Mine heat furnace kiln waste heat recycling system

A technology of waste heat recovery system and submerged arc furnace, applied in the direction of furnace, preheating, furnace components, etc., can solve the problems of waste, dust cleaning, unsatisfactory heat absorption effect of heating surface, environmental heat pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

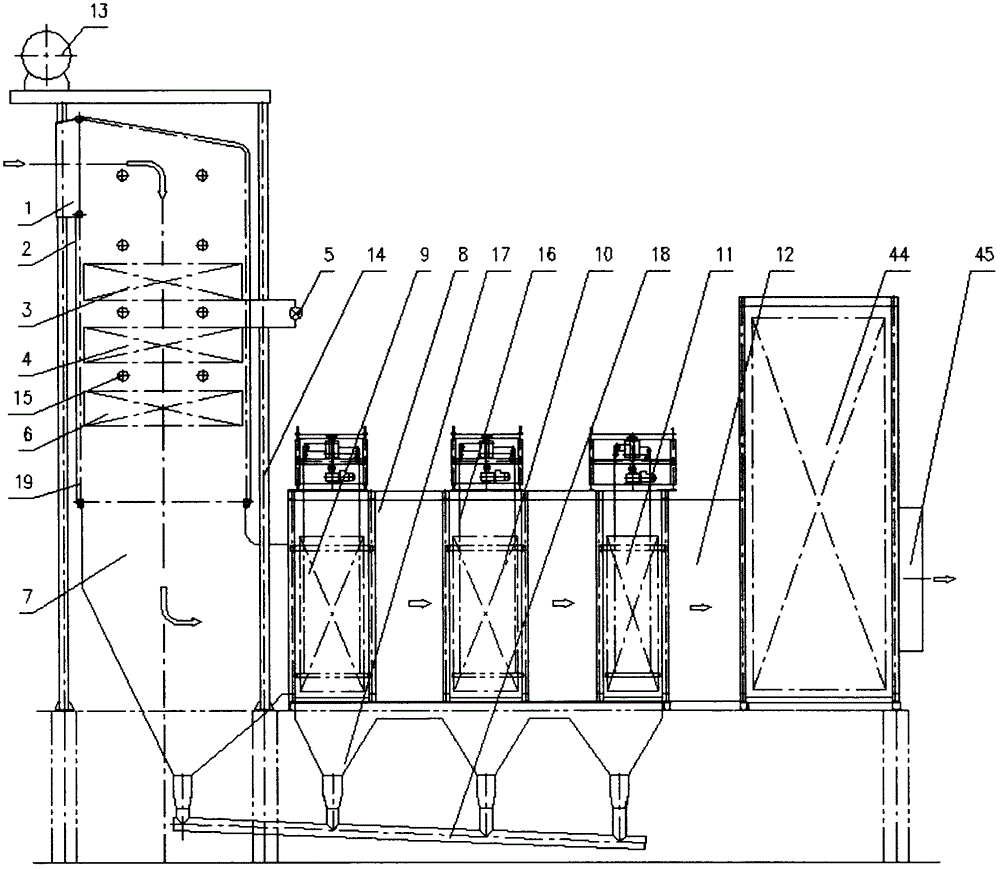

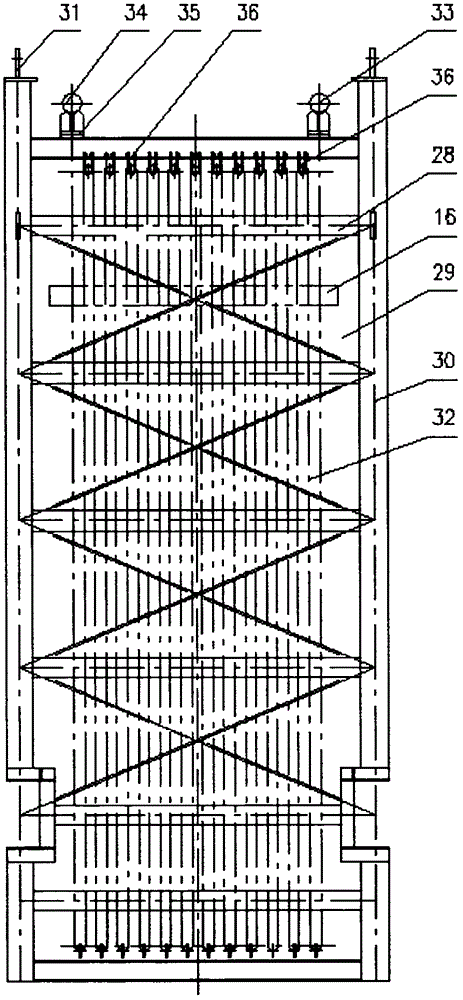

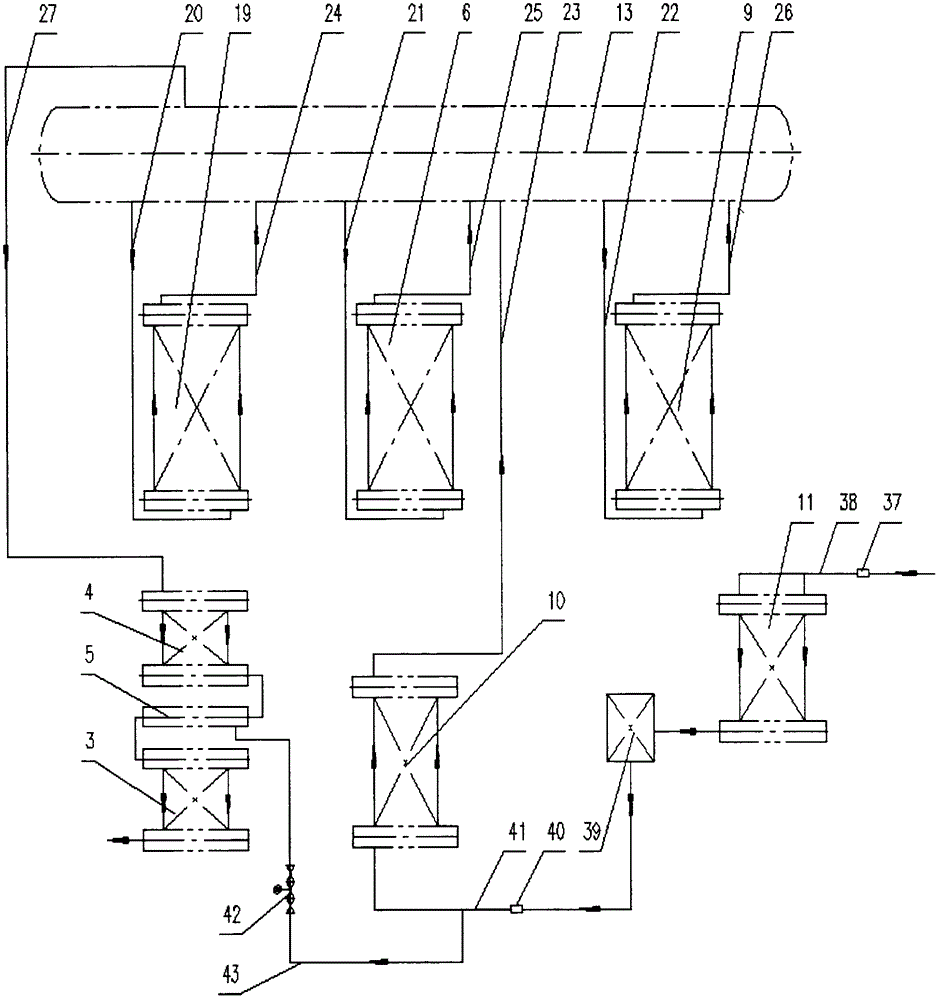

[0014] Such as figure 1 The shown waste heat recovery system of a submerged arc furnace includes an inlet flue 1, a water-cooling passage 2, a high-temperature superheater 3, a low-temperature superheater 4, a temperature reduction adjustment device 5, a high-temperature evaporator 6, a diversion flue 7, and a horizontal Flue 8, low temperature evaporator module 9, economizer module 10, water heater module 11, outlet flue 12, drum 13, steel frame 14, shock wave soot blowing device 15, steel brush soot cleaning device 16, ash hopper 17, ash discharge device 18.

[0015] The waste heat recovery system of the submerged arc furnace is arranged in an L shape, the inlet flue 1 and the water cooling channel 2, the water cooling channel 2 and the turning flue 7, the turning flue 7 and the horizontal flue 8, the horizontal flue 8 and the outlet flue 12, The outlet flue 12 is connected with the pollutant co-removal device 44 , and the pollutant co-removal device 44 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com