Glass kiln smoke deep purification process

A glass kiln and deep purification technology, which is applied in the field of flue gas treatment and purification, can solve the problems of high temperature and high corrosion resistance of filter bags, high operating costs, easy to reverse corona, etc., to reduce energy consumption, large ventilation, and avoid blockage. with poisoning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

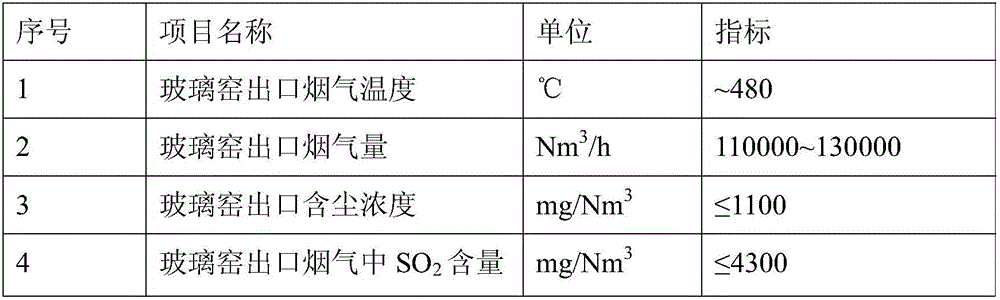

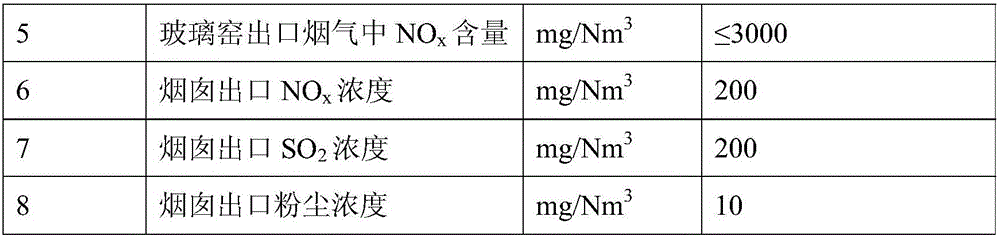

[0027] The specific flue gas conditions of the glass kiln project of the 600t / d production line whose fuel is petroleum coke are as follows:

[0028]

[0029]

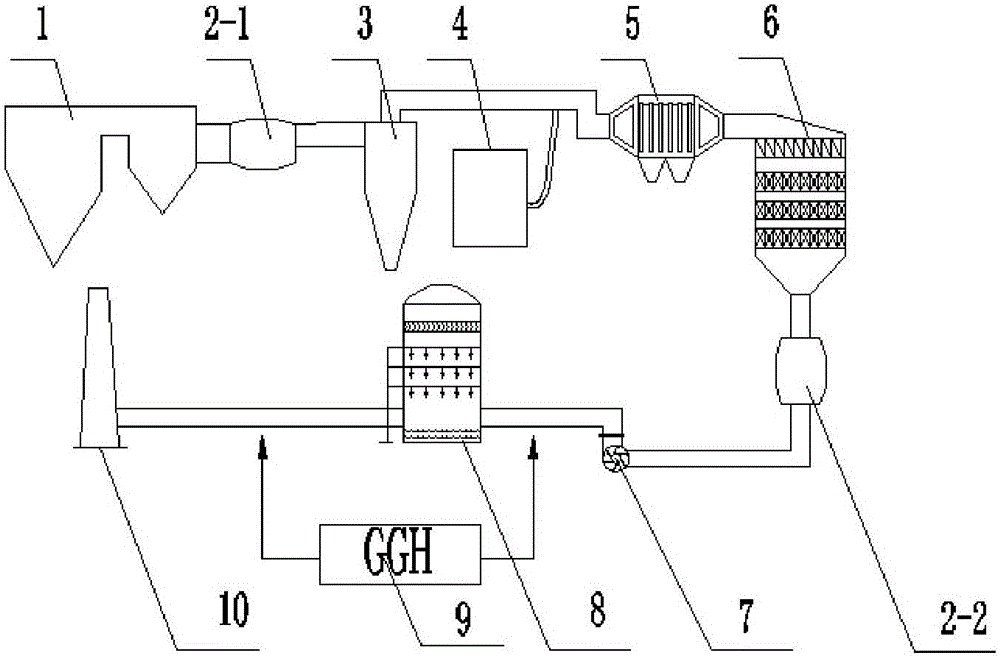

[0030] The specific process of glass kiln flue gas deep purification process is as follows:

[0031] The temperature generated by the glass kiln is at 480°C, the fume, SO2 The concentration is 4300mg / Nm 3 , NO x The concentration is 3000mg / Nm 3 , dust concentration 1100mg / Nm 3 , after entering the high-temperature waste heat boiler, the temperature of the flue gas drops to 375°C; enters the cyclone dust collector, and removes the larger fly ash generated by combustion, and the dust concentration at the outlet of the cyclone dust collector is 700mg / Nm 3 ;In order to prevent the dust collector from sticking to the bag, when the entire purification system is in operation for the first time and after the solenoid valve of the metal sintered filter material dust collector is blown back to clean the dust, the duster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com