A reaction fluidized bed system and stream guiding type rotating circulating fluidized bed desulphurization equipment including the system

A fluidized bed and reaction technology, applied in chemical instruments and methods, gas treatment, dispersed particle separation, etc., can solve the problems of easy scaling, large consumption of sodium and alkali, difficult regeneration, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

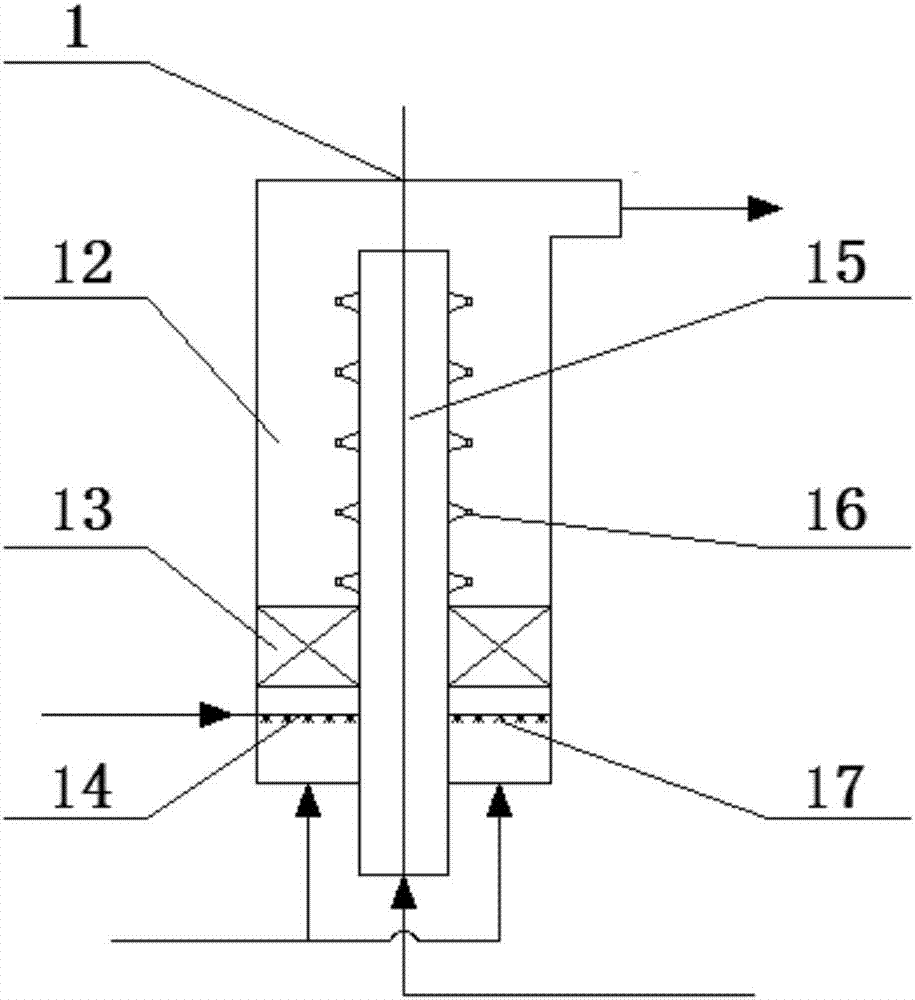

[0094] This embodiment provides a reactive fluidized bed system, a diversion type rotary circulating fluidized bed desulfurization device containing it, and a method for applying the desulfurization device to flue gas desulfurization.

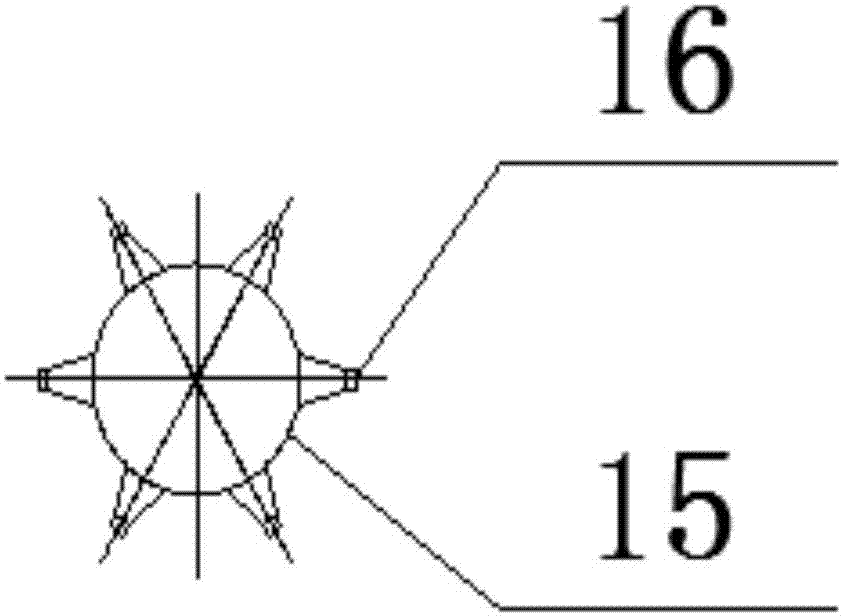

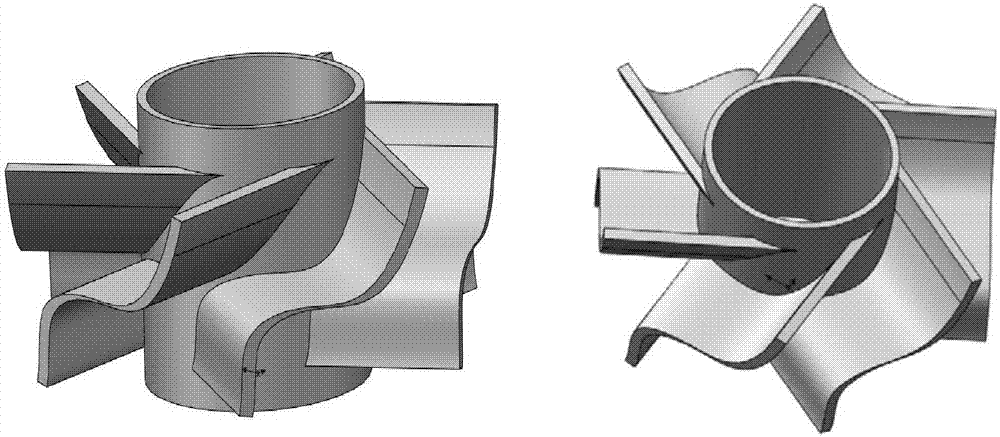

[0095] Such as figure 1 As shown, the reactive fluidized bed system 1 includes a reactive fluidized bed 12, a first guide vane 13 capable of rotating and rising the gas, a water ring pipe 14, a spray nozzle 17, a desulfurizing agent nozzle 16 and a desulfurizing agent pipeline 15, The desulfurizer pipeline 15 is a cylindrical pipeline;

[0096] The reactive fluidized bed 12 has a cylindrical shell structure with both ends closed;

[0097] The desulfurizer pipeline 15 extends axially through the bottom of the reaction fluidized bed 12 into its interior, and the tail of the desulfurizer pipeline 15 is in the reaction fluidized bed and closed; the central axis of the desulfurizer pipeline 15 is connected to the The central axis of the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com