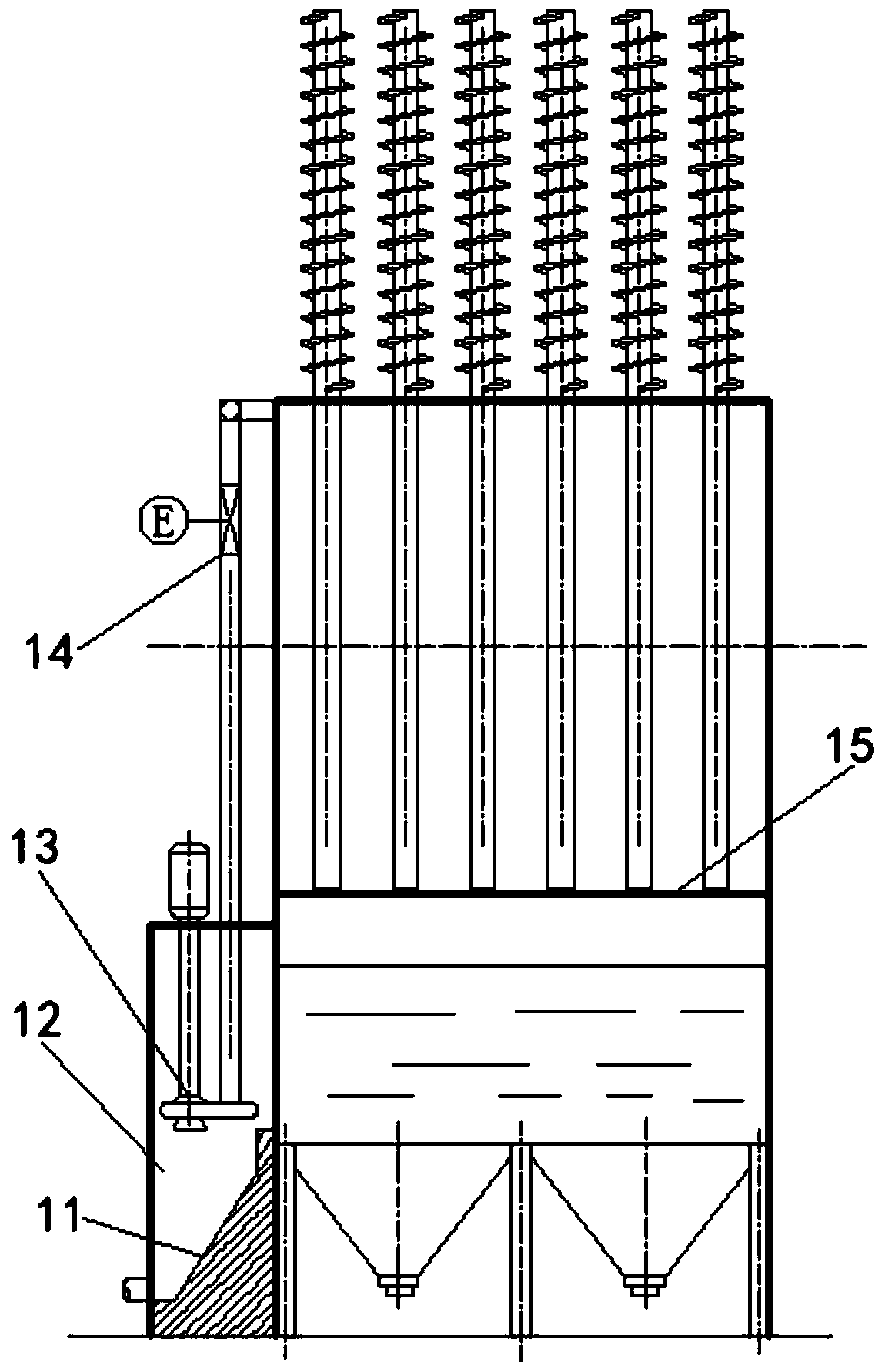

[0039] refer to Figure 1-2 , the flue gas terminal dehydration and fine dust removal device based on phase change in this embodiment includes:

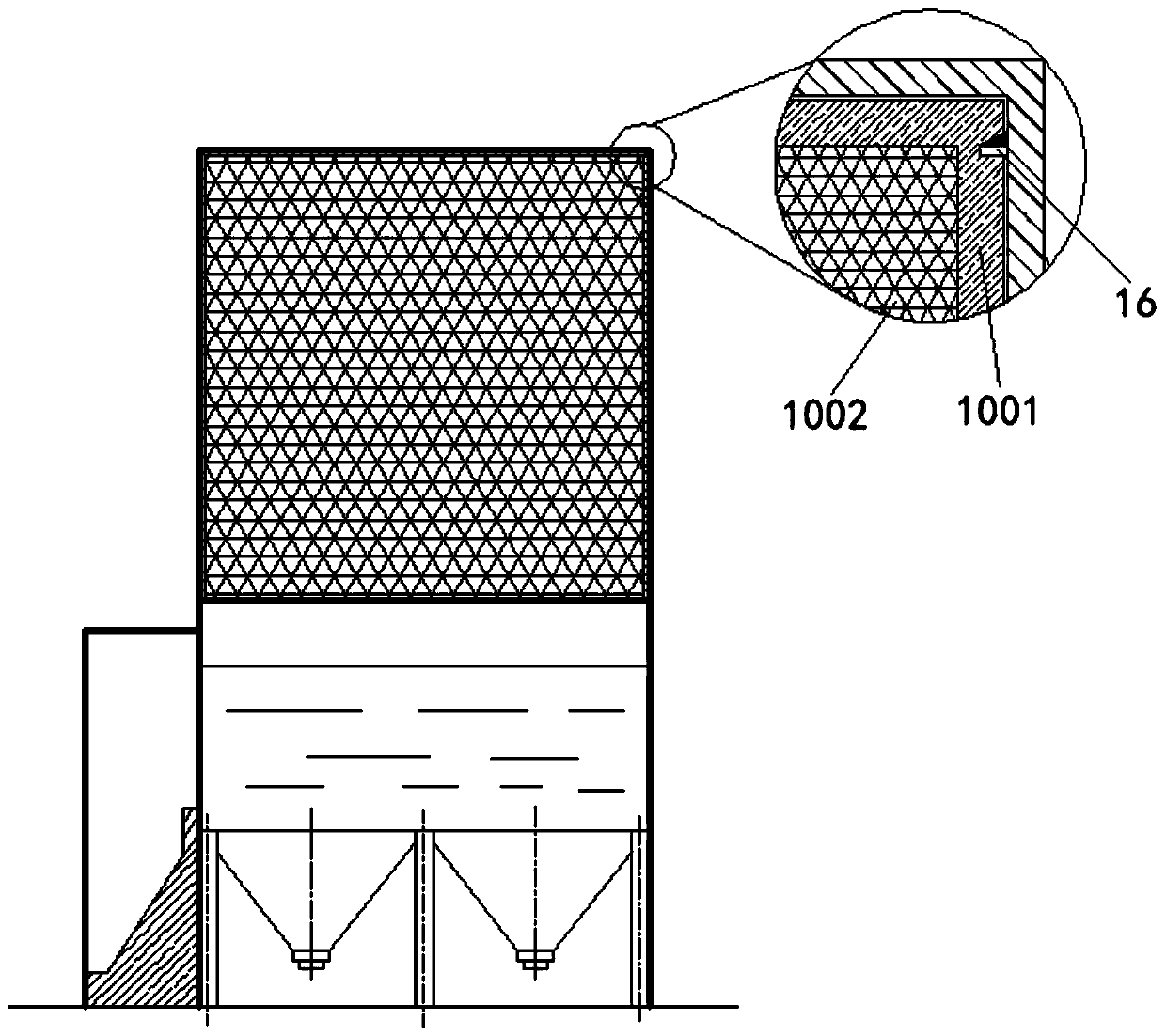

[0040] The dust removal box is arranged horizontally, one end of the dust removal box is connected with the flue gas inlet flue 1, and the other end of the dust removal box is connected with the flue gas outlet flue 5; The direction of the gas outlet flue 5 is successively provided with a phase change cooling zone 2, a spray cooling zone 3 and a filter dust removal zone 4; the phase change cooling zone 2 includes several layers of heat pipe heat exchange layers, and each layer of heat pipe heat exchange layers includes several parallel Arranged heat pipes, and the evaporation section of the heat pipe is located inside the dust removal box, and the condensation section of the heat pipe is located outside the dust removal box; the spray cooling area 3 includes several atomizing nozzles 301; the filter screen dust removal area 4 include...

Embodiment 2

[0047] The flue gas terminal dehydration fine dust removal device based on phase change in this embodiment has basically the same structure as that in Embodiment 2, further: the bottom of the sedimentation tank 6 is connected to several funnels 7, and the bottom of the funnel 7 is provided with a sealing plug 8 (Specifically in this embodiment, the sealing plug 8 is a pressure handle type rubber plug).

[0048] In this embodiment, several funnels 7 are connected to the bottom of the sedimentation tank 6, and the bottom of the funnel 7 is provided with a sealing plug 8. When the water in the sedimentation tank 6 accumulates to a certain extent, the seal at the bottom of each funnel 7 can be easily opened. The plug 8 discharges excess accumulated water, wherein the design of the funnel 7 is conducive to the sedimentation of the smoke and dust in the sedimentation tank 6 to fall into it due to sedimentation and be discharged.

Embodiment 3

[0050] The structure of the flue gas terminal dehydration and fine dust removal device based on phase change in this embodiment is basically the same as that of Embodiment 1, further: 1 place near the flue gas inlet flue and 5 places near the flue gas outlet flue on the dust removal box Observation holes 9 are respectively provided.

[0051] In this embodiment, observation holes 9 are respectively provided on the dust removal box near the flue gas inlet 1 and near the flue gas outlet flue 5, through which the dust removal and whitening effect of the flue gas in the dust removal box can be monitored. Carry out comparative observation and regular inspection and maintenance of the dust removal box; when the equipment has been running for a period of time, there is a small amount of sticky matter on the surface of the heat pipe and the surface of the filter screen 1002, and high-pressure water can be passed into the observation hole 9 to check the heat pipe and filter screen 1002. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com