Dehumidification and emission reduction system and process of smoke of coal-fired power plant

A coal-fired power plant, flue gas technology, applied in the direction of gas treatment, combined devices, membrane technology, etc., can solve the problems of misunderstanding of the visual effect of white smoke plume, no reduction of pollutant emissions, and large energy consumption of GGH, so as to reduce smoke and dust and Emission of multiple pollutants, good environmental benefits and social benefits, and the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

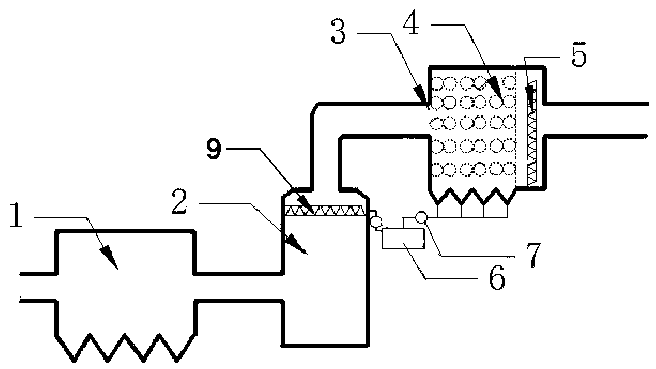

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0027] see figure 1 , 2 And 3, a kind of coal-fired power plant flue gas dehumidification and emission reduction system in the present invention, comprises high-efficiency electrostatic precipitator 1, wet desulfurization device 2 and dehumidification and emission reduction device 3 connected successively along pipeline, high-efficiency electric precipitator 1 adopts Synergistic methods such as low temperature and pulse power supply ensure that the concentration of smoke and dust at the outlet is less than 10mg / Nm 3, The desulfurization absorption tower adopts double circulation, adding demisters and other synergistic methods to ensure SO 2 Outlet concentration3 .

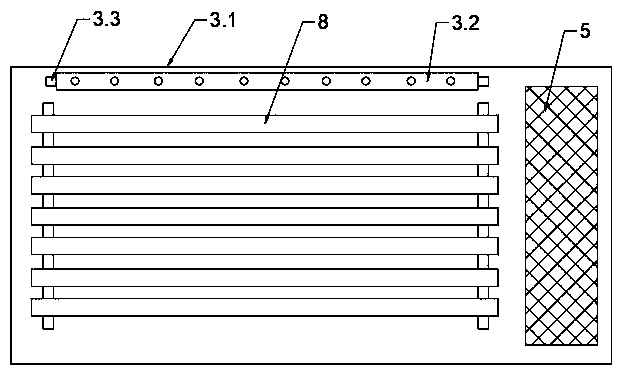

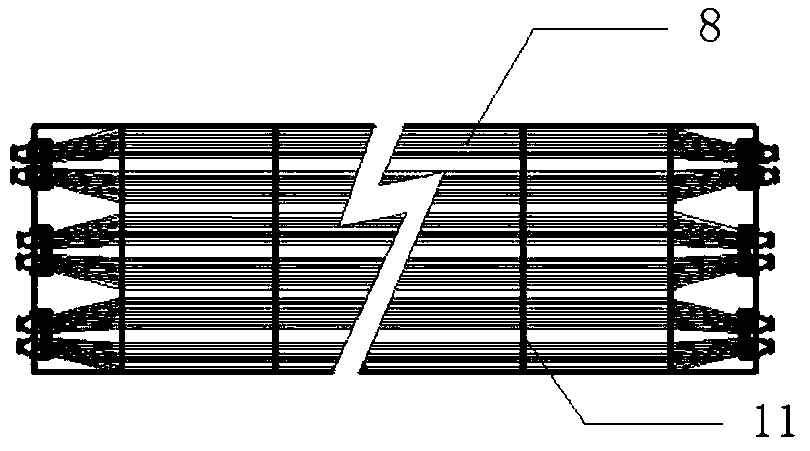

[0028] The dehumidification and emission reduction device 3 includes a cylindrical shell 3.1, and the shell 3.1 is provided with a tubular heat exchanger 4, a cleaning mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com