Dedusting method and device for achieving ultralow emissions of dusty gas

A technology of dust removal device and gas, applied in separation methods, combined devices, chemical instruments and methods, etc., can solve the problems of high operation cost, large space occupation, increase system fluid resistance, etc., and achieve high dust removal efficiency and increased purification capacity. , the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

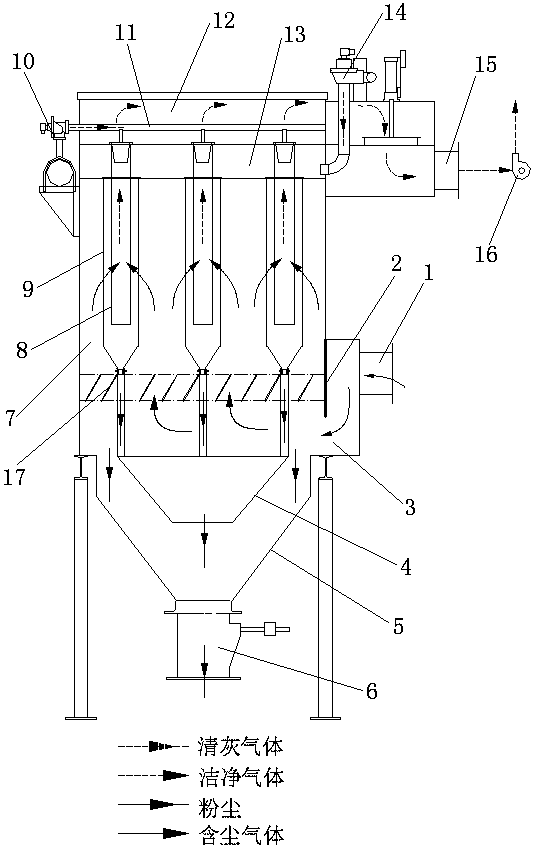

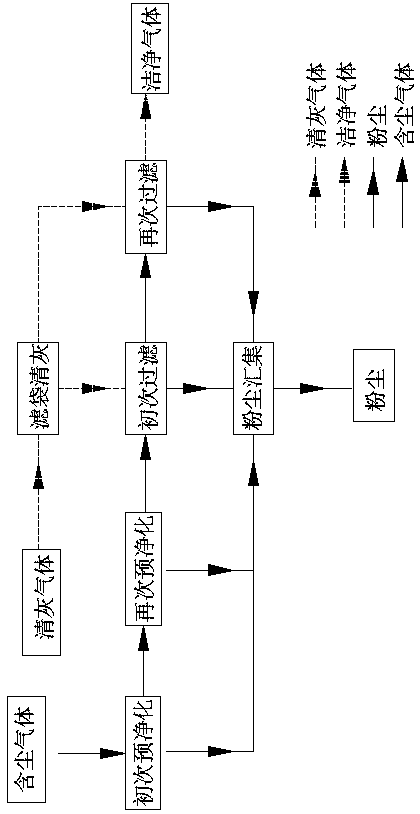

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0045] Such as figure 1 As shown, the dust removal device for ultra-low emission of dusty gas includes air inlet 1, wind deflector 2, settling chamber 3, dust hopper, filter chamber 7, clean air chamber, inner blowing device 10, and outer blowing device 14. The air outlet 15, the exhaust fan 16, the air inlet 1 and the settling chamber 3 are connected, the air guide plate 2 is set between the air inlet 1 and the settling chamber 3, and the ash bucket is set under the settling chamber 3, and the ash bucket is divided into inner The ash hopper 4 and the outer ash hopper 5 have two layers inside and outside, and there is a gap between the inner and outer ash hoppers. The lower part of the outer ash bucket 5 is equipped with an air lock and ash discharge valve 6, the filter chamber 7 is located above the settling chamber 3 and the two are connected, the connecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com