Integrated treating apparatus and treating process for exhaust gas of setting machine used in dyeing and finishing industry

A technology of a treatment device and a shaping machine, which is applied in the gaseous discharge wastewater treatment, combined device, water/sewage multi-stage treatment, etc., can solve the problems of potential safety hazards and incomplete treatment, and achieve the value of cascade utilization and recycling. High, the effect of eliminating fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

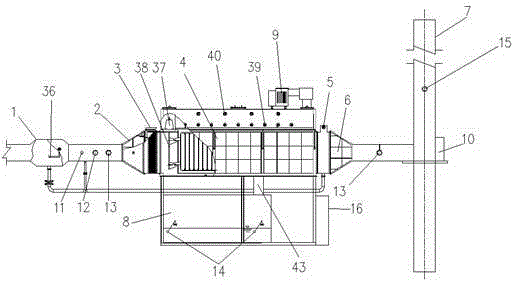

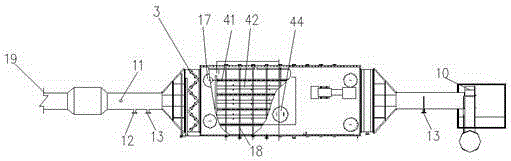

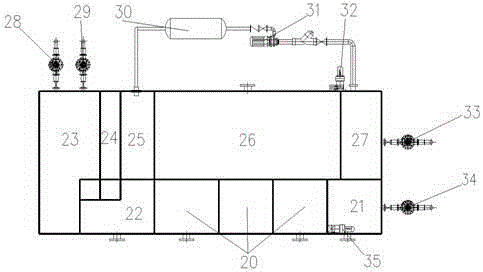

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] An integrated waste gas treatment device for a setting machine, including a spray condensation unit, a wet electrostatic degreasing unit, a smoke discharge unit, an electronic control unit, and a water treatment unit 8; a spray condensation unit, a wet electrostatic degreasing unit, and a smoke discharge unit in sequence connected. The water treatment unit is connected with the wet electrostatic degreasing unit, and is used for treating and reusing the waste water generated during the treatment process of the wet electrostatic degreasing unit. The electronic control unit includes various electronic control equipment, such as anemometer, flow meter, liquid level gauge, etc., which are used for real-time monitoring and automatic control of each unit of the entire device. Specifically:

[0047] The spray condensing unit includes a spray condenser 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com