Method for controlling considerable coal-fired boiler NOx discharge by multilevel reduction wind

A coal-fired boiler, large-capacity technology, applied in the field of NOx emissions, can solve problems affecting the economical and safe operation of boilers, achieve the effects of eliminating negative problems in the furnace, realizing ultra-low NOx emissions, and increasing operation regulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

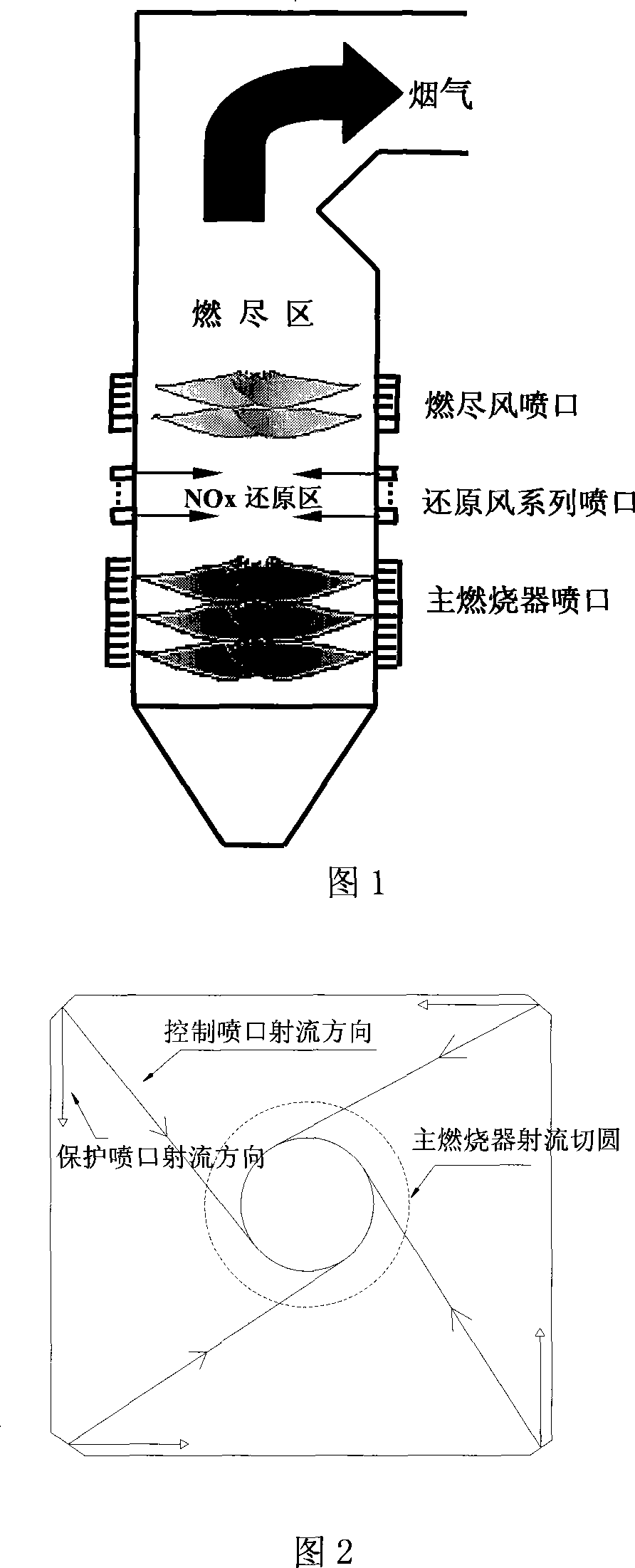

[0019] As shown in Figure 1, the schematic diagram of the method for controlling NOx emission of a large-capacity coal-fired boiler with multi-stage reducing air in this embodiment includes a main burner group, an overburning air nozzle group, and a reducing air series nozzle group. The main burner group is composed of multiple layers of primary and secondary air nozzles alternately, and the layout of the nozzles is the same as that of the usual four-corner tangential combustion system. According to the characteristics of pulverized coal combustion area, the furnace i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com