Coal slime fluidized bed boiler desulfurization collaborative optimization operation method

A fluidized bed boiler and collaborative optimization technology, applied in chemical instruments and methods, separation methods, design optimization/simulation, etc., can solve problems such as frequent occurrence of acid rain, social and economic development losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] The present invention will be further analyzed below in conjunction with the accompanying drawings and specific embodiments.

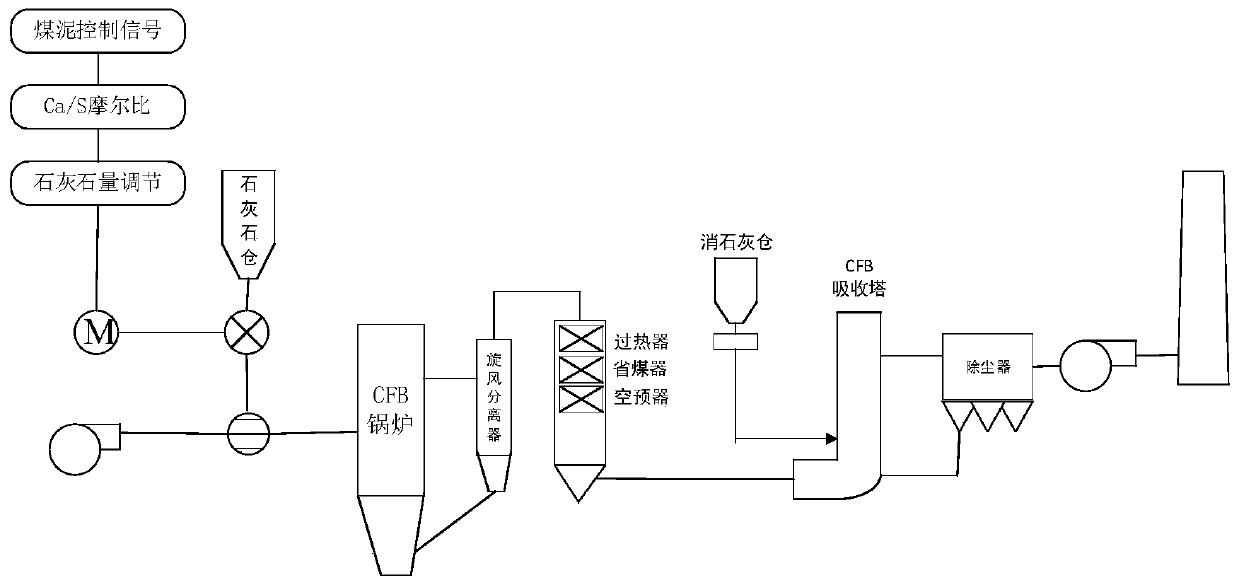

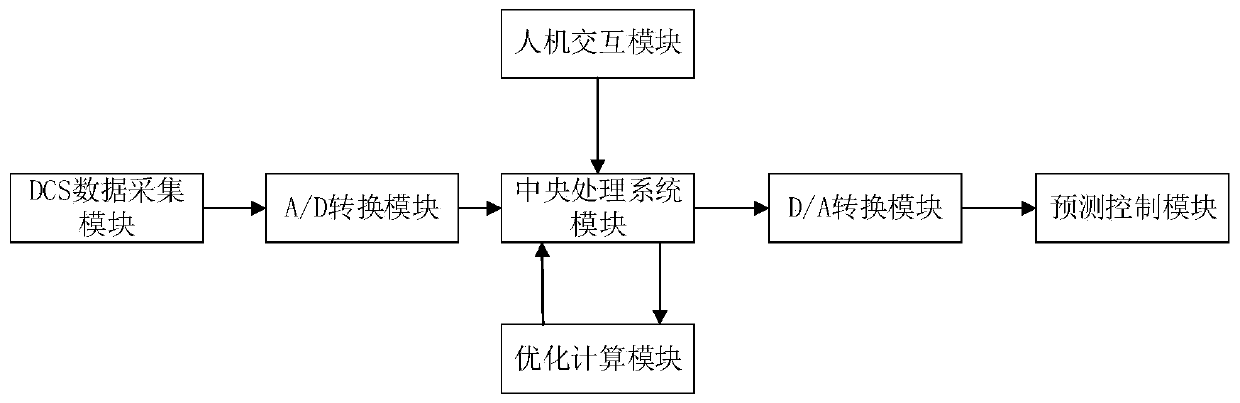

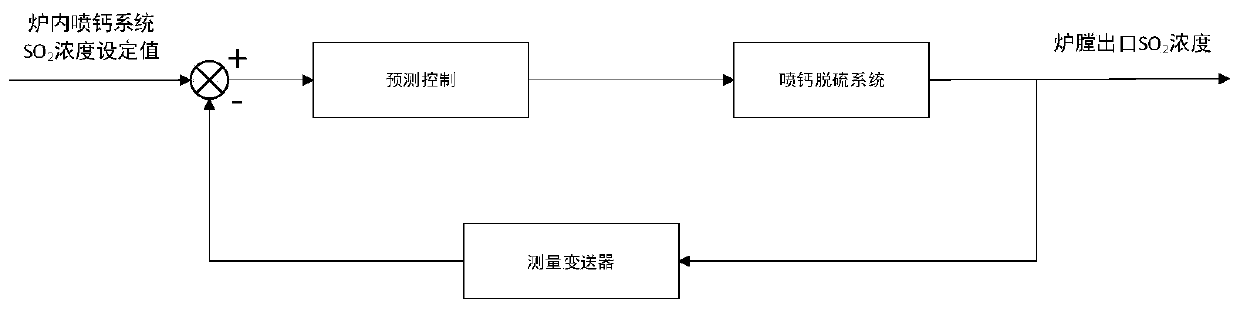

[0102] Such as figure 1 As shown, a coal slime fluidized bed boiler desulfurization collaborative optimization operation method, the specific implementation adopts the following steps: the optimization operation system provided by the present invention includes the following modules, such as figure 2 Shown: DCS (distributed control system) data acquisition module, A / D and D / A conversion module, central processing system module, predictive control module, human-computer interaction module and optimization calculation module. The DCS data acquisition module is used to collect the parameter data of the whole coal slime fluidized bed boiler desulfurization system, including its coal slime volume, bed temperature, primary and secondary air volume, limestone volume, slaked lime volume, etc.; A / D and D / A conversion The modules are respectively used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com